Roll roof: advantages and disadvantages

The quality and functionality of roofing materials largely determines the life of the entire building. This is not surprising - after all, it is on the roof that the main task of protecting floors from adverse external natural factors lies. Due to the good performance over decades, roll roofing is in great demand.

Special features

Soft roll roof is equipped on the roof with a tilt angle not exceeding 30 degrees. At the same time, the number of skates on it is of no fundamental importance.

Structures are used both for the repair of such roofs, in this case even the removal of old coatings is not always required, and for the equipment of new ones.

Roll roof has enjoyed unchanged over the years. due to its exceptionally high performance and durability - this coating has been serving for more than 25 years provided it is properly installed.

The coating is made in accordance with GOST 30547-97, which defines the basic requirements for roll roofing materials.

Roll products found wide application at arrangement of country houses and household outbuildings. They everywhere cover terraces, gazebos, summer kitchens and barns. Some even use them for arranging the roof of a country house.

Advantages and disadvantages

Roofs equipped with rolled materials have a relatively low cost, since their prices are an order of magnitude lower than for alternative types of finishes.

The material has many advantages, the main of which can be called ease - it greatly facilitates transportation and direct installation. Due to the low weight, all the work can be done independently without inviting assistants, and therefore the cost of installation is reduced.

Well, in addition, the fastening of the material is quite fast. With continuous work, the minimum amount of work per day is 30-40 square meters. m roof.

The fact that roll materials absorb noise is important, creating perfect sound insulation in the living room. This means that the residents will not be disturbed by the sound of rain or hail, which means that the level of comfort will increase significantly.

All materials of this type are still impregnated with special fire retardants at the production stage, which increase the fire resistance of the roll coating - this roof is non-combustible, the material does not ignite spontaneously and even for some time holds back the spread of flame.

Roll roofs do not need regular maintenance, once covering the roof, you can simply “forget” about it for several years.

And, of course, insulation from moisture. This is the parameter that largely determines the effectiveness of the entire roofing pie. The material does not absorb water and does not let it inside, and therefore contributes to the preservation of wooden floors in working condition and participates in the formation of a favorable microclimate in the room.

What is important - roll products withstand temperature changes, do not lose their consumer properties either in the cold or in the summer heat.Under the influence of heat, the material does not emit harmful and toxic substances, being safe for life and health of the inhabitants of the house.

This led to a long service life of the material - the roll roof will require renewal only after 15-20 years.

In fairness, we note that the material is imperfect and has its drawbacks. All of them stem from the literacy of the installation work and the operation of the coating.

Sometimes there is a violation of the integrity of the waterproofing layer due to mechanical damage.as a result, cracks are formed, and the water begins to flow. At the same time, it is rather difficult to localize such a leak.

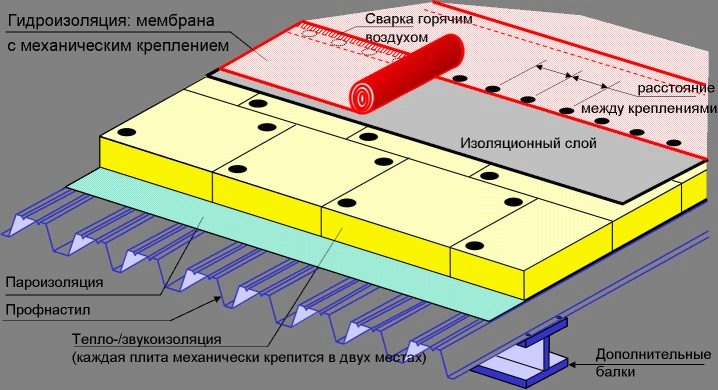

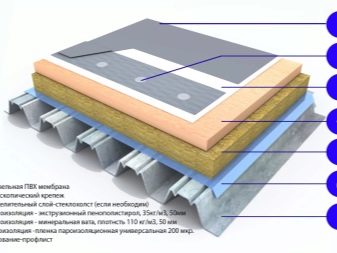

Another drawback of the material is the need to create an additional layer of vapor barrier, otherwise the water will accumulate in the insulation, spots appear on the ceiling, and the roof itself begins to collapse.

Kinds

Roofing roll materials come in several basic types.

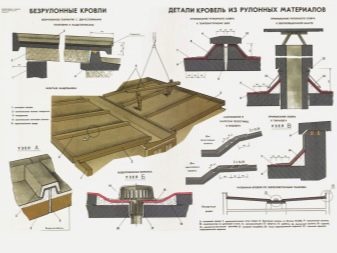

Groundless

These are products made from rubber processing products (isol), as well as bitumen (brizol) or butyl-kuchuk (hydrobutyl). This coating is obtained by rolling pre-crushed raw materials through special rolls, which form the sheet itself. As a rule, the thickness of the product is 2 mm.

Such coatings are used for waterproofing at the very bottom of the roofing pie.

On the basis of roofing paperboard

The raw material is impregnated with bitumen and is covered with mineral powder on top. The undoubted advantage of such a coating is its low price, however, and operational characteristics are low. Roofing material does not tolerate sharp fluctuations in temperature, begins to crumble at t -15 and +50 degrees - this significantly reduces the area of its application.

Nowadays, this material is almost never used even to cover household outlets, unless they are temporary.

Fiberglass Coatings

Dense but inelastic material. At occurrence of the movement of a roof the probability of a separation of a cloth from a basis remains. However, it breaks in quite rare situations. Most often fiberglass equip auxiliary, lining products.

Polyester

This is perhaps the most durable, practical and durable coatings.

Their operational parameters are impressive:

- high tensile strength;

- the canvas is stretched by 30% without breaks;

- possibility of use in all weather conditions;

- long period of operation - up to 25 years.

One drawback is the high price, which is why of this type of coatings perform the upper layers of the roof, and other, cheaper materials are used in the lower part of the cake.

Below we dwell on the parameters of each of these types of roll materials.

Composition

The basis for modern types of roofing materials are often polyester, fiberglass, fiberglass.

Polyester is considered the most practical base. It is a synthetic coating that is made from polymeric fabric. The material is able to withstand stretching by 50%, and the tensile strength is 35 kgf / cm.

Fiberglass and fiberglass are made from thin strands of fiberglass, interwoven. Usually, two types of fabric are used to form the canvas: smooth and frame. Smooth are obtained as a result of torsion of the threads and coating with a sizing. Their main advantages are low cost, while the coating can be deformed during storage and transportation.

Frame canvases are made of elements that are treated with a thread of glass. Such a base does not shrink and does not break, it is it that serves as the basis for modern and practical roofing.

The basis of the rolled material on both sides is processed by a special binder, most often used:

- bitumen;

- tar;

- stekloizol (rubber-bitumen composition);

- rubber-polymer solution;

- polymeric.

The highest performance characteristics show rubber-bitumen. as well as polymer-bitumen solutions, some of their varieties tolerate frosts down to -40 degrees, while others can withstand temperatures up to +150 degrees.

Specially for the southern regions with elevated temperatures, rolled coatings based on foil are created - this is folgoisol. At the same time, from the inside, a bitumen-rubber binder is applied to the foiled surface, thanks to the reflective properties of the foil, the average temperature of the roof will be significantly lower - at least 20 degrees. In this case, the upper surface may be covered with heat-resistant enamels.

A slightly different structure for baseless roofing materials. They already contain a special base, which allows you to mount the roof without arranging the frame.

Depending on the main component in the composition of the material emit:

- insulated coating;

- debris coating;

- film materials.

For the production of isolate used rubber, which went for scrap. It is vulcanized with bitumen and special asbestos components are introduced (most often asbestos fibers and special additives play the role). Isol coating does not lose its properties at temperatures from -35 to +100 degrees, it is characterized by high waterproofing ability and vapor resistance. The material is resistant to decay, does not break and does not deform over time.

Brizol materials are based on the use of rubber and bitumen compounds: 55% are bitumen, 30-35% are rubber components, 13% are asbestos, and less than 6% are plasticizers. Brizol is often used as a finishing coating, as it retains not only water, but also gases, is a durable and durable coating resistant to acid-base solutions.

Baseless materials also include all kinds of film coatings. They are characterized by moisture resistance, ease and ease of installation. And the price of this material is much lower than that of all other coatings.

There are several types of roofing roll materials.

- Ruberoid coating - its device is based on a roll basis. Among the advantages point out the ease and simplicity of installation, however, its useful life is also low. This is the main disadvantage of roofing material, which led to the widespread rejection of its use.

- Rubemast - another version of the guided roof. In general, it is similar to roofing felt, but it has a special protective film that prevents the layers from sticking to each other and creates a mechanism to protect the front side of the roof against mechanical damage of all types. However, this coating also has a short lifespan.

- Glass reinforced ruberoid - based on the use of fiberglass and polyester. Its strength is quite high in comparison with cardboard materials impregnated with bitumen, due to this, the resistance of the web to mechanical damage and the lifetime of the coating increase.

- Membrane materials - This is the last word in roofing technology. The advantages of membranes include durability and resistance to any atmospheric factors. A nice bonus is the fact that the installation of the membrane does not require professional equipment.The only disadvantage of such products is quite high cost.

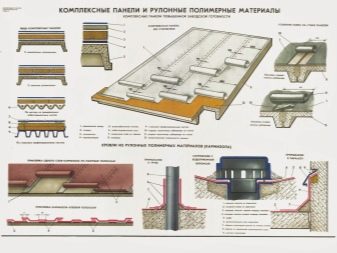

Device

Roofs equipped with a roll roof are widespread in the modern world. In civil engineering, they account for up to 60% of all areas, and in industrial construction - up to 90%.

Regardless of the type of buildings, there are a number of principles that must be kept in mind when arranging such a roof.

- The number of layers of roofing material depends on the angle of inclination of the roof. If the angle of inclination is more than 15 degrees, then at least 2 layers of coating are required. If the roof is sloping at an angle of 5 to 15 degrees, the coating is applied in three layers.

With a small slope of less than 5% will need at least 4 layers.

When arranging the roof with an angle of less than 2.5%, preference should be given to special biostable products - hydro-glass insol and filizole.

Single-layer roof does not settle down.

- When the slope of the slope is less than 15%, the sheets are rolled upwards and transferred to the opposite web by 10-15 cm. With a greater angle of inclination - in the opposite direction with the material being transferred to 20-25 cm.

- If the material is attached using bitumen mastic, then the roll coating should first be removed from the filling.

- Roofing material and other bitumen products are glued on bitumen mastics, roofing materials - on degtevye.

- Cover type materials are mounted on both hot and cold compounds, and coverless materials are mounted exclusively on hot ones.

Separately dwell on adhesive mastic and method of their preparation.

To produce a hot composition, bitumen is taken and melted to a boiling point until foaming stops, then necessary fillers are introduced into the composition, as a rule, it is asbestos and fuzz (up to 10% of the total solution).

The cold mixture is prepared a little differently: diesel fuel is introduced into the molten bitumen and delivered to the site of roof works in a barrel.

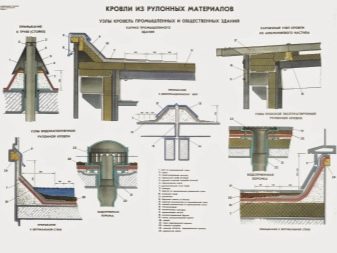

Installation and repair

Before roofing, the old coating or base should be cleaned of dirt and dust, after which a layer of mastic is applied to it, using brushes and combs, as well as pumps with spray nozzles.

Different layers of roll cake are fixed layer by layer or step method - It depends on the installation conditions. If the slope of the slope is more than 15%, as well as on the roofs of a small size, all work can be carried out manually.

If the roof is steeper, or the area is large, it is necessary to use professional gluing machines.They effectively apply mastic, as well as lay down and finally roll out all the working roll materials, firmly fix the edges. The use of professional equipment makes it possible to increase the overall efficiency of labor and reduce the consumption of mastic.

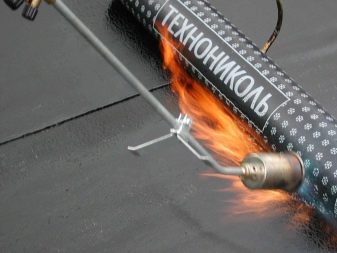

The installation technology of roofing roll coatings is constantly being improved. Laying of built-up roofing material is very popular, on which mastic was already applied under factory conditions. For laying such materials use burners, under the action of which the self-adhesive surface is heated and placed on the surface.

If bitumen-kukersol coating is used as a base material, the mounting technology is slightly different. With the help of a sprayer or by gravity, a solvent is applied to the base, under the influence of which the lower layers of the coating are converted into mastic, which effectively glues the sheets together.

Regardless of the technology used, after laying the roof must be thoroughly rolled.

With continuous work, one person can lay up to 50 square meters per day. m roof. However, the work will be faster if you use 1-2 assistants who could prepare and smooth the material, and then feed it up for mounting.

In the case of flat roofs, the angle of inclination in which less than 10%, the rolled carpet is additionally covered with a protective layer of mineral dressing, as a rule, limestone or gravel is used.

During the operation of the roof, it may be necessary to repair it: this happens when the integrity of the roof is impaired due to adverse weather conditions or due to mechanical damage.

Often, cracks appear at the joints of the canvases, to eliminate them, the roof is not disassembled., it is possible to correct the situation with the help of self-adhesive films, which are specially made for repairing roofing materials. The technology is simple: you first need to clean the deformation site and the crack itself, pour the primer that comes with the tape into it, and after 1-2 hours fix the tape itself.

Note that even if a small crack has formed on the roof, it is necessary to glue the entire joint.

If lichens appeared on the roof, it is necessary to treat it with compounds with fungicides, they are used as antiseptics and prevent the reproduction of unnecessary flora.

If a bulge appears on the surface, then you should just pierce it, wait until the mastic runs out and roll it in, and then fix the patch.

So that the roof after repair has retained its attractive appearance, it is possible to cover it with a paint with a reflective effect or powder it with small pebbles.

Tips and tricks

Obviously, the installation of roll roofing can be carried out independently without the involvement of professionals. Nevertheless, the work requires accuracy and time-consuming.

If all the necessary steps in the process of mounting the roof are performed in the correct sequence, carefully and exceptionally painstakingly, an effective, durable and reliable roof will delight you in the next 15-20 years.

Pay special attention to the quality arrangement of the roof, because it is from its functionality that the strength of the whole house and the maintenance of a healthy microclimate conducive to adults and children depend.

So that you do not have to repair the roof, there are several recommendations for the operation of the roll coating.

- Upon completion of the installation work on the roof there should be no remnants of building materials. Any garbage is gradually recessed into the soft material and destroys it.

- Walking on the roof is better to move to another place, even on the hottest day you should not walk on the roof,this can disrupt the uniformity of the powder layer, and therefore, deteriorate the strength of the material and resistance to external factors. If you have noticed such “bald spots”, then it is necessary to restore the layer of powder with the help of small fraction stones.

- In the fall, when the leaves on the trees begin to fall, it is necessary to pay special attention to the state of the drain, otherwise the craters can become clogged and significantly shorten the life of the entire drainage system.

- In no case can snow and frost be cleaned with metal shovels, as it breaks the top layer of the roof even with very careful handling. And it makes sense to start the cleaning itself only when the snow crust exceeds the permissible load on the roof.

Rolled roofing materials are known since the times of the USSR. However, since then technologies have made an impressive step forward and today roll roofing is a practical and durable material that requires almost no maintenance.

See the following video for the advantages and disadvantages of roll roofing.