The subtleties of the choice of roofing screws

The roof is an important component of any structure. Materials for its arrangement in the modern construction market are presented in a large assortment. Together with them are sold a variety of fasteners, among which is to provide roofing screws.

Special features

The popularity of such products is directly related to the trend, due to which ordinary slate gives way to the popularity of products for laying the roof of the last generation. And they need special parts for mounting. Screws for the roof are screws, the main function of which is to secure the fixing of roofing materials to a specially constructed base of metal or wood.

In comparison with other fasteners, some features are inherent in them, so that the screws provide a strong connection of materials under climatic conditions.These properties of products are explained by the specifics of their production, during which carbon steel is used.

High quality characteristics of roofing screws greatly expand their range of applications.

- The main area of use is the creation of roofs of various configurations, where during the course of work professional sheets, metal tiles and others can act as roofing material.

- Wall decoration of buildings used for industrial purposes.

- Construction of fences and metal fences, the construction of which involves installation to a wooden frame.

In addition to the features associated with the operating conditions of roofing screws, their important quality is a certain design, due to which elements will be in harmony with the overall appearance of the roof.

Products have certain advantages, among them are the following:

- raw materials for manufacturing is characterized by the ability to withstand heavy loads;

- products have a corrosion-resistant coating, due to which the operating life of products increases - on average it is about 50 years;

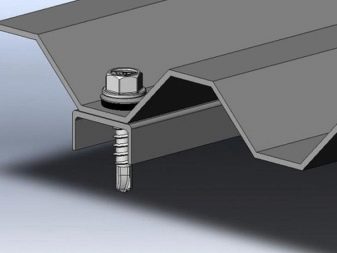

- the presence of a rubber gasket, which ensures reliable waterproofing of the roof at the joints;

- the washer allows you to evenly distribute the load on the roofing material, and also increases the sealing properties in the area of the holes for the screw;

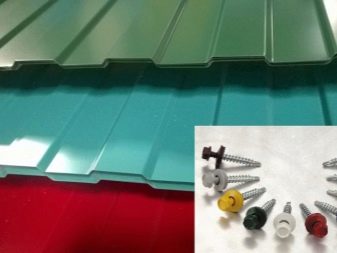

- wide selection of colors.

Specifications

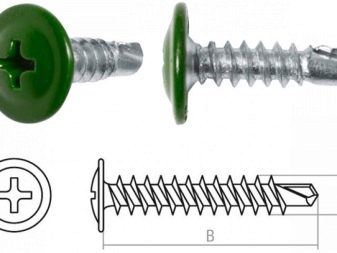

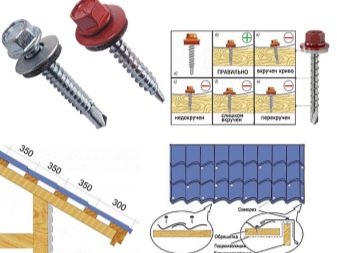

Roofing elements have three components.

- One end is a drill or a drill, which makes it easier to penetrate the material.

- The body is threaded. Its presence is responsible for screwing the part into the crate.

- The head is responsible for fixing the screw.

In addition to galvanized products, on the shelves of supermarkets there are products from the "stainless steel", which have a higher cost.

A hat at the roofing screw is round - the most common option. Its twisting is possible with the help of a conventional cross-head screwdriver. Also there are instances with a hex head. The size of the product is determined based on the length and diameter. Available in a huge selection of roofing screws of various sizes and configurations. The weight of the product directly depends on this parameter.

Special attention is given to such a component of the screw as a washer, since this part, made of metal and rubber by heat treatment, tightly fixes the element to the structure.

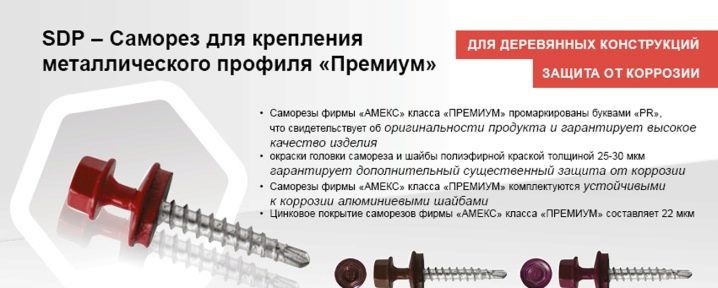

Painted products are treated with special compounds and are fired., due to which color products retain their color for a long time. It is possible to make sure of the quality of such products even during installation - if the coating peels off, then the reliability of the purchased products is doubtful.

And the self-tapping screws made in accordance with the GOST standards are guaranteed to have a high level of quality, and therefore a long operational period, since the production of products, as well as the raw materials used, are clearly controlled by the established uniform standards.

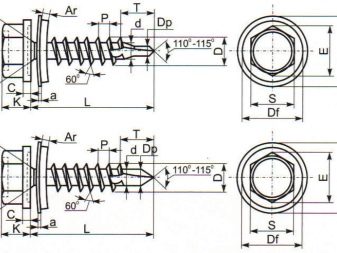

We can distinguish general characteristics for this group of products:

- their size can be the following: 4.8x19, 5x25, 5x32, 5x38, 5.5x19, and also 6.3x25, 8x29 mm;

- the weight of the package will depend on the size of the packaged product - so, in a package weighing 1 kg there may be a different number of screws;

- product price, as well as weight, depends on the size of the product.

Kinds

Regardless of the combination of roofing screws in one group and their visual similarity, classification of products occurs according to three main criteria.

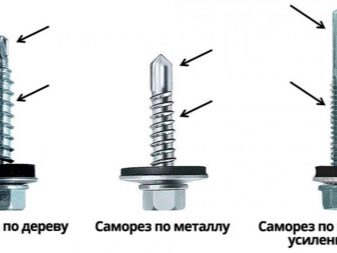

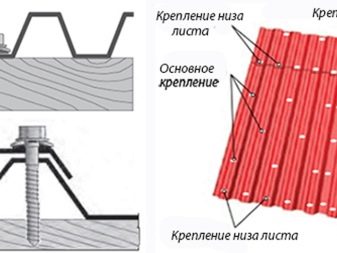

- Hardware is produced for work with a metal base. The end of this product has a sharp drill with a metal press washer and gasket. If there is a pre-made hole in the material, such a screw can be used for metal raw materials with a thickness of up to 6 mm. If you do not drill a working hole, the fasteners can be operated with a material whose thickness does not exceed 1.2 mm.

- Self-tapping screws for mounting roofing materials to a wooden crate or fixing wooden elements between them. Galvanized steel parts are considered the most common.

- Products for work with sandwich panels and corrugated flooring. At fastening of such self-tapping screws there is no need for drilling of openings. The hardware may bond materials whose total thickness does not exceed 12.5 mm.

Differences can be noted in the configuration features.

- Fasteners for metal works are performed with an elongated drill, compared with products for wood work. In addition, their diameter will be almost the same as the body itself, since the products will be subjected to a large load at the time of installation.

- Metal hardware has a slightly different thread - its pitch will be much less.

The drill at roofing self-tapping screws happens three types:

- for woodworking with a drilling thickness from 0.91 mm to 2 mm;

- for metal, where the thickness will vary from 0.91 mm to 5.3 mm:

- for attachment to a metal crate with a minimum drilling thickness of 0.91 mm and a maximum of 4.17 mm.

Roof screws are galvanized or painted. The latter option is most in demand due to the aesthetics of the combination of colors in combination with the additional moisture protection that the paint provides. The most popular products are white, green and blue, but they are also painted in other colors. As a rule, they are purchased for fixing corrugated board.

Based on the shape of the cap and method of installation, there are such varieties of roofing screws:

- conventional fasteners, to work with which you will need a standard screwdriver;

- products whose head has special faces for bit nozzles.

In order not to be mistaken when buying roofing screws, you should take into account the thickness of the roof sheathing. Unsuitable products will not be able to provide reliable fixation of the roofing material to the structure. And it will also be a mistake to assume that the elements for working with metal will also be suitable for installation to a wooden crate.The result of the use of a large metal drill will be the formation of a hole of an unsuitable size, since the wood is much softer. The trail of the screw will be more, and this is fraught with a situation when the product is not tightly located in the material.

But a small drill for wood with a large thread pitch will not be able to safely and seamlessly enter the metal, which will also reduce the quality of fixing raw materials.

Distinguish screws of one type from another can be on the label applied to the head. Some manufacturers of materials for the roof include in the product kit corresponding to the type of screws.

Dimensions

The size of the hardware is chosen from the calculation of exactly where the roof will be used fasteners. Their length can be from 12 to 150 mm.

The largest products, the size of which exceeds 50 mm, are purchased for fastening the individual components of the structure, as well as for working with wavy raw materials as a fastener for a multi-layer sheathing. Hardware of an average length of 25 mm is recommended for fixing the roofing material to the frame made of wood. The rest of the products ensures the bonding of the component parts of the material.

The standard diameter of screws is 4.8 mm, 5.5 mm and 6.3 mm for products intended for work with metal. Their length can be from 19 to 70 mm.

For wood use parts with a length of 12 mm with a diameter of 3-6 mm. Choosing screws for wood, you should take into account the fact that the maximum spinning product in wood, it should go deep into not less than 4.5 mm.

How to calculate the flow?

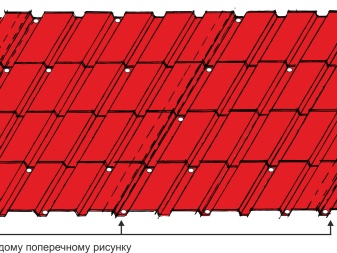

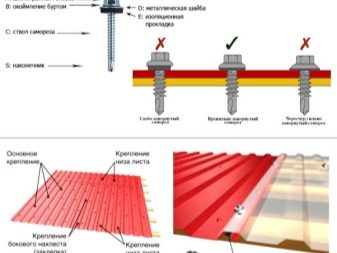

So that the reliability of installation of the roofing material does not cause doubts, it is necessary to correctly calculate the future consumption of fasteners. As practice shows, for fixing to the base 1m2 of the product you need to have about 10 self-tapping screws on hand. Such an amount is relevant only for a sheet of raw materials, which will have standard dimensions.

For the arrangement of the roof, involving a rather complicated configuration, or in the case when the material will have a thickness exceeding the usual values, the flow rate may increase.

There are a number of nuances that affect the consumption of fasteners:

- the type of material used for the arrangement of the roof;

- the area of the roof itself;

- sheet stacking step;

- raw material thickness;

- roof configuration - some types of roofs have additional details, due to the arrangement of which the number of self-tapping screws will increase.

Assembly process

The technology of laying the roof requires the use of such a useful tool as a screwdriver with the ability to change its rotation speed, because:

- conducting drilling holes for hardware is better to use the device at maximum power;

- and threading in the profile is performed better if working with the machine at minimum speed.

In the course of screwing hardware, the force with which the work will be performed also plays an important role. If the element is not screwed up to the end, it will not allow the raw material to be fully pressed against the frame, as a result of which there is a risk of spoiling the roofing material. And too tightened hardware deforms the puck, destroying its integrity, which is fraught with unpleasant situations.

When installing screws it is important to observe maximum perpendicularity to the crate - the angle formed between the fastener and the base must be straight. Even small errors in this matter will inevitably lead to the formation of a leak in the roof, breaking the material in a strong wind.

Having studied all the necessary steps of the roof mounting process, works can be performed personally without the involvement of qualified professionals.

- The first thing you need to decide on the type of construction of the roof where you want to perform installation work. Sophisticated configurations need a certain approach.

- Next, the number of self-tapping screws is counted, having previously determined which type is needed for work.

- Together with fasteners should get a screwdriver with a bat. It is advisable to give preference to lightweight tools - to perform the tasks with them will be much more comfortable.

- Having completed all the preparatory activities, the sheet is laid on the base, and the screw is placed in the screwdriver. Since the device is specially equipped with a magnet, it will be easy to perform, even while on the roof.

- Screwing into the corrugated sheet of material is carried out from the lowest wave. The device of the self-tapping screw involves cutting the material with a drill with further fixation to the crate.

- It is necessary to screw in fixture in a checkerboard pattern (through one wave).

- In places of overlap of sheets of roofing material fasteners are screwed into each of the existing waves.This technology will provide an opportunity to further strengthen the structure and avoid peeling of the material during the operation of the roof.

- In order to avoid corrosion of the part, installation should not be carried out with maximum effort, since an extra load will lead to the destruction of the gasket.

If during the work with fasteners mistakes were made, the product must be removed from the holes, which should be repaired using a sealant. With a wrench, you can easily unscrew the element from the base. If this is not done, the unprotected gaps will rust, and moisture will be able to seep through the roofing cake.

Tips

The question of choosing a quality and suitable fastener excites every consumer.

Experts recommend to adhere to the following basic recommendations that will help make a purchase.

- When selecting, first of all, the material from which the lathing of the roof is equipped will be fundamental. Since, based on this primary criterion, the choice of roofing screws.

- As for the size of the products, the most acceptable option would be to buy copies that have an average length,based on the table of available lengths for parts intended for work with metal, wood or corrugated flooring. This may entail a slight increase in expenditure on products, but will help protect against possible errors associated with the size mismatch.

- When buying branded products, it is worth checking the appropriate marking on the hat of the hardware - it will serve as confirmation that the funds were spent on truly certified and high-quality products.

- The main feature of roofing screws is a special treatment that prevents corrosion. On the original packaging, in the technical information posted by the manufacturer, the thickness of such a coating must be indicated. If this indicator has a value of less than 12 microns, then you should refrain from purchasing these products.

- Products that have no labeling and documentation, can be safely considered a low-quality fake.

- Manufacturers of roofing materials may refuse warranty service if its installation was accompanied by the use of poor-quality fasteners.

Experienced experts advise to adopt the following method of self-testing the quality of products:

- for this purpose, the washer is fixed between the pliers and compressed;

- if during the testing of parts, the paint and zinc coating were not peeling off, and the screw was left in place, then you can safely buy such products, since the product meets all standards and quality standards for this group of products.

Externally, good products can be distinguished from low-quality goods in the following ways:

- rubber gasket should be as close as possible with the washer;

- paint on all products in the package should not differ;

- A chipped tip at the screw will indicate that the product is not of a high level of quality, and the use of such an element will result in the formation of an uneven hole, as a result, rust will appear.

In order not to stumble upon low-quality goods, go only to proven and branded outlets. If you have any questions, always contact the sales consultants. Thus, you will save yourself from buying bad fasteners.

All about roofing screws, see the video below.