Vapor barrier for the roof: design features and subtleties of installation

Reliable and high-quality roofs consist of several important elements, among which is a vapor barrier. First of all, this component is necessary to avoid the formation and accumulation of pernicious moisture in the inner part of the skin. If we neglect the installation of a vapor barrier, the roof can rot and decay. Today we will examine in detail what are the design features and the subtleties of mounting such an element of the roofing “pie”.

Purpose

Vapor barrier is an important element that performs many functions. The main purpose of this material is to protect the roof from the accumulation of excess moisture.It is not a secret for anyone that in such conditions any structures can rot or corrode, which in time leads to devastating consequences. To avoid damage to the insulation and the individual elements of the roof, should be laid high-quality and reliable vapor barrier.

If there is no vapor barrier on the roof, then condensate may accumulate on its various elements. It is unlikely to be able to avoid its appearance, since the source of condensate is most often steam, a permanent satellite of the living space. Without a heat-insulating layer, wooden beams and floors can simply rot, being under the constant influence of accumulated moisture.

A damp roof that accumulates condensate will have to be repaired with time, which means extra waste and time. In addition, if the design in some places or as a whole has a complex structure, then this will be more difficult.

It is worth noting that high-quality vapor barrier, established by all the rules, makes the roof more robust and durable.

All the materials that make up such an important part of the house will last much longer.You do not have to annually overhaul the roof, if you take care of the presence of vapor barrier material.

Vapor barrier extends the service life of insulating materials, because for them the effect of moisture is very harmful. After a couple of seasons (maybe even earlier), insulation that is not supported by a vapor barrier coating will lose its positive qualities and will simply become unusable.

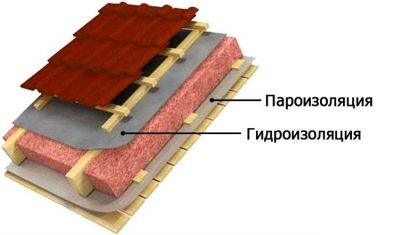

However, it must be borne in mind that vapor barrier materials are not the same as waterproofing coatings. In general, these concepts have a lot in common, but their main difference lies in the fact that waterproofing protects the foundation from the liquid, which often accumulates on the roof. Such protective material will be very helpful if excess moisture has spread around the roof.

The vapor barrier saves the roof not only from the liquid itself, but also from the damaging effects of steam.

Another function of the vapor barrier material is a significant reduction in heat loss from the living space. This ability is especially relevant when the cold season is outside the window. If you equip the roof with high-quality heat and steam insulation, then homeowners can save on heating and purchasing expensive heating appliances.

Roof structures in which there is a vapor barrier material, become not only more durable and reliable, but also fire resistant.

According to experienced craftsmen, vapor barrier is a necessary component in the construction of any roof. With its use, the roof will last much longer, as well as warming materials under it. Fortunately, modern manufacturers produce reliable and durable coatings with vapor barrier properties.

With such materials you can not be afraid for the service life and performance of the roof.

Device

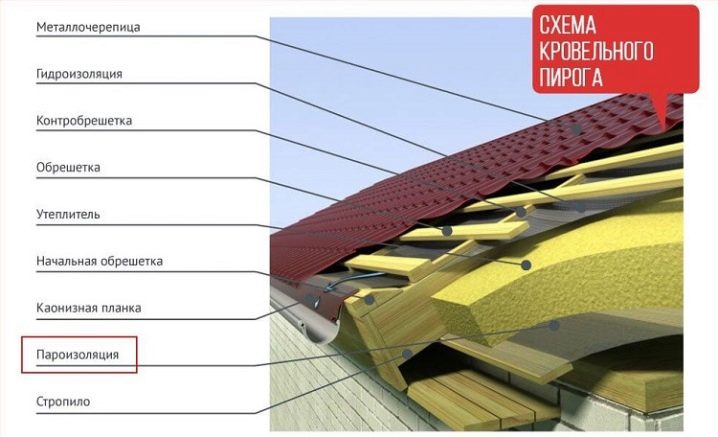

Roofing "pie" is the name because it consists of several layers, each of which performs a specific function. Different designs can have several layers in their composition, but only steam, hydro and heat insulating layers remain unchanged.

In this case, the waterproofing is aimed at preventing moisture from getting into the interior of the dwelling from above, and the vapor barrier does not allow the internal evaporation to get directly into the roofing multilayer foundation.

It is very important to install a vapor barrier below the heat insulating material.

If you ignore this simple rule, then the insulating layers will absorb the vapor that moves from below. Over time, this will lead to swelling of materials and even their destruction.

However, it is worth noting that roofing structures may not have any insulation at all (the so-called cold roofs). Many homeowners are wondering whether it is possible to leave such grounds without additional vapor barrier. Of course, it is better not to make such mistakes, because the vapor-insulating materials are aimed not only at protecting insulation, but also at maintaining a comfortable microclimate inside the dwelling. If you neglect the installation of such a layer, the house will be hot and stuffy, as in a greenhouse.

In order to understand how a vapor barrier device looks like, it is necessary to consider in more detail the device of the roofing “pie” itself.

- Roof can have a solid structure. or consist of separate elements (for example, it can be a tile or slate). These materials are laid and fixed on prepared structures made of wood (crate). And you can also install roofing coatings on monolithic bases.

- But also waterproofing layer should be present in the roof structure. It protects other layers from the ingress of external moisture. Waterproofing in this case, as a rule, is a special non-woven material, which is fixed on the crate. A small gap should be left between the waterproofing and the other layers.

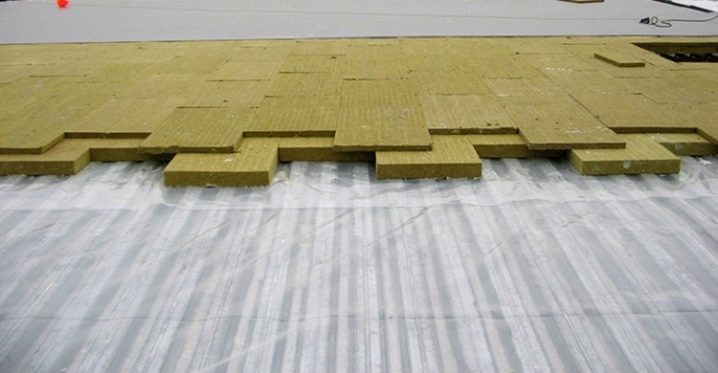

- No less important in the device of the roof and high quality insulation. This component is a plate with a minimum thermal conductivity. They are made from different raw materials, for example, mineral wool or polyurethane foam. And if the foam or PPU almost does not fear the moisture, the mineral wool requires the installation of high-quality vapor barrier.

- The vapor barrier itself in the roof structure can be represented as a membrane or film. These parts are installed directly on the crate after the insulation. At the same time, there is always a small gap between the ceiling materials to ensure adequate ventilation.

Thus, when the water vapor next to the bottom will collide with the membrane, condensate will appear, which then simply flows down and then dries under the influence of airing the under-roof base.

Even the most high-quality and expensive vapor barrier will not work "at full capacity", if you do not provide the roof with good ventilation.

This component is important at any time of the year. So, in the winter ventilation will allow to keep heat in an internal part of the dwelling, and also will warn icing of a roof. In the summer season, the ventilated design will allow the room to remain pleasantly cool.

If on the roof of the house the vapor-insulating material was installed incorrectly or is completely absent, then this will inevitably lead to accumulation of uncontaminated condensate, followed by mold and fungus. As a result, the design simply rot and collapse.

Variety of materials

At present, in specialized stores one can find various variations of vapor barrier coatings suitable for installation on the roof. Choose the best product for any roofing design.

Consider what types of vapor barrier offer modern manufacturers, and how they differ from each other.

Polyethylene

Quite often in shops paroizoliruyuschie films of polyethylene. Not long ago, similar materials began to be reinforced additionally, in order to give them more strength and reliability.

Currently, there are two main types of polyethylene vapor-proofing films:

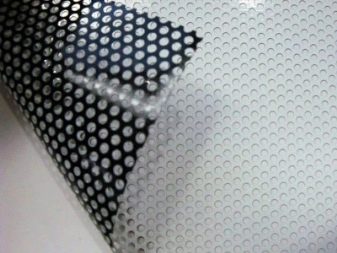

- perforated;

- non-perforated.

It is believed that for vapor barrier roofing bases most often choose exactly non-perforated coating. Standard perforated materials have high vapor permeability, therefore they are hardly suitable for protecting the roof from condensate. Such features of the plastic film should be considered when choosing it.

We should also highlight the modern polyethylene films, which are coated with aluminum foil on one side. Such materials are much more effective in resisting a couple, which makes them more popular and in demand.

Very often, such films are installed in baths and saunas, therefore, according to experts, it makes no sense to put them on the roofs.

Polypropylene

Polypropylene paroizoliruyuschie materials in many ways superior specimens of polyethylene. The main advantages of such coatings are:

- high strength;

- resistance to ultraviolet rays.

Particularly attractive are such films with antioxidant coating. On the one hand, they are covered with viscose fiber with cellulose. Such basics seamlessly and effectively absorb moisture, while maintaining it for some time. When the cause of the appearance of condensate disappears, its layer dries quickly, while not allowing excess moisture into the insulation.

Such a film is especially important to lay correctly. Remember: the antioxidant layer should be directed downwards.

Diffuse membrane

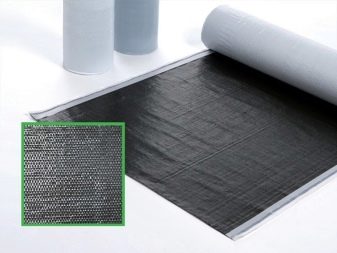

Such vapor barrier materials are considered high-tech. They have a micro-perforated structure. In membrane coatings are present components such as non-woven polypropylene and polymer film.

These coatings are good because their life expectancy is on average 30-50 years. They are made single-layer and multi-layered.

Coating

Roofing vapor barrier also differs according to the type of its device. So, for reinforced concrete and metal foundations, a coating material is considered the best option. In this case, coatings with a liquid consistency are used. It can be a quality primer based on bitumen, mastic or emulsion.

At present, such vapor barrier materials are considered the most affordable, and you can meet them at any building materials store. However, before they are laid, it is necessary to properly prepare the foundation.

For this, a special primer is often used to ensure that the materials adhere securely to each other.

Liquid rubber

Environmentally friendly material of a liquid consistence is special liquid rubber. Such a vapor barrier is recognized as safe for human health. On a flat base such raw materials are applied on a variety of bases.

Getting on the surface of the base, liquid rubber freezes as quickly as possible. At the same time, it turns into a solid membrane of elastic structure. Such material is glued to the surface without any problems. In addition, it perfectly seals all joints and junction elements.

Liquid rubber is based on polymers and elastomers. In addition, it contains water emulsion and other safe ingredients.

Such a tool is addressed not only in the design of the roofing “pie”, but also in the processing of pipes (to protect against the appearance of corrosion).

Pasty

Vapor barrier material may be adhesive.Such coatings should be laid in the same way as roll roofing. In this case, the protective layer, as a rule, is sealed with the use of a special construction adhesive tape, as well as an additional soldering of the edges.

Gasket

For cushioning vapor barrier roofs it is permissible to use materials such as hydrosol, isol or bizol. But also many masters turn to ruberoid: here it is necessary to take into account that it is not the most reliable and durable. In addition, over time, such material loses its positive properties, and it has to be changed / repaired.

The cushioning vapor barrier is carried out on a dry boarding floor with overlapping of canvas (10-15 cm each). Such materials are attached to the crate with nails.

On top of the cushioning layer is recommended to press down the roof of metal.

Styling rules

To make the roof more reliable and durable, it needs to provide high-quality vapor barrier. To do this, protective materials should be laid, adhering to a special technology. It does not matter whether you are making a vapor barrier for flat or pitched, soft or hard substrates - film or membrane material will still have to be installed only after laying insulation.

Let us consider in more detail what rules for installing a vapor barrier must be observed when arranging the roof.

- The vapor barrier can be laid both vertically and horizontally.

- If you put the vapor barrier horizontally (transversely to the rafters), then you should start the work from the top row and then gradually move down.

- Do not forget to leave an overlap of 10-15 cm.

- It is recommended to attach a protective film to the crate with a construction stapler.

- To fix the joints, you can use two types of tapes: double-sided or one-sided. Bilateral options are glued to the inner strip of film, and then closed next.

- Unilateral copies are used for fixing external seams. They are glued to the junction.

- If the insulation is planned to be laid vertically, then it is necessary to calculate in advance, so that the joint falls on the crate. Otherwise, the vapor barrier material (especially if it is a film material) may simply tear, even if you glue it with tape.

- In places where the film is adjacent to the windows (for example, if it is the roof of the attic), it is recommended to use a special apron.If there is no such part with a vapor-insulating coating, then a special tape can be glued to the joint.

- Next, an additional timber is installed on the fixed vapor barrier material. This detail is necessary so that the vapor barrier of the roof and the inner lining have a ventilation gap between them. In this case, the timber should have a minimum thickness of 25 mm (it is better to take a material with a thickness of 50 mm).

- Pay attention to the fixation of the film - it should not sag anywhere.

Useful tips

- Sites of insulating materials are recommended to be strengthened with special clamping strips. This decision is especially important if we are talking about the arrangement of the roof with a slope of 30 degrees and not very dense thermal insulation.

- You should know that all roof insulation works start from the inside. When laying each new layer of film or membrane should capture at least 10 cm from the previous laid flooring.

- If water pipes pass through the roof, then in these places it is worth wrapping the vapor barrier material down, and then wrap up communications with them and carefully tape everything up with tape.

- To seal the seams is not recommended to use a narrow adhesive tape. So, strips whose width is only 5 cm (or less) will simply peel off from the base. It is better to buy tapes with a width of 10 cm.

- Always leave a strain stock.working with window openings. In any homes (especially wooden) over time, shrinkage occurs, so experts strongly recommend leaving a spare fold width of 20-30 mm.

- A suitable vapor barrier must be laid under such a material as a professional sheet. In this case, it is acceptable to use household polyethylene (it is recommended to lay it in two layers), a reinforced film, polypropylene and a material with foil. However, choosing such a layer of roof, you need to remember about its impressive weight. Because of this, working with him can be quite difficult.

- If you decide to lay roofing felt on the roofthen you should take into account that it often takes a lot of time to pack it. In addition, this cheap material may soon need to be repaired.

- Experts strongly recommend to buy only high-quality materials. for vapor barrier roof, because in case of damage to change them can be quite problematic. Even minor repairs can be time consuming and costly.

- Choosing a roofing vapor barrierOne should pay attention not only to its manufacturer, but also to the thickness of the material itself. The thicker and thicker the film, the more reliable and durable it is. Of course, such materials are not cheap, but you cannot save on their quality.

- Note that most non-combustible vapor barrier materials have two sides. One of them misses steam or water, and the second does not. That is why during the installation work it is so important to correctly install the canvases. Otherwise, the roofing “pie” will turn out to be of poor quality and will not last long.

- Picking up adhesive tape, it is necessary to take into account that it does not fit all materials. In order not to spend money on an unsuitable product, you should consult with the seller-consultant.

- If you attach paroizoliruyuschuyu film to brick (or wooden) wall with a rough surface, then you can do it more reliably and efficiently only with the help of polyurethane,rubber or acrylic glue. A good alternative to the listed compounds is synthetic rubber.

- In places where the vapor barrier material joins the walls inside the house, as well as mines, stoves and pipes, you should take into account the irregularities to which the material will be attached. Only this way will you be able to ensure that the vapor barrier has sufficient tightness during installation.

- Experts do not recommend using polyurethane-based adhesive tapes when installing insulation. Do not use butyl rubber tape. Such materials are kept weak and short-lived. They quickly peel off from the base, thereby delivering a lot of inconvenience.

- If you want the dwelling to remain warm, and the vapor barrier of the roof served as long as possible, it is necessary to ensure the roof structure with good ventilation.

- Paroizolirovat roof is quite possible with their own handsHowever, experts do not advise to take up work, if you have never encountered similar processes. In this case, it is better to turn to professionals who will do everything more reliably and efficiently (in accordance with the requirements of SNiP).

You can find out how to put the insulation film on the right way by looking at the video below.