Which side of the insulation to lay a vapor barrier?

Warming is a very important stage in the construction or repair of a house, on which it depends whether you will be comfortable in it. Improper implementation of this "procedure" can lead to unpleasant consequences, for example, condensation, increased humidity in the air. But this will not occur if you take care of the vapor barrier and put it on the right side to the insulation.

Special features

During the insulation of the house should carefully observe the correct sequence of actions and use only the best materials. Unfortunately, often the owners, who take on their own to insulate their home, forget about one very important aspect - the vapor barrier.They install only insulation and do not even think that it is in contact with too warm or too cold air inside the room, and that soon it will begin to form condensate in the form of water droplets.

And this not only does not contribute to the weatherization, but also damages the material itself - it moistens it, and if the steam still does not have time to evaporate, a mold appears, and the insulation design deteriorates. Moreover, taking into account our climatic conditions, a similar situation occurs at least four times a year - when the seasons change and, accordingly, the temperature in the room and outside it “conflicts”, and the insulation becomes the battlefield.

That is why an important step of warming is the fastening of a “vapor barrier”. The steam insulator becomes an impassable obstacle for steam, prevents it from turning into water, as it “closes” it inside the room and does not allow it to come in contact with excessively warm or excessively cold air.

Materials

Vapor barrier can be made with several materials. From this set it is necessary to distinguish three main types.

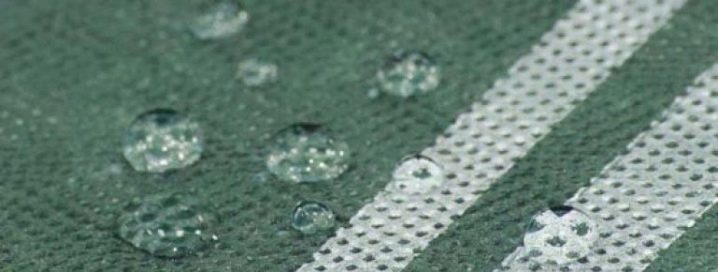

- Film. Deaf vapor barrier, which does not pass through water vapor. One of the main advantages is low price. It is usually made from polyethylene or butylene, their derivatives. Steam condensate films are double-layered with a smooth inner and rough outer surface. Lingering on the outside, condensate droplets do not flow down and evaporate over time. In the case of a deaf vapor barrier, you also need to take care of the air gap in order to avoid the greenhouse effect, but more on that later.

- Diffusion membrane. The main difference from the film is that the membrane passes part of the steam through itself - but only that optimal amount of it that does not linger inside and evaporates instantly. Therefore, the vapor permeability of membranes can be attributed to limited. The diffusion membrane is made of polymer film and polypropylene, it has two sides.

- Reflective or energy saving film. The outer layer of such a film is metallized, which allows it to withstand high temperatures. Therefore, it is most often used in baths or saunas, reflecting part of the infrared radiation.

As is known, for the insulation of houses in modern conditions, materials such as mineral wool, polystyrene foam, ecowool are used. Vapor barrier is needed in the case of mineral wool insulation.

In fact, vapor barrier is always needed, regardless of how expensive or high-quality material for insulation you use. Mineral wool or mineral wool is otherwise the cheapest material, but its thermal conductivity is low, which reduces the likelihood of heat loss in the room. Minvatu do not like rodents, mold, fungus, it has a high sound insulation and is easy to mount. But it still requires vapor barrier for itself.

The most commonly used vapor-permeable limited diffusion membrane. It fits to the walls, after it you need to lay the mineral wool, and in symbiosis they allow the walls of the house to “breathe”.

The issue of vapor barrier arises when the house is ecowool. In general, ecowool is loose cellulose fibers that have the ability to absorb warm moisture while remaining dry. It does not start up fungus, mold, the air in it just does not get wet (if the change in humidity does not exceed 25% percent).From all of the above, it follows that just in the case of ecowool, the paro-insulator can not be fixed.

Another popular insulation - polystyrene foam actually has another name more easily foam. It lays on both external surfaces and internal ones, and in the case of external insulation of loggias, balconies or attic floors, vapor barrier does not require - he himself copes well with the technology of heat insulation. But if you warm the interior of the foam, vapor barrier and waterproofing are required to avoid the formation of fungus, mold and wet walls.

Device

The acquisition of a set of quality materials - only a third of success. In fact, these materials must be properly installed, arranged in the correct sequence. For this it is necessary to find out which side of the vapor barrier is laid, how it is fixed, in what order and what to nail earlier - a vapor barrier or a heater.

First you need to carry out the preparatory work. At this stage, the type of coating that you will insulate, its performance characteristics and material requirements for insulation and vapor barrier is detected.

So, the surface needs to be carefully prepared. This takes into account the type of material from which it is made. Wooden elements must be treated with anti-aging, rotting and burning compounds. In the case of concrete and brick, deep penetration antiseptic compositions are used. From the correct surface treatment depends half the success in its operation.

If you carry out repairs or renovations, then pay attention to the fact that before insulation all traces of the previous finishing must be removed, a full cleaning is carried out. And if we are talking about a wooden house, then all the elements should be treated with fire retardants and antiseptics.

Further, the technology of vapor barrier device varies slightly depending on the purpose of the surface - for the floor, ceiling and walls, the action varies slightly.

Vapor barrier on the ceiling

In the case of roofing and interfloor overlapping, the installation of vapor barrier is assumed on an already prepared and properly treated surface. It is best to use a diffusion membrane.

The main difference between the installation of vapor barrier on the ceiling from laying it on other surfaces is that in this case the insulation is first laid, and then the membrane.It can be mineral or basalt wool in blocks or rolls. It is mounted between the lags and rafters. If the insulation thickness will be equal to the height of the lag, you will need to additionally perform lathing counter grilles so that the ceiling is ventilated. After all this, you can do a steam isolator.

It should fall a little on the walls around the perimeter, the joints should be mounted on the logs - to ensure that moisture does not fall into the space between the membrane and the insulation. Pay special attention to corners - these are problem areas, it is better to glue them in addition. Use a tape on a reinforced base or a construction stapler as a fixer.

In the case of warming a flat roof or a concrete ceiling from the inside, you can also use a regular vapor barrier film. It is attached to the self-adhesive tape also after the insulation, and then the batten is installed - metal or wood.

Vapor barrier on the floor

In the case of laying a vapor barrier on a wooden floor, you should additionally install hydroprotection. The floor is also insulated according to the logs. In the space between the lags is established mineral wool or wool on a basalt basis.Next, without any additional work is carried out flooring vapor barrier.

If we are talking about a rolled vapor barrier, but it fits overlap by 12-15 cm with the most careful sizing of the joints, gaps and cracks on both sides with metallized adhesive tape. As in the case of ceiling insulation, walling should be within 10 cm.

For a concrete floor, you will need a batten. You will need to put a waterproofing layer in the sheathing cells, on top - a heat insulator, and already after the mineral wool, the third layer is a steam insulator.

Vapor barrier on walls

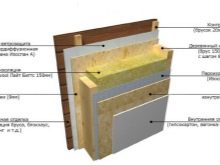

The process of insulation and vapor barrier walls a little more complicated than doing the same work on the ceiling or floor, and implies a slightly larger number of stages. Consider the process of laying vapor barrier film on the wall.

The first thing of the bars of a small section is mounted frame. The size of the batten is determined by the width of the heat insulator block - the distance between the cells is equal to the width of one plate. Classic use of mineral wool.

Next, the heater is placed between the crate, and now you can proceed directly to the creation of a vapor barrier.The film or membrane is secured from above close to the insulation using brackets / slats.

At this stage, special attention should be paid to possible gaps arising from the difference in the width of the insulation, the frame and the vapor barrier. The gaps are sealed with reinforced tape, and the sheets of film are glued horizontally overlapped by 15 cm.

Subtleties of installation

When installing a vapor barrier should pay special attention to important issues.

Which side to lay the vapor barrier?

Very often, masters find it difficult to answer this question, but everything is not so difficult. An ordinary film has the same front and back side - and then it does not matter which side to lay it. But in the case of one-sided films, the situation is a bit more complicated.

For example, in antioxidant films, the inside is made of fabric, and according to the requirements of installation, it should look inside the room. Steam-condensate films should be laid smooth side to the heater, rough - out. But with diffusion films you should look directly into the instructions, since such films can be both one-sided and two-sided. Energy-saving films are laid foil side, on the contrary,outward - because they must reflect, not absorb heat. The same applies to metal coatings.

How to distinguish the outside from the inside?

This information should be specified in the instructions or on the manufacturer's website; you can ask a consultant or a master about this. However, if none of the above is right for you, you will have to learn how to determine the sides of the vapor barrier yourself.

So, remember: if the vapor barrier has two-colored sides, then the bright side will always fit to the insulation.

But also pay attention to how the roll of vapor barrier is rolled out - that side that faces the floor will be internal, and should be put to the insulation. In the case of a paro-insulator with a different surface, a smooth layer will always be internal, and a fleecy or rough surface will always be external.

What fastener should I use?

It can be either a regular construction stapler, or nails with a wide head, but the best option is considered to be a counter rail.

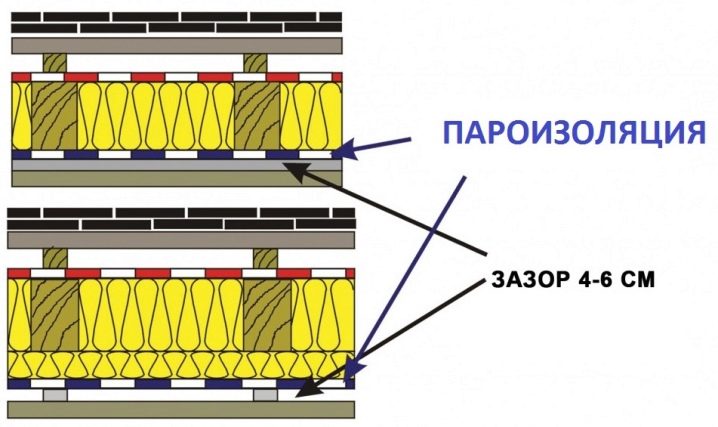

Is a layer of air needed near the membrane?

It is believed that this is a mandatory point - it is categorically impossible for the wall to come in close contact with the membrane; you should leave a gap for ventilation of about five centimeters. Condensate will not accumulate this way.In the case of a diffusion vapor barrier, the air gap is made with the outside, and the film itself is laid directly on the insulation.

Do I need to glue the joints?

It is also necessary - separate parts of steam insulators should be hermetically attached to each other without gaps, the same applies to the vapor barrier attachment points to windows or doors. Self-adhesive tapes are used for this - bilateral or one-sided - as a rule, made from polyethylene or butylene, propylene. These tapes not only fasten the membranes together perfectly, but are also used in their repair - they can be used to repair holes and crevices.

In no case do not use scotch tape for this, it is better to contact the sales assistant in the building materials store or go to the website of the company from which you purchased the steam insulator - as a rule, companies produce materials for the repair of their products.

Tips and tricks

The main purpose of the vapor barrier is not to allow water pores to leave the room through the heater and the surface. This means that the vapors, anyway, remain in the room, and in order that the humidity does not increase, and the microclimate is not disturbed, it is necessary to conduct natural or forced ventilation in time.

If you are interested in the question of how to overlap in case of parts of the membrane overlapping each other, then we advise you to pay attention to the films themselves. There is a marking along their edges - it tells you exactly what the film overlap should be. Depending on the type and company, the value indicated there is not less than 10 cm and not more than 20.

And also pay attention to the angle of the roof slope. If it is less than 30 degrees, the overlap cannot be more than 10 cm. If it is less than 20 degrees, the overlap cannot be less than 20 cm.

On the installation of the vapor barrier of the roof and on which side to lay the vapor barrier to the heater, see the following video.