Slate roof: features of elite materials for roofing

Natural slate is widely used in construction, including roof finishing. Slate roof not only has an attractive appearance, but also has high technical characteristics. Such a coating can last more than 200 years without losing its original properties. Shale roofing and features of elite materials for roofing will be discussed in more detail in this article.

Main characteristics

Slates are rocks that have a layered structure, so that natural stone is easily divided into plates of various shapes and sizes.Their thickness can be from 3 to 8 millimeters. With the help of grinding plates give a certain shape.

Slate roof has unique properties:

- The service life of slate roof is 200 years. The appearance and technical characteristics of the material remain unchanged.

- The thickness of the produced shale slabs is usually from 4 to 9 millimeters.

- Tiles can vary in shape and size. Square plates are produced with sides from 20 centimeters.

- Slate roof when laying creates a load on 1 m2 more than 25 kilograms.

- The optimum angle of inclination of the roof for the installation of slate tiles is 22 degrees. For angle values above 22 degrees, it is recommended to use plates of the smallest size.

Advantages and disadvantages

The coating of natural slate has a large number of advantages over other types of roofing materials.

Highlight the main advantages of slate roof:

- Slate does not belong to the category of porous materials, and therefore does not absorb moisture.

- Slate coating has good thermal insulation properties. In the hot period, the roof will not be exposed to overheating, and in winter it will protect the house from the penetration of cold.

- Good sound insulation.

- Fireproof. Slate is not combustible material.

- High service life.

- Environmentally friendly material.

- Aesthetic appearance. By combining tiles of various shapes and shades, you can create interesting compositions. In addition, there are many ways of laying the roof, which will allow you to create an original coating with a unique geometry.

- Resistance to sudden temperature changes.

- The roof does not deteriorate under the influence of severe frosts, and also does not lose its characteristics and appearance under the influence of direct sunlight.

- High strength.

- Resistance to deformation.

- Material does not corrode.

Despite its many advantages, shale roofing also has some drawbacks. Among the drawbacks of the coating there are several qualities:

- Natural slate does not differ in a wide range of shades unlike many other roofing materials.

- The large weight of the plates creates a high load on the roof truss system, which, in turn, must be strengthened.

- The high cost of the roof of slate. The price is due to the cost of extraction of natural stone and the manufacture of plates. It is worth noting that the slate roof is made by hand.

Kinds

In the modern market of finishing materials can be found several varieties of slate roofing.

First of all, this coating is divided into two main types:

- natural;

- artificial.

Natural tile is made of natural stone and belongs to the category of elite roof coatings. Artificial analogue is made from polymer composite materials. This tile has a similar appearance and some properties similar to natural paving. A distinctive feature is the low weight and a wide range of color options. The service life of artificial turf is not as long as that of natural material and is about 100 years.

As for the color range, there are not many options for various shades of natural slate tiles. Mostly roofing is available in gray tones. But you can also find options with a brown, green or burgundy hue.

Slate tiles also have differences in shape and size.

If we talk about the length and width of the plates, the most common are the following options:

- 15x20 centimeters;

- 20x20 centimeters;

- 20x25 centimeters;

- 60x30 centimeters.

The structure of natural shale allows you to create tiles of various shapes. Currently, there are more than 200 options for forms of coverage.

The most common types of tiles are:

- rectangle or square;

- angular shape;

- with a rounded edge;

- honeycomb coating;

- hexagons;

- in the form of fish scales.

How to choose?

Shale rocks can have different components in their composition, which will affect the technical characteristics of the roof. When choosing a material, it is recommended to pay attention to the country that is the manufacturer of the goods:

- The best quality is considered to be slate roofing of English and German production.

- Practically the coating from Spain is not inferior in quality, while the price for the material will be lower than on the roof from Germany and the UK.

- When buying Chinese-made material you need to be extremely careful, as there are many fakes.

- In Russia, shale roofing is practically not produced, and the quality of the material is significantly inferior to foreign analogues.

When choosing a roof, you must take into account the configuration of the roof, as well as its angle of inclination. The recommended angle of inclination of the roof for the installation of slate tiles is 22 degrees. However, to create a more reliable coverage the optimum angle is 30 degrees.

It should also be remembered that the higher the angle of inclination, the smaller should be shale plates.

Manufacturers

The quality of slate roofing depends not only on the material used in the manufacture of tiles, but also on the manufacturer. Before buying, it is recommended to familiarize yourself with the leading companies in the production and sale of shale coatings.

Rathscheck schiefer

The German company Rathscheck schiefer is engaged not only in the production of roofing materials from natural stone, but also in the extraction of slate rocks. Slate is mined in Germany, Spain and countries that belong to the New World. The production of slabs is modernized, which means cutting of rocks with diamond tools. However, further processing of the plates is done manually.

The shale roof of Rathscheck schiefer is of high quality, which affects the cost of the material. The finished tile must pass a quality control at the enterprise, which allows to avoid production defects.

Theis-boger

Theis-Boger is one of the first companies that launched the production of slate roofing. The company was founded in 1907 and to this day occupies a leading position in the sale of natural roofing, not only in Germany, but throughout Europe.

Theis-Boger provides an official 50-year warranty on its products from natural stone. The company produces tiles not only gray shades, but also color variants in the form of red and green plates. The material is highly resistant to weathering and mechanical damage.

Welsh slate

Welsh Slate has been producing natural English slate roofing since 1780. The materials produced by Welsh Slate adorn the roofs of many world-famous buildings that have already become architectural landmarks: Buckingham Palace in London, the Louvre Museum in Paris, European cathedrals.

Welsh Slate roofing materials are made of high-quality slate, which does not contain any impurities, so that the surface of the plates will not appear rust or ugly plaque. In addition, the material used is highly resistant to delamination. In the production of tiles from natural stone, the company focuses not only on the creation of high-quality material, but also on the unique design of the roof.

Styling options

With the help of slate tiles you can create completely unique coatings, combining various shapes and colors of the material.

The standard styling methods are English, French and German:

- English The method is used for laying plates of rectangular or square shape. The edges of the tiles can be both sharp and rounded. The cover is fastened with nails or special hooks. If the angle of inclination of the roof is less than 40 degrees, then two nails will be enough to fix the plate. The English way involves laying shale cover in horizontal rows. At the same time, it is necessary to form an overlap along the vertical and a gap on the sides (from three to 6 centimeters).

- French The method is used for mounting square-shaped plates with cut side corners. Fixing tiles produced with nails. On the ridge of the roof laying material is produced in two rows, which is necessary for sealing the joints of the plates.The angle formed at the same time must be sealed with a special reinforcing mixture.

- German laying used for mounting plates in the form of a square with rounded edges. Such plates are fixed in any chosen direction. Most often, the lower horizontal rows of tiles are closed by the upper ones, which allows you to create a coating that visually resembles fish scales.

Installation

The term of its operation and quality of a covering will depend on correctness of installation of a slate roof. Despite the fact that the tile is mounted quite easily, during installation you must follow all the rules and recommendations, or entrust the finishing work to experienced craftsmen.

Crate

A necessary step before laying roofing material is the installation of a reliable batten. The base under the slate tile is most often formed from wooden bars with a cross section of 4 to 6 centimeters. Fixation of the timber to the truss system is carried out with the help of nails, the minimum length of which can be 9 centimeters.

The distance between the elements of the batten is calculated depending on the size of the used shale plates. Usually the bars are mounted at a distance that is half the length of the tiles.Do not make a continuous crate to create a more reliable coverage. Wooden slats are recommended to be treated with water-repellent compounds and covered with a waterproofing wind-proof vapor-permeable membrane.

Laying tiles

Before proceeding with the main assembly work, it is necessary to determine the direction in which the plates will be laid. When choosing, the most frequent direction of the blowing winds in this climate zone should be taken into account.

Before attaching the roofing material to the roof, the tiles must be tapped gently with a hammer. If there is a dull sound when tapping, then such a plate is not used, since there are defects in the form of cracks on it. Fixing slate plates is made of galvanized or copper nails with large caps.

One tile requires at least two nails. Plates of large size or located at the edges of the roof are fastened with three nails. The elements of the roof are not nailed close to the crate: there should be a small distance between the cap and the tile. This is necessary in order to prevent the formation of cracks in the event thatif the base under the shale surface begins to deform.

The following video describes in detail how to properly lay slate tiles.

Interesting examples

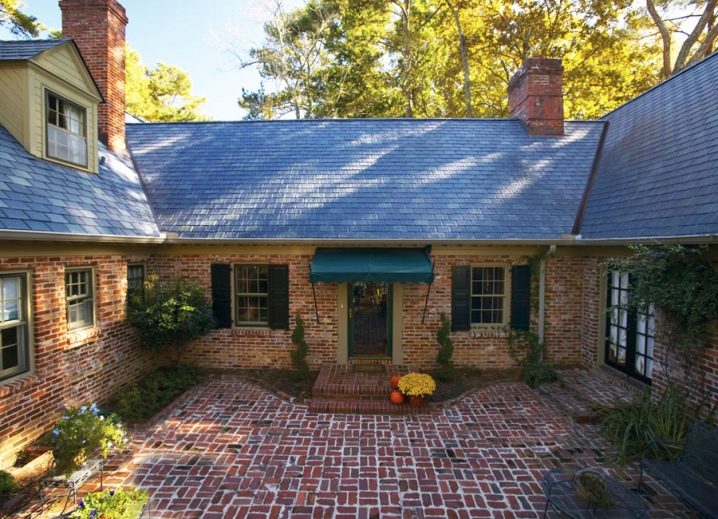

Slate roof looks great not only on old buildings, made in classical styles, but also on the roofs of houses in modern architectural styles.

Slate slabs can even cover roofs that have a complex structure.

The variety of forms of slate plates and methods of laying allows you to create original roof coverings.

When laying shale roofing, you can combine tiles of different shapes and sizes.