Izospan A: features of use and rules of laying

Izospan materials are used to isolate surfaces from moisture. They demonstrate the necessary level of fire safety and, in addition, help to keep the heat indoors. The consumer is presented with a wide range of products with the necessary properties for the organization of high-quality insulation.

Properties

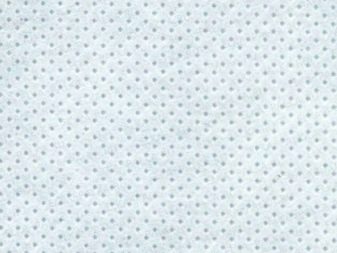

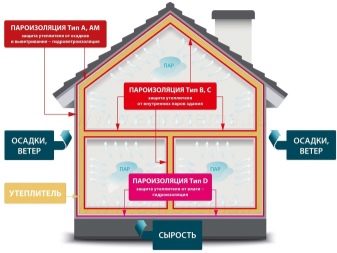

When waterproofing the device, Izospan is mounted directly on the rafters in order to protect the insulation from moisture accumulation. Also, vapor barrier film is used for insulation of attic floors, ceilings, walls of rooms. On wooden structures, in order to isolate them from the outside, a vapor permeable membrane is applied.Before buying a film, you need to understand what types the market offers by characteristics and purpose. The range includes rolled materials from non-woven fabrics produced according to GOST. The differences of the supplied product can be traced not only in their density, but also in structure.

The membrane of the nonwoven fabric (to create a vapor-permeable barrier) is intended for external insulation of roofs and wall structures. Material protects from moisture and wind. In addition, the diffusion film performs another function — it does not condense moisture inside the wall structure. Class A Izospan does not pass water, it is easy to use and is able to withstand different temperature loads., which allows to increase the life of buildings. In addition, it perfectly protects them from moisture, decomposition, mold and corrosion.

Such material is worth buying due to its high resistance to negative factors, strength and excellent technical characteristics. It can withstand the power loads and not lose its shape, as well as withstand the influence of ultraviolet rays. Ease of installation will also please you: the user will be able to independently install a barrier using the minimum amount of available tools. Izospan A is used to protect basements and mansards.Its density is 110 grams per 1 square meter. It is produced in rolls 140 cm wide and 50 meters long.

General specifications:

- excellent strength;

- elasticity;

- not a source of harmful substances;

- can handle high pressure.

Material maintains temperature drops from - 60 to + 80 degrees. There are refractory particles in the composition, which endow it with unique properties. Izospan A is a type of membrane that protects the surface of walls and ceiling from moisture condensation. Strength of stretching is 190/140 mm, resistance to ultraviolet radiation is 3-4 months.

When installed on the roof, the material is cut into wide strips and applied in such a way that the smooth surface remains outside. Installation begins at the bottom of the roof. At the same time, when working with Izospan, one should not allow contact with it, since the waterproofing properties in this case are significantly reduced.

The product is made of pure polypropylene. It does not absorb moisture, so it is permissible to use a membrane for insulation of residential and industrial buildings.

Due to its properties, Izospan guarantees long-term protection against rotting to the tree and metal against corrosion. It is especially important to use the material in regions with harsh climatic conditions, as well as increased wind loads.

The membrane perfectly holds back not only moisture, but also guarantees the absence of a draft (if it was installed in compliance with the requirements of building codes). The membrane has a simple principle of removing moisture to the outside: a rough surface collects steam that forms in the room, after which it seeps out through the existing microperforation. The back side is smooth, so the drops either roll down on it or evaporate.

That is why it is so important to properly lay the material, not confusing the sides: the rough surface of the film should always be inside, that is, turned towards the room or insulation. If this requirement is not met, then the membrane will not work effectively.

Advantages and disadvantages

Material advantages:

- strength;

- reliability;

- supplied with flame retardant additives;

- multifunctionality;

- environmental Safety;

- easy installation;

- vapor permeability;

- resistance to high temperatures (suitable for use even in bathrooms and saunas).

Due to its structure, Izospan prevents condensate from entering the walls and insulation, protecting their structure from the formation of fungus and mold. A lot of positive reviews ensured the popularity of the material for many years. Izospan A is a film membrane impenetrable for air and moisture. Its use reduces the number of drafts, prevents the ingress of moisture and helps to improve the quality of the atmosphere in the room. Additional use of a primer is not required before laying the membrane on most building surfaces.

Isopane A is an innovative material that has components in its composition that make it possible to use it on a surface with a high temperature. This is important in the construction of the roofs of baths and saunas. Unique properties allow you to extend the construction season and provide year-round construction of buildings in cold climates.

The product can withstand up to 12 months of direct exposure to ultraviolet radiation, while maintaining the integrity necessary for long-term construction projects. The material has a lighter weight than competitive products.This property is indispensable when you need to reduce the load on the structure. You can install long sections of the canvas, which will increase the speed of work on the object. The vapor barrier is installed horizontally or vertically, always with a cross between the cloths of 5 centimeters.

Overlapping allows you to avoid drafts. The membrane is compatible with various construction materials such as plaster, plywood, OSB, cement board, concrete, CMU, sealant. You can save at the level of heat consumption, which allows you to install and use heating equipment in smaller rooms. Energy costs can drop as much as 40%. The risk of mold and mildew is also reduced.

Among the main drawbacks are:

- poor moisture resistance;

- small scope.

If too much water accumulates on the surface of the film, moisture will begin to roll inwards. To use a single-layer film for the roof is not worth it. In this case, a multilayer membrane is best suited. The manufacturer’s instructions state that Izospan A can be used in the roof construction, but preferablyso that the slope does not exceed 35 degrees. You should not buy material if you plan a metal coating on the roof.

Application area

- Manufacturers offer a wide range of materials. All types of Izospan differ in density, as a result of which they can be laid on the floor of a frame house or used in the roof structure.

- Izospan is one of the most popular types of insulation due to its price and unique properties. It is suitable for walls, ceiling and basement floors, attics and mansards. Hydrophobic cloth is widely used as a waterproofing layer on dirt floors, cement screeds in wet areas and as a windscreen. Vapor barrier - one of the main advantages of the material.

- The moisture protective membrane can be used in the construction of a heated floor. Windproof function significantly expanded the scope of the material. Depending on the operating conditions, it may be necessary to create a ventilation gap of 40–50 mm, due to which weathering of moisture occurs. A feature of the canvas is the ability to reflect thermal radiation.

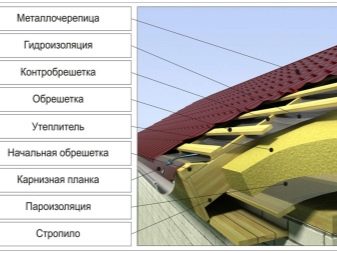

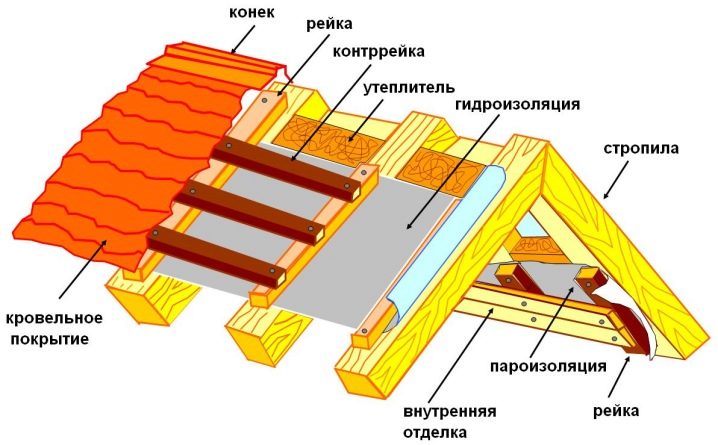

- Rolled material is not afraid of water, durable and easy to install, it is easy to use in the attic. It is widely used as a roofing vapor barrier for pitched roofs, as well as partitions. At the preliminary stage of construction of the roof plates are installed between the rafters. The second layer of the film overlaps the top one by 15–20 cm without tension.

The instruction manual Izospan specifies the basic requirements for the use of the material.

- It is advisable to avoid adherence of strips to the edge of the ridge.

- Be sure to create a ventilation gap (50 mm), which provides air flow, contributing to the weathering of moisture.

- All connections are processed with sealing tape.

Izospan with AF marking is characterized by the presence of protection against ignition, therefore it is used in flammable rooms. The presence of the letters AM means a three-layer construction of the film, capable of protecting the structure of the building from any external influence.

On sale you can find material labeled AQ. Such a film has the maximum insulation properties.

Subtleties of installation

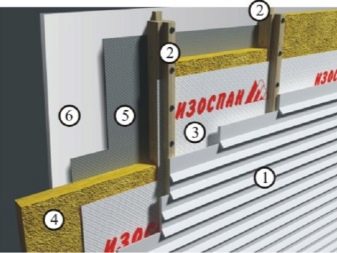

Before using the film Izospan, it is necessary to check the insulation of the gaps between the insulation blocks, in case of detection - to eliminate the shortcomings.Seal the contact points of the membrane with structural elements, for example, with windows. For vapor barrier walls Izzopan A is used on the outside of the building, and Izospan B - on the inside. When building walls Izospan A is laid in layers on their surface. Works are conducted from the bottom up. Fixation is performed using a stapler. At the same time, it is necessary to eliminate sagging of the canvas, otherwise with a strong wind load on the facade, unnecessary noise (clapping) may appear.

During the installation of the roof material is cut directly on the rafters above the insulation. Laying is done horizontally. Begin at the bottom of the roof. Fastening is done with the help of nails (sometimes screws). It is recommended (but not necessary) to leave a space of about 5 cm between the bottom of Izospan and the insulationand a gap between the membrane and the roof, the width of which is usually equal to the size of the rail.

As noted above, the placement of Izospan begins with the bottom row of horizontal stripes. The overlap should be not less than 10 cm. Places of a film adjoining to a surface should be stuck together with an assembly tape. This method is suitable for wood veneer.

It is very important to stack the material with the right side to the insulation. Before installation, you must carefully read the instructions for use of the canvas. For external insulation of roofs and facades of buildings, it is necessary to use the brands Izospan AND, AM, AS, providing the necessary protection.

Different variations of Izospan A have different material densities. For model A it is 110 g / m², for AM it is 90 g / m². The AS model has a figure of 115 g / m², and the highest density of AQ proff is 120 g / m². To create a high-quality hydro and vapor barrier, experts recommend using an additional vapor barrier Izospan V.

The installation scheme depends on the design purpose. If it is an inclined roof without insulation, then the main structure is mounted, then a vapor barrier, and then wooden flooring.

In the attic are laid first overlap, then - the vapor barrier, then - insulation and rails, and in the last turn - the beam. When using a membrane on a concrete floor, a base is created at the first stage, then a screed, a film is laid on it and then only a finishing finish. If you want to achieve good results,It is necessary to strictly follow the recommendations of the manufacturer, observe the subtleties of using the Isopane material and be sure to take into account the peculiarities of the surface over which the film layer will be laid.

For fastening to a wooden shroud or rafters, a stapler and an adhesive tape of Izospan KL or SL are used. Izospan brand DM is mainly intended for installation under a metal roof. To ensure the proper level of vapor barrier used brand Izospan RS, C, DM. For the device of warm floors, thermal insulation of walls and roofs there is a need to simultaneously provide hydro and vapor insulation to prevent heat dissipation. In these cases, use Isospan FD, FS, FX.

The use of a membrane is a mandatory requirement for laying insulation in the roof structure. Thanks to it, mineral wool can be protected from steam and condensate. If polyurethane foam is used, then there is no need to use Izospan.

As a waterproofing, it is recommended to use a diffusion type membrane that allows steam to pass through without blocking it and prevents moisture in the room. It is necessaryso that there are at least 50 mm ventilation holes between the heat-insulating layer and the waterproofing material. The ultimate goal is to remove excess moisture.

For any building vapor barrier plays an important role. Izospan offers a modern and simple solution to this issue. Moreover, it provides security for insulation, roofing and walls. The use of the material allows to significantly warm the room, although the waterproofing is greatly undervalued by the modern consumer.

Izospan products are represented by a wide range of products, each will be used for a certain type of work. It is possible to lay the film not only in the construction of the roof, but also as an insulating material when organizing the base, including from rubble, sand and soil.

Some species absolutely do not let moisture in, so they can be fixed only in rooms with forced ventilation. For a warm floor as a reflective lining can not find a better film.

Each product is packed in a specially created sleeve made of polyethylene. Included is an information sheet and instructions for use.

See also the video for how to use Izospan A: