Sandwich pipe for chimney: device design and installation rules

The chimney is an integral part of many types of boiler equipment and plays a crucial role in ensuring the safety and efficiency of heating devices. Chimney is the main part of any chimney, so the trouble-free functioning of the heating system as a whole will depend on the correctness of its selection and installation. One of the varieties of chimneys is a modular product, which, due to the multi-layered structure, has been called a sandwich pipe.

Specifications

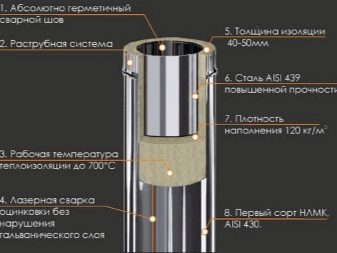

The sandwich pipe is presented in the form of a cylindrical structure made of "stainless steel" and consisting of two pipes nested in each other of different diameters.The annular space in such models is filled with non-combustible insulating material, which prevents the chimney from overheating and reduces the amount of condensate that forms on the inner walls of the pipe. For the manufacture of the internal contour of the sandwich pipes used different materials, such as heat-resistant stainless steel, brass and copper. Several materials are also used as the insulating layer, such as basalt wool, vermiculite and ceramic wool. The use of basalt wool is the most profitable option in terms of cost savings.

However, the maximum permissible level of thermal load for such a material is only 600 degrees. Vermiculite is intermediate in its operational properties position between basalt and ceramic wool. The material is lightweight and can withstand temperatures up to 1150 degrees. Ceramic wool has a special deformation, thermal and chemical resistance, and is designed for temperature loads up to 1260 degrees.

The thickness of the insulation can vary from 3 to 15 cm, and depends on the installation site and the functional purpose of the model. The outer tube is made of stainless steel and coated with zinc.Galvanization significantly increases the resistance of the external module to corrosive processes and significantly extends the life of the chimney. With proper installation and regular maintenance, metal specimens can last up to 15 years.

But sandwich chimney pipes are made not only from metal. Ceramics are used for the production of particularly powerful and durable pull devices. Ceramic models are more heavy weight and require the arrangement of the capital base during installation. The advantage of such products is the lack of risk of corrosion and a longer service life. With timely and proper maintenance, ceramic models can last up to 30 years.

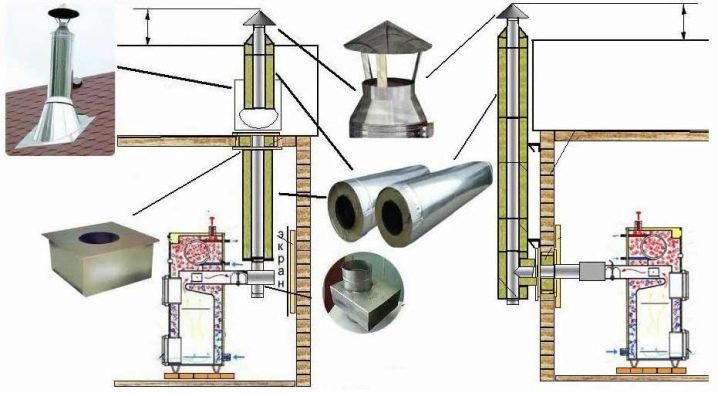

Metal copies represent modular sets from which the flue of the necessary form and length gathers. One module has a length of 100 cm and joins the other on the principle of connecting sewer pipes when the narrower end of the pipe is inserted into the wider one. A sandwich pipe set consists of fasteners, with which the structure is fixed to the bearing supports, a condensate collection and drain unit, a wind vane, which prevents the appearance of a back thrust effect, a protective fungus and cones.The fungus and weathercocks are not used in the construction of chimneys of gas boilers, so this fact must be taken into account when choosing a complete set of products. The shaped parts of the chimney are represented by tees, which provide a tight connection with vertical sections, branches required to change the direction of the pipeline and have a rotation angle of 45 and 90 degrees, as well as revisions and nodes that provide passage through the roof and overlap.

Audits for chimneys are made in the form of insulated tee and are equipped with a door. The element is installed on the lower part of the chimney and serves to ensure unhindered access to the internal surfaces of the pipes. Mandatory installation of audits is caused by the need to regularly check the status of the system, as well as for carrying out routine cleaning. Models designed for arranging chimneys of wood stoves and solid fuel boilers are additionally equipped with spark arresters.

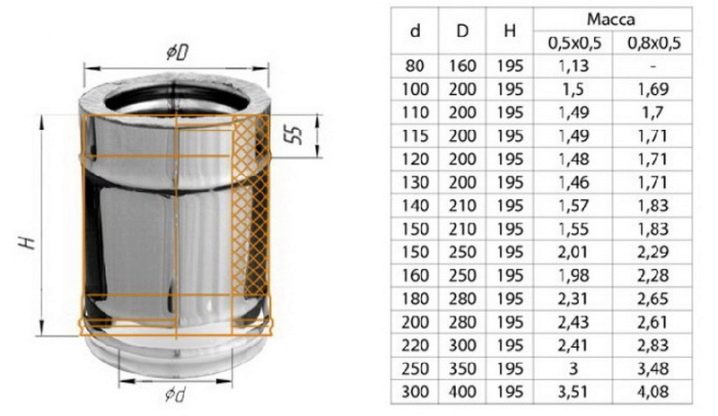

All factory products are marked on the body indicating the external and internal size of the pipe section. For example, the digital symbol 150 * 250 indicates that the diameter of the inner tube is 150 mm, and the outer one is 250.Sandwich pipes for the chimney are available in a wide variety of sizes, which greatly facilitates their choice and allows you to easily purchase a model of the required dimensions. The size of the cross section of internal pipes connected to stoves or fireplaces varies from 200 to 280 mm, while for heating boilers with a capacity of less than 40 kW, thin models with a diameter of 130 to 200 mm are produced.

The thickness of the metal used for the manufacture of internal pipes is 0.7 mm. This is dictated by the features of operation, during which the inner tube is subjected to significant temperature loads, often reaching 850 degrees. This thickness provides reliable protection of metal from burning and increases the service life of the chimney. In addition, for the manufacture of the internal contour is used high-alloy steel grade AISI-321, which includes molybdenum. Such an alloy is distinguished by maximum resistance to the effects of acids, high heat resistance and the ability to serve up to 100 years. However, the cost of such products is quite high.

A more budget option is a model made of steel grade AISI-430.The material is able to withstand short-term temperature jumps up to 900 degrees and is designed for 10-15 years of operation. The thickness of the outer pipe walls is usually 0.5 mm. If there is no marking on the product, you can check the presence of additives in the steel yourself.

This requires attachment to the pipe magnet. Steel containing alloying additives will not react to the magnet. Such a product is of fairly high quality and you can safely buy it. The seams of the inner and outer tubes can have different designs. So, laser welding is used for the manufacture of the internal contour, while for the outer pipe there is quite enough of the seam obtained by the rolling method.

Special features

A large number of positive feedback on the use of sandwich pipes due to a number of undeniable advantages of these structures.

- Fire safety during operation of boiler equipment is possible due to the presence of an insulating layer that does not allow the external pipe to heat up.

- The quick and easy installation is explained by the fact that when arranging conventional chimney pipes it is often necessary to wrap them with thermal insulation material, which, in turn, itself needs additional cover.When installing sandwiches, this need disappears: the pipes already have a heat-insulating layer and do not need additional materials.

- Lack of necessity of arrangement of the capital bases under metal models. Steel sandwich pipes are perfectly supported by brackets and do not need additional fixing devices.

- Due to the presence of fittings, the pipeline can be given any configuration. This is especially convenient in prefabricated houses and with non-standard layouts, which imply additional architectural forms in the form of columns and protrusions.

- A significant reduction in heat losses and a reduction in the formation of condensate make the operation of boiler equipment simple and efficient.

- The design features of the sandwich pipes relieve the room from the unpleasant hum that occurs when exposed to thrust. This allows you to equip the chimney halls with sandwich chimneys without the risk of disturbing the peace of those present.

- Thanks to audits, chimney cleaning can be done independently. Works can be performed without partial disassembly or complete dismantling of the pipeline.In addition, the smooth walls of the inner contour are not prone to the accumulation of soot and fatty deposits on them, which compares favorably, for example, with corrugated pipes.

- The aesthetic appearance of the sandwich tubes allows them to be installed in any premises without the risk of cluttering up space or spoiling the design.

The disadvantages of such pipes include the likelihood of a decrease in leaktightness, which occurs as a result of the material's response to sudden temperature changes. The downside is also the high cost of ceramic and some steel models. In addition, many consumers are unhappy with the short lifespan of low-cost metal models that can last no more than 15 years.

Scope of application

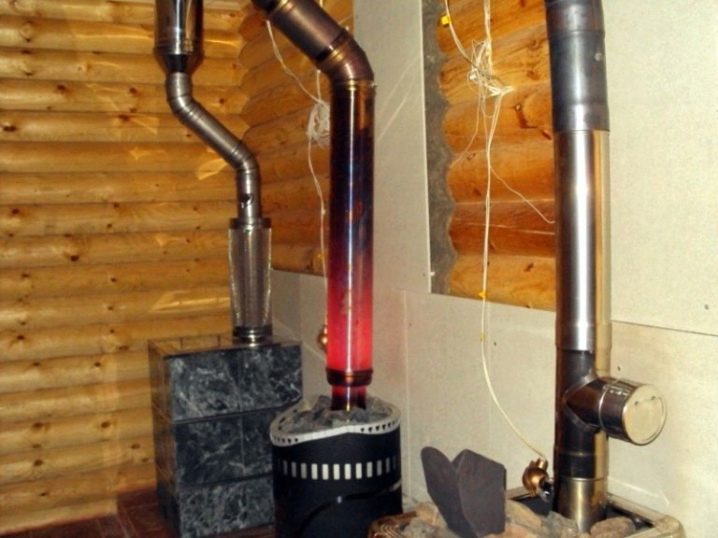

The use of sandwich pipes includes all types of boiler equipment, including gas boilers with an open combustion chamber and solid fuel models. The design is often used as chimneys for wood-burning stoves, significantly reducing heat loss and compare favorably with traditional brick pipes. For the same reason, sandwiches are often installed in saunas and heated in stoves, garages.Due to the modern and aesthetic appearance of the model is often used for the arrangement of chimney chimneys. Products harmoniously fit into the interior of kitchens and fireplace rooms, and do not cause dissonance with the room.

Installation

The assembly of the chimney using sandwich pipes occurs according to a certain scheme, which includes two types of pipe joints in one design. The first one received the conditional name “by smoke” and is used to set the external contour so that the penetration of smoke into the surrounding space is excluded. The inner part of the pipeline is mounted “by condensate”, which, accordingly, excludes its penetration into the insulating layer. Structurally, the principle of assembly “by condensate” is as follows: the wide end of the inner contour is directed upwards, due to which the smoke will go from the bottom upwards, and the drops of condensate will freely flow downwards. When assembling the internal modules of the "smoke" drops of water will linger on the joints and leak into the heat insulator.

If we collect the internal system “by smoke”, the condensate formed due to the temperature difference will begin to flow into the sandwich through the gaps that have arisen as a result of improper assembly.As a result, water will accumulate in the insulating layer, and with the onset of sub-zero temperatures it will freeze and tear the outer shell of the sandwich. Therefore, in order to properly perform the installation of the chimney, the inner pipe needs to be collected “by condensate”.

With this arrangement of pipes, the resulting moisture will flow through the junction and, moving down, into the condensate trap. The same picture will be observed outside the building: rainwater will flow through the pipe, not being able to leak to the heat insulator, leaving it dry. At the same time, the external contour of the sandwich should be installed “by smoke”, that is, the wide end of the pipe should look down.

Installation of sandwich pipes in the arrangement of chimneys does not require the presence of certain skills. If you have the necessary tools and helpers, then such work can be done by hand.

Installation of indoor chimneys should begin with connecting special adapters to the flue opening of boilers or other heating equipment. The place of its connection with the heating devices should be well lubricated with a sealant capable of withstanding temperatures up to 1500 degrees.The first element connected to the exit from the heater should be a conventional non-heated pipe, to which the sandwich connection will be carried out. The pipe must be equipped with two valves required for the removal of gases. A layer of insulation, which will be located at the end of the sandwich construction, is covered with a plug or a special starting block is installed, in which the insulation is reliably closed by the construction housing.

Starting a simple pipe and the site before the first tee is recommended to dock "smoke." In the case of its horizontal position, it is recommended to maintain a small slope equal to three degrees. Such an arrangement of the pipe is dictated by the risk of condensate formation inside the heating boiler. The installation of a horizontal pipe should be carried out simultaneously with the installation of a tee or revision coupling. After the tee is in place, its lower part should be closed with a plug intended for the subsequent removal of soot. The audit is already equipped with a door, so the use of any additional devices does not require.

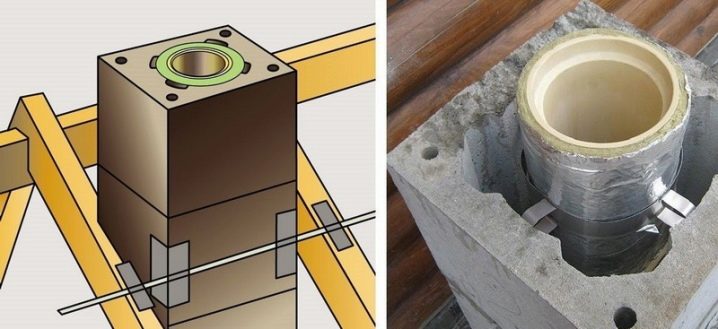

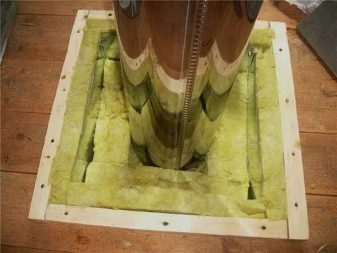

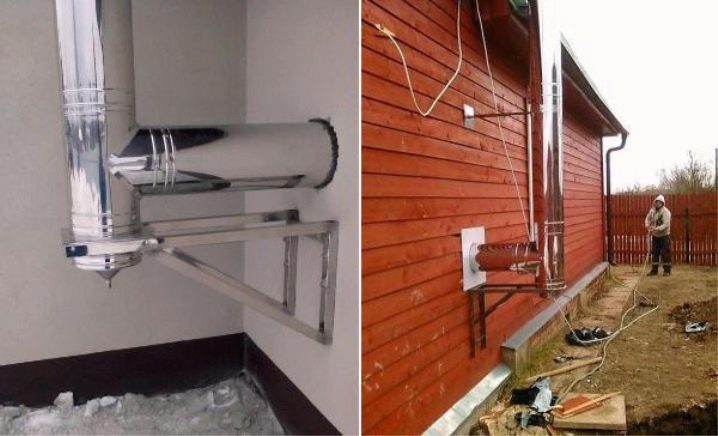

The next stage of installation work should be the transition of the pipeline through the walls of the room. If the walls of the building are built of non-combustible materials, it is recommended to equip the chimney duct with an additional sleeve, which may be suitable for a metal or asbestos pipe of a larger diameter. In this case, the cavity between the sandwich module and the sleeve can be filled with an asbestos cord or basalt fibers. An important condition for arranging the transition of a sandwich module through a wall is the absence of adjacent sections in this area. If the house is built of wood, then you will need the equipment of a special metal passage node.

To do this, a square section opening is cut into the wall, into which a sandwich pipe is installed. The distance from the pipe to the wooden surface should be not less than 20 cm. After installing the pipe, this gap is filled with basalt cotton wool, and the opening is covered on the front side with a metal plate or decorative rosette. To facilitate installation, you can purchase a factory pass unit, which is already equipped with a thermal insulation layer and is completely ready for installation.

After crossing the wall, the vertical channels are laid in the direction from bottom to top, and fixed with the help of clamps and steel brackets. A heat-resistant sealant is used to ensure better mating between adjacent sections. When installing fasteners, clamps should not be allowed at the junction of two pipes, and nozzles or umbrellas will need to be assembled at the location of the sandwich slices.

The next stage of installation of sandwich pipes is to go through the roof. To do this, a hole is made in the roof of a certain size that needs to be well strengthened. The inner side of the roof is strengthened with the help of an under roof metal sheet, and to make the joint more airtight, it is recommended to attach an adjustable apron to the roof trim. Ready-made elastic assemblies (rats) are on sale, with the help of which the tight connection of the adjacent sections of the roof to the chimney pipes is ensured. However, if the roofing material is any non-corrugated material, for example, a professional sheet, then a galvanized steel sheet will be enough to ensure a tight connection.

After the hole is formed, install the adapter, and then through the top, through the hole, lead pipe. When connecting two modules, it must be remembered that it is prohibited to join sections at the pipeline crossing section through the floor slabs or the roof. The upper part of the pipe that goes out is crowned with a tip. This prevents mechanical debris and precipitation from entering the chimney. When the connection of the sandwich pipes is completed, they proceed to isolating the gap between the pipeline and the ceiling, which is carried out with the help of any fire-resistant material. Then the place of transition is plastered and painted.

If it is impossible to make a hole in the ceiling, resort to outdoor installation of the pipeline. For this, a starting fitting is installed on the boiler and a horizontal pipe is attached to it, without forgetting the necessary inclination. If it is necessary to turn the pipeline, use the knee with the desired angle of rotation. Then a technical hole is made in the wall through which the chimney pipe is passed.To arrange the hole, it is necessary to carefully disassemble a section of the wall, and then reinforce it with wooden bars or special elements.

Then you need to mount the bracket with runners, designed for easier passage of the pipe, and install an adapter into it, with which you will need to connect the pipes that are suitable on both sides. The section of the wall around the sandwich pipes is covered with plywood panels, on top of which an asbestos sheet is fixed and covered with galvanized metal. On the outside of the building, the gap between the pipe and the wall is filled with heat insulating material, and under the section leaving the wall, if necessary, a support cantilever is mounted. Next, proceed to the preparation of the installation of the vertical section. For this purpose, brackets are attached to the wall at a distance of no more than 2 meters.

As they are mounted on vertical pipes, special hoop rings are worn. This increases the overall stability of the structure and makes the connection of sandwich tubes with brackets not so rigid. Due to this mounting, pipes can freely change their parameters due to linear expansion,without compromising the integrity of the connections. After the installation of the sandwich pipe is completed, measure its height above the roof level. In case this value is more than one and a half meters, it is recommended to install additional stretch marks supporting the structure. The final stage of installation will be the installation of the tip.

In conclusion, it should be noted that chimneys, equipped with sandwich panels, are added and internal. The first ones assume the shortest pipe outlet outside the room and the location of its main part on the street. The advantages of such placement are simple maintenance and the absence of the formation of transitions through the ceiling and the roof. In addition, this type of installation does not imply that the pipeline is inside the house. However, with the internal arrangement of pipes, the structure is less susceptible to the aggressive influence of external factors, which is not the case with the pipeline outside.

Thus, each of the methods has its strengths and weaknesses, and which one will be chosen is usually dictated by the location of the boiler, the material used to make the walls, and the personal preferences of the owners.

Tips

In order to install the chimney successfully, and the use of the heater was comfortable and safe, you should take into account several recommendations given by experienced specialists. The main guarantee of successful installation is the presence of stable traction, for the creation of which it is necessary to fulfill a number of conditions.

- The height of the chimney should be at least 5 meters.

- When installing the chimney on flat roofs, the distance from the tip of the pipe to the roof surface should be at least half a meter, and in case the roof is blocked with combustible materials, then at least 1.2 m. and the ridge is less than one and a half meters, then the pipe should be raised above the roof level by 50 cm. If this distance corresponds to 1.5-3 m, then the height of the pipe should be equal to the height of the ridge. In case this distance exceeds three meters, then the upper point of the pipe should lie on a line drawn from the top point of the ridge to the horizon at a 10-degree angle.

- Installation should be done vertically. In some cases, it is allowed to make inclined sections with an angle not exceeding 45 degrees.

- The length of the horizontal sections at the outlet of the boiler should not exceed 1 m.However, with a chimney height of 5 meters or more, it is allowed to increase to 2 m - when arranging the chimney for stoves and fireplaces, and up to 3 m - for heating boilers.

In addition to ensuring stable traction, for a safe and trouble-free operation of heating equipment, a number of conditions must also be fulfilled.

- It is prohibited to connect chimneys made of stainless steel to solid fuel boilers or furnaces that work on coal.

- Do not place flammable materials or containers with flammable liquids near the chimney duct.

- The use of sandwich pipes with galvanized external contour in residential spaces, as well as in rooms of high humidity is not recommended.

- Sealants used for processing joints must withstand temperatures up to 1000 degrees, and the means by which the point of attachment of the starting pipe to the boiler is processed is up to 1500 degrees.

- When installing tees, it is desirable to arrange support sites or supporting consoles. This will significantly reduce the load on the bends and tees, which they experience due to the weight pressure of the chimney elements located above.

- The use of sandwich pipes for drying clothes or shoes is prohibited.

- During the operation of the boiler or furnace solid fuel equipment it is strictly prohibited to use as a fuel items containing lacquer or enamel coating, as well as construction debris and household appliances.

- When arranging the sandwich pipe exit through the ceiling, it is necessary to equip the adjacent section with a metal apron.

- In no case is allowed narrower chimney. The diameter of the inner contour of the sandwich pipe must be equal to or greater than the size of the cross section of the outlet of the boiler. Adapters are used to connect a small output with a large internal circuit.

- When fixing the modular design with brackets, the distance from the pipe to the wall surface should not be less than 25 cm. The interval between the brackets should be two meters in the vertical position and one meter in the horizontal position.

- In case the roof is covered with combustible materials, then to ensure fire safety it is necessary to install a deflector with a spark arrester. And if there is a superstructure on the roof or there is a fact that the roof adjoins the neighboring building, then the height of the pipe must overlap the height of these structures.

- When building a chimney, it is necessary to reduce the number of bends and turns to a minimum, and not to make more than three of them. Tees and elbows should have a rotation angle of 45 and 90 degrees.

- When calculating the height of the chimney of solid fuel boilers, it is necessary to take into account the distance from the upper cut-off point of the pipe to the middle of the grate. In gas, diesel or pellet boilers, the measurement is made from the burner.

- When choosing tees to which the horizontal section is connected, it is necessary to additionally purchase a condensate unit. In addition, you should carefully examine the end, which is joined by a sandwich pipe. In the absence of a socket on it or the presence of a narrowing, to purchase such a product is not worth it.

Chimneys made with the help of sandwich pipes are becoming more and more popular. High consumer demand due to the ability to do the work yourself, without the use of professional skills and expensive equipment. In addition, modular designs provide high safety of operation of boilers and significantly reduce heat loss through the pipe.A large model range of modular designs facilitates the selection of the required product, and a wide price range makes it possible to purchase the product at a price that is comfortable for the buyer.

The combination of these factors makes the sandwich pipe even more attractive and affordable.

How to install a sandwich pipe for the chimney with your own hands, see the following video.