Bikrost TechnoNIKOL: advantages and disadvantages

The rolled cloth "Bikrost" of the producer "TekhnoNIKOL" - the modern material used when carrying out roofing works. This product due to its technical characteristics significantly improves the quality of waterproofing and facilitates this time-consuming and dirty process. Practical experience shows that the product, along with the advantages, has disadvantages that the consumer needs to know about.

Structural composition

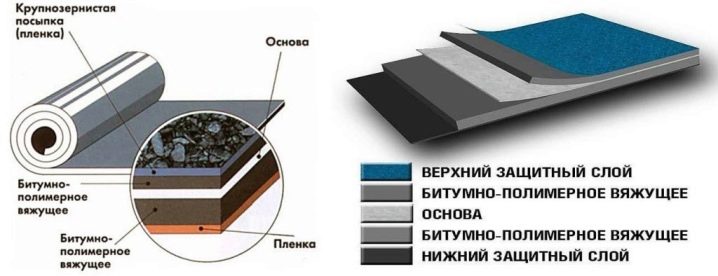

The main purpose of the material is to create an absolute tightness of the coating. Since we are talking about the roof, this means a high level of water resistance of the canvas. This applies to all types of building materials. The product has a two-layer structure and resembles a sandwich.

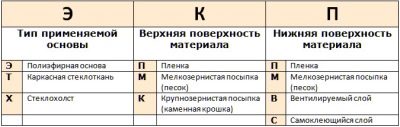

Synthetic polyester fiber or fiberglass, viscous bituminous mixture or bitumen modified with polymers, applied on both sides under high pressure, are taken as the basis. Three letters in the classification terminology of the material provide information on the composition of the web.

The reinforcing (main) layer or the first letter may be indicated by the symbol:

- "X" (fiberglass);

- "C" or "T" (fiberglass);

- "E" (polyester fiber);

- "O" (cardboard backing).

Surface coating information is indicated by the second letter:

- "K" (shale screenings or granulated rock);

- “P” (polymer film);

- "M" (mineral sand).

The third letter in the marking - covering the back of the material:

- "P" (polymer film);

- "M" (mineral mix).

The material is produced in the form of a roll web with a width of 1 m and a length of 7 to 15 m. The weight of the package also depends on the meter. It can be 30-45 kg. The consumption of the canvas in use is calculated taking into account the overlap (approximately 8 cm).

The material is in demand because of its widespread use. It can be used to cover the roof, including its sloping options. Brand products suitable for use as a vapor barrier and waterproofing, suitable for restoration, renovation of roofs.The material has a relatively affordable price, which is fully consistent with the stated qualities of the material.

Specifications

The parameters of the material and its distinctive properties are confirmed by certificates and other documentation that must be viewed when choosing a product. The product is applicable for different types of roofing. It can be used on straight and flat planes, there are several basic characteristics.

It is worth noting the advantages of this material.

- Plasticity and flexibility. This indicator is important because at low temperatures the web bends poorly and is subject to the formation of cracks. Fragility is found at -15 degrees (this applies to the model of HPP).

- The material has good heat resistance parameters. These useful properties make it possible to avoid the spreading of the web from the reinforcing coating at high temperature.

- Tensile strength. Reinforcing mesh can withstand up to 30 kg load when stretching, while the bitumen is not damaged.

- In addition, the material is water absorbing. During the day, it absorbs water in the amount of 1% of its own mass.

- High fire safety "Bikrost" due to its compliance with the flammability of B3.It belongs to the class of combustible materials G4.

- Easy installation, installation in a short time. Installation can be carried out within a few hours.

These characteristics can be considered the advantages of such products, but it has drawbacks.

- The main disadvantage is a short service life of about 5 years (with the exception of fiberglass-based material, which serves from 7 to 10 years).

- The builders note that the material is rather heavy, and this is an undoubted shortcoming in the working conditions for the roof.

- The working process will require special construction tools and a gas burner, otherwise you can not hope for a qualitative result.

Features of different types

The two main types of material "Bikrost" have some differences. These are waterproofing cloths most demanded for roofing works.

- Bikrost K - products used for the top layer of the roof. Its outer surface is made of large-scale slate or sand, the material thickness is 3.7 mm.

- "Bikrost P" - a distinctive feature of the product is a protective lower layer in the form of a polymer film, the total thickness is 2.7 mm.

It is worth noting other varieties.

- CCI - frame glass fabric obtained by weaving glass yarns and impregnated with a mixture of bitumen. It is considered the most durable. From above and from below has a protective polymeric film. Such coverage can last up to 7 years.

- HSP used for lower laying of multi-layer roofing carpet. The base material is fiberglass, treated with bitumen and polymer mixture, covered with polyethylene on all sides.

- HKP It is based on fiberglass. From the outside, it has a slate sprinkle. From the inside there is a polymer. The canvas does not fade under the influence of the sun and is considered quite durable due to protection with the use of granules.

- TCH - treats especially strong versions, fiberglass serves as a basis. In addition to bitumen, the upper side is covered with gray roofing granulate (shale). Such type of a soft roof is suitable for a ballast and not loaded flat roof. This is the most expensive product, the cost of which is determined by high quality and reliability.

- EKP - a plastic type of waterproofing sheet, successfully applied to roofs with a slight slope.

- EPP - a material suitable for thermal insulation is coated on both sides with a polymer film.

It is not necessary to do only one layer of waterproofing. With the help of two layers of "Bikrost" (HPP and HKP), superimposed one on another, a higher quality of coating is achieved, the service life increases to 12 years.

Waterproofing installation

Laying waterproofing materials of this brand can be yourself. In this case, it is desirable to have a basic knowledge of the process and comply with safety procedures. All work is carried out in special clothes and shoes.

For the installation will require:

- gas stove;

- propane tank;

- special roofing knife;

- bituminous primer;

- rolling roller with metal needles;

- hoses;

- hook;

- brush;

- roll cloth.

Preparation is reduced to cleaning the surface of old coatings, small litter, moisture and dust. It is necessary to maximize the plane. To do this, apply a solution of cement or bitumen mastic.

After brushing or applying a primer mixed with gasoline. Its layer should dry before further work.

- Roll roll at the place of fixation with a margin of 20 cm on both sides.Cut off the excess, the prepared sheet is folded again.

- Work should be done together. Rolling is done from the bottom to the top using a hook. At this time, the second worker heats the material and the roof, trying not to destroy the layer of bitumen.

- This is followed by the connection of the material with the base, followed by a roller at the edges, paying special attention to the seams.

- After drying of the lower part proceed to the front coating, using products with granules to protect against external influences.

- With a roof slope of more than 15%, a soft roof is fixed along the edge of the eaves, less than 15% is fixed perpendicularly and in parallel.

Walk on the floor until it is completely dry.

Roofing materials "Bikrost" - widely demanded products. Especially popular waterproofing fabric of this brand. This is a relatively affordable material, the cost of which depends on the characteristics of strength.

On the roof covering of the garage with technonicol do-it-yourselfers in the next video.