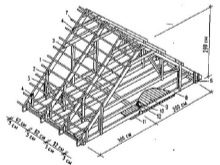

The design of the truss system gable roof

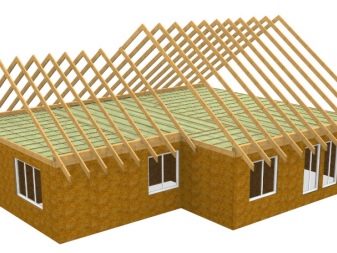

The gable roof is very popular because its construction is considered to be a relatively simple and quick step in building a house. Different types of gable roof allow you to choose the appropriate option for a particular building. To put such a roofing structure would not be difficult if there is even a little experience in construction, but alone, of course, can not cope. All work is performed in stages, taking into account the peculiarities of such a roof.

Special features

When erecting a gable roof, a truss system and the main details of the roof structure are installed. This includes the frame (in the form of rafters with struts), power plate. They are made from high-quality wood - these are bars of 150x150 mm and boards with a section of 50x150 mm.The traditional are gable roofs of the symmetric type, with straight slopes (gable roof). The slope angle of the slopes of such a roof reaches 45 degrees, which allows you to avoid stresses on the structure (for example, in case of snowfall and wind).

Other types of gable roofs, for example, with broken slopes, allow equipping the attic under the roof. In this case, the slopes on top of the roof are more gentle slopes, and the bottom - with a sharp slope. The gable roof should be constructed on a more complex and durable structure. During the construction of an asymmetrical roof, the ridge of the roof is carried out with an offset from the center. This is done taking into account the design features of the building.

Kinds

The frame construction of a gable roof can be:

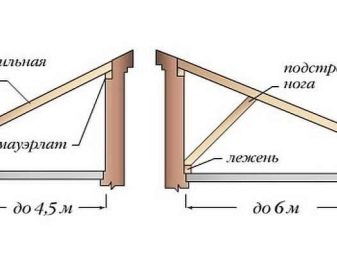

- on the slope;

- hanging

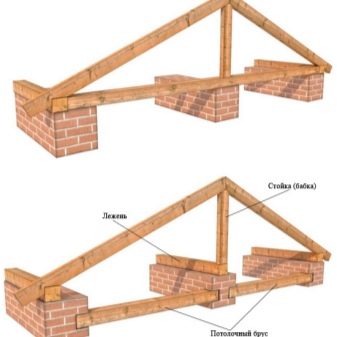

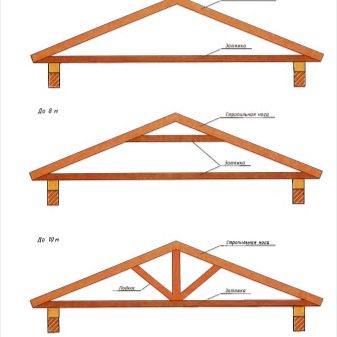

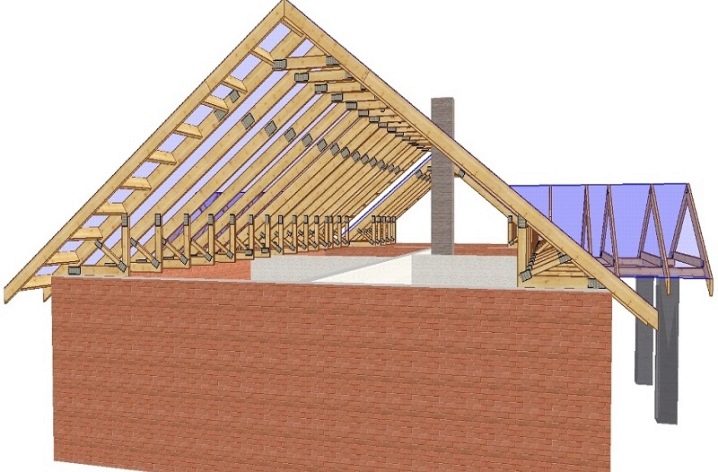

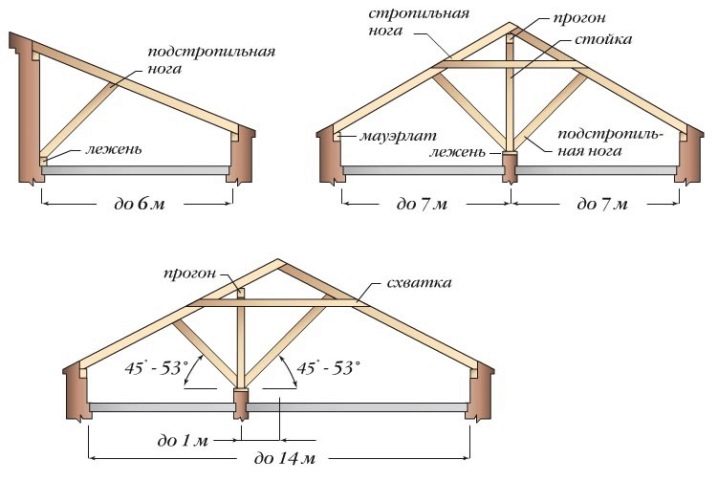

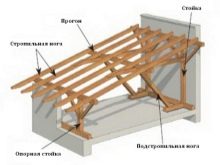

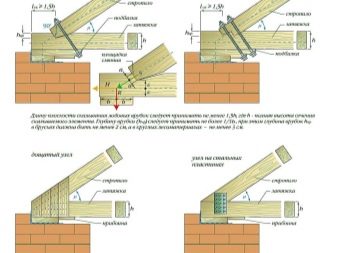

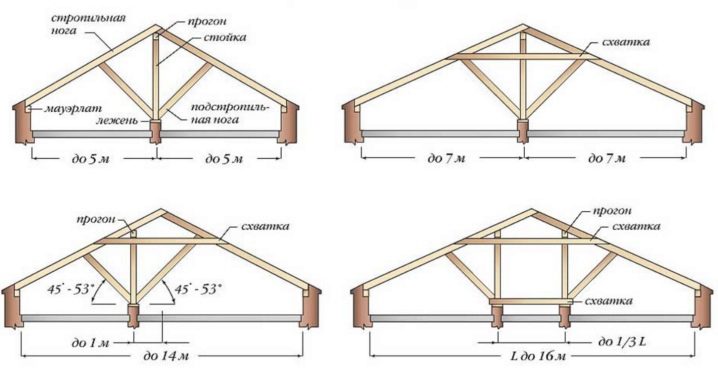

It is characteristic that most buildings use a railing system of the nacelle type, within which there are load-bearing walls. The frame thus serves as an intermediate support. When the width of the roof is not more than 10 m, one support is usually used. A roof with a width of more than 10 m has several proportional supports. The frame in the form of a truss system of the hanging type is possible in the case when the structure can manage with one support without having internal supporting walls.This roof is built from two belts - the top (two rafters), the bottom (rigidly connected puffs). The rafters are supported on the mauerlat, and the ends of the rafters extend onto the outer walls.

The gable broken roof may have a reinforcement in the form of support frames that do not allow the inclined roof to sag. So you can get a more solid construction. Hanging sloping roof has additional support frames, to which the walls of the attic are installed. The support frame, which is located under the bearing wall inside, takes on part of the load, which allows a little to facilitate the construction of the roof.

Device

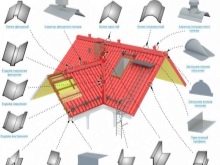

The design of the gable roof is characterized by the presence of inclined surfaces on both sides. The area of the base of the roof has a rectangular surface. Ramps do not allow to gather on the roof of snow and melt water. The roof is naturally cleaned. The roof consists of structural units: the mauerlat, the system of rafters, ridge and fillies, the overhangs of the roof, struts, drawstring, crates and racks. It is necessary to understand what is characteristic of all elements of the design of a gable roof.

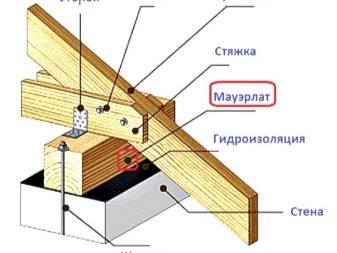

Mauerlat is necessary for the correct distribution of the load on the supporting walls from the rafters. For this purpose, usually choose solid wood - timber (it can be oak, larch, pine). The choice of timber by section is determined by the type of wood (solid or glued). For example, 100 by 100 mm or 150 by 150 mm. It is worth noting that when choosing a metal truss system, the mauerlat must also be made of metal.

The main element of the gable roof system is the rafter foot. These elements are made of durable timber and logs. When connecting a truss foot, a truss with a different type of intermediate support is formed from above. The important role here is played by the parameters of the rafters and components of the structure.

Tightening is necessary to connect the truss system (truss foot) and to impart strength and the necessary rigidity of the structure.

The run is of two types: ridge, in which installation is performed at the place of junction of the rafters (in this place the roof ridge is installed later), and the side run, which provides additional rigidity to the roofing elements (trusses) (the size and number of such runs depends on the load on the structure ).

Racks for rafters in the form of a vertical bar also take on a significant part of the load from the roof. Rack for rafters gable roof is usually located in the center.If the width of the span is larger than usual, then it is also on the sides. When erecting an asymmetrical roof, racks are installed depending on the length of the rafters. For a broken roof, the installation of the racks is performed on the sides, while remaining free space. If you plan two rooms under the roof, then the rafters are placed in the center and on the sides.

The struts are supports for racks. When bracing at an angle of more than 45 degrees, the roof is better protected from deformation (snow, wind). Depending on the climatic zone, both longitudinal and diagonal struts of the truss pair can be installed on the same plane.

Lent serves as a reliable support of racks. This is the place for mounting the brace

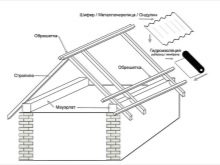

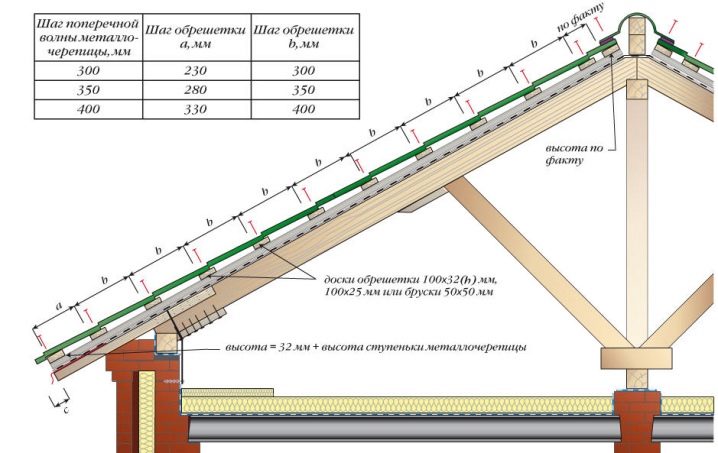

Lathing is necessary for fixing materials and structural elements of the roof. The crate is installed perpendicular to the rafter legs. One of the important purposes of crates is the redistribution of the load from the roof onto the rafter system.

Requirements for building materials

The choice of materials for the truss system is an important step in preparing for the arrangement of the roof structure. When calculating the material on the gable roof, you need to proceed fromthat it must be high-quality wood, the material has no knots, damage and wormholes, is well processed and impregnated with special compounds (for safety and reliability during operation). For the reliability of the design should be a stable connection of the elements of the entire truss system. The roof should be a solid construction of modern quality materials.

Such wood species as larch, cedar, spruce or pine are easily processed, so they are most often used in the truss system. Rafters are made of timber with a width of 10 to 15 cm and a thickness of 5 cm. In this case, a used timber is usually used, which will no longer change shape after the arrangement of the roof. This is necessary to increase the stability of the structure. In addition to timber, boards are taken for the rafters, especially when it comes to cocking the roof of a private house.

In high-rise construction used metal rafters. The disadvantage of a metal truss system for private house-building is that such a structure is not able to retain heat. Wood has more advantages in this respect - the material is distinguished by a high degree of thermal insulation and energy saving. Wood is divided into grades.First-class material goes to the creation of hanging rafters and puffs. From the material of both the first and second grade perform racks and struts.

Projects and Drawings

In the process of planning a gable roof drawing is prepared. This is the scheme of the future construction, where there are slopes, pediment, horse. In fact, the plan is a drawing with elaborated elements in different projections, reflecting the methods of tying the rafters. Drawing drawing gable roof is carried out taking into account all phases of work.

The scheme of its construction includes:

- bars for crates;

- beams and rafters;

- laying scheme of heat and waterproofing;

- roofing layout;

- installation scheme of additional mounts;

- drawing of the installation of the ventilation system, chimney.

A well-designed roofing plan will reduce the cost of the purchase of building materials. To create a project of any type, one or another type of materials is used, based on calculations and taking into account the reliability of the coating. The size of the roofing is also taken into account. In the drawing, a part of the roof system must be prescribed, which allows to understandhow much load can be on the roof.

The plan also includes:

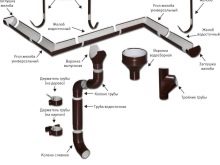

- stormwater plan (storm sewers of a certain length);

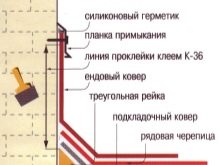

- elements of the connection of stingrays;

- construction area;

- scheme of places of contiguity of the roof (pressure profile).

In the scheme of construction should be clearly displayed type of roof. Detailed details on the diagram will allow you to perform work faster and better.

Mapping

Depending on the characteristics of the roof (single or double gable, form, etc.), project documentation is compiled.

This work takes place in several stages:

- a sketch of the future roof is being compiled (at this stage the drawing should have a ready-made roof with the elaboration of the building's styling);

- the main roofing elements are being worked out (the drawing shows the degree of load and the amount of materials);

- the scheme displays the construction of the roof.

It is worth considering that the differences in the pitched structures associated with the type of rafters (hanging or padded), with uneven angles of inclination, with the size of the overhang of the eaves. Also worth considering and errors in the design. One of the most common of them is an error with the calculation of the expenditure of materials for the entire complex. The process of drawing up drawing schemes is best entrusted to specialists.Roof construction is being built in accordance with accepted building codes. In addition, it is important to minimize possible errors and defects. So, if the choice of the type of roof and the method of installation is chosen incorrectly, this will cause the collapse of the roof structure. With an incorrectly drawn slope and its construction there is a risk of increasing the load on the roof. Although errors are made in the design of ventilation elements. The drawing itself should not be complicated, but the rules for installing all roofing elements should be observed, respectively, they should be spelled out. Professionally executed roofing plan increases construction safety.

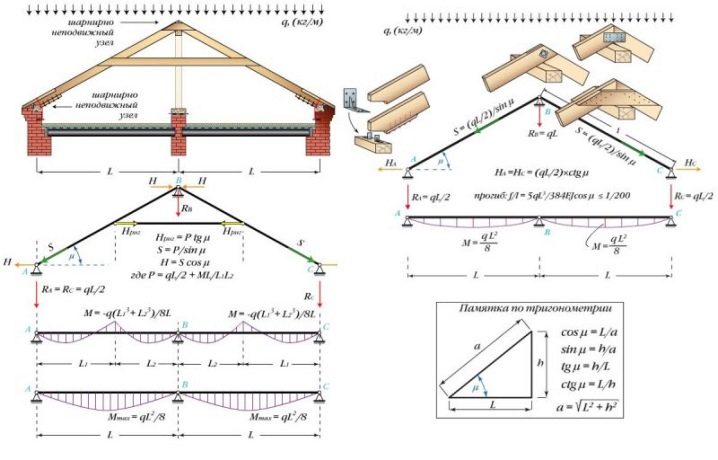

Payment

It is impossible to underestimate the importance of the calculations of the roof system of a gable roof. In the design process, it is necessary to calculate the usable area and, based on the data obtained, decide how high the uprights will be. In this case, several factors matter.

Load

When erecting a roofing structure, it is important to calculate the maximum load on the roof of the house, on all the rafters and overlapping beams. Strengthening of rafters may be needed, then adjustments are made to the project.For example, you may need to use additional linings or timber with a larger section than planned. The weight of the entire truss system is important. In this case, the calculation is carried out taking into account not only the cross-section of lumber, but also the density and moisture content of wood, determines the distance of the step between the rafters.

Today, there is a special classification of loads on the roofing system:

- The main load concerns the weight of the truss structure, temperature load, snow and other weather factors.

- Additional load concerns the calculations of the effect of wind and ice.

- Force majeure loads are associated with man-made circumstances (modern roofing must withstand everything).

Limit calculations of the truss system taking into account all loads are based on two criteria (limits or states): the limit at which the structure can be destroyed, and the limit at which the probability of deformation and deflection is taken into account.

Bias

It is important to correctly calculate the angle of the slopes. With a standard house width of 6-8 m, the angle of the slopes is 45 degrees, but this is not enough for the space in the attic.When the angle of inclination is 60 degrees, the construction will cost more, but the whole roof will be made better. At 45 degrees of inclination, you can choose any roofing materials. If the gable roof was originally planned to be asymmetric, then in the attic space you can safely equip a residential attic, but for this you need to calculate the usable area. The standard gable roof is usually selected. It is important to take into account the load on the roof due to wind and snow. With an increase in the slope angle of the slopes, the consumption of materials will also increase. But the performance characteristics of such a roof will compare favorably. If you plan to build a gable roof with unequal angles of slopes, then all the work can be done in the original design. However, when designing, it is better to build on the classical construction in the form of a symmetric roof with an isosceles triangle at the base.

Step

The rafters pitch used in building the roof is one of the fundamental ones in the construction of the structure. There is a dependence of the truss system on the roofing material. The last one is profiled, slate, soft roofing or metal roofing.

Slate for roofing is used everywhere. This roofing material is characterized by relative strength, low cost and resistance to temperature differences. However, the material has a certain weight, respectively, it is necessary to provide the roof with a powerful truss system. It is worth considering that for slate roof there should be at least three points of support (in the center and along the edges).

In recent years, metal roofing has become quite widespread among roofing materials. The material is easy to install and has an attractive appearance. Metal sheets for roofing are convenient to use, as they are lightweight. In this regard, the distance between the rafters may be large (for example, 600-950 mm with a sectional bar 150x50 mm).

The coating of corrugated can be made of galvanized steel sheet with a special protective coating (from external weather influences). The modern professional flooring differs in color, width of corrugations. Externally, this coating is different in design. The step between the rafters for corrugated board will depend on the type of profile, on the angle of inclination and the configuration of the roof.In this case, a truss with a section of 50-75 mm is used for the truss system. This may be a board 20-50 mm wide.

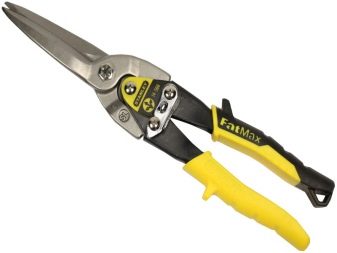

Instruments

When installing the truss system requires a set of tools. For this purpose, they usually manage with traditional tools - a power saw (it could be a hacksaw), a hammer and screwdrivers. Sheeting of the roof with metal sheets is performed with special scissors for metal. It is impossible to cut the material with a polymer coating with a simple grinder, so as not to damage the top layer with sheet protection. Otherwise, the skin will rust quickly. To cover the roofing with ruberoid you need a barrel in which bitumen will be melted.

Undoubtedly, in the performance of installation and any construction work can not do without a reliable ladder. It is also worth thinking about your own gear. For example, during work you need shoes with non-slip soles.

Installation

Do-it-yourself installation of the truss system of a gable roof is better with assistants, and even many elements of the structure cannot be installed alone. Installation of the truss system is carried out in several stages.

Consider them step by step:

- First you need to make a template.Rafter trusses are assembled according to a pattern. So, you need to take two boards the same length as the rafter foot. They are attached to each other from the edges with one nail. The result is a scissors design.

- This construction by other edges must be placed in those places where there are supports on the rafter legs. The angle obtained in this way (along the slope of the roof slope) is fixed on several nails. Mounting corners need to do on the additional crossbar between the boards.

- Next is preparing another template. With it, you can continue to assemble the structure. Mounted on the rafter installation. The template itself is easier to make out of plywood.

- Gash cut on rafters using a template. The connection of elements occurs at an angle of inclination of the slope. The finished triangle is the roof truss. It is lifted to the roof and fastened to the power plate (this will require logs and stairs).

- Fixture truss system to mauerlat do with nails, brackets, corners. And wooden “korotyshs” help to fix the structure from the displacement along the axis, they must be set up over the whole area.

- At the initial stage, two gable trusses are installed at the edges.Installation and correct fixation horizontally and vertically is done with the help of temporary struts to which the structure is attached.

- For reliability and convenience at the edges (between the tops of the trusses) a cord is pulled. It should be fixed in such a way as to designate a place for the future skate. Also, the cord will be needed when installing intermediate rafters.

- At the next stage, the other trusses are lifted and installed (at a certain distance (usually 0.6 m) from each other).

- In the presence of bulky structures, if there is a need to strengthen the structure, they are reinforced with bolts, struts and supports.

- Run (ridge beam) put on special supports. Then rafters of different types are attached to it (short, intermediate or diagonal).

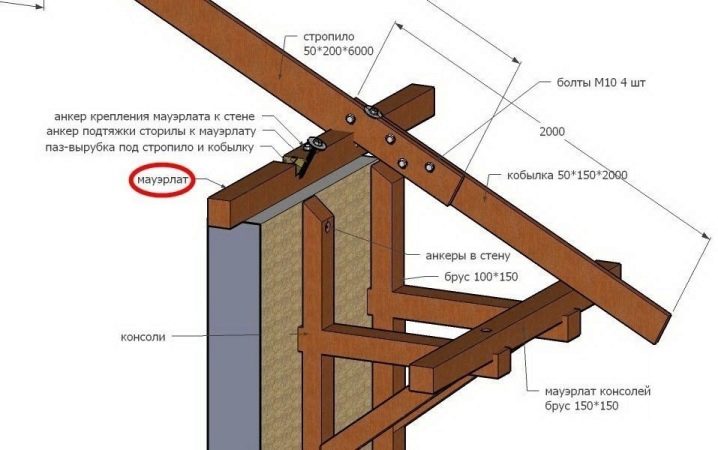

The basis of the frame is mauerlat. Its manufacture and assembly is the basis of the roof structure.

Fastener power plate

The frame construction of the rafters is fixed to the beams of the floors. However, in this case, the load on the truss structure is distributed at the points of fastening of the beams. This approach when installing a roof structure is possible for small and light buildings.Mauerlat is needed to evenly distribute the roof load in the upper part of the walls. Mauerlat mounted parallel to the ridge of the future of the roof. So is the main frame. A wooden bar with a section of 150x150, 100x100 or 100x150 mm leaves for the manufacture of Mauerlat.

There are different ways to fasten the wall cover

- For installation, special metal studs are used, which are embedded in a metal beam (it is poured over the entire length of the wall). The mounting pitch in this case is up to 120 cm. The fastener is carried out in a staggered manner. This selects the thread of the M12 studs. The element can project above the concrete up to 30 mm. The height of the beam can be exceeded, taking into account the waterproofing layer of roofing material. In the wooden beam, holes should be drilled through which the material is fastened (attracted) to the beam (with nuts and washers).

- If you plan to install a gable roof area of less than 250 square meters. m, the studs with which the mauerlat attached to the wall, laid in the walls themselves during construction. To ensure greater durability and reliability, the future wooden frame is fastened with studs, sealed to a sufficient depth (more than in a concrete beam).

- Wire-rod, which is mounted in a brickwork, allows installation of a power plate. This method is good because a small area is taken into account when installing the roof.

An important part of the roofing structure - the gable - is a continuation of the wall with roof slopes. On the gable roof erected pediments in the form of a triangle. Installation of the truss system in this case involves the installation of extreme trusses, which will serve as their frame. For competent construction of the frame, the verticality of structures with the same height must be checked. On top of the gables are mounted on the ridge (run), then the rest of the truss structure is mounted.

The installation of the truss system is carried out on the batten with a pitch designed for the installation of a specific roofing material (dimensions, degree of rigidity, method of installation are taken into account). For flexible materials (bitumen tile, PVC film, rolled bitumen roofing material) is made even flooring in a continuous layer. Warming of the roof is a mandatory step in the construction of the structure, as it is necessary to take care of minimizing possible heat losses.This may be sheet material, which is placed on the frame with a certain step based on the calculations.

The gables are usually closed (sewn up) after all the roof construction has been completed. Although this stage of work can be done earlier, providing windows with gables. Often, work on the insulation of gables.

Tips

To date, experts recommend using the most effective way to install a truss system gable roof.

For high-quality installation, a combined installation method for hanging and inclined rafters is used. With this combination it is possible to reduce the consumption of materials and increase the level of structural strength.

In order to avoid leakages during the rain, around the edges of the walls make the overhang about 55 cm. This will help protect the upper parts of the walls from dampness. Before installing the rafters, they must be treated with antiseptic, antifungal agents, and fire retardants.

To enhance the design as a whole, tightening is performed. Strengthening rafters with the help of puffs is performed according to the principle: the closer to the ridge, the more massive they are. Tightening make a wooden bar with a large cross-section.At the same time it is important to control the reliability of fixation and connection of nodes.

Rafter systems are bolted. It is important to use washers and plates made of metal. So the nuts will be less buried in the wood surface.

You will learn more about installing the roof system of the gable roof in the next video.