The details of the process of installing a chimney of sandwich pipes through the roof

Properly installed high-quality chimney - a pledge of safe operation of the furnace in country houses, baths and country houses. Recently, chimneys made of sandwich pipes have become popular. Despite a number of nuances in installation, such pipes are popular because of the low price and good technical characteristics.

Design features

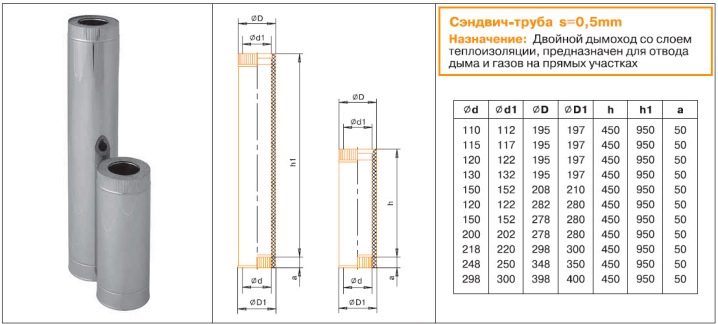

Most of the fires in private households occur due to gross violations of the technology of installation of furnace equipment, including pipes for smoke extraction. Modern sandwich pipes are more fireproof than ordinary ones. The chimney-type sandwich is a three-layer pipe. These products are made of stainless or galvanized steel.

As a rule, galvanized models are used for boilers and gas boilers, as the material is poorly resistant to high temperatures and burns out.Therefore, stainless steel sandwich pipes are more versatile and can be installed to solid fuel boilers.

Sandwich consists of three layers.

- Inner contour. It is a round cylinder with a thickness of 1 mm or more. The inner tube is made of a whole sheet of metal by means of a hermetic welding seam. Due to the anticorrosive properties of the material for the manufacture of a sandwich pipe, it is not afraid of exposure to moisture and condensate.

- Insulation. Located between the inner and outer layers. It does not allow the heat from the pipe to heat the roof and other nearby elements, and also does not allow the smoke to cool down while moving along the chimney, which significantly reduces the formation of soot on the pipe walls. This allows the chimney to be cleaned much less frequently than with conventional pipes. For the insulation layer, fire resistant materials of the highest class are used, for example, mineral wool from basalt, capable of withstanding temperatures from 7000 C. The thickness of the insulation layer, depending on the material and manufacturer, can vary from 40 to 60 mm.

- Outer shell. It can be made from stainless steel or from other metals. In order not to damage the galvanic layer of stainless steel, which prevents corrosion, the seam is performed by laser welding. Variants of stainless steel sandwich pipes with the outer contour are the most cost-effective ones, made of copper and brass are expensive, but very spectacular in appearance.

Sandwich type chimneys consist of additional elements. Their height and diameter can vary greatly depending on the manufacturer, so it is best to purchase all the components and components of the same brand.

Advantages and disadvantages

Like any products, the sandwich chimney has both its advantages and disadvantages.

Positive aspects include some aspects.

- High-quality insulation. The inner layer reliably protects the elements of the roof located next to the chimney from heat and fire. Thanks to this feature, the sandwich pipe can be displayed both on the roof and on the facade of the building.

- Inexpensive and easy maintenance and repair. Since soot does not form, there is no need to clean it often. In the event of a breakdown, finding and replacing additional parts is also not difficult, even independently.Moreover, there are many manufacturers and models of sandwich pipes on the market.

- Low weight design. Sandwich chimney several times easier than the classic version of the brickwork. This allows not to create an additional load on the foundation of the building.

- No condensation. In conventional chimneys, due to the difference in temperature inside and outside, moisture is formed, which leads to metal corrosion and gradual destruction, which can be very dangerous. Sandwich, due to the special design is devoid of this significant drawback.

- Attractive appearance. In comparison with conventional pipes made of steel, the sandwich looks more presentable and neat, especially if the external circuit is made of noble copper or brass.

- Easy installation. Flange or bayonet fastening is used to fasten a chimney pipe from a sandwich, which allows you to independently remove the chimney through the roof and fix it.

- Low cost. Stainless steel sandwich chimneys - the most budgetary option, brass and copper - more expensive.

Not a lot of disadvantages.

- Short life.After 10-15 years, such a chimney becomes unusable and requires replacement, while a brick pipe can last for 20 or more years.

- Reduced tightness during operation. This is due to the constant impact of temperature differences on the sections of the sandwich pipe.

However, despite the shortcomings, the sandwich pipe is a great alternative to classic chimneys, with quicker and easier installation.

Mounting principles

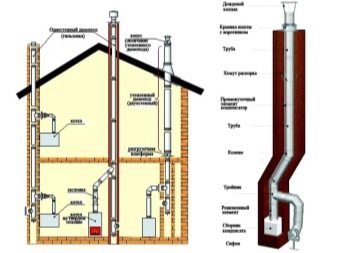

In order for the chimney to be installed correctly and there is no risk of fire or carbon monoxide poisoning, building codes and fire safety regulations must be observed.

It is necessary to be guided by the following principles:

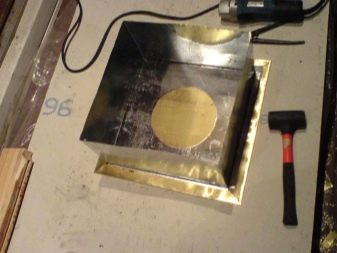

- in the place where the chimney comes in contact with the roof or facade of the building, thermal insulation should be laid using a pipe or a steel box;

- in no case should the sandwich pipe be directly connected to the inlet pipe of the furnace; such chimneys are installed only at the outlet;

- the chimney is assembled so that the joints do not fall on the border with the roof;

- the diameter of the sandwich pipe along the entire length should coincide with the diameter of the heating boiler pipe;

- the length of the horizontal sections should not exceed 1 meter, as they greatly reduce cravings;

- A revision window is installed at the bottom of the chimney through which the condition of the pipe can be easily monitored;

- all additional elements must match in diameter so that no gaps are formed that reduce the fire safety of the pipe;

- to easily install a pipe between the roof truss system, elbows are used with an angle of 450; two 450 elbows are used to form a right angle;

- if the chimney passes in close proximity to the walls, they are protected by asbestos fiber.

When installing the inner contour of the pipe, each next element is inserted inside the previous one, and the external contour is assembled in reverse.

Assembly sequence

The device sandwich chimney through the roof requires to take into account the location of floors and carrying beams and take into account the minimum distance from the pipe to flammable objects (walls, ceiling) of 13 centimeters.

The installation sequence is as follows:

- There is an opening in the ceiling with an indent of 250 mm from the edge of the pipe. The edges of the hole are closed with insulation.You can use minerite, which is attached with screws or nails.

- The chimney pipe is put into the box. It should be placed vertically.

- Excess space is laid with mineral wool from basalt. On the front side of the design sheet stainless steel.

- At the conclusion of the attic, a hole is cut through the roof. In place of the passage is placed hydro- and vapor barrier criss-cross.

- After that, a master flash is put on the pipe close to the roof, the necessary form is attached to its skirt.

- The junction of the master flush and pipes are thoroughly coated with a heat-resistant sealing compound. As the roof under the rubber.

- Each attachment is additionally tightened with a special clamp.

Sandwich pipes - the perfect solution for chimney equipment not only stoves, but also a boiler or a gas boiler. Its installation does not require much time and effort and can be performed on its own, provided that the installation instructions and fire safety standards are observed.

In more detail about installation of a flue from a sandwich pipes look further.