How to cut PVC panels?

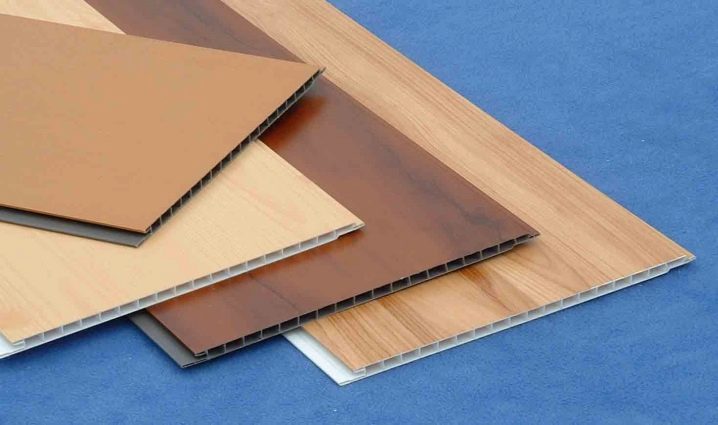

PVC panel is one of the most popular materials for interior decoration. Its use in the interior attracts not only the appearance, but also an affordable price, ease of maintenance and installation. Due to the listed characteristics, many people prefer PVC panels rather than tile, when finishing personal hygiene rooms.

Material Features

PVC panels are one of the modern types of finishing materials, which are made by extrusion and are used both in the bathroom and in the living room. The main raw material in the manufacture of such products is polyvinyl chloride, which is filled with a mold. So that the panels can be given the desired color, a certain amount of crushed natural chalk is added to their composition.

PVC panels can be decorated in one of the following ways:

- staining;

- thermal printing;

- offset printing.

Thermal printing is applied to the plastic surface using a special roller heated to high temperatures, which presses the film to the surface of the product. Thanks to this technology, it is possible to quickly and clearly apply the pattern without losing the brightness of the image. The panel itself does not need additional varnish coating. Offset printing is used much less frequently, due to its high cost.

The choice of tools for cutting

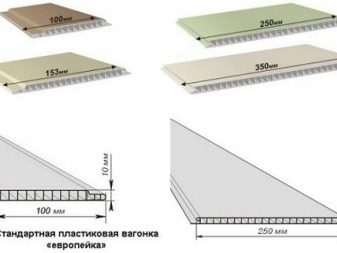

In the process of installing such a finishing material at home, users face a small problem: the panels sold in hardware stores have a length of 3 meters, and the ceiling height in most panel houses is 2.5 meters.

Specialists in the implementation of repair work, which have in their professional activities to perform the installation of PVC panels, know a lot of secrets about the correct cutting of plastic materials up and down. After analyzing them, every owner who wants to make repairs himself can choose the most suitable professional tool for him or use the available tools.

The choice of the method of cutting panels usually depends on the tasks and capabilities of the wizard. Below are the types of cutting materials.

Cutter

Most experienced specialists, whose tools have a great variety and are designed for high-quality processing of plastic, prefer to cut PVC panels with a special cutter. Thanks to him, without much effort on the plastic surface creates an even cut, characterized by the absence of chipping and chipping. The cutter is sold in almost every hardware store and has an affordable price.

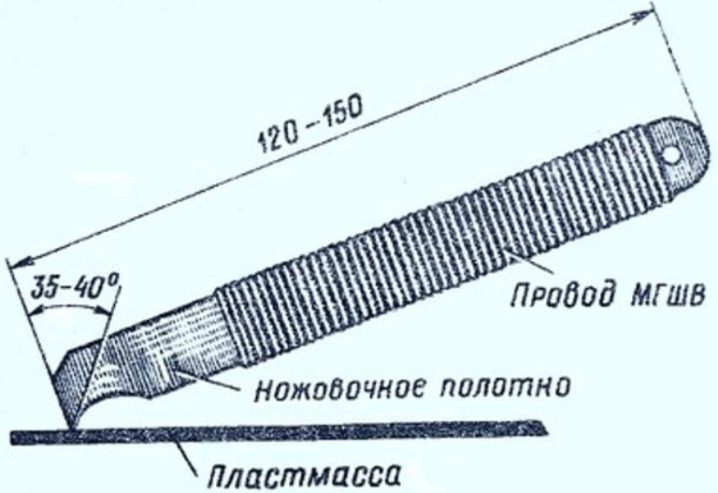

If necessary, this tool can be made independently from available tools, for which it is enough to adhere to the following recommendations:

- it is necessary to prepare a metal strip, the thickness of which is not less than 2 mm, and the width is 1 cm;

- then you should cut one of the edges of the workpiece at an angle of 45 degrees;

- it is necessary to sharpen the edge of a homemade product using a grindstone;

- The opposite side should be wrapped with tape that will allow in the process of work to protect the hand from damage.

A professional plastic cutter has a relatively low cost, so its acquisition can serve as a profitable investment, because thanks to this tool, the process of cutting PVC panels becomes not only more convenient, but also quite fast.

Hacksaw

One of the universal devices for cutting any material is a hacksaw, which certainly will be in the arsenal of any master. It will help if necessary to cut the plastic wall panel. Such work will take more time than using a special cutter, but with significant lining volumes this will not significantly affect the total duration of the repair.

When using a hacksaw, you should listen to the following recommendations of experts:

- To work with plastic finishing materials, use a tool with small teeth, which is usually designed to work with metal or wood;

- to shorten the PVC panel there is no need to exert strong physical effort, which can lead to material damage;

- it is possible to cut several parts with a hacksaw at once by folding them together and securing them to avoid bending or shifting.

In order to make the incision not jagged, it is not recommended to use the tool with teeth apart in different directions.

Power tools

The hand-held power tool is best suited for quickly sawing PVC panels. For this purpose, you can use almost any device, which will help to significantly reduce the time spent on preparation for installation.

Often, cutting is performed using the following instruments:

- jigsaw;

- Bulgarians;

- circulars.

To work with plastic material, it is allowed to use only low revolutions, because with substantial heating it begins to melt and release toxic fumes for the human body, and the incision will be torn.

The use of jigsaw will help make the process of preparing PVC panels for installation significantly faster than when using hand tools.

However, with such a processing method, the following nuances should be taken into account:

- before starting work it is necessary to turn off the pendulum swing;

- should use a file with the smallest teeth;

- you need to set the lowest speed of the file, which will avoid excessive heating of the plastic in the place of the cut.

Using an electric jigsaw, it is very convenient to cut stacks of panels, but you should make sure that their height does not exceed the length of the file installed in the tool.

Bulgarian recognized as the most convenient and practical power toolswith which you can cut wall PVC panels. By installing a cutting disc, you can make not only straight, but also figured cuts on the surface of the plastic. When processing plastic around the grinder, it is turned on only at low revs, which will avoid material damage due to melting edges.

Knife

In the absence of more practical and convenient tools, PVC can be cut off with a knife.

To solve this problem, the following types of cutting products are suitable:

- Kitchen knife. This tool is suitable for cutting multiple panels in the process of repair or replacement. For large-scale wall decoration, this procedure is unnecessarily long and painful.

- Construction knife. Among the manual cutting tools, such a device is one of the best options for achieving a smooth cut with a relatively small effort.

- Stationery knife. With the help of a wooden ruler or a square, this tool allows you to achieve a perfectly flat cut of the panel, so it is often used for cutting them.

Basic cutting rules

So that the efforts to cut PVC panels are not in vain, and the result of the work meets expectations, experts recommend that you follow a number of rules for working with plastic. These small secrets will help not only significantly reduce the amount of damaged material, but also save the master from unnecessary financial expenses and injuries.

When working in the heated season, you should not start cutting panelsthat have recently been entered in the room. Plastic should naturally warm to room temperature, which is achieved in at least 12 hours. The fact is that at low temperatures the plastic panel becomes fragile, and therefore can crack and break off large fragments.

Regardless of the material processing method chosen, it should be placed facing towards you, thus avoiding deformation of the panel and difficulties in its further installation. When cut from the wrong side, you can detect microcracks on the front, which will manifest itself over time and significantly spoil the interior.

It is necessary to pre-mark the straight line of the planned cut, which can be done with a simple pencil and clerical ruler.

To speed up the process of preparing the material for installation work, you can cut or saw multiple PVC panels at the same time. To do this, simply stack them up and create a two-point support. The opposite edge of the stack is best to rest against the wall, which will help to avoid shifting products, respectively, the result will be parts of the same length.

Safety regulations

Like working with any building materials, the processing of PVC panels requires compliance with several safety rules. These recommendations are especially relevant if you plan to work with the help of a power supply tool, such as a jigsaw or grinder. In the case of cutting plastic with a power tool, there is a great danger that fragments and sawdust can fly off the panels. Therefore, experts recommend pre-purchase goggles and gloves that should not be removed before the end of the work. These seemingly simple personal protective equipment will help protect your hands and eyes from injury.

These tips should help you decide which tool to use., as well as create the interior of your own dreams and avoid most of the mistakes, because with a little effort you can achieve the desired result, saving a considerable amount of money.

How to easily and clearly cut the plastic panel, described in the video.