Roofing funnels: purpose and types

Excess water on the roof and improper drainage of it affects the entire structure. This issue is particularly acute for flat roofs, and for sloping and hip roofs, thanks to the slope, the liquid flows down. With the help of a drainpipe, you can solve the problem of excess water on the roof.

What it is?

Roofing funnel - an indispensable thing in the drainage system. It allows waste water to be drained from the roof. With this element, the liquid enters the drain pipe, and then - either in a special sewage system, or to the ground.

When operating a flat roof, a certain slope is required so that the wastewater does not linger on the surface of the roof. This allows you to increase the durability and reliability of the building.

The optimum slope for flat roofs ranges from 2 to 5%. With such a slope the liquid will never linger on the roof. But in some cases, the slope is not enough to drain the water mass. Therefore, now with particular attention are attributed to stormwater systems that operate smoothly, and also provide competent drainage from the roof. The most common option is to install roofing funnels.

Reliability and reliability of the drain system are provided with absolute tightness. In particular, this also applies to roofing funnels, since the rate of rainwater removal, the strength of the roof, and the safety of the entire structure depend on the quality of its installation.

Where does it apply?

Repair drainage funnels used in the repair work on the roof. They can significantly reduce material costs for repairs. The funnel includes a nozzle with numerous flexible skirts across the diameter.When the rainwater drain is damaged or the need to replace the waterproofing appears, you can do without dismantling it. The repair funnel is located inside the old one, and a new insulating material is installed under the flange, which ensures easy and fast repair.

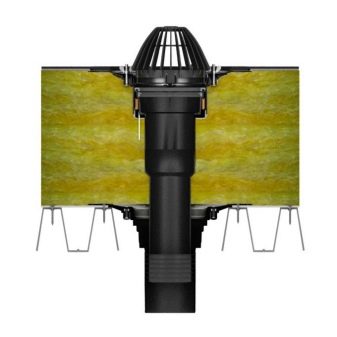

When combining roofing funnels with an additional drainage ring, extension pipe, ladder, adapter, water masses can be removed from several levels.

For simple roofs, there are special models with a duct for installation, which allows you to securely install the structure on the roof.

On operated flat roofs, funnels are used, which have a flat cover, so that it is convenient to walk on them. And also options with special ladders or with a steel, pig-iron lattice can be applied.

For our climatic conditions, we use devices that are resistant to frequent temperature changes. They are made from heat-resistant plastic, polymeric materials and stainless steel. The main advantages of these types are high strength, resistance to corrosion and durability.And they are also resistant to ultraviolet rays, which allows them to be used not only under mild conditions, but also at temperatures from -50 to +75 degrees.

The average lifetime of the craters for the roof is 50 years. During this time, waterproofing is often destroyed, so there is no need to replace only the funnel. But with various mechanical damage, any device fails, and the roofing funnel is no exception.

Materials

Gutters are made from materials such as copper, cast iron, PVC, and galvanized metal.

- Due to low prices, galvanized options are more common among buyers. Zinc is considered an element strong, reliable and immune to destructive corrosive effects.

- Copper funnels are suitable for all roofing materials, moreover, due to the high price, copper funnels are not very popular.

- Steel structures are characterized by high strength, which allows them to be installed on roofs with high traffic.

- PVC funnels are combined with materials such as soft tile, ondulin and shinglas.

- Pig-iron options differ in durability and reasonable price.

- Plastic products are resistant to negative external influences and loads. They are simple to install, as there is no need for adhesives, and have a democratic cost.

- Combined funnels are made from several materials. Most often plastic is used as the main component, and metal is used for additional elements. Options with galvanization and cast iron are possible. Combined structures are suitable for roofs with medium flotation and load.

Models and device

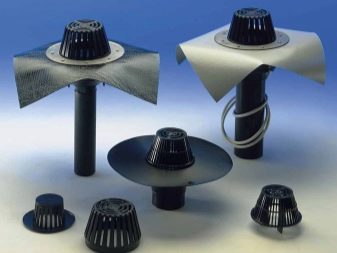

Roofing funnels differ in a variety of models.

- Roofing funnel of Termoclip of type VB creates an effective and practical water intake of precipitation from under the roof, from the roof surface, from under waterproofing. The use of high-strength materials in the manufacture allows you to increase resistance to negative environmental influences.

- Funnel type VF They have an additional crimping flange and a leaf-trap that allows them to be installed with roofing materials with various types of waterproofing materials. This option is the most durable and effective.

- Funnel type VFO electrically heated provide efficient operation at any time of the year, suitable for use with various types of waterproofing.

- Nad-type element NE-M creates a functional drainage system for roofing carpets. Suitable for pitched roof.

- Repair design of the VFOR type has a leaf trap and crimp flange. Heated neck supports design in cold weather.

- TD2 type gangway It has a drainage ring that provides a reliable, efficient and functional drain. Installed for the inversion, ballast and roofing.

- Roofing funnels with vertical and horizontal outlets They consist of several components: an extension cord, a superstructure, and a drainage flange. They differ from each other in the location of the side opening for draining the liquid. Horizontal funnels are not entirely profitable compared to vertical ones, since when replacing a fitting or a pipe, it is necessary to open a large area of the roof.

- Funnels with external drain consist of water intake funnel and gutters, risers and drain pipe.

This option is recommended to be installed in the southern regions with little precipitation.

Dimensions

Standard sizes of roofing funnels:

- height - more than 100 mm;

- diameter of the exhaust pipe 110 - 160 mm;

- output diameter 110 - 210 mm;

- dimensions (height x length x width): 110 x 110x450 mm.

Usually, the diameter of the receiving tube and the output diameter are the same, but in some cases they can differ up to 50 mm.

Manufacturers Overview

The modern building materials market is represented by a huge variety of domestic and foreign roofing funnels. The most popular is the German company HL, produces about 50 types of fittings.

Domestic company "TehnoNIKOL" also well established itself in the market of building materials. The company's products are much cheaper than foreign manufacturers.

How to choose?

Gutter funnels are selected depending on the design of the roof.

Before going to the hardware store, you need to decide on the number of fittings.

To calculate the number of funnels you need to know:

- roof dimensions;

- diameter of the storm pipe and the material from which it is made;

- is there a need for heating;

- information on mechanical loads, high level of waterproofing.

Taking into account the average rainfall and stock, it can be concluded that the roof area per funnel is 200 square meters. meters If the surface is larger, you can mount several funnels with a diameter of 100 mm. These values are typical for all materials, whether it is cast iron, plastic or polyvinyl chloride.

As for the choice of material, you should focus on the material of the roof. The best option - the funnel with the rest of the details of the drain are made of the same material. For example, if the roof is made of copper, then the roofing funnel and the entire drain should be chosen from copper.

When choosing a roofing funnel, the council of manufacturers will not interfere: they will recommend a suitable device depending on the cut of the roof.

How to make yourself?

The most affordable and popular material for the roofing funnel - galvanized sheet. For the manufacture of the fitting it is necessary to purchase a square sheet with a thickness of 0, 7 mm.

The manufacture of the drain funnel occurs in stages.

- Cut blanks with scissors for metal, making a mark in advance on the sheet.

- Edges are folded for folding.

- Form pipes and chutes with the use of rollers. For the mandrel, you can use a bar or pipe - under them lay the workpiece and bend until the edges meet. Then they are connected by folding.

- For the manufacture of the funnel itself you need several parts: a cone, a rim and a glass, the diameter of which is equal to the diameter of the drain.

- The catchment funnel is cut at a certain angle.

Installation

The first place to choose the installation of the roof funnel. This should be the lowest point of the cap. It should be borne in mind that they are evenly distributed over the entire surface of the roof, which will help to achieve maximum efficiency of the drainage system.

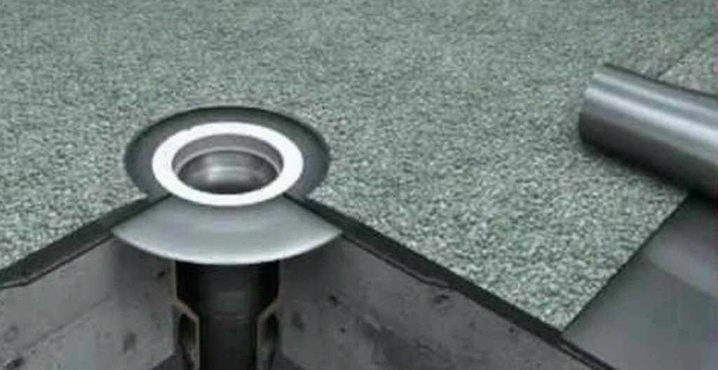

Then make a hole in the intended place and proceed to the direct installation of the structure. It is impossible to fix the funnel to the surface very tightly, as this may lead to its damage due to temperature changes. Next, go to the weatherization and waterproofing. Then you can fix the upper part of the fitting to the bottom.O-rings can be installed to seal at the pipe joints.

The film apron of a funnel is placed between the lower and upper roofing felt and connected with mastic from molten bitumen.

The water intake cannot be installed near the supporting columns, because various deformations occur most often here, which reduce the durability of the drainage system.

For a flat roof, fittings are mounted at the rate of 1 piece per 150 m2 of surface, and there must be at least two craters.

At the final stage, a layer of roof is laid, which is brought into the bowl of the funnel and strengthened with a pressure flange. Then it is necessary to check the operation of the system, for which water is poured near the water intake and it is observed whether the entire volume of liquid is taken away.

If everything is in order, proceed to the facing work and further refining of the roof.

Pro tips

Certain requirements are imposed on the individual elements of the drainpipe.

- Tightness of the whole structure. In the opposite case, the water mass will flow into the building, which will lead to the destruction of the roof and interior decoration.To avoid this, it is advised to create an additional protection of waterproofing material, which covers the side of the funnel.

- The best option for the design is a removable cover. Today, almost everywhere, removable structures are common, but you can also find old models of roofing funnels with all-in-one elements. Removing the cover will allow you to easily clean the inner surface of various blockages: foliage or sand.

- The protective cap must be securely fastened in its place.

In order to reduce the pollution of the internal space of the drainage system, you can install a special filter called a safety umbrella.

When self-installation of the roofing funnel, you need to pay attention to the recommendations of experts:

- installation work starts from the bottom, gradually rising to the top;

- internal water supply channels and shafts after installation of the fitting are covered with panels, which allows maintaining a stable temperature;

- the water drain funnel has to approach a roofing material;

- the installation place of the funnel must necessarily be below the main surface, if necessary, you can specifically make the slope.

Metal pipes are equipped with heating, because in the cold season the liquid in them will freeze, which will lead to rupture of the pipes.

How to install the roofing funnel, see the following video.