Vapor barrier and waterproofing the floor in a wooden house

Wood - a unique building material, which is used very often for interior decoration of the house. From it often form the floors and walls, characterized by durability and original design. The disadvantage of wood is the ability to absorb large amounts of water. This in turn causes it to swell and lose its strength characteristics.

To minimize this impact can vapor barrier and waterproofing in a wooden house. Such operations are performed at the construction stage, which is important to consider when designing a structure and purchasing materials.

Features: pros and cons

The operation of a wooden house involves the observance of certain rules that allow you to create optimal conditions for the tree. Thus, wood retains its structure longer and does not crack.

Particular attention should be paid to the floor, as it is through it gets a lot of moisture, which settles on the walls. Therefore, the arrangement of vapor barrier is one of the best ways to deal with this problem.

The use of an insulating layer is welcomed not only on the floor, under which the ground is located, but also on top of concrete bases when finishing them with decorative materials.

Surface insulation is the arrangement of a kind of multi-layer "cake", which is based on a substance that does not allow moisture.

It should be understood that the concepts of steam and waterproofing are radically different, although they have several similar properties:

- Waterproofing materials contribute to the retention of water, but at the same time perfectly breathable. This allows you to organize the optimal microclimatic conditions not only inside the room, but also under the flooring.

- The purpose of vapor barrier substances is water and air retention. This prevents even small water molecules from penetrating through the structure of the protective layer.

Both of these materials are very often used together, which allows for optimal results.

The disadvantage of waterproofing the floor is an increased level of humidity in the rooms, which will already adversely affect the wood from the inside.

In order to achieve optimal results, it is important to build high-quality ventilation when forming such bases. She will be able to remove moist air from the house, creating an optimal microclimate in a particular room.

Floor device

Floor coverings inside wooden houses can be made of various materials. It all depends on the capabilities and desires of the owner. But they all always have about the same structure, which involves the installation of several layers.

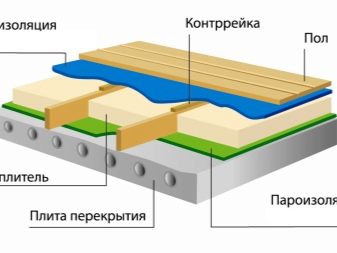

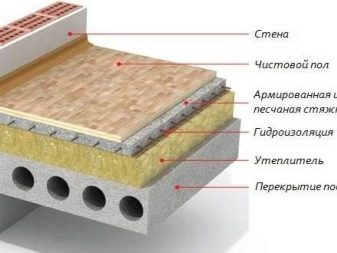

The approximate scheme of the floor consists of the following elements:

- Rough floor. This part is made of wooden lag and planks of the first grade. Bulk surfaces in the form of sand, concrete screed, etc. can also act as such a base.

- Waterproofing layer. It prevents the penetration of moisture from below, protecting the rest of the structure from it.

- Thermal insulation. It is located mainly between the supports of the finished floor (lags). For such purposes, use mineral, basalt or stone wool.If the rough floor is durable, then bulk insulation (for example, expanded clay) can be used as a heat insulator.

- Vapor barrier. This layer also protects the internal structure of the cake. But he no longer allows the couple to accumulate inside the room.

- Finishing layer. It also uses a variety of finishing materials from natural boards to plywood with parquet or laminate.

Please note that the sequence of layers must be strictly followed. If you accidentally change the materials for steam and waterproofing, this can lead to the accumulation of moisture under the floor covering. In such conditions, the floor will last for several years and just rot.

If the base for the floor is concrete, then for some materials only one waterproofing film is used. This is especially true of the floorboard or laminate, which are stacked on the insulation and plastic film.

Types of waterproofing

Waterproofing the floor is a process of applying protective materials that form an impermeable layer.

Depending on the application technology, this procedure can be divided into several types:

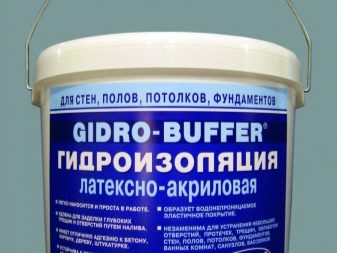

- Coating The best option for the base of the concrete floor. Arrangement technology involves the application of solutions on surfaces that need to be protected. It is relatively rare for horizontal bases.

- Pasty. This type of waterproofing is the most common and versatile. It is used not only in the construction of floors, but also to protect the walls. This approach involves gluing rolled waterproofing materials (plastic film, etc.) to the base with special adhesives.

- Tough. Waterproofing of this type involves the use of special plasters. Put them in thin layers on rough bases. Apply this approach rarely, since it is the most difficult and time consuming.

Materials

Insulating properties today have many substances that are used in the arrangement of the floor.

Many experts recommend using izospan for such purposes, but besides it there are several groups of waterproofing materials:

- Waterproofing paint. The main component of such solutions is bitumen, which is mixed with various polymers.Application is carried out with an ordinary brush, which allows it to be covered even in hard-to-reach surfaces. To obtain a quality result, the surface must be carefully prepared before processing. Therefore, this approach has not found wide distribution.

- Insulating fill. Products is a liquid that is simply poured into the base. Make it of asphalt concrete and bituminous components. Experts recommend the use of fills on concrete surfaces, as they practically do not crack and do not diverge, like wood boards.

- Loose materials. This type of material consists of granules that are not able to absorb liquid. The substance is not only a high-quality hydro-insulator, but not a bad heat insulator. Therefore, the use of bulk mixes eliminates the introduction of mineral wool or other insulating material.

- Roll products. This group of materials is the widest and most popular. The main elements here are the films that do not pass moisture. In this case, the structure of a substance may suggest the presence of pores or a dense structure.Some of them are complemented by self-adhesive layer. This allows speeding up the installation several times.

The latter group includes isolon, polyethylene films, thermal fibers, bitumen rolls, as well as several types of membranes. The last type of materials used to organize the vapor barrier. The structures of membrane products suggests the presence of several layers of fabric that form an airtight substance.

Application

The use of waterproofing materials today is quite popular. They are used not only to protect the floor, but also the foundation during the construction of buildings. In some cases, waterproofing of walls is also carried out in private wooden houses.

Waterproofing is also necessary in such places:

- In the bathroom. The constant use of the shower or washbasin leads to the formation of high humidity on the floor, which needs careful protection.

- The apartment is on the first floor. A feature of these premises is that under them is often already a basement, which is not isolated from moisture. It constantly forms condensate, which penetrates to the first floors through concrete layers.

- Waterproofing the floor on the balcony before insulation. This option is not mandatory and depends only on the materials used for this. If you plan to equip a warm balcony with a wooden floor, then it is necessary to isolate the insulation.

Theoretically, in a wooden house, hydro and vapor insulation can be used in almost any room.

But it is important to consider also the type of floor that will be formed in the building. If the kitchen will be laid tile on concrete, then this material is great even with constantly high humidity.

How to lay?

The waterproofing layer involves not only the insulation itself, but also intermediate materials forming the frame and thermal insulation.

Laying such constructions involves several preparatory operations:

- First of all, the old base should be inspected for damage. If the floor is made of wood, it is important to remove rot and sagging boards. But waterproofing is best done on a concrete slab, especially if the surface is on the first floor. The overlap between the floors must be checked for durability and quality.

- If the surface is ready for decorative finishing, then the base should be treated with special reinforcing solutions. For wood, impregnations are used that increase resistance to burning and rotting. Floors without screed are treated with reinforcing primers.

- When the surface is ready, a rough floor should be formed. In some cases, it is built directly on the ground. But this approach will not allow the wood to serve for a long time. Therefore, as a rough base, it is better to use concrete screeds, which are already laid lags for finishing wooden structures.

Arrangement of the protective "cake" consists of the following sequential actions:

- Begin the procedure with waterproofing the subfloor. For this film is rolled over the entire surface, placing it between the lags. It is important to fasten it in such a way that there is no tension. If the width of the sheet is not enough, it is joined with another, forming an overlap of at least 20 cm. When everything is normal, the material is fixed to the base with adhesive tape, staples or special nails.

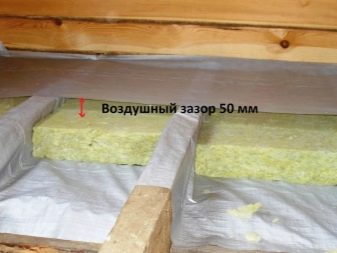

- On top of the film is mounted insulation. Fastening it is done in different ways depending on the selected substance.If wooden logs are used, then mineral wool is inserted between them. It should fit tightly between them, without forming gaps.

- At this stage, a vapor barrier is spread on top of the insulation. Joining it also with overlap. All joints are glued together with tape to prevent moisture from penetrating through them.

The procedure ends with the installation of a decorative floor. As you can see, the arrangement of vapor barrier is not very complicated.

It is only important to use high-quality protective materials and follow the sequence of their installation.

For how to make the installation of roll waterproofing, see the video.