Vapor barrier "TechnoNIKOL": types and technical characteristics

Modern construction can not be imagined without thermal insulation. Thermal insulation materials are increasingly used in the construction process. But even the highest quality insulation will not work effectively throughout the life of the product. Vapor barrier "TechnoNIKOL" plays an important role in preventing the occurrence of moisture on the insulating material.

Features and benefits

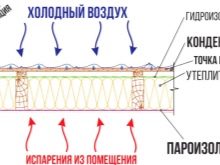

Vapor barrier "TechnoNIKOL" prevents the impact of steam on the roof. Due to its properties of vapor and water impermeability, it prevents the penetration of moisture into the structure. Thus, the vapor barrier regulates the temperature and water balance in the building.Its multi-layered structure not only reliably protects the roof from the formation of condensate, but also prevents the accumulation of dirt and protects against noise. The main advantages of the vapor barrier "TechnoNIKOL" include the following:

- simple installation;

- availability of material. Rolls can be purchased at any specialty store or ordered online;

- reliability, durability and resistance to external factors: the risk of material deformation is minimal;

- value corresponding to quality. The price per square meter belongs to the average price policy category;

- high environmental friendliness of the film. Only those materials that do not form toxins and harmful components are included in the vapor barrier. As a result, vapor barrier materials are widely used - from public buildings to residential premises;

- versatility. The material is used not only to arrange the roof, but also to protect the surface of the walls from condensation.

But there are also disadvantages of this material, such as:

- a strong stretch of the film can lead to its destruction at temperature drops;

- ready-made mastic can be used only when processing surfaces to the moment of laying or installation of a finishing decorative finish. Otherwise, the film will pass air through itself, as well as trap fluid.

Description

Steam insulation material "TechnoNIKOL" is a perforated or membrane film. It is available in rolls. On the outer side of the roll is marked with a gray line at 12 cm from the edge, which ensures vapor tightness. The material is absolutely safe for health, serves for many years and is not exposed to environmental factors. Vapor barrier "TechnoNIKOL" has the following technical characteristics:

- vapor permeable properties: from 1 to 5 g / m² x day;

- material density: 80–120 g / m²;

- withstand force in width and length: up to 180 N / 5 cm;

- resistance to ultraviolet rays: up to 3 months;

- operating temperature: up to 70 degrees.

The technical characteristics of the film have compliance with all certificates of fire and explosion safety since the film is non-combustible. Experts in the field of construction advise to use "TechnoNIKOL" especially for flat roofs.

Since the vapor barrier has increased strength and moisture resistance, as a result, it can be used for wooden or metal roofs with rough edges.

Species

Vapor barrier "TechnoNIKOL" classified according to the type of roof. Vapor barrier for pitched roofs is represented by several solutions:

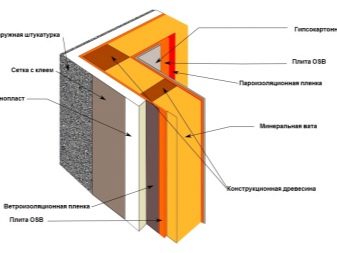

- Vapor barrier films have a three-layer structure, two layers are responsible for the reliability and durability of the material. They are made of prokleechnogo propylene canvas. The third layer is designed to control vapor permeability. These layers are interconnected by cold welding. The notorious advantages of such films are considered increased strength and resistance to ultraviolet radiation. They can protect rafters from snow and rain throughout the year.

There is another type of universal films - it is reinforced (a combination of perforated and non-perforated membranes), which is made of polyethylene. Due to such material properties as strength and vapor permeability, reinforced films are widely used in construction.

Polyethylene has a loose structure, often with defects due to the presence in the raw material of foreign components and dust in the production. For the production of such vapor barrier involve special equipment.

- Bag cloth made of polyethylene filaments that are laminated with a low-density polyethylene melt. Such a product does not have vapor barrier properties, since polyethylene melt unevenly laminates the originally uneven base. But this does not interfere with the use of bag fabrics when arranging cold roofs in the role of under-roof waterproofing.

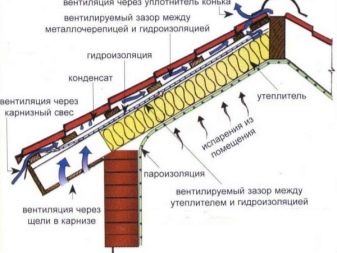

- Super diffusion bilayer membranes perform several functions at once, which facilitates the construction process. The membrane is a polyvinyl chloride fabric with a built-in mesh, which serves as reinforcement. PVC gives high strength and minimizes the risk of deformation during temperature changes. However, you need to be prepared for the fact that if the membrane is damaged, moisture gets inside the room. This can be warned if it is good to seal the joints and leave a gap over the insulation for independent removal of moisture.Membrane films retain heat indoors, as well as create the necessary microclimatic conditions.

- Foil vapor barrier has unique properties. It is practically not subjected to deformation, even when falling tools. As well as foil film is considered to be reflective. Thus, its properties are much better than other vapor barrier materials.

A striking example of foil self-adhesive vapor barrier is considered "Parobaryer". It is used for roofs with a bearing base on the professional sheet. The main advantage of this vapor barrier is a self-adhesive base. Since this will not only accelerate the process of laying material, but also in the process of operation the roof will not be afraid of strong winds. We must not forget about the maintainability of the foil membrane. Workers can safely walk on the roof. During breaks in work, it can also serve as a temporary roof.

Vapor barrier for flat roofs is made by applying a bitumen polymer on a fiberglass or polyester substrate. It is suitable for non-insulated roofs. Coating vapor barrier is also used to treat the surface of the floor and walls.In this case, use heated mastic.

Dimensions

The paroizolyatsionny cloth for a flat roof has the following sizes: 3х30 m and 0,3 thick, and for a cattle roof and walls - 1,5x50 m and 0,15 thick.

Recommendations for working with the material

When planning the organization of roofing vapor barrier should consider the type of roof. Usually, membrane materials are used for membrane materials, and for flat materials - perforated ones. Before buying, be sure to check the certificate of vapor barrier. This is done in order not to purchase a fake. Experts recommend the use of thermal insulation "TechnoNIKOL" in the event that the roof is insulated with ordinary material that can absorb moisture.

It is necessary to adhere to several basic rules for the installation of a vapor barrier material "TechnoNIKOL":

- When using double-sided film, where one side is rough and the other is smooth, the film has a smooth surface on the insulation. The other side of the film in contact with the condensate will allow it to evaporate unhindered. Otherwise, a smooth surface will only accumulate moisture. Its main function is to protect the surface, not letting in steam accumulated by a rough surface.

- When working with polypropylene material one layer is also put a smooth surface inside.

- When working with foiled material, it should be borne in mind that the foil should reflect the sun's rays. Therefore, this film is laid foil out.

- If it is necessary to put insulation vertically, it is necessary to calculate that the junction coincides with the crate, otherwise a vapor barrier may break, even if it is glued together with tape.

All these rules can be applied in almost all cases, but each manufacturer makes some changes, so before installing the vapor barrier you should read the instructions. With proper installation of the vapor barrier material, mold and fungi can be avoided.

The method of installation varies depending on which part of the room you need to install a vapor barrier film.

Roof vapor barrier

For proper installation of the vapor barrier film on the roof you need to follow some recommendations. So, rolls with a vapor-insulating material are rolled out, starting from the top and pushing the next layer to the previous one by 2–4 cm.To combine the individual parts of the tape is used, which helps seal the seams. Usually, aluminum tape, rubber tape is used as such tape. For the vapor barrier of the non-insulated roof, the material is attached horizontally to the crate.

Ceiling vapor barrier

When installing the ceiling vapor barrier, it is necessary to prepare the surface. To do this, wipe the surface with dust and leave to dry completely. After that, they proceed to the removal of irregularities and grooves using a primer mixture and wait for drying. To avoid the appearance of irregularities where moisture accumulates, a stretch of vapor barrier film is necessary on the ceiling. To do this, adhesive tape is applied to the ceiling beams. Segments of the film set overlap, and the joints are stuck with tape. Nails are nailed at the junction line every 40 cm. Instead of nails, you can use a furniture stapler that securely holds the material on the surface.

Ceiling vapor barrier material is attached with rails with insulation or separately. The slats are also screwed every 40 cm. Most often, in building stores you can find sheet films for the ceiling.To install them, you need to purchase a special profile. In this case, attach a frame to the ceiling, install a vapor barrier sheet, and then insulation.

Vapor barrier walls

When installing a vapor barrier material on the walls, it is necessary to roll out the rolls, starting from the bottom, while the horizontal parts of the vapor barrier are fixed with metal slats. So that air can circulate in the room, you need to take care of the vent. It is made between the vapor insulating material and interior decoration at a distance of 5 cm. It is important to observe this rule in all structures with a high level of humidity and non-constant heating.

To prevent water from getting inside, the lower part of the vapor barrier is placed below the base level of the structure.

Vapor barrier floor

Prior to installation, the wooden base should be processed: boards, bars and logs. The process is carried out by antiseptics, which allow to protect the surface from rotting, mildew and fungi. If there is already a floor, then it should be disassembled. At the same time it is necessary to get rid of heat and vapor insulating materials that have become unusable.After that, you need to clean all the wooden elements with an antiseptic. Only then can we proceed to the installation of a new vapor barrier.

To learn how to make a vapor barrier on the attic ceiling, see the following video.