Tyvek Soft: description and specifications of the diffusion film

Any construction professional is familiar with DuPont products. This German company produces a variety of materials, not only for construction, but also for agriculture, food industry and energy. Especially among the products stands Tyvek diffusion film, which allows you to organize hydro, steam and wind protection of the roof and facade of buildings. This article will discuss in detail the features and characteristics of this material.

Characteristic

Tyvek was invented after a successful case in 1955. One of the scientists from the research department of the DuPont plant noticed a light white fluff that was inside the laboratory tube.This observation made it possible to create in 1967 a material from polyethylene foundry, which quickly gained popularity in the international construction market.

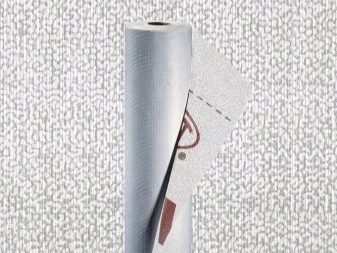

Tyvek is a non-woven material that is made of high strength polyethylene (HDPE). In the process of material production, continuous beams are connected to a durable synthetic fiber. The unique canvas combines the technical characteristics of paper, fabric and film. It is light and durable, not afraid of moisture and perfectly removes it. Soft types of material are used in food and construction areas, and more rigid - in printing business for printing banners and other high-strength products.

Membrane Tyvek has a single-layer porous structure, and accordingly a low weight, which greatly simplifies the installation and transportation of the material. The uniqueness of the diffusion film of the manufacturer DuPont is that it has no pronounced seamy or front side and can fit any of them without affecting the quality of the coating. This is especially true in the conditions of the so-called "quick" installation of the roof and when laying material without recourse to the services of professional builders.

About the high quality of the material speak numerous positive reviews about it. In many countries over the past 15 years, its popularity is only growing.

Advantages and disadvantages

Despite the fact that Tyvek is an innovative material that was invented by scientists, it is still not without flaws. By cons include the following points:

- The material is not combustible, however, it should not be located in close proximity to sources of open fire. Experience shows that the membrane can burn, which is confirmed by the recurring ignition of the facades of buildings in which a heater of this type has been used. However, if all safety measures are observed during welding and other works, this disadvantage is easily eliminated.

- High cost compared to other membrane materials. This disadvantage is hardly significant, since the more expensive price is easily compensated by a long service life.

The material has few minuses, but the pros are significant. Among them are:

- Long service life. Tyvek is able to retain all its properties for 50 years.

- High chemical resistance. The material is immune to most known salts and acids.

- Products perfectly maintain mechanical influences both in a dry, and in a humid climate. The percentage of strain is only 0.01%. The membrane can withstand a tension of 300 N.

- The film is resistant to ultraviolet radiation.

- There are good indicators of elasticity. Flexural strength exceeds 20,000 cycles.

- The external structure of the material is perfect. He is not “shaggy,” and there are no pellets on its surface.

- High moisture resistance. At the same time wet material does not lose its waterproofing properties.

- For vapor permeability, Tyvek is unique among films from other manufacturers.

- Relatively high resistance to dirt. However, the material is not resistant to oil and grease stains.

- Impressive temperature difference of use. It can be used at temperatures from -73 to +80, without losing its properties. Shrinkage of the material begins after reaching a temperature of +130 degrees, and melting at +135.

- Environmental Safety. The membrane does not emit substances hazardous and toxic to humans and nature, as evidenced by numerous certificates of conformity.

- Versatility.The material can be used in many industries due to its unique properties.

- Low weight due to the porous structure of the film.

The advantages of the DuPont membrane ensured the wide distribution of this material in construction.

Types and scope

Currently, the manufacturer offers several types of membrane materials:

- Tyvek Soft;

- Tyvek Solid;

- Tyvek Housewrap;

- Airguard;

- Tyvek Solid Silver;

- Tyvek Supro Tape.

Consider more:

- Tayvek soft - excellent protection from wind and moisture. The film effectively removes steam, which is inside the roof or facade, to the outside, is easily mounted on insulation by any side, is especially well used on inclined (150 and higher) planes. The material has a high vapor permeability and hydroprotection (over 1.5 meters). It is designed for waterproofing pitched roofs, attic and can be mounted directly on the insulation. Insulation weight is 58 grams per square meter, roll size is 50x1.5 meters and weight is 4.5 kg. The film thickness is 0.18 mm, and the temperature range is from -400 C to +1000 C.

- Tyvek Solid - rolled non-woven vapor barrier for walls and all types of roofs. It is used as an active waterproofing with high vapor permeability. The material does not support combustion.Insulation weight - 82 grams per square meter, roll - 6 kg. Thickness - 0.22 mm, roll size - 50x1.5 meters. Temperature range - from-400 C to +1000 C.

- Tyvek Hauswap - white superdiffusion membrane. This type of nonwoven material is used only as a windbreak in the hinged facade structures. It actively protects against precipitation and blowing fibers in the wind. Material weight - 61 grams per square meter, roll weight - 4.5 kg. The thickness of the membrane - 0.19 mm. The size of the roll is 50x1.5 meters. The range of allowable temperatures - -400 C to +1000 C.

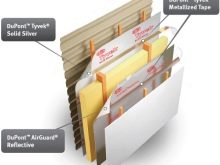

- Tyvek Airguard It is an ideal hydro and steam room for frame houses and cottages. The film maintains optimum indicators of humidity and temperature indoors, is mounted from the inside of the building. Material weight - 108 grams per square meter, roll weight - 9 kg. Thickness - 0.3 mm. Dimensions - 50x1.5 meters. Temperature range - from -400C to + 800C.

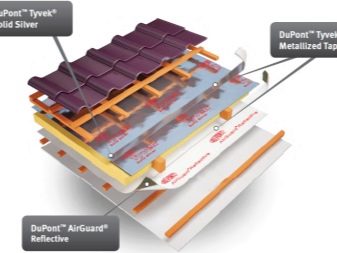

- Tyvek Solid Silver - reflective non-woven material made of dense polyethylene, which is covered with a thin metallic coating. It is used for roofs and facades, mounted in conjunction with DuPont Airguard, which allows you to save energy.These materials are similar in effect to a thermos and can significantly save on cooling a house in the summer (air conditioning systems) and heating in the cold season. Material weight - 82 grams per square meter, and a roll - 13 kg. Thickness - 0.19 mm. Temperature range - from -400 C to +1000 C. The dimensions of the roll are standard - 50x1.5 meters.

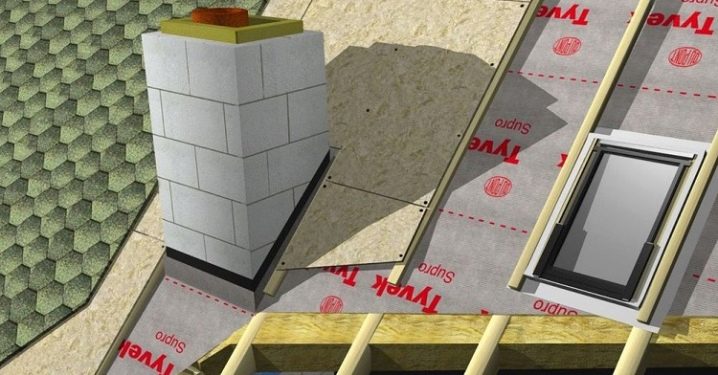

- Tyvek Supro Type - two-layer non-woven material, which is supplemented with adhesive tape, greatly simplifying the installation of this type of membrane. The film has a high vapor permeability, is used for waterproofing roofs, roofs and mansards. The weight of the material is 148 grams per square meter, and the coil is 11 kg. Thickness - 0.42 mm. The temperature range is from -400 C to +1000 C. The dimensions of the roll are 50x15 meters.

Installation recommendations

The membrane Tyvek can be used for the installation of a pitched roof, vapor barrier, waterproofing and wind protection of building facades.

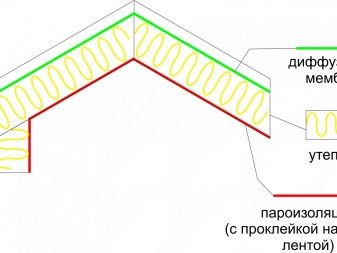

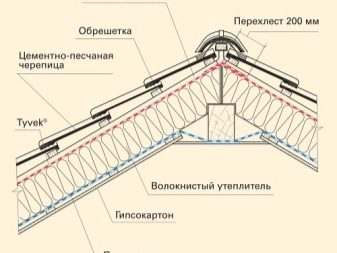

When installing on the roof, observe the following sequence:

- A roll of the selected material is rolled out and fixed to the truss system with a counter grill.

- Waterproofing is placed directly on the insulation without the formation of gaps.

- The horizontal overlap depends on the angle of inclination (> 340 - 10 cm, from 150 to 340 - 15 cm, <150 - 10 cm), and the vertical overlap for all three cases is 10 cm.

- Overlap on the ridge is 20 cm or more, on the valley - 30 cm or more.

- The joints are glued with a special butyl rubber tape.

- The width of the ventilation gap - 5 cm or more.

Please note that if the waterproofing is included in the drain chute, then you should consider and install the anti-icing system. It is also necessary to make in the area of skates and cornices areas of space that will help the air circulate freely.

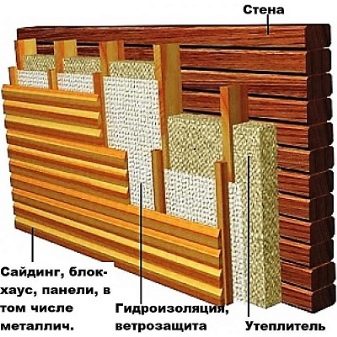

When arranging the windshield of the facades of buildings, act as follows:

- First, special mounts (brackets) are installed and insulation is laid down.

- The membrane is rolled close to the insulation and fixed with dowel-nails.

In places of contact with the fastening elements of the facade holes are cut. You should also glue with special tape the place of junction of the Tyvek membrane to the window and door openings. This is necessary in order to avoid unwanted acoustic phenomena in strong winds.

Vapor protection

For its arrangement suitable Tyvek Airguard. Installation instructions are as follows:

- The material is rolled out from the inside of the roof and fixed with staples every 30-50 cm.

- For proper ventilation, a counter grill is installed.

- All joints are carefully taped with a butyl rubber tape.

In cold attics, you can do without vapor barrier. It can be put in the floor slab below the attic.

DuPont's Tyvek is a high-tech membrane material that allows you to efficiently organize wind, steam and hydraulic protection in a private or industrial building.

In the next video you will find step-by-step instructions on ensuring the waterproofness and functionality of the roof with a DuPont ™ Tyvek® membrane.