Repair of the roof: the sequence of works to eliminate leaks

“The roof of his house” is not only perceived positively by people, even songs are composed about it. Always after a long journey or life troubles tend to go there to enjoy the peace and comfort. But all this is possible only under the condition that the roof itself is working properly and does not allow precipitation, cold winds.

Where to begin?

Even the most reliable and stable structures periodically need to be repaired. Repair of the roof of a private house can be almost always carried out by the residents themselves. There is no need to turn to professionals and just pay them for their work.Inspection of the roof - both when there is a clear need for repair, and in regular mode, usually start from attics or attic.

First of all, looking for an answer to such questions:

- how strong is wear of the rafters and their individual parts;

- are single elements intact;

- there is a damp, rotten smell;

- Are there any areas affected by mold, other fungi and corrosion?

It is recommended to inspect the roof at the time of heavy rain; then even the weakest leakages and their causes are most likely to be detected. Regardless of the result of internal diagnostics, the roof should be inspected from the outside.

There, the assessment of the state of the elements is carried out in this order:

- the horse;

- points of contact of pipes to the roof and other vertical structures;

- steel aprons;

- endovy;

- curtain boards and overhangs;

- total coverage;

- ventilation and waterproofing.

Types of device

Finding certain defects, you should not immediately rush to make repairs. We must first consider the subsequent actions, taking into account the characteristics of certain types of roofing. According to their specificity, an optimal approach is chosen. For a flat folded roof, airtightness must be ensured, and therefore even partial separation, violation of the integrity of its surface should be immediately eliminated.It is recommended to observe at repair the same type of fold, which was originally chosen.

Violation of this rule may lead to a mismatch of the facial finish with the substrate or the appearance of sections looking ridiculous, alien in appearance. Folds can be formed not only manually, but also using an electromechanical tool. It is necessary to think through this nuance in advance. Experts believe that the most reliable variant of a seam is a standing double seam.

Choosing the folded roof again (if the former surface was destroyed or extremely worn), it is worth remembering that the simplicity of repair is marred by a high probability of avalanche snow dumping and high sensitivity to shocks. In many cases, preference is given to a more modern membrane roof, which has no seams. Using a PVC-based membrane to restore the integrity of the roof is not very reasonable. Yes, it is durable and easily bent, but it is quickly damaged by aggressive substances, including acids. Lubricating oil or solvent coatings on such a coating is extremely detrimental.

EPDM is more resistant to open flame, acid and hypothermia compared with polyvinyl chloride. Somewhat increased cost and the mandatory use of glue should be considered when choosing and subsequent work. If the sealing is carried out with a TPO membrane, the charge for it will be very high. But on the other hand, strength, stability with negative impacts will be guaranteed. In addition, when working you will need to use a system that supplies hot air, because the mounted joints must be heated.

Mechanically fix the membrane is justified if the roof is located under a slope of more than 10 degrees. For work, fasteners with a wide cap are recommended, which will be fixed in steps of 0.2 m. The most reliable layout, however, turns out to be heated with a special apparatus. Therefore, if it is firmly decided to carry out repairs on its own, you will have to abandon the use of membranes. But when the goal is set to achieve excellent waterproofing, not skimping on costs, this is one of the best types of coating - only profile metal and ceramic tile can compare with it.

Much easier to use bitumen roofing. It is completely immune to moisture, able to withstand almost any conditions prevailing in our country. The only place where it should not be used is the pole of the cold, perhaps. Soft bitumen canvas reliably absorbs sounds when struck on the roof. And let it be pleasant to read about the characteristic “rain drum” in fiction, it’s not so romantic to feel the same at home.

It is also not necessary to use bitumen material to seal the roof where the slope is less than 12 degrees. This immediately weakens the closure of the joints. Since the flooring will be flexible, it is required to lay a foundation with increased rigidity under it. To perform work in the cold more than 5 degrees for technological reasons should not be. Repair of such a roof is made only in its entirety; it is impossible to disassemble its separate part and repair the damage.

The choice of an inversion system for a pitched roof is inadmissible; it can only be laid on a perfectly flat plane. But with significant solar activity and with significant temperature differences, this solution is most reasonable.Inversion is different from the usual roofing cake in that the sequence of layers is reversed; no polymer, bitumen or a mixture of them is taken out. No matter how hard manufacturers try to increase the protection of these materials from the destructive effects of atmospheric elements, they have not yet succeeded. The transfer of waterproofing in the middle means raising to the surface of the ballast, covering the lower layers from the harmful effects of solar radiation.

Thanks to the ballast, the flat roof can not be mechanically fixed over the whole area. The smaller the holes, the better, because each of them increases the likelihood of water seeping down.

Be sure to have to mount material:

- where it adjoins the bearing wall;

- on the border with the parapet;

- on the perimeter of the roofing penetration.

In addition to increased stability, this method of mounting the roof during construction or repair saves time. It is not necessary to mount a vapor barrier in an inversion scheme; its role is assumed by a layer that protects against water. As the amount of materials used is reduced, the charge for them is significantly reduced.

It should be remembered that the inversion roof is very heavy, that the search for water ingress is difficult. To raise the ballast and return it back, you will have to spend a lot of effort or involve construction equipment.

Materials

In addition to the arrangement scheme, you need to choose carefully and roofing materials. Fans of atypical solutions and original design can use the glass roof. Contrary to the stereotype that has been preserved from recent times, such a solution is quite accessible. Modern types of glass have decent strength and are in no hurry to collapse from the slightest blow, which is often afraid of home owners. But there is another problem: maintaining a good microclimate inside during hot or cold weather. The thermal conductivity of glass is consistently higher than that of any traditional materials.

Each seam of the panoramic structure should be carefully treated with high quality sealant. If water seeps down, it is first necessary to look for the source of the problem in sealed surfaces. Only when there everything is in order, you need to inspect other parts of the glazing.On the concrete, brick wall instead of glass often use the roof of wooden material. It is much easier to find a problem place in it, however, you will have to spend quite a significant amount on the acquisition of the blocks themselves and carry out laborious work.

Important: stacking piece wooden products, you will need to process them with flame retardants. In places where the chimney is removed, even this protection may not be enough. There are sure to put fireproof slabs or rolls.

It is recommended to choose conifers. The presence of resins in them increases resistance to moisture and service life, postpones the moment when the next repair is required. From hardwood it is best to use durable and long-lasting unchanged oak.

Selecting raw materials for preparation, you need to carefully examine it. Even a single knot or move, laid by gnawing insects, makes the material unusable. Only the central part of the logs is suitable for work, the sapwood is rejected. Wizard wood must be cut by hand using a special technology. This allows you to maintain the integrity of the capillaries and the tightness of the pores, delay the timewhen the wood starts to let the moisture down.

Polymer materials are no worse than wood in practice. Some of them have already been discussed. The advantage of this solution is a wide variety of sizes - up to 2 m in width and up to 6 m in length, which allows you to minimize the number of joined parts. Polymer coating is recommended for homes that must have a high level of protection against fire. There is no need for auxiliary rassek, stopping the spread of fire, and therefore you can put a layer of waterproofing a continuous cloth.

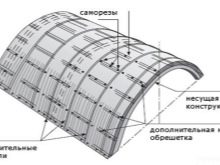

More and more in the construction of buildings are beginning to use polycarbonate array to create a roof. It is not suitable, of course, to cover the whole house, but for protection from the top extensions or ancillary facilities is quite acceptable. Polycarbonate covers the building from the sun's ultraviolet rays, but does not detain scattered light. The lightness of the design and the excellent level of thermal protection also allow us to recommend it. It is possible to crown polycarbonate with any building even with a solid snow load (200 kg per 1 sq. M).

If such a roof leaks after a strong hail, it will almost certainly have to be changed. Polycarbonate is not very resistant to impact and abrasive effects. Both at construction, and at repair it is required to cut material, directing stiffening ribs in the same direction, as a roofing slope. Rafters can be formed from a board up to 5 cm thick, which is necessarily impregnated with protective reagents. Carefully look at the orientation of the sheet - the ultraviolet retarding layer should be on top.

All gaps and holes, of course, are carefully treated with sealant. If an arched roof is formed, the fold is made according to a pattern. The slightest distortion of geometry immediately deprives the meaning of further work. Do not apply excessive force to polycarbonate, although it is durable, it has limited hardness. In choosing the angle of inclination, such material is not limited to the owners and repairmen.

With all the desire of some people to experiment, most still prefer durable and opaque structures. An example of such a roof is a galvanized iron profile coating. Pure steel without additional protection is completely impractical, and will last a maximum of a year or two. Therefore, all the benefits when buying it will be absorbed by frequent updates and unnecessary expenditure of energy.Even compared to more modern and reliable solutions, the metal surface is quite competitive and will be used for a long time.

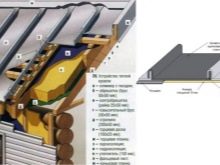

Ordinary roofing with a zinc layer is used to obtain a folded picture. A more advanced type of this material is professional flooring. When forming it in production, trapezoidal or wavy parts are used. Such a technique helps not only to form a characteristic attractive appearance, but also to increase the rigidity of the coating, to increase the tolerable load-bearing loads. The front side of the flooring is always covered with a decorative layer, unlike in contact with the lining.

A kind of steel roofing is a tile reproducing material. The outer surface of it is covered with a layer of polymer, which is characterized by increased resistance to harmful effects, especially corrosion. There are species that mimic the appearance of not only ceramic, but also bituminous, modular tiles. When using metal tiles, you need to take care to enhance the sound insulation below. It is also worth thinking about how to compensate for the active heat leaving outside.It is not recommended to use sheets with a base thinner than 0.6 mm. Even professional builders are unlikely to be able to build from such a reliable structure. It is very good if the external protection is made of bitumen, rubber or polymer, but the paintwork is too unreliable.

It must be at least 0.25 cm thick. Also it is necessary to prefer products whose cuts are protected on a par with the upper plane.

Ways to solve the problem

Having dealt with the peculiarities of specific materials, it is now necessary to figure out what to do if not the entire roof flows, but a separate section of it or several places. To change the coating completely in such cases, unless it is required by the technology, it is simply unprofitable. Repairing the old bitumen roof of a country garden house or an urban cottage with your own hands using sintering helps reduce the consumption of valuable resources.

Its essence is that the properties of materials containing bitumen are restored with uniform heating of the entire surface. First, the problem area is heated to 100-110 degrees.

This treatment causes an increase in pressure between the layers.As a result, moisture evaporates, and the air leaves the roofing material through the slightest cracks and special punctures. When the electric heater stops working, the damaged area is compacted using a roofing roller. Its passage eliminates large swollen areas and cavities, expels even significant air bubbles. The second step is to drain the carpet with warming up to 160-1900 degrees.

At this temperature, bitumen is mixed with other layers, impregnates the facial coating and leveling base. As a result, the interlayers stick together firmly, the mechanical strength and protection from water grow. It's not limited to the passage of the rink, you need to add more crushed bitumen. Thanks to him, all defects will be closed, and the bituminous binder that has already served its time will be replaced. The final step is the formation of a complete monolith, which will occur 6-8 hours after the completion of processing.

The restoration of the roofing according to the described technology does not simply compensate for the temporary loss of basic qualities. The main parameters of the renovated roof will be higher than before the start of work.Sometimes it is still practiced to apply external waterproofing, for which take roll material based on polyesters.

This material must be issued by leading firms, and another requirement for it will be the presence of coarse-grained topping. It is recommended to equip all the repaired space with aerators, which will begin to supply air to the insulation and eliminate the soon appearance of new swellings.

In comparison with other variants, the sintering technique has a number of advantages:

- expenses are reduced by 50-60%;

- precipitation during the production of works will not be able to get inside the house;

- with strict adherence to technology and the use of quality materials, the next repair will be required at least 10 years later;

- it takes relatively little time;

- roof repair will give good results regardless of the season;

- fire risks are reduced, environmental damage is almost eliminated.

Sintering is performed without removing the previous coating. There is no need for the reconstruction of interior decoration, repair of ceilings or attics. Almost no garbage is formed, the removal and removal of which presents known difficulties.Work can be done even when people live or work below. It is recommended to clean the roof in advance and open all cracked, swollen places with a perforator.

You can not overlook and repair cement screed under a flat roof, which is used for maximum alignment, or vice versa, to create a pronounced slope. Like all constructions, this piece of cake loses valuable qualities over time and needs to be repaired.

The problem is that it is almost always possible to detect defects only after dismantling the waterproofing. Only occasionally can they be identified at an earlier stage of work and be prepared in a timely manner.

Assessment of the condition of the screed is as follows:

- even material with single cracks or grooves does not even always require cosmetic finishing;

- if there are relatively deep cracks, the length of which is equal to 1/3 of the short edge of the roof or less than this value, it is impossible to do without repair;

- when the surface is completely covered with a grid of flaws, has many "mountains" and "lowlands" - perhaps due to excessive thinness the material is deformed, it should be thoroughly repaired, almost always need professional advice;

- in the presence of a mass of cracks, significant distortion of the relief and other problems, the screed is almost always dismantled, and the work is best entrusted to professionals.

A variety of materials for the correction of defects cement screed is large enough. The optimal choice involves taking into account the load on the roof and climatic parameters, it is recommended to receive advice from professionals. The screed should be free from extraneous contamination, problem areas are marked with chalk or a marker. The technology of working with minor deformations implies cutting cracks 1 cm wide and 0.3-0.4 cm deep, since this is the weakened area.

After cleaning the affected area, it is treated with a penetrating primer. Making sure that the mixture has filled the material to the limit, you need to use the actual repair composition. It is applied, achieving some excess over the rest of the screed. When everything hardens, the site will have to polish. If deep cracks are found, they are supposed to be carved to the lowest point using perforators.

Then you need to make shtroby that go across the course of the crack and leave it to 50 mm. At the end points of the strobe, holes are drilled 30 mm deep.After removing the formed debris, crack crack the ground and pour the composition to the bottom of the gate. When it hardens, brackets are formed from reinforcement or durable wire, the ends of which are bent and inserted into the holes. The constricted crack is filled to the end and thoroughly polished; then you can use the fused materials.

Action algorithm

Often flows roof, covered with a soft roof. In some cases, you can limit the application of patches on the joints or cracks. But there are cases when it is impossible to do without a full overhaul. The first stage of repair and repair of leaks is, of course, a visual inspection.

Attention is paid to:

- any slides that collect moisture;

- small cracks and flaking material;

- swelling;

- tears from mechanical stress;

- penetration into dampness.

For work both in the case of minor local repairs and in case of major restoration, the following can be applied:

- bikrost;

- membrane products;

- ruberoid;

- bitumen;

- glass elastite (deposited by fusing).

Maintenance repairs help to cope with minor deviations from the norm.It is also practiced when individual joints diverge, when rubbing is detected. Problem areas are poured with bitumen, and roofing material or other material of exactly the same size is glued onto the mastic. For attaching patches on top, another layer of bitumen mastic is applied, which is uniformly distributed.

If there is a discrepancy between the joints:

- lift, dry a surface (the torch will help);

- lubricate the surface with bitumen mastic with a roller;

- lower dried layer;

- re-coat the boundary with bitumen.

As with the surface and overhaul need to remove the coating as carefully as possible. The damaged base of the roof involves only additional vain work. If there is a dormer window at the top or a pipe used for ventilation, it is necessary to use a solid roll, and not individual fragments.

Violation of this requirement means an increased risk of new leaks. In order to maximally protect all protrusions from moisture, nonwoven cloths from a mixture of lavsan and viscose with bitumen impregnation are used.

Seasonality

Unpleasant "surprises" when water begins to pour from the ceiling of a country house or town housecan overtake the owners regardless of the time of year. And quite understandable is the desire to fix the problem as soon as possible, without delaying it. After all, dampness does not just violate a comfortable life, it can damage the rafters and walls, provoke rust and damage to the finish, lead to the appearance of mold or short circuit in the wiring. But not all craftsmen will undertake to repair the roof in winter.

After all, professionals are well aware: despite the assurances of manufacturers of coatings, it is best to work when the air is warm and there is no or very little rain. If these conditions are not met, the repair period is delayed, the quality is very difficult to guarantee.

It is recommended to exclude contact of heat protection with water and even with snow or ice. Between laying out the individual layers should be as little time as possible, so the work is divided into parts that can be done in one working day.

Laying metal tiles can be made in all weather conditions, but it must be covered with polyurethane. In cold weather, such material turns out to be more elastic than usual, but one cannot ignore the fact that the wind can injure installers or even carry away material. Composite tiles should be stored with strictly normalized parameters of the external environment.

Do not put it at air temperature less than -10 degrees. Whenever work is done, the selection of tools is made according to one requirement. In winter and autumn, safety at height must be approached even more vigilantly than in summer.

Pro tips

Repair of the roof in the country can be simple or difficult, depending on the used coating. If it is made of slate, minor deformations can be eliminated by strips of glass cloth. However, with significant defects, a full replacement is much more profitable and more practical. The galvanized roof is first rubbed with kerosene, cleaned with emery paper. When cleaning is completed, it is required to lubricate the surface with linseed oil and a primer, only after that a paint and varnish coating can be applied.

Correctly choose the type of roofing and the design of the "cake" will be obtained only when accounting:

- basic functions;

- the slope of the structure;

- architectural features of it;

- used in the construction of materials.

If the roof is created or reconstructed later than on the main house at the site of extension, it is necessary to think about the main aesthetic concept and style right away.Best when roofing materials are identical. If this cannot be ensured, it will be necessary to select similar or harmonized coatings.

It is hardly advisable to use completely new technologies that are not yet sufficiently proven in practice. The pitch of the batten is determined by the piece format of the roofing material (in some cases, the lining is carried out in a continuous layer, in others - with a clearly defined interval).

In the next video you will find the repair of the roof with your own hands from A to Z on the example of the roof of the garage.