Scotch for vapor barrier: features and varieties

The implementation of construction, installation or repair work, is associated with the use of sealing and fixing compositions. However, to perform such tasks, there are not only liquid or powder products, among the variety of products there is also a specialized adhesive tape, most often used for vapor barrier of buildings and structures.

Features and Purpose

Any construction of premises, especially residential buildings, is not complete without the use of vapor barrier materials. The presence of such materials, most often a vapor barrier film, ensures that important components of the whole structure are well protected from moisture penetration, which has a destructive effect on most surfaces.

In addition, the presence of a membrane eliminates the risk of penetration of condensate into the room, which will save it from the formation of fungus and mold on the grounds.

Mistakes made during the installation of materials for vapor barrier will lead to the accumulation of excess moisture in the apartment or house, as a result of which the raw materials for insulation will lose their qualities, over time the ceilings on the ceiling and walls will be destroyed. That is why a competent installation, as well as gluing the vapor barrier material is an important task for the construction and durability of the residential structure.

When arranging the roofing cake of the building, adhesive tape for vapor barrier is a fundamental element that provides the necessary waterproofing barrier, together with the main roofing materials. Usually, bitumen tape is used for roof waterproofing, which looks very similar to building tape.

Window constructions, the installation of which is necessarily carried out in the construction of buildings for any purpose, requires reliable protection of the joints of the frame with the wall. Therefore, in addition to the traditional foam, you will need a sizing of the corners and joints of windows with reliable sealing material, which is presented on the building materials market with building tape.

The product is a special purpose tape designed for gluing together different elements. A feature of adhesive tape is its ability to provide reliable insulation of joints and seams from moisture and steam penetration. It should be noted that the use of conventional stationery tape for the above works is not justified, because the product after some time will gradually peel off, passing moisture through the gaps, which destroys the layers of insulating material.

Characteristic

Adhesive tape for vapor barrier is a construction tape of various sizes and structures, the scope of which is to ensure good sealing of the joints of vapor barrier products. In fact, it is an adhesive tape for steam and waterproofing, which is a new product on the modern market of goods for construction and repair. But thanks to its properties and characteristics, such adhesive products have already become popular and in demand among consumers.

This demand for a product is explained by the poor quality of insulation of joints and seams, which is carried out in buildings built not so long ago.For the newcomers, whose dwelling is adjacent to the attic space, this issue is particularly relevant, because poorly executed vapor barrier, with time, adversely affects the microclimate in the apartment. In addition, the tightness that provides vapor barrier tape, makes it possible to prevent the rapid release of warm air from the apartment, and the penetration of cold air masses from the street.

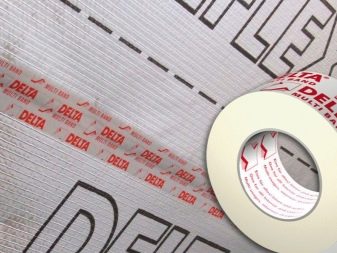

Based on the characteristics of the connecting tape, it can be used to fix and seal the joints of the film located in the horizontal and vertical direction. The adhesive tape is stuck on the very edge of the base, making sure to place the adhesive paper on top. After that, another overlapping film is laid with overlapping tape, pressing all the joints.

To ensure high-quality sealing at the joints of materials with component parts, installation of adhesive tape must be performed on a solid basis, for example metal, concrete or brick.

Double-sided mounting products can be mounted on the material itself. To perform such a task it is necessary to remove the adhesive paper from the surface, and then,having placed the whole roll with a ribbon in a given direction, roll it over the base, slightly pressing it in the direction of travel.

In this case, a certain distance recedes from the edge of the cloth.

The tape should be used only for sealing the joints between materials, fixing them to the working surface during the installation process, performed using fasteners, most often nails are purchased for such works or the fastening is done with a construction stapler.

Scotch for vapor barrier has the following characteristics:

- UV resistance;

- low moisture absorption of 0.2%;

- resistance to atmospheric conditions;

- the product does not lose its properties in the temperature range from +75 C to -40 C;

- high level of adhesion to the concrete surface, metal, film, wooden bases;

- operational period is about 15 years.

Kinds

Without exception, vapor barrier tapes have an adhesive base, this feature eliminates the need to apply the adhesive composition on their own, thereby reducing the risk of poor-quality fixing products, which would entail the ingress of moisture to the insulation.

Product classification is based on the raw materials used for the production of the tape, as well as the structure of the product.

The structure of the construction tape for vapor barrier is bilateral and unilateral. The latter type of product is used for the butt-fit fixation of materials. Products of the first type carry out the fastening of cloths with overlap.

Taking into account the raw materials from which the tapes are produced, the products are divided into the following types:

- Aluminum Scotch - it is a peculiar composition in which there is a strip of aluminum, the thickness of which can vary from 20 to 40 microns, as well as an adhesive substance and a protective base. The products have positive reviews, however, the disadvantage of such a tape is the fact that it can not be used for all types of vapor barrier films. Aluminum tape usually has a width of from 50 to 100 mm.

- Aluminum reinforced products - such products are characterized by greater strength, in contrast to the previous type of tape. This characteristic is due to the presence in the composition of products reinforcing reinforcing layer. The tape has a width of 50-100 mm.

- Polypropylene tape - products have a low cost and are sold in any building department. In this case, the statement about the relatively low quality of cheaper analogues is completely justified, since experts note unreliable fixation when working with such material and vapor barrier films. Typically, the width of polypropylene tape does not exceed 50 mm, with a thickness of up to 100 microns.

- Scotch TPL - It is a textile-based product with a rubber-based adhesive as well as a polyethylene surface on the upper side. Rubber self-adhesive products, for the installation of vapor barrier is used infrequently. It has an impressive thickness of about 200 microns, with a width of 50 mm.

- Butyl rubber tape - the product stands out with its advantage - butyl tape has a high level of adhesion to vapor barrier materials. The disadvantages of products include a large proportion of the tape, which is five times higher than the similar value of aluminum tape. The width of the product varies in the range of 15-50 mm.

It should be noted that tapes from rubber are used most often for windows,balconies and door designs. In rooms with high humidity, metal-based products are used.

In addition, the tapes are classified and based on the climatic destination:

- for operation at negative temperatures, “winter” products are produced that do not lose their properties from the effects of frost;

- “summer” type films are recommended for use at medium positive temperatures.

Dimensions

The overall mesh of products on the market is as follows:

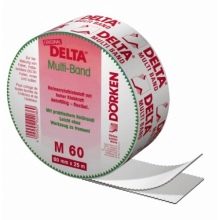

- products 25000 mm long, having a width of 15 mm, 30 mm, 50 mm, 60 mm, 75 mm;

- options 3000 mm long with a tape width of 15 mm and 60 mm;

- products 23000 mm long with a width of 152 mm.

How to choose?

To make the right choice of scotch for vapor barrier, you need to pay attention to the following characteristics of the product:

- Tape for sealing can be used in specific places of residential buildings and structures, so the resistance of the product to ultraviolet radiation is a fundamental criterion when buying a product.

- Adhesive tape should not absorb water, otherwise there is a risk of spoiling the insulating and vapor barrier material.

- High quality products should be resistant to heat of 90 C.

- Adhesion of tape to various surfaces. There are some types of products that are incapable of adhesion to metal bases.

- As a rule, the average service life of adhesive tape for vapor barrier is about 15 years. However, it may vary for each manufacturer.

When buying a tape is to clarify this information.

Tips and tricks

Technology works with tape requires compliance with certain rules.

- Any manipulation of the tape can be performed only on cleaned and completely dried surfaces.

- Then the vapor barrier sealing sheet unfolds, which is glued with tape over the entire width and length.

- After that, the top layer of scotch tape is removed.

- The final stage is the laying of the second layer of insulation, which is glued to the product located under it.

Steam insulation materials are more correct and reliable to fix with double-sided tape. And for the second layer already use products with one-sided application of adhesive composition. According to consumer reviews, butyl rubber types of construction adhesive tape provide the highest quality fixation of vapor barriers.

As for the door and window openings, in this case, experts recommend to perform the work according to the following scheme:

- After cleaning the surface, a line is marked that will be used to install the adhesive tape. This task is performed when installing the frame or box into the opening without fixing.

- Further the construction is taken out, and the tape is pasted on the designated area.

- The final stage of mounting the tape is to cover it with foam; before that it is necessary to remove the paper base on the scotch tape.

- Work with the place of joints of the material under the window sill is performed last.

In some cases, after laying the vapor barrier and installing adhesive tape on the surface, it is planned to apply a plaster layer. For such options, experts advise to give preference to tapes, in which the open part will be from raw materials that have good adhesion to the decorative coating.

It is not recommended to purchase products of unknown brands, especially in the Asian direction. Residential use of such products may be unsafe for health, since there is no guarantee that there will be no toxic substances among the components.In addition, when sealing seams with such products, the quality of fixation is unlikely to have a high level of reliability.

It is best to opt for products manufactured by world-renowned companies.

See below for how to use adhesive tape for vapor barrier.