Filing roof overhangs: the details of the process

Roofing - step required. As a result of such work, the house receives not only a pleasant appearance, but also additional protection from the effects of precipitation.

What it is?

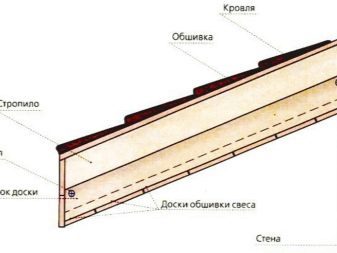

Overhangs - protruding parts around the perimeter of the roof. From the task is to protect the walls of the building from falling raindrops and other contaminants that may fall on the walls from the roof slopes. The overhangs can be of various sizes, traditionally their width varies between 0.4-1 m. By and large, it is not necessary to do a binder. This is more due to overall aesthetics than functionality.

Be that as it may, the binder performs several important tasks:

- With its help, you can protect from prying eyes the "stuffing" of the roofing pie. No one wants the layers of waterproofing, insulation, vapor barrier film to be visible.

- Hemming does not allow the wind to rip the sheets of the roof. If you do not hem the roof, then a strong gust of wind can penetrate the ventilation gap and simply lift the roof, completely destroying it. So binder can be considered mandatory in windy regions.

Filing is performed only in the very finale of all finishing works after the full lining of not only the roof, but also the building itself has been completed. Professionals call the hemming of the roof the final touch, giving a finished look to the whole structure.

There are several varieties of skates themselves, as well as tailoring. Each method of filing is suitable for a particular ramp, and you need to keep in mind all these subtleties. Analyze exactly which slope you are going to draw up, and only then proceed to the calculations, the purchase of materials and other preparations. Also consider the overall style concept of the house and decide if you need stitches at all in your case.

Types of construction

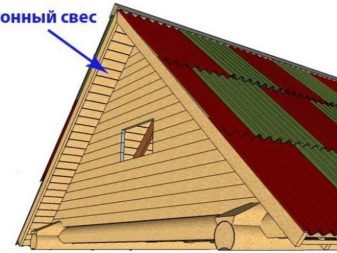

Overhangs are curtain or pediment. Eaves are arranged horizontally, and gables - vertically. Keep in mind that the gable overhangs are only sewn in a certain way, because protecting them is much more difficult than horizontal ones.

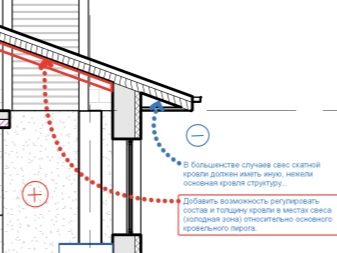

The main purpose of the eaves overhangs is to provide roof ventilation.

It is well known that between the layers of the roof be sure to leave gaps, otherwise they will not fully perform their functions and in many ways the roof will become ineffective. For example, if you do not provide the necessary space between the vapor barrier layer and the insulation, the insulation can soak, mold, and stop retaining heat. The presence of good ventilation - one of the main rules in the construction of the roof.

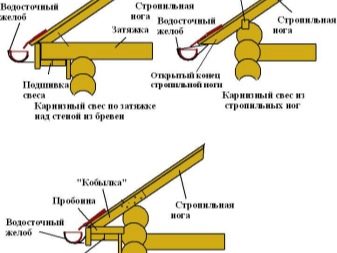

Eaves overhangs are simple or with the removal. An ordinary overhang is easier in the device, but it has several drawbacks, the main of which is the booming sound that occurs every time a strong wind blows. When performing filing with the removal of such trouble does not occur. It is possible to make ventilation through the eaves overhang both in the first and in the second case. The presence of the removal is not an obstacle.Gable overhangs perform a protective function, protecting the walls of the building from atmospheric phenomena.

Filing under the overhang is a standard component of the node, which is taken into account at the planning stage. It is worth noting that the options for nodes may be different, but each of them provides for the presence of a hem.

Pay attention that they make the filing of different roofs: mansard, flat, dvukhskatnoy, hip. Whatever the roof, it must be hemmed in order to guarantee not only the best aesthetic, but also functional performance. Not every option has gable filings. For example, chetyrehskatnaya or flat roof cost only eaves, since they have no pediments.

Straight along the rafters

Filing of overhangs straight along the rafters is the easiest way to set up. It is used mainly for roofs with small angles of slopes (up to 30 degrees). Even a beginner can perform a similar binder.

The technology is as follows:

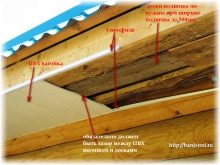

- an additional crate is made from the bars or planks, which will be used for further filing;

- the crate is screwed to the rafters, placed it parallel to the wall.

Keep in mind that the overhang must necessarily protrude 40-50 cm behind the walls. If the value is larger or smaller, it is preferable to choose a different method of filing.

If desired, and having a certain experience, you can arrange the crate perpendicular to the rafters, and not along them. However, it is important to monitor the condition of parallelism of the wall. The lining can be slightly directed away from the wall in order to protect the walls more, but it is the parallel arrangement that is the reference.

An important condition is to find overhangs in one plane.: if they fluctuate in height relative to the ground, then it is better to prefer another way of filing. In addition, smooth overhangs hem a lot easier, because you do not have to collect a binder of pieces. It will be enough to use a solid board or bar.

To facilitate installation, experts advise the use of a rope. So, first the corner elements of the overhangs are stitched, then the rope is stretched between them, and further installation is done along it. On the rope, you can immediately assess the flatness of the hemming, their sameness, and this greatly influences the overall aesthetics of the whole type of roof.

Horizontal

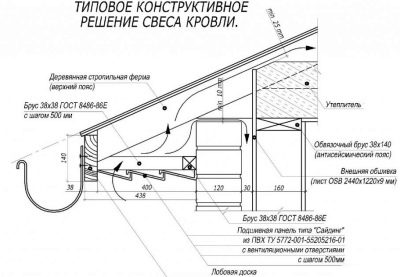

Horizontal binder is chosen in cases where the roof has steep slopes. In these situations, hemming looks harmonious and impressive. By and large, the horizontal filing is a box that is nailed on the eaves. In the future, it is specially bordered with boards. This is done to avoid moisture inside the box.

If the overhang is more than 45 cm wide, then it must be further strengthened. To do this, use additional beams, stacked in the middle of the box. So the lower part of the filing is nailed to this bar too, therefore the load on the overhangs and the specially constructed crate is significantly reduced. There is a second point here: this mount is necessary if the house is located in a windy area. Too wide slaughter can simply be blown away.

One of the intermediate stages of work is the installation of perpendicular bars. They are stuffed perpendicular to the wall. This is done to strengthen the overhang, to reduce the load, so that the snow and wind effects do not negatively affect the shape of the curved edges, and the entire load is redistributed to the transverse beams.

The above methods of filing overhangs are suitable for curtain rods. As for gables, it is permissible for them to use only one of the methods, the features of which are described below. This is connected with the unusual form of gable overhangs, and with the peculiarities of the load that falls on them. If the eaves with side wind are practically not affected, then gables, depending on their angle of inclination, can suffer from this.

Taking into account all the features and a method of filing on the crate for gables was developed.

By crate

An interesting feature of the trim of the gable overhang on the crate is that the method remains unchanged regardless of how exactly the eaves overhangs were hemmed. The beam is directly attached to the crate, making up the frame for the subsequent plating. In the future, cladding boards are attached directly to these parallel bars running along the entire gable.

A great influence on the filing technology has what kind of construction at the gable. is he it can be located almost flush with the wall (when there are practically no overhangs) or it can be strongly extended. In the first case, the binder is also made so that the water does not fall under it, because the probability of such an outcome is much higher here. In the second case, the entire filing is done from the bottom, where the drainage chute is fixed.

It should be borne in mind that in some cases it is still necessary to leave the eaves or gables not hemmed. Of course, this does not apply when the overhang is practically absent or shortened.

In rare cases, the cornice is stitched and the pediment is left without stitching, and vice versa, but this is rather an exception, since such a combination not only often looks unpresentable, but is also not the most convenient to use. Most often, there are cases when the filing of both the cornice and the pediment is made in the same way or both of them are left without it.

Thus, each of the methods of filing can be used when filing the overhangs with your own hands. This will not cause difficulties, especially if the person undertaking the construction has relevant experience.

How to hem?

A greater influence on the general appearance of the building is exerted not only by the way the filing of the roof overhangs was carried out, but also by the material chosen for this.For filings, you can use a variety of raw materials, ranging from the well-known wood and ending up with specially designed soffits.

There are several criteria on which to rely when choosing:

- An important influence has an aesthetic component. The material must be consistent with the general appearance of the building and the surrounding landscape. For example, hemming overhangs of a single-sided roof of a house in the hi-tech style with carved wooden panels is at least strange.

- Another crucial factor is the life of the material. Remember that overhangs and cladding, in particular, have a much greater negative impact than the roof as a whole, so the material must be strong and durable. Ideal is the choice of such an option, which has a service life approximately equal to the lifetime of the roof itself.

- Easy installation also means a lot. Many decide to hem overhangs alone, so the material should not be too heavy, brittle, or in any way complicate further work.

Among the variety of materials used for filing the overhangs, only a few have all of the above qualities.Some of them are more traditional and known since Soviet times, while others have appeared quite recently.

Nevertheless, each of these options deserves attention, since it is their professional builders who recommend to take note.

Board

Natural wood to this day remains the leader among the materials chosen for filing. This is due to the well-known technology of working with wood, the relative cheapness and the lack of need to acquire additional tools. Saw the board, giving it the right look and shape, you can use an ordinary hacksaw, and use screws to fix it.

Another advantage is that the tree "breathes", creating the most favorable microclimate under the roof. Properly equipped air vents, coupled with this feature, give an excellent result: the under-roof space does not dampen, does not perish, excessive moisture does not accumulate there. As a result, all layers of the roofing “pie” serve for a long time and optimally cope with their functions.

At installation of a board it is worth considering several factors.

- She, like any natural material, is easily exposed to parasites or other microorganisms, so the material must be properly treated before starting work. This will not only protect the board from fungus and mold, but also improve its water resistance and appearance.

- Under the influence of temperature changes, the wood shrinks and expands, so it will be necessary to leave a small compensation gap of a couple of millimeters.

However, not only the board is the "representative" of wood. This also includes two more varieties that are widely used in the cushioning work: clapboard and plywood.

Clapboard

In many ways, the quality of lining is similar to the board, but there is one important difference. Lining slats are distinguished by the fact that they are very well processed. Also, as a rule, these are narrow boards, while a planed board can be of any width.

When buying lining there are some nuances that professionals especially pay attention to. So, not any raw material is suitable for filing overhangs. Lining should not be too thick, but extremely thin - a bad decision. It is optimal if the thickness is 2-5 mm.Plays a role and humidity. Extremely dry, dried boards will quickly crack, and too wet boards will swell up.

For filing it is customary to choose moisture-resistant lining specially designed for these purposes, which is treated with a composition that prevents moisture from being trapped on it.

You can make a similar coating yourself, using ordinary varnish for wood. It is possible to carry the strips to the open air only after they are completely dried, otherwise there is a great risk that the varnish will dry out unevenly and, as a result, swell. Before installation, it is necessary to hold the paneling in the open air for about a month so that the material adapts to the surrounding conditions and does not warp over time.

Lining - the best choice, if you do not want to mess with the processing, as is the case with the boards. It should be borne in mind that the wall paneling is somewhat more expensive than a planed or edged board. Its price is about $ 6 per square meter against $ 2.5 (the price per square meter of the board).

Plywood

As in the case of the previous two options, when choosing plywood, special attention should be paid to moisture resistance.Unfortunately, it’s impossible to endow plywood sheets with this quality. It is necessary to initially buy plywood with water-repellent properties.

By themselves, the plates of moisture-resistant plywood are rigid and practically defy to deformations, therefore their installation can be done with a solid cloth. The plates are attached to a specially constructed frame of bars.

Ventilation must be provided in advance, since it cannot be made out of plywood. Be sure to purchase special ventilation grilles.

For many, the appearance of such filing is a big question. Without staining or other processing, plywood boards do not look very attractive, so not everyone is determined to make such hemming. However, all redeems durability and strength of the structure. In addition, the plywood is light with respect to the wall paneling and boards, which also speaks in its favor.

Thus, among the wooden products there is plenty to choose from. Many are bribed by their environmental friendliness, others by their appearance, and third by an affordable price. A number of qualities are inherent only in wood, others can be found in alternative materials, such as plastic or metal.In any case, do not get hung up on one thing. Before making a final choice in favor of one option or another, it is recommended that you familiarize yourself with all the available materials in detail. Only then can a decision be made that is reasonable and balanced.

PVC siding

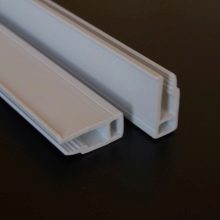

Polyvinyl chloride siding was not originally intended for filing overhangs, but some enterprising craftsmen adapted it for this. In order to make the files from siding, you need a whole set of parts:

- U-shaped strip for finishing the edges;

- "Corners" for finishing joints;

- ventilation grates.

Pre-worth considering that professionals do not recommend using siding when finishing gable overhangs, since its rigidity will not be enough to withstand all the effects. So, PVC siding is suitable mainly for finishing the eaves.

A large role is played by the number of fastenings falling on each bar. There can be at least two of them, but often the number reaches four. This is due to the overhang width: the larger it is, the more often the fixings are installed.

Many prefer PVC siding because of the large selection of colors, as well as affordable prices, which average $ 4 per square meter.

A serious disadvantage is the instability to ultraviolet: three years after the start of operation, the siding loses a significant proportion of saturation. It burns out unevenly. First of all, those parts that are directly in the open areas suffer, while the parts located in the shade can completely retain their original color. Because of this, over time, the filing may become spotty and unattractive. However, such metamorphosis does not affect the lifespan.

Professional sheet

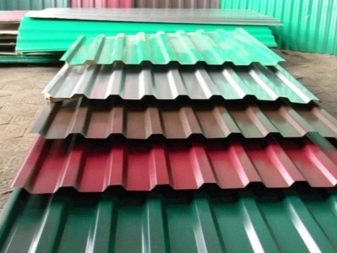

Sheathing profiled easily done. This is mainly due to the fact that the material is easily cut and from it you can easily "cut out" any kind of "flap" for filing.

Professional sheet - steel corrugated sheet, treated in a special way so that corrosion does not appear on it. The material is highly reliable, durable, durable, and also has some other advantages., among which - a huge selection of colors.You can choose decking almost any color. The most popular are dark brown, white, dark green. This choice of colors allows you to make a binder, ideally coinciding with the roof or walls.

During the work with a professional flooring any special tools are not necessary.

It will be enough those that are in each house or they can be easily borrowed from a friend or neighbor. To cut a professional sheet you need a circular saw for metal, and fix it with ordinary self-tapping screws, pre-drilled the holes in the drill.

An interesting find was the "corners" of the professional sheet, allowing the best way to close unnecessary gaps and gaps. At the same time, the necessary space still remains due to the relief of the material.

The professional flooring is considered the best material when work on stitching of overhangs is to be carried out by a novice. It is he who is least laborious to install and causes the least difficulty. In addition, the price of this material is also democratic, which can not please everyone who wants to save.

Spotlights

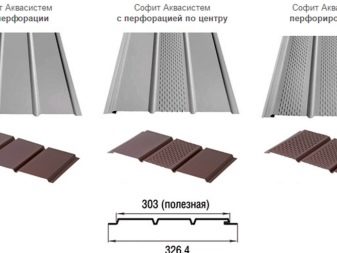

Soffits most resemble siding, but there is one significant difference.If PVC siding was designed for wall cladding, then spotlights is a material specifically designed for filing overhangs. Soffits have many improvements designed to make this material ideal for hemming:

- The presence of special vents. Some strips of spotlights are perforated, therefore difficulties with air access under the roof do not arise.

- Additional protective coating. It does not allow ultraviolet radiation to affect the spotlights, so they do not fade even for a long time under the open sunlight.

- A wide variety of materials. Soffits are made from both metals (copper, aluminum, steel) and vinyl. The plastic version is most common. This is mainly due to its cost.

- Ease of installation. Soffits are supplied with sets in which there are fasteners, solid and perforated strips, and connectors. Thus, the process of filing utterly simplified, and the result is a beautiful and neat overhang. Specialized equipment is also not needed. All the tools in the house will fit.

Despite the abundance of merits, the material has one major drawback. Spotlights cannot be used for hemming of the gable overhangs of the roof. They are suitable only for eaves. It is this little feature that makes many abandon them in favor of other, more traditional options.

Dimensions by standards

The sizes of overhangs are quite clearly stipulated in GOST. According to these norms, as well as SNiP, the optimal size of the overhang is 40-60 cm, but practice shows that sometimes these rules have to be neglected.

It is primarily about buildings belonging to certain architectural styles. For example, for an alpine chalet, it is appropriate to take the overhang for a distance of one and a half to three meters, and for a modern high-tech home, to completely abandon any overhang.

As for materials, there are no mandatory requirements, however there are recommended sizes, the usability of which is confirmed in practice. When choosing a planed board, pay attention to samples of at least 20 mm thickness. It is these that are best suited for filing, as they do not bend, do not suffer from the wind, and do not warp.

The length can be any, but it is best if it is equal to the length of the overhang itself (or its width with transverse fixing). This will avoid many joints, and the filing will be correspondingly stronger.

There are no standard sizes even for spotlights, although they are specially produced for filing overhangs. However, each of the major manufacturers considers it their duty to offer a different size than that offered by its competitor, so buyers have the opportunity to choose exactly what they need. Thus, the width of the panels varies from 30 to 80 cm, length - from 3 to 4 m. Soffits with indicators of 3.6х0.3 m are considered to be the most popular. As for aluminum soffits, their thickness can be from 0.3 to 0.6 mm The thickness of the vinyl - from 1 to 1.2 mm.

How to do?

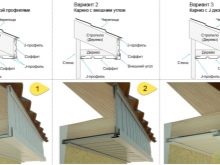

There are several options for filing. Depending on which option is chosen, the execution technology will vary:

- Parallel to the roof. In this case, the trim is made immediately under the rafter legs. Roughly speaking, the material is simply stuffed onto the rafters. This method of finishing is suitable when the roof has a small slope (up to 30 degrees).

- With the arrangement of hanging fillies. Bars are nailed to the rafter leg: some close to the wall, others parallel to the ground. It turns out that under the eaves triangles are formed. Further they are coated with the selected material. This technology is the most common.

- To the wall. Here the bar is nailed to the wall at the level of the lower edge of the overhang. Further between the rafter foot, forming the overhang, and the beaten bar, the facing material is simply packed. This method is the simplest, but not suitable for wooden buildings because of their tendency to warp.

The first stage of the plating is precisely the construction of such a box, which in the future will be finished with filing materials. Notice how well the bars are installed. If the work is not carried out with sufficient quality, then there is a high risk that the filing may warp, or even completely collapse in the future. Also here it is important to take into account the amendment for ventilation, leaving a special compensation gaps.

Finish

As mentioned above, the finishing of boxes is carried out using materials traditionally used for this purpose.Since you can intuitively guess how it is worth stuffing boards, lining or profiled sheets, it makes sense to consider finishing with new material - spotlights:

- Prepare all the necessary materials. Their set does not depend on what raw material was used to make the spotlights themselves. So, you need to have a J-profile, J-chamfer, a finishing profile and the spotlights themselves. For mounting screws with wide caps are required.

- Measure out the J-profilesaw off too much. Do the same with the spotlights. The easiest way to produce cutting grinder, but in the absence of such, you can use an ordinary hacksaw.

- There are holes in the profiles for their fastening. Use screws to fix the profiles in their places. It is necessary to leave a compensation clearance of 1 mm between the profile and the caps of the self-tapping screws.

- Trim the soffit strips so that they are 6 mm narrower than the distance between the grooves of the profiles. When installing in winter, it is necessary to make them already 10 mm.

- Insert soffits into the grooves of the J-profiles and fix them. Clearances should be maintained (and between the cap of the screw and the soffit, and 6 or 10 mm).

On this all the work is finished.It remains only to fix the "corner" on the lower outer edge for aesthetic reasons, but this step is optional.

Useful tips from professionals

Professional builders give some recommendations on how to make the overhang of the overhangs as quickly, easily and with good results:

- Be sure to match the material that sheathed overhangs with the environment. Pay attention not only to the price of raw materials and the ease of working with him, but also to its relevance.

- If you are not sure that you will carry out the installation correctly, refer to a friend who is more experienced in these matters or a specialized company. Of course, nothing terrible will happen if you approach the roof overhangs incorrectly, but you will lose time and money.

- Carry out the work better in the warm period - from April to October. Then the materials will not compress so much and you will not have to make corrections for compression. The same applies to the intense heat: during this period it is better to refrain from construction work.

- Be sure to decide in advance exactly where the gutters will be. Do not ventilate in the vicinity of this place, otherwise moisture may enter the ventilation gaps and cause damage to the roof layers. The best solution would be the arrangement of internal drainage.Although it is more difficult to implement, during operation such drainage system is much easier.

Filing of overhangs is a step not necessary, but desirable. Remember about safety when getting started.

See the video below for a few secrets to filing roofing overhangs.