Roof steel: types and characteristics

The roof of the house - a symbol of reliability, confidence in life. In a direct practical sense, it is the main protective element of any building. And the roof is the top layer in direct contact with the external environment, the quality of which will largely depend on not only the durability of the roof and the whole house, but also the comfort inside. Roof steel - one of the options for coating.

What it is?

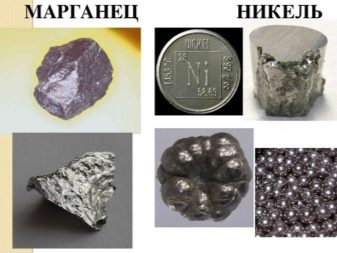

Ordinary steel (black) is an alloy of iron with carbon, therefore, it is susceptible to corrosion, that is, it simply rust quickly. To increase the corrosion resistance and strength allows alloying. Most often, manganese, chromium, silicon, titanium, nickel and molybdenum are used as alloying substances. The content of such additives in the roofing steel is usually 0.8–2%.

High alloyed brand used for durable metal structures and tools. The quality of the material depends on the percentage of harmful impurities, it can be phosphorus or sulfur. Their presence (in the amount of more than 0.7%) makes the steel brittle, reduces its resistance to corrosion. In a high-quality alloy, the content of such substances should not exceed 0.015%. According to GOST 8075-56, it is necessary to galvanize a sheet of roofing steel on both sides, which is also an anti-corrosion measure.

Features and purpose

There are two ways of applying zinc: electrolytic and hot.

In the first case, an electric current is passed through a steel sheet, which is lowered into a special bath, and the zinc particles that have disintegrated as a result of this process are deposited on the surface of the steel.

In the second case, the sheets are immersed in molten zinc.

When choosing steel, it should be noted that a hot method gives a better result.

The main advantage of galvanized steel over other materials is its relative cheapness.

At the same time, it fully satisfies the requirements for roofing.

- strength and durability - service life up to 15–20 years;

- resistance to weathering, temperature changes, ultraviolet radiation - a mirror surface reflects the sun's rays, does not allow the surface to overheat;

- lightness and plasticity - bends, easily cut, makes it possible to cover the roof of any configuration;

- ease of installation - no specific tools are required;

- environmental friendliness - no harmful substances are released when heated.

There are drawbacks too.

- Noise Raindrops, wind, hail create loud and unpleasant sounds.

- Inconsistency with modern aesthetic categories. When the house is covered with steel roof, a rather dull monotonous surface is created, which does not fit into the design concepts.

- Increased requirements for accuracy when mounting. The technology is really simple and low-cost. But the slightest damage to the surface, even a simple scratch, will lead to the fact that soon repairs will be needed, rust will appear in this place (and the zinc coating is usually only 0.02 mm thick).

- One more thing - increased trauma. On such a smooth material it is easy to slip and break down.

- The fact that steel is light and thin really allows you to bend it in any direction and in the most unusual form. But it is recommended that the angle of the roof was not less than 18 degrees.Otherwise, the water will linger, it will contribute to corrosion processes, the roof will start to leak quickly.

All this led to the fact that in the construction of private houses galvanized steel is rarely used. Most often used in the coverage of non-residential buildings on the farm. In order to avoid the above disadvantages, they are now producing roofing steel with a polymer coating.

Species

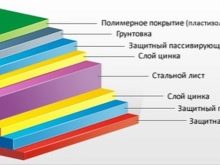

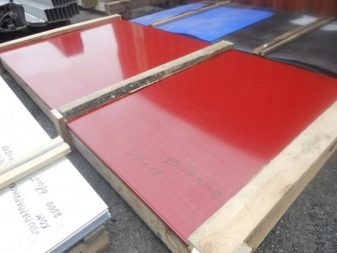

Improving the properties of roofing iron, in particular, anti-corrosion, is achieved by using the following polymer coatings (paints).

- Polyester - can be considered the most inexpensive option. The protective layer is created with a thickness of 25 microns, so you need to work with him as carefully as possible to prevent damage.

- Pural - polymer paint with polyurethane and acrylic, thanks to it creates a hard and durable rough surface, a layer thickness of 50 microns. Installation can be carried out even in frosty weather (at a temperature not lower than –15 degrees). Material with such a coating is durable. Ideal to cover the roof of the house in an atmosphere with high humidity or chemical activity.

- Plastisol - perhaps the most expensive of protective roofing polymers, but also the most reliable (thickness 200 microns). It consists of polyvinyl chloride and plasticizers. Structural pattern formed on the surface makes working with this material more comfortable and less traumatic.

The use of polymer paints increases the service life of the roof for another 10-15 years, improves the appearance of roofing steel and expands the possibilities of its use in various design projects.

Roof steel, except sheets, can also be purchased in the form of a roll. This creates a certain advantage when mounting the roof of a small area, reducing the number of seams.

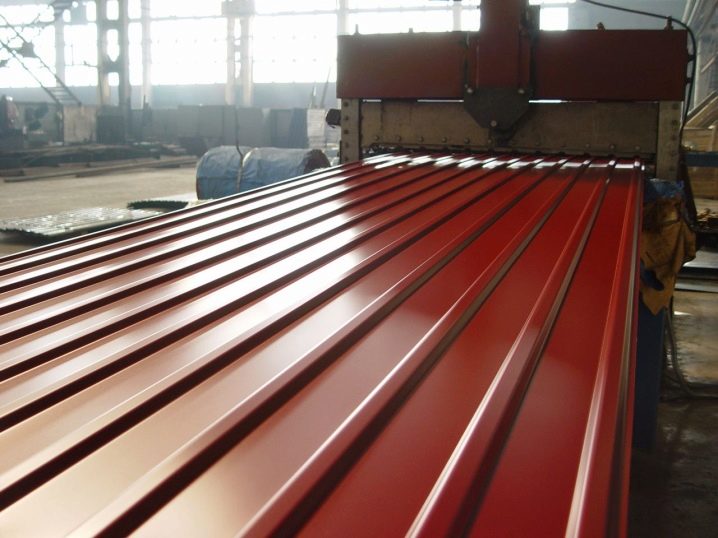

If a smooth roof is not suitable, you can purchase a professional flooring, then you get a corrugated surface.

Read more about sizes

Roof steel varies in sheet thickness. According to this parameter, thin-leaf (up to 0.4 mm) and plate (from 0.4 mm inclusive) are distinguished. According to GOST, the thickness of the material should be even more than 0.45 mm, so it is natural that 0.5 mm steel is more in demand for the roof itself. For other elements, drainage systems, collars of chimneys and air ducts, sheets with a thickness of 0.6 mm are used. And for the manufacture of apron parapets - up to 1.2 mm.

The length of the steel sheet can be from 0.7 to 3 m, but the most convenient for work is the 2-meter length, width - 0.5–0.75 m.

Sheet steel is sold in packages weighing up to 80 kg - if manual loading is supposed, and 5-ton packages - if it is possible to use loading mechanisms.

Galvanized steel, in addition to the smooth sheet and roll forms, is available in the form of sheeting. In addition to roofing, it can be used for wall decoration or fencing, as there is a choice of colors from a wide range. The quality of profiled sheets is determined by GOST 24045-94. Sheeting can have a thickness of from 0.4 to 1.2 mm, a length of up to 12 m.

Subtleties of installation

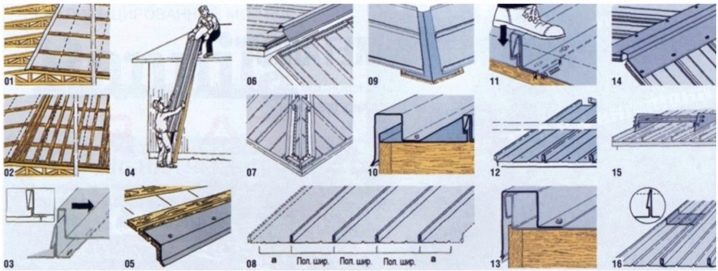

Laying of galvanized steel should be made on the prepared sheathing. It is made from a variety of lumber: timber, boards. The best option is a flat continuous crate with a pitch between elements of 15–20 cm. This will avoid material sagging. The beam is used with a cross section of 5 to 5 cm. The width of the planks, which will have horizontal seams, must be at least 10–12 cm, at least 2.5 cm thick. Insulating material is put on the finished frame: asphalt resin or roofing felt.Solid lathing and a vapor barrier protect the steel from evaporation from the attic and prevent corrosion of the inner surface.

If you nail the roofing material to the grille with ordinary nails, you will be able to do everything quickly, but the result will be of poor quality, the roof will be short-lived. After a short time, moisture will begin to get into the nail holes and rust will appear. Therefore, this method is suitable only for not requiring long-term operation of outbuildings.

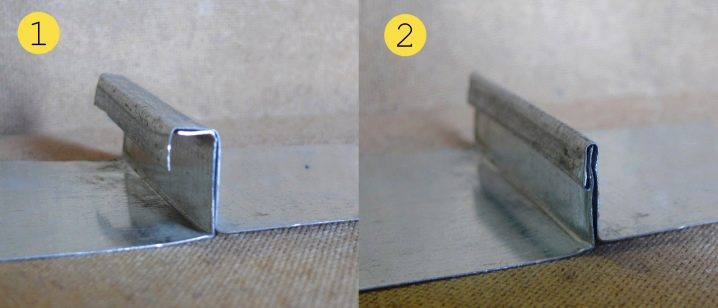

Most often when laying galvanized steel is used the folded method. At the same time, the material is connected with special seams - folds, the edge of one sheet is wrapped around the edge of another sheet. More durable will double seam seam. Prepared strips of steel, called paintings, are connected by vertical - standing, and sheets in horizontal paintings - by recumbent seams.

Installation of a faltsevy roof

First you need to prepare the material. Along the entire length of the edge bent for vertical folds. Then, with the help of horizontal reclining seams, the sheets are joined to each other in the picture. The distance between joints should be 2–5 cm less than the length of the sheets,that is, this is the width of the edge that goes into the seam. When the device slope with a small angle, it is possible to prepare paintings at once along the entire length.

Directly on the roof, the long sides are connected by a standing seam. Pictures are attached to the crate with the help of clamps, one end of which is inserted into a vertical seam, the other is nailed to the roof. Installation step - 5-7 cm.

To secure the edge of the material, use T-shaped crutches, which are nailed along the edge of the cornice. Step — 6–7 cm. If there were no special mounts on the farm, the alternative would be metal stripes. Their width can be from 3 to 5 cm, length - 15 cm. The interval of their installation will be less than that of crutches and will be 3-4 cm.

With particular care you need to treat the installation of roofing sheets around the collars of chimneys and air ducts. The very structure of the collar is made on the ground and only then completely lifted to the roof.

When installing the roof of a low roof, it is possible to use rolled steel, which will significantly reduce the number of horizontal transverse joints. And the fewer compounds, the less risk of corrosion.In terms of price-quality ratio, this method seems to be very profitable, therefore, roofs covered in this way have to be seen quite often.

Installation of profiled sheet

For laying corrugated sheet folded technology is not suitable. Before the start of the installation, the sheathing is made. Its type will depend on the type of material being laid. If the roof is covered with profiled sheets C-8 or C-10, then continuous crate is required. When working with other brands, the type of frame will depend on the size of the profile and the angle of the roof slope.

Profile sheets are fixed with special screws with EDPM-gasket. The use of such hardware prevents the penetration of atmospheric moisture into the mounting holes. Self-tapping screws usually require from 5 to 7 pieces per 1 m2. Fasteners matching the color of the roofing material are selected.

When installing a profile roof, it is necessary to provide wind strips made of the same material. The contact points of the sheets with the walls should be closed with angular planks, fixing them with silicone sealant. The ridge is fixed in the crest of the profista wave.

Repair damaged surface

Any roofing may need to be repaired sooner or later. If there are small spots of rust, you can remove them by rubbing this place with a steel, but not very stiff brush. Next, the sheets need to be cleaned from the old paint, washed and dried. Before painting the surface should also be degreased. It is possible to paint with oil paint, ocher with iron red lead. The best result is the use of acrylic enamel primer, but it is more expensive in price.

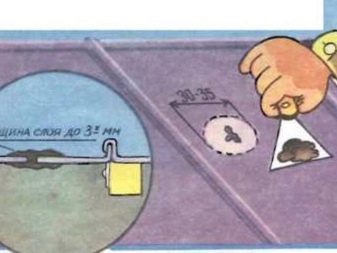

If the individual sheets are leaky, you can put patches of burlap or other thick fabric. Cut pieces of material for a couple of hours soaked in a thick solution of paint. After that, the patch closes the place of damage, carefully pressed and ironed it. After waiting for the fabric to dry, you need to paint the entire roof with patches, preferably in 2 or 3 layers.

Also for repair, you can cut a suitable sheet of the same material that was used for the roof, with seam allowances. In this case, the connection is made by folding technology. Soldering is acceptable. After repair, carry out the painting in the same way as when working with fabric patches.

Application for repair of rolled steel is possible. She lay on a cleaned surface covered with hot bitumen, along and across the seams. Sealants can also be used for fastening.

It is important to note that there is a point in carrying out such repairs when the area of the damaged surface does not exceed 40% of the size of the entire roof. If the scale of damage is greater, then replacing the roof is completely cheaper and in terms of money, and in time, and in labor costs.

Tips and tricks

What brand began to choose? Different manufacturers give their recommendations on the basis of the method chosen for laying the material, the terrain in which the construction takes place. For example, the Tin Smith Pro (TSP) and DX52 are offered for use in complex roofing work when a double vertical rebate is used.

DX51 and S280GD are good at manual folding work or using a machine, in the manufacture of slats or single fold. If the high price is not decisive, another manufacturer recommends paying attention to stainless steel to obtain a quality coating.

Among them:

- AISI304 - chromic and AISI430 - enriched with titanium.Recommended for use in rural areas with a non-aggressive atmosphere.

- 316 - nickel-molybdenum. Suitable for construction in a city where the external environment is more polluted.

Calculate the amount of material, so as not to spend extra money, you can use the program-calculator. It gives a very accurate result, taking into account the design of the roof.

Even if the installation of steel roofing is made in compliance with all technological requirements, for the longest possible service life, the coating must be properly maintained.

- From time to time to inspect and clean the roof of dirt that interferes with the flow of water.

- Paint the surface. Some paint the steel coating immediately after installation. There is no urgent need for this. Painting is required only in the seventh - tenth year after the flooring, and it needs to be repeated every next 2-3 years.

- It is necessary to paint with two or even three layers of oil paint or more expensive, but also more reliable acrylic enamel.

Another technique will help protect the interior of the roof from moisture. Solid crate itself is a reliable version of the frame, but it can be improved.To do this, you need to fill the seams between the boards with a special paste, which is prepared from chalk, drying oil and small sawdust. After the composition dries, apply oil paint in two layers.

Compliance with all recommendations will make the roofing and the entire roof durable and reliable protection of your home.

An overview of the installation of a folded roof, see below in the video.