Types and features of the installation of pipes for the chimney

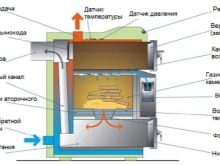

Heating is not only stoves, fuel reserves, radiators, bypasses and automatic controls. Even the popularity of electricity and the growing demand for alternative energy do not make conventional boilers and stoves less relevant. And they almost inevitably need a chimney? if there is no desire to constantly suffer from the smoke in the home or in another building.

Special features

It is unreasonable to approach chimney pipes with the same standard as for water, gas or to ensure draining. None of these types of communications are faced with the same heating as smoke channels. Accordingly, the difference between the temperature of the moving stream of gases and the temperature of the outside air is great. This automatically eliminates the very idea of using polymeric materials and other easily igniting substances.But the thermal conductivity of the material used should be maximum so that it does not overheat.

Very important circumstance - protection from the wind. Even a small chimney height (5 m) is experiencing significant loads from the movement of air masses. And the windage of higher structures increases as they "grow" in an arithmetic progression. This means that among the non-combustible materials one will have to choose only those with high strength. But strong constructions have a considerable weight, and they will have to be fastened thoroughly.

Of the other nuances that will have to be considered when choosing and installing, special attention is paid to:

- construction time and its complexity;

- chimney channel geometry;

- composition of flue gases, their quantity, speed and heating;

- the intensity of the use of the boiler (furnace);

- cost of construction used;

- the need to attract specialists or the ability to do without them.

Standards

Smoke pipes must always comply with GOST standards. But standards adopted in the Russian Federation describe each type of material separately (for example, cold-rolled steel).Therefore, it makes sense to get acquainted with them only after the final version has been chosen. For private developers, it will be enough to make sure that the purchased goods have the necessary certificates. More important for them is the height above the roof and other practical parameters reflected in the SNiP.

According to building codes, ceilings in a room where a gas boiler (water heater) and chimney are required to be installed for it cannot be lower than 2 m. Unless otherwise specified by standards and regulations, the manufacturer's instructions should be followed. The speed of passage of fresh air to the combustion chamber should not be less than 15 and not more than 20 m / s. It is forbidden to connect one device to several smoke channels or several devices to one smoke channel, even if the formal indicators of air and gas passage allow this.

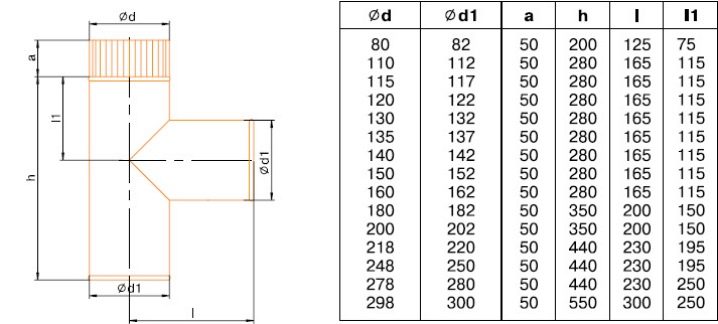

Do not install a chimney that is narrower than a pipe outlet from a furnace or boiler. The minimum pipe thickness, regardless of heater power and other circumstances, is 0.5 mm (for alloyed steels with enhanced rust protection). To facilitate the cleaning of the chimney help pockets, which reaches a depth of 0.25 m.The maximum allowed number of chimney turns is 3; each of them is made with a radius equal to or greater than the diameter. The lowest pipe should be 5 m in height, otherwise it will not be possible to provide full traction.

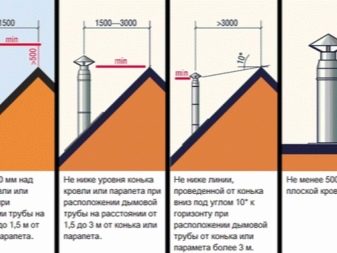

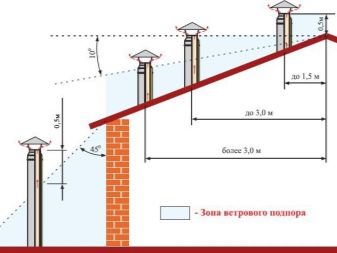

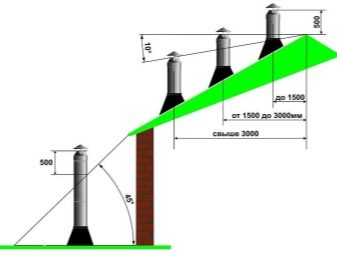

As for the height above the roof, it is as follows:

- on flat roofs - up to 50 cm;

- 1.5-3 m from the ridge - at least equal to the axis of the ridge;

- for closer placement - no more than 50 cm.

It is forbidden to build chimneys inside walls made of flammable materials. This also applies to substances with the lowest level of flammability. Structures placed in unheated attics and on the street are equipped with a waterproofing layer. This will help avoid the occurrence of such an unpleasant phenomenon as condensate. Already after construction for the entire period of operation, the chimney must be at least twice checked by experts (commissioning is not taken into account).

Kinds to destination

Chimney channels for furnaces largely determine the efficiency of heating and the consumption of combustible materials. In the houses of the old building, you can still find pipes made of asbestos cement or black steel. Zinc coating is categorically unacceptable, because already at temperatures from 100 degrees it begins to evaporate and get into the room.Of course, the vapor of this metal is clearly not conducive to improving the health of residents. Asbestos cement, although not harmful to people in this case, is still not very suitable by modern standards.

It was originally made without calculating the heat. Such a tube sometimes breaks already at 300 degrees. So what can be done from asbestos cement unless the areas are closer to the roofing cake so that the smoke is already slightly cooled. The hot part of the pipe and fragments through the attic are wrapped in sheet iron. This helps prevent uncontrolled scattering of debris in the event of structural failure.

But even with this condition, it is undesirable to install chimney from asbestos-cement. This material is rough inside, and therefore soot will accumulate abundantly there. Any connoisseur of furnace heating will confirm that soot in large quantities can quickly and suddenly flare up. Such a flash due to a sharp rise in temperature and pressure will simply tear the pipe in a matter of seconds. Therefore, it can only be put on because of complete hopelessness or out of stupidity, especially since asbestos-cement is easily damaged by condensate and does not allow making inspection windows.

The geometric shape (sectional view) is directly reflected in the aerodynamics of the gas flow. A round pipe is not prone to create obstructive smoke whirlings in the corners. If the structure is located inside the house, it is possible to increase the heating efficiency and ensure stable traction even in case of severe frost. The exit of the chimney to the outside will slow down its heating and will not allow to achieve decent traction. Unlike furnace, chimneys for boilers on any fuel can have natural or forced ventilation.

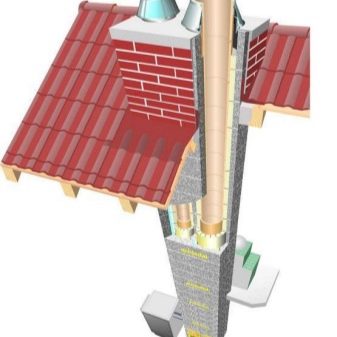

The second option is more stable than the first, but under the condition of a stable supply of electricity to the fan. Wall chimneys are carried out in the internal volume of the main walls. Indigenous call those who have a separate riser. And the outer pipes are displayed on the facade of the building. For your information: if the house is built of brick, preference should be given to the wall variant, then no additional materials and extra work will be needed after construction.

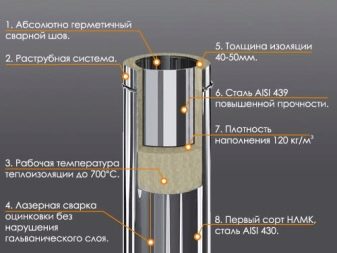

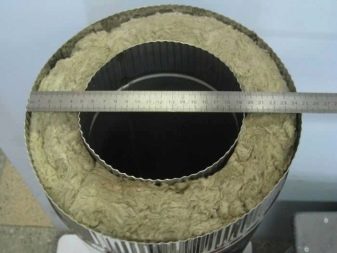

Single-wall smoke ducts are stainless steel tubes from 0.06 to 0.1 cm thick. They are placed mainly inside the house or in brick channels.Then the increased thermal efficiency helps to heat the house more efficiently. But the construction with two walls formed by a pair of layers of the same steel, separated by basalt wool. Double-walled chimneys are recommended to be installed outside the house, but if it is built of wood, it can be placed inside.

Attention should be paid not only the choice of one of these options, but also the use of a brick chimney. Another pipe made of fire resistant materials is introduced into the brick contour. Most often from all the same stainless steel. Used pipes must have the same geometric shape as the external contour.

The sleeve helps to cope with such a characteristic problem of old brick chimneys, as the abundant accumulation of soot. The roughness of this material is well known, and as it is used, it only grows. The only alternative to the introduction of the liner is the total dismantling of the previous construction and its replacement with a completely new one. Spending money and time are naturally incomparable, so the choice in most cases is obvious.

It should be noted that even pipes based on polymers can be used as a sleeve (this is the only case when they are acceptable).Almost all products intended for this purpose have a reinforcing layer of glass fiber and are characterized by increased mechanical rigidity. Restriction: these channels are allowed to be inserted only when using liquid or gaseous fuel, which gives a flow of gases no hotter than 250 degrees. With solid fuel boilers and conventional furnaces, they are categorically incompatible.

Steel is good because it allows you to ignore the temperature barrier. All the same, the critical temperature will not develop in the domestic heating system. Even non-professionals can install a simple steel structure, and the type of fuel used does not matter. You will have to accept the fact that you will not be able to insert a steel sleeve into the winding main pipes. Corrugated stainless steel constructions tolerate warming a little better than plastic, and therefore their use with bath stoves is not allowed.

Chimney nozzle for solid fuel boiler for the already mentioned reasons can only be made of steel or bricks. When designing and assembling it, it is required to pay attention to the proportion of heat generated and its losses.Although the materials used by themselves do not ignite, they include a number of specific fire regulations. From any flammable surface to the outer shell of the smoke channel must remain at least 38 cm. Extremely carefully equip the thermal protection in places where this channel intersects with the ceilings separating the floors.

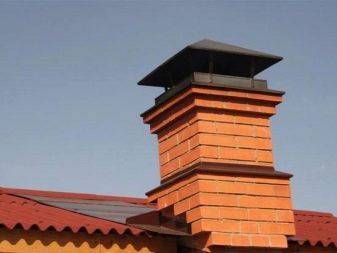

Brick chimneys, despite the heaviness and high price, are actively used for solid fuel boilers. To reduce the risk of exposure to acids and condensate can, if the internal surface is treated with refractory solutions during construction. The placement of the movement inside the walls is done in the form of a shaft with a width of brick around the branch canal. Its internal section is very simple to calculate. At 1 kW of power equipment should be 0.008 square meters. m chimney.

Materials

Something about the use of chimneys from various materials has already been said. But it is important to know their features as precisely and clearly as possible.

Stainless steel smoke ducts are different:

- long period of use;

- mechanical strength;

- reasonable price;

- possibility of use in a variety of conditions and with a variety of furnaces and boilers.

For durability, even low-cost stainless steel construction will give odds to any brick products. Since the material has undergone a special modification, it will not corrode. It will not be affected by caustic substances, very humid or over-dried air, strong heat. Due to the modular design, the replacement of damaged parts is not difficult. The installation process allows, if we apply taps, to bypass various obstacles of engineering and architectural purpose.

You can move the pipe axis in an arbitrarily chosen direction. The boilers, stoves or fireplaces themselves will remain in place. The round, flat surface significantly increases the cleaning intervals. The classical single-layer pipe can be applied only indoors with insulated walls. The main disadvantages are excessive fuel consumption for heating and the risk of condensation in case of violation of operating rules.

Systems like "sandwich" combine the positive properties of conventional and corrugated pipes. In any case, it is worth considering what kind of steel is used. So, 304 is a metal that is highly weldable, highly resistant to corrosion,strong in severe frost. 310S should be used if the flue gases are very hot (warmed to 1000 degrees). The 316th steel, to which nickel with molybdenum is added, surpasses the 304th analogue with resistance to destructive substances and high temperature.

If a wood-burning stove is placed at the bottom, it is recommended to use steel 316i and 321. These two alloys are very plastic, can survive heating up to 850 degrees and contact with acids. As for the 430th steel, it is advised to use it only in the details that least encounter aggressive media. With all the versatility and practicality of the metal, it does not exhaust the diversity of existing options. Ceramic tube - one of the most modern solutions.

A solid price is justified by a not less respectable period of service.

Ceramics is used in heating systems:

- with gas boilers;

- with coal-fired boilers, pellets and even coke;

- with liquid boilers;

- with fireplaces.

Excess gas density completely eliminates the breakthrough of fuel waste in a heated space. It is extremely difficult to linger on particles of soot and soot on the ceramic surface.Insignificant thermal conductivity destroys the threat of condensate. Earlier it was said that the galvanized pipe does not cope well with its tasks. But the main thing is to make the right choice.

Galvanization immediately stands out in appearance. One end of the pipe is wider, and the other is intentionally narrowed, which makes installation easier. It is even easier to buy a completely finished product that is not needed and assembled. Zinc covers the base metal well against corrosion. Apply the zinc layer as it should be possible only in industrial production conditions. We must not forget that the coating is extremely thin, and in a few years may lose its protective and design advantages.

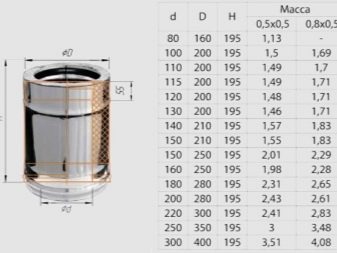

Dimensions

In addition to the type of material, the diameter of the pipe to be installed is also of great importance. The size of the thermal insulation layer can reach from 4 to 6 cm, the length of a single fragment - from 500 to 1000 mm. The thickness of the internal fragment in the "sandwich" can be 1-5 mm. Outside diameter ranges from 200 to 430 mm.

But the internal section is often also:

- 110 mm;

- 115 mm;

- 120 mm;

- 125 mm.

For heat sources up to 3500 W, it can be limited to a 140 mm chimney. If the boiler or stove produces 3.5-5 kW, a diameter of 0.2 m is recommended.In the range from 5 to 7 kW, a section of pipes of 27-30 cm is used.

You can improve the accuracy of calculations, if we consider:

- type of fuel used;

- rate of burning;

- traction speed;

- construction height;

- air speed.

Plugs and clamps often have a diameter of 80 mm, although there are twice as big products. All leading manufacturers also offer chimneys with 130 and 180 mm cross sections. The relationship between channel size and throughput is not always direct; Moreover, very wide pipes often work poorly. The reason - the formation of turbulence and obstruction of the flow of air or flue gases. The cross-sectional area of round and rectangular sections cannot differ by more than the magnitude of the error in the calculation.

At 1 kW of power when using gas should have a cross section of at least 5 square meters. see. For systems using solid fuels, this figure is even greater - it reaches 8 square meters. cm.

Additionally taken into account:

- floor space;

- dimensions of the furnace;

- portal value;

- the cross section of the neck that brings up the smoke.

Manufacturers

The demand for heating with the use of stoves and boilers draws attention to this market from many commercial firms. But not all of them do their work thoroughly enough.

Chimneys "Volcano" in practice, proved to be good. The design is made in the form of a three-layer “sandwich”, its popularity is confirmed by its attractive characteristics. Especially good is a similar product for fireplaces, where the heat load on the structure is relatively small.

The company "Volcano" supplies its products (modular stainless chimneys for domestic and industrial facilities) since 1996. She claims the use of high-tech highs and a focus on ease of installation. The technology involves cutting with laser equipment, volumetric molding in an automated mode, laser welding.

Has a good market position Rosinox company. In its lineup there are products for particularly harsh natural conditions, made of steel category AISI 304; lovers of German quality should focus on Keranova brand.

The company "Vesuvius" supplies individual components from which you can assemble a full-fledged chimney.

At the Tula enterprise they produce:

- head;

- umbrellas;

- hose clamps;

- gates;

- telescopic fasteners;

- tees;

- dampers;

- brackets and other products.

How to pick up?

If you plan to do the work on your own, it is advisable to abandon any solutions with the use of bricks. It is relatively practical, but the installation is very complicated. The fee for the services of professional stoppers will also be significant for most people. The use of metal products is justified not only by ease of installation, but also by their comparative ease (less will be the load on the floors, walls and foundation).

But galvanized metal allows more heat than brick, and therefore its normal operation is possible only with insulation. Ceramics combines the practical properties of brick and metal. However, it has become more expensive, but cheaper than baked clay. If you have to create a curving chimney, ceramic construction is unlikely to work. It is well placed only in vertical areas.

Chimneys located outside the house are rarely created, so they are perceived as a manifestation of originality and fresh design delights. But at the same time, their use is limited to cases when a heater is installed in a house that does not correspond to a previously drafted project.The ideal vertical is most easily created when installing an internal chimney. If the traction is not too good, it is best to choose such an option. We'll have to reconcile with increased complexity and the need to carefully work on the prevention of fire.

It is undesirable to make smoke channels with horizontal sections (in total) more than 1 m. Deviation from this rule dramatically reduces cravings. The key points in the selection of pipes and in assessing their configuration are the norms of fire safety and compliance with the characteristics of the heat source. Exterior design excellence and footprint in the house itself and beyond are secondary. Black steel seems to save, but its practical performance is noticeably less than that of stainless, especially with regard to strength.

The low level of alloying additives is good because such a material is more resistant to corrosion. Chimneys of this level are preferable at summer houses, in baths and similar places, since their regular use is almost impossible. You can extend the life if you take designs with as thick walls as possible.The longer the segments, the better, since even flawlessly made seams and joints significantly accelerate the degradation of the chimney. Welding with overlapping or rolling joints are contrary to technological standards.

When selecting pipes, you should carefully check whether there are any dents on them. If a layer of insulation is placed inside, it must be exceptionally dense so that the thermal qualities are not disturbed. The insulating material itself is also important, it depends on the resistance to ignition and the stability of the composition in a highly heated form. Solid and responsible manufacturers must include connecting couplings in the delivery sets; they also include instructions from manufacturers, and the pipe should be labeled.

Installation

You can install the metal lead out channels yourself without any difficulty. For cutting use typical scissors. Processing is done with simple metal shears.

For installation will need:

- LBM;

- jigsaw and screwing mechanism, which is connected to the electrical network;

- screwdrivers with a working part in the form of a cross;

- hammers and spatulas;

- chisels;

- gloves and eye protection;

- drills.

Delivered inside is not very well suited for large boilers. And external demand mainly in industrial enterprises, where the heating devices are large. In addition, such a scheme is expedient when breaking through plate elements is simpler and less laborious than forming a passage in a concrete plane. The channel for laying the stroke must be 2-4 times larger than its external section, otherwise there will be no place for fasteners and insulating materials. In advance fit all pipes along the length.

When the assembled structure is mounted, it is required to connect the furnaces and condensers. A sufficiently rigid fixation of the metal pipe is ensured by fastening in increments of 150 cm. External insulation is most effectively carried out using refractory clay. It also helps to decorate the point of connection of the chimney with the chimney. The cast-iron pipe, although it lasts much longer than steel, is harder mounted (cutting is done with the help of a grinder).

Knee multilayer pipes are installed on the principle of "dolls", for fixing them do not need auxiliary fasteners. It should be borne in mind that such chimneys are extremely susceptible to condensate,and therefore not suitable for the creation of street smoke ducts. Competent work allows you to ensure the life in half a century or more.

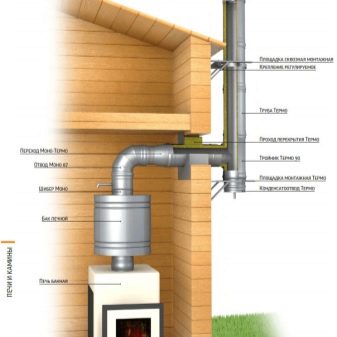

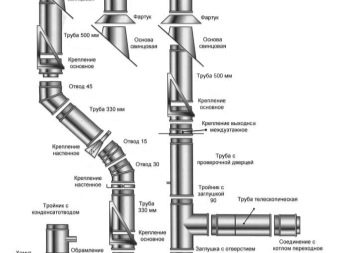

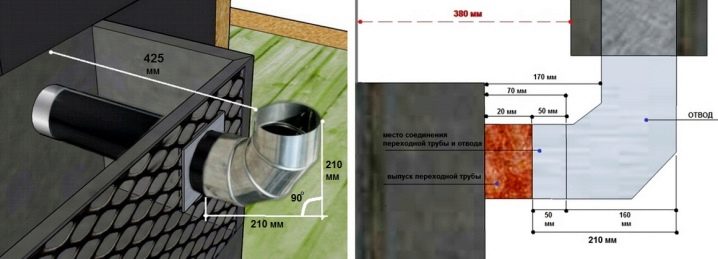

The sequence of study of the external smoke course implies:

- the formation of a hole in the area approaching the boiler (50 cm from the top point);

- placement of fixing blocks on the outer wall (in increments of 1 m);

- connection of the opening segment of the flue pipe with the boiler;

- removal of the bent knee outside the room;

- installation of the condensing device;

- fastening to external walls;

- attaching the head of the stroke and its protective elements.

For information on the types and properties of pipe installation for the chimney, see the following video.