How to make a polycarbonate roof?

The main element in the construction of the house is the roof, and not only the life of the building, but also its aesthetic appearance depends on the choice of roofing material. Therefore, to date, most homeowners choose to cover the roof of polycarbonate, which opens up huge opportunities for design design, as well as characterized by high quality.

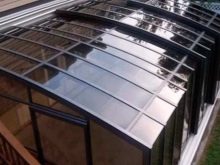

With the help of polycarbonate, you can create single and dual roofs., to make original arched structures. Such roofs ideally fit into any architectural project, they look stylish and easy to install. The sheets of the product are also suitable for decorating the verandas, gazebos and garages, they let the light in well and retain heat.

Special features

Polycarbonate is a modern material that is produced from polymers using special technologies, so it turns out to be very durable, it withstands temperature changes and mechanical effects. In addition, polycarbonate has a unique structure, it contains air chambers that make it an excellent sound and heat insulator. To install the roof of a polycarbonate sheet, choose a material with a thickness of 4 to 16 mm, its weight is from 900 to 2700 grams per 1 m2 and does not require additional reinforcement of the structure.

Polycarbonate roof is considered the most reliableSince the coating retains its performance properties in the temperature range from -40 ° C to + 120 ° C, it is resistant to various reagents and chemical compounds, is not afraid of shocks and lasts up to 20 years or more.

As a rule, the material is used for arranging roofing structures over the attic, cold attics, balconies and terraces.

Due to the fact that polycarbonate sheets come in various shapes, you can easily install the roof with a slope, a flat surface in the form of domes, prisms and pyramids.In order for the roof to get the desired shape, you first need to make a frame, then fix the material. Steel and aluminum profiles are used for the frame.

The main feature of polycarbonate is its high light conductivity.therefore, such coatings are transparent and have no visible joints when joining. Polycarbonate roofs look original and create a floating effect above the building. The material can be combined with other types of finishes, so the buildings, covered with polycarbonate, fit well into the landscape design.

Advantages and disadvantages

Polycarbonate is widely used in roofing construction, this is due to its high quality and the presence of many positive properties.

Unlike other building materials, it has certain advantages.

- Reliable protection of the premises from the direct rays of the sun. Light passing through the roof is evenly diffused. Polycarbonate cloth does not allow UV light to pass through.

- Low weight. Profiled fox is lightweight, which allows the roof to be mounted without an additional mounting system. The roof is inexpensive, which in turn opens up opportunities for design creativity in creating structures of various modifications.

- Good thermal conductivity.When installing the roof there is no need to use insulation and lay insulation.

- High hydro, steam and sound insulation.

- Provide ventilation. In the event of a fire, the material does not ignite and ensures a rapid fuming.

- Resistant to moisture. The surface of the coating is smooth and does not delay precipitation.

- The durability of the product contributes to cost savings.

- Flexible structure. Polycarbonate lends itself well to formation, it can be bent in any direction.

- Easy installation, transportation and handling. Sheets quickly stick together, cut and drilled.

As for the shortcomings, there are few of them in polycarbonate.

- During a strong deflection, the material under the influence of internal stress loses its integrity and color, and may become turbid.

- Polycarbonate needs careful handling, since it is inferior to glass in its transparency and hardness. Sheets should be stored in well-ventilated areas where there is no access to the penetration of the direct rays of the sun. It is best to place the material in a horizontal position and cover it with a special protective film on top.

Species

Recently, many masters choose polycarbonate for roofs overlapping, and it is not for nothing, since it is a modern type of roofing,which reliably serves and allows to make original designs.

Manufacturers produce two types of polycarbonate.

Monolithic

It is a smooth coating, its transparent structure is not inferior even to glass. Monolithic polycarbonate roofs are installed in both simple and curvilinear forms. Well it turns out a single structure. The main disadvantage of the material is the high price, but unlike other types it is easy to attach, does not require a large number of tools for installation and is conveniently stored.

Cellular

It is made of special polymers, therefore it is characterized by low weight, it is much lighter than silicate and acrylic glass. Externally, it looks like a profile panel connected by rigid ribs. The material is used for arranging covered pavilions, loggias. A dome and an arched construction is originally created from it.

Types of polycarbonate differ not only in their properties, but also in color, texture.

Wavy and corrugated material is very popular. Its wave flat surface allows you to decorate the original inserts in the designs, thanks to which the roof acquires an unusual design and style.

How to choose

Before beginning the process of installation of polycarbonate, it is necessary to prepare a roof project and choose the right roofing material. Depending on the model of the roof is determined by the frame and mounting system. If you plan to install a completely monolithic roof that does not have joints, then it is recommended to purchase not only a profile sheet, but also carbonate stands. Thus, the coating will get a cast look.

A huge role in the choice of material and plays its thickness, on which will depend on the exposure loads on the structure.

Most often, sheets of a certain thickness are used to cover the roofs.

- 4 mm. Suitable for finishing small areas with rounding. Usually such polycarbonate is purchased for the design of visors or individual parts of the roof.

- 6-8 mm thick cloth used to cover buildings that are exposed to snow and wind loads. In addition to residential buildings, sheets can be covered shelters for swimming pools and cars.

- 10 mm layers Usually used for the construction of buildings that are located in areas with extreme climatic conditions and require protection from the negative effects of the environment.

In addition, when choosing polycarbonate, you must also take into account the architectural features of the building.

The material should beautifully emphasize the exterior of the building and harmonize with the overall design. Therefore, it is worth paying attention to the main background of the design and, already focusing on this indicator, to decide on the color of the coating. Recently, bronze, green, dairy, blue and brown panels have been widely used. As for yellow, orange and red, it is recommended to use it only if there are materials of a corresponding shade under the shed.

For mounting the roof, you can choose both transparent and silver or black sheets. Such panels will shade the interior of the rooms as much as possible. At the same time for the original projects it is best to give preference to monolithic polycarbonate, which opens up huge opportunities for design design.

How to install

Installation of polycarbonate roofs can be easily performed by yourself. To do this, you must first make a project of the roof, because of the finished drawings it will be much easier to calculate the consumption of material.The diagrams should indicate the size of the house and the shape of the future structure.

If the installation is carried out by the master for the first time, then the instruction will help him.

- In the first stage, you need to decide on the roof truss system. Before bedding polycarbonate, choose the desired slope of the roof, it should not be less than 50 degrees. Then the carriers are made for the construction of rafters with a cross section of 60 × 80 mm or 60 × 40 mm, while the distance between the rafters and the edges of the roof is 1 meter. If the roof will have a semicircular shape, then on the rafters it is necessary to fasten the end and connecting profiles, leaving 2 cm at the edges.

- At the second stage, the side surfaces of the sheets are sealed with tape, which will protect them from the reflections of the sun's rays. It is worth paying attention to the fact that the upper edges of the panels are plastered with ordinary adhesive tape, and perforated are used for the lower ones.

- After preparation of the base and the material begins the direct assembly. In that case, if the work is done correctly, there will be no seams between the joints, so the need for their treatment with mastic will disappear. Fastening is done with screws; for this, the sheets are laid with the outer surface upwards and a gap of 5 mm is left between them.First you need to fix the cover to the profiles, and then attach the plugs.

At the end of the installation, the integrity of the coating is monitored.

In order for the polycarbonate roof to last reliably for many years, you need to take care of it and maintain it in constant cleanliness.

Useful recommendations

Polycarbonate is easy to install and works well, so they can cover the roofs on their own without the help of skilled craftsmen. Before performing the installation with your own hands, it is necessary to choose the right material, study the reviews about it and decide on the most suitable method of fastening.

The following recommendations will help.

- Polycarbonate sheets are best cut with the help of special equipment, but if there is none, it is possible to use a regular saw, jigsaw or hacksaw. In this case, the tool must be configured to cut plastic material and have small well-sharpened teeth.

- The protective film is removed from the panels only at the end of all installation work, otherwise the material surface may be damaged. Sheets during installation should not have burrs and uneven cuts.During the cutting of polycarbonate, dust and fine chips are formed, which should be blown out with compressed air.

- In case an electric saw is used for cutting the panels, it should be set to a low-speed feed. For sheets with a thickness of less than 3 mm, it is desirable to use hacksaw or band saws.

- To get the holes of a certain size, polycarbonate is firmly fixed on a flat base and provide it with additional support, which will help avoid vibration. Fixtures for the fasteners are drilled from the edges of the panels, leaving a small distance, as when fixing the screws or bolts, the material can be compressed and expanded under thermal influence.

- For the installation of polycarbonate is often used welding, thanks to which the panels are finally fixed. Details of the design can be welded in various ways, it all depends on their shape and size. In order to secure the sheets, it is recommended to choose a hot lining, it is carried out at a temperature of 300C. Hot air welding is also considered a good option, before it is done, polycarbonate should be dried well.

- The material is amenable to grinding, so it can be processed in a dry or wet way. To do this, use chilled water and sandpaper. Finishing grinding is best done sandpaper with a grain size of not more than 600.

- If the sheets are glued together, they must first be cleaned of dirt. In addition, they should be smooth and smooth. Apply special varnishes and solvents for bonding. Work must be done outdoors.

- All items made of polycarbonate must be cleaned with isopropyl or methyl alcohol, you can also wipe them with hexane and soapy water.

Interesting examples

Polycarbonate is widely used in the decoration of roofs and roofs. Such designs originally fit into the architectural ensemble of buildings. Beautifully look polycarbonate panels on the roofs of residential buildings, verandas and balconies. Due to the special structure of the material from it you can create beautiful forms of roofs, which in a special way emphasize the design of the building. At the same time, polycarbonate roofs on gazebos are very popular.

The construction market is represented by panels of various textures and colors.therefore it is easy to pick up them under an arbor roof of any style and design. The roof can be designed in the form of a continuous batten, and make curly elements, taking into account the angle of the roof. Arbors with palm, hip and doll structures will be an interesting solution for the suburban area. It is best to use opaque polycarbonate for covering their roofs, it does not require reinforcement in the roof system and does not let the sun's rays through, which will allow you to relax comfortably in the fresh air. At the same time, the color of the panels must be selected, taking into account not only the decoration of the arbor, but also the design of the entire area.

An interesting solution will also be the shelter of the veranda with polycarbonate, which will look great against the background of the entire building.

Creating a design for the terrace, it is recommended to select a polycarbonate of a shade that is already present in the yard. For example, if the roof of a residential building is brown, then the cover for the veranda should be of the same color. An extension thus designed will create a summer garden in which, regardless of weather conditions, potted flowers will grow. Climbing plants can be placed under the roof,and arrange the decorative flowers on the shelves; in the middle of such a composition, a coffee table and soft armchairs will look beautiful.

Will add landscape design and a canopy from polycarbonate which will serve as reliable shelter for the car. Inside the design it is recommended to put several benches and a table, then you will get an original place for rest, which will replace the arbor.

To learn how to make a polycarbonate roof yourself, see the following video.