Device and purpose of vapor barrier

Protection against water and moisture is an important component of any construction. The use of wooden materials obliges to think about the vapor barrier, because steam can cause mold and fungus. Insulation from steam is also successfully used when mounting the roof, while isolating the dwelling from the basement.

Special features

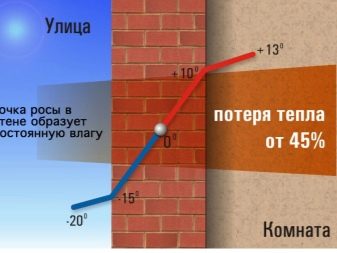

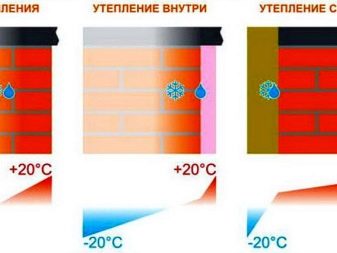

The issue of vapor barrier arose with the advent of mineral insulation. Sometimes it may seem that the air in the room is very dry, but in fact it turns out that the insulation gets wet from the existing moisture and gradually collapses.Moisture occurs due to temperature differences. In winter, the side of the wall that faces the street freezes, and the side in the room is heated by heating.

With a large temperature difference, a “dew point” is formed. In this case, the insulation accumulates condensate. It has been established that with an increase in the amount of moisture in heat insulation by 5%, the heat insulating properties are reduced by 50%. Interior partitions do not tolerate temperature fluctuations, so the vapor barrier for them is superfluous.

When building a house, pay attention to what materials you build and what you plan to insulate the house with. The vapor barrier is a waste of money, if you use foam as a heater, foam plaster, or you decide to do without the insulation of the building, using foam block or brick.

One of the reasons for the vapor barrier in a house is saving. With correct calculations, the cost of additional materials for building insulation is paid off by further savings on heating resources. Modern material mineral wool - insulation, losing its properties when wet. It is easier to spend money once and save all the subsequent time than to constantly change the insulation.

Vapor barrier for its intended purpose is divided into:

- Wall. To prevent the admission of steam to the insulation on one side and the output of steam to the outside when it is hit from the other.

- For interfloor overlapping. Prevents bottom-up condensation.

- For vapor barrier floor. If the floor slab of the first floor is located directly above the ground, in addition to thermal insulation, protection from water is necessary. Waterproofing is placed on the bottom, and vapor barrier on top. The same method is suitable for any rooms with high humidity.

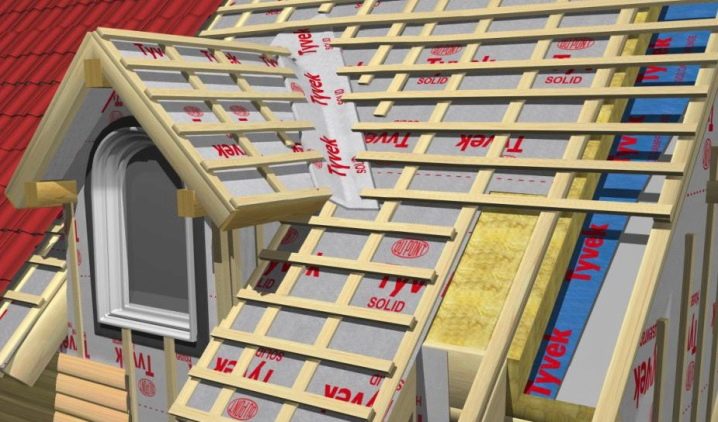

- To protect the roof. Roof insulation from steam is necessary only if there is a heated attic or attic in the house. All pairs go up, thus falling into the roof insulation materials, and again forming condensate.

Vapor barrier is different from waterproofing by the fact that waterproofing materials collect moisture from the surface, so they are ideal for places where droplets can form, such as roofing or a plinth.

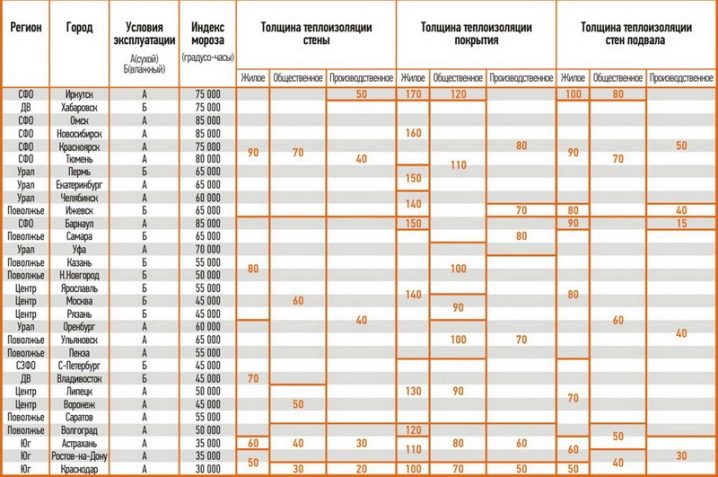

Regulatory requirements

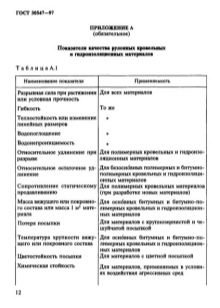

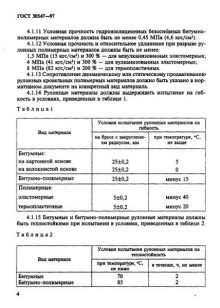

Any construction is based on GOST and SNiPs. Rolled vapor barrier material also complies with standards. GOST 30547-97 states that in the classification “by purpose” the vapor barrier refers specifically to rolled roofing and waterproofing materials.

The main characteristics of the material for its use according to GOST:

- the canvas must be solid, without mechanical damage;

- each roll must be marked, in the absence of marking it is not recommended to use it.

The document on the specific type of material should include:

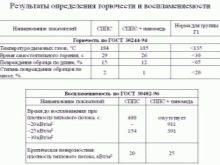

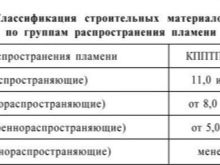

- combustibility group - calculated for vapor barrier thickness of more than 0.2 cm;

- flame spread group - for vapor barrier materials when using them for the device of a single-layer or top layer of a multi-layer roofing carpet;

- flammability group - for vapor barrier materials with a thickness of more than 0.2 cm.

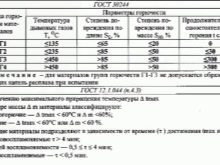

The flammability and flammability groups of a vapor barrier material are determined according to GOST 30244, flame propagation groups - according to GOST 30444, flammability groups - according to GOST 30402. For rolled vapor barrier materials with a thickness of less than 0.2 cm, it is allowed not to determine fire hazard indicators. Keep the material should be in places remote from sources of moisture and sun.

Despite the fact that the purpose of the vapor barrier material is to isolate it from steam, storing it near sources of moisture may impair its characteristics and the material will not be as effective during use.

Requirements for work:

- According to SNiP III-B 12-69, insulation work in the open air can be performed only in the absence of precipitation and at an outdoor temperature not lower than 5 C.

- Vapor barrier coatings should be arranged in compliance with the rules for waterproofing works.

- When a vapor barrier joins horizontal surfaces to the walls, it must be 10-15 cm on a vertical surface, so that the vapor barrier is connected to the waterproofing layer and prevents the thermal insulation layer from moistening from the side of the walls.

According to safety regulations, it is necessary to choose a vapor barrier film that is non-flammable.

How does it work?

The main function of the vapor barrier is to prevent the ingress of steam and moisture from both sides. The barrier is so tight that it does not allow moist air to seep through building systems. By itself, a vapor barrier film is a roll material that prevents the ingress of moisture and steam into thermal insulation and other materials associated with construction. The principle of operation is as follows:

- Steam should bump into an obstacle in the form of insulation.

- Under ideal conditions, the film should repel steam, not allowing it to settle on the material.

- We know that ideal conditions do not exist. Molecules can seep through microcracks, cracks, joints. All this is brought back thanks to ventilation functions.

- In order for the properties of the film to be used, it is necessary to lay the film under the insulation.

- During construction, the vapor permeability of the material is taken into account in any technical documentation. It is indicated as mg / m2 per day.

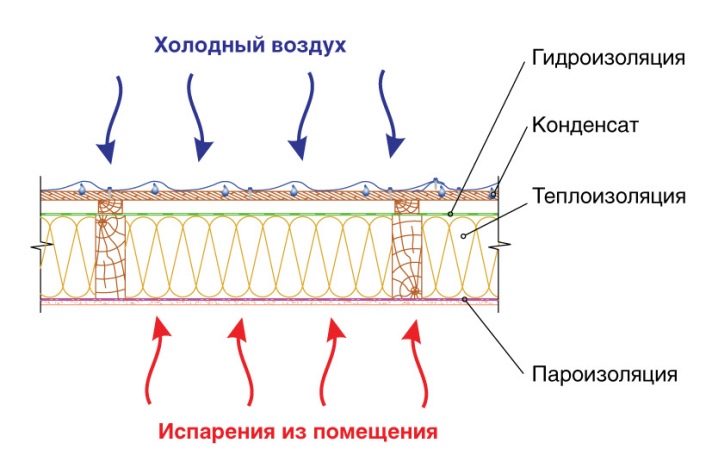

For completeness of the effect, use the following scheme for laying material steam insulation-insulation-waterproofing. Thus, the evaporation, which still penetrated through the vapor barrier, gets into the insulation, and he, in turn, tries to push the molecules, after which they fall on the waterproofing layer, which removes the remaining steam into the ventilation gap left in advance.

Application area

The vapor barrier can be used in many areas. Recall the well-known greenhouse since childhood. The film does not allow a couple to go outside. Most often in the construction of a vapor barrier isolate the roof, equip the attic and warm attics.The device in the outer walls of the house allows you to retain heat. Vapor barrier on the basement floor prevents evaporation from the ground.

Below are main applications of vapor barrier:

- Warming rooms. This is especially important if the insulation is made of materials, which are based on wool. Glass wool and mineral wool allow the walls to "breathe", but absorb moisture. And the more moisture in the insulation, the faster it collapses. And the house wants to be built immediately and “for centuries”.

- The walls of the "frame". "Pie "wall consists of many different layers. Such walls are called frame, but because of the multi-layered construction does not do without vapor barrier materials.

- Exterior walls and ventilated facade. A vapor barrier is an excellent protection from the wind, air currents can not actively circulate, so the load on the facade is reduced.

- Ceiling. When building a house, it is important to isolate the floors from each other. The vapor barrier of the ceiling allows to maintain the strength of the ceilings for longer, prevents the formation of fungus.

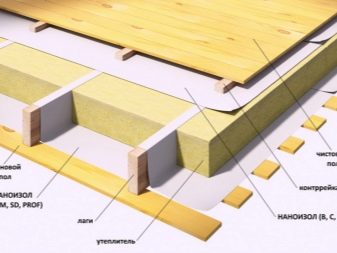

- Floor. The flooring is often subject to temperature fluctuations, regardless of whether the floor is heated or not, is located on the first or last floor. Most often the flooring is made of wood.Laying conditions for laminate is a perfectly even base, so most often it is leveled with screeds or blends. So there is excess moisture, which, without a vapor barrier, can damage the laminate boards.

- Balcony. The reasons for the need when building a vapor barrier on a warmed balcony are exactly the same as when insulating walls - to prevent the formation of condensation in the insulation.

Operating principle

The principle of operation of roll insulation from steam outside and inside the building is different. The frame walls are insulated from the inside, so the vapor barrier is laid from the inside. On the ground floors and in the basement, a vapor barrier is performed outside. In pools, vapor barrier is needed on both sides, and the technology of its installation is similar to the work on the basement floor.

To achieve the desired effect when mounting the film there should be no gaps, therefore The material is overlapped. If you are afraid of insufficient packing density, you can glue the edges together to form a single web.

If the vapor barrier “works”, the steam encounters an obstacle on the way and remains inside the room, while it is not cooled and remains in the gaseous state.

Kinds

Previously, except for ruberoid, there was no other vapor barrier material. Now the choice is varied. All materials can be divided into several groups:

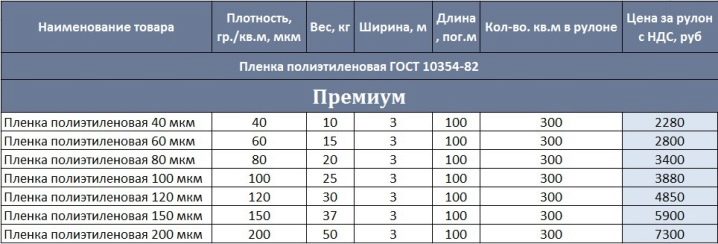

- Plain film. Standard insulation is made by mineral wool, and in this case polyethylene film is needed so that when the temperature difference on the warmed walls and the roof does not form condensate. Perforated polyethylene is the best option on the market.

- Film with aluminum foil. The foil film has a higher barrier, thereby reflecting and returning a certain amount of heat in the room. This film is ideal for use in the bathroom, sauna, bath or pool, i.e. for any room with a high level of humidity, steam, temperature.

- As a vapor barrier, you can also use a modern material called kraft paper. This vapor barrier insulation has a polymer coating, which works due to its extreme resistance to all types of exposure from external factors.

- Mastic - another version of the vapor barrier. The consistency during curing allows to achieve the necessary vapor protective effect.

- Membrane film. This film has the effect of limited vapor permeability, which allows you to control the removal of excess moisture from the room. In addition to the standard membrane film, there is a membrane film with variable vapor permeability for wet and dry conditions. The capacity of the material increases with increasing humidity.

A group of membrane films can also be divided into several subgroups. So, allocate the following roofing membrane films:

- Perforated. It is a reinforced film or original fabric. The vapor passes through the holes in the material, so the water vapor permeability is very low. For this reason, the membrane is used only for roofing waterproofing of a sloping non-insulated roof. During the entry of water or sudden changes in temperature, it loses its properties.

- Porous. The steam passes through a large number of intervolume pores. The vapor barrier level of the material may be different and depends on the pore size and the degree of hydrophilicity of the walls. It can be said for sure that the level of steam conduction will be worse on the fibrous membrane.It is undesirable to use it in conditions of high dustiness, for example, in urban houses located along roads. In dry or warm weather, dust through cracks can settle onto the membrane material and close the pores.

- Three-layer superdiffusion membranes. Produced from several different layers and having no holes into which dust or moisture can enter, the membrane has an obvious advantage over the porous one. The material does not lose high vapor permeability in a dusty environment, but one can not but say about the excellent windproof ability.

- Two-layer film membranes. Less expensive option. They do not have one of the protective layers, which significantly impairs their reliability. A thin waterproofing film can not protect the coating from more or less serious damage.

How to choose?

When choosing a vapor barrier, you need to be guided by the volumes of the warmed surface and the place of use of the barrier. The difference in the use of materials for floors, walls, roofs and floors is significant. To simplify the choice of material, you need to analyze each model that has intrigued you according to the list of criteria below.

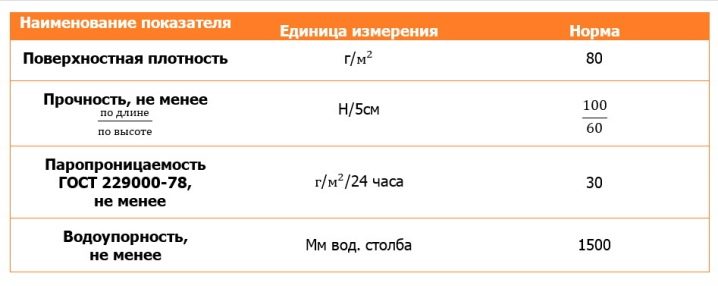

Vapor permeability

Vapor permeability is measured in g / m2 per day. The lower the number, the higher the quality of the material. To insulate a dwelling, it should not exceed 1 g / m2 per day. Anti-condensate polypropylene films with a nonwoven adsorbent layer and diffuse breathable vapor barrier membranes have the best indicators of vapor permeability.

There is another indicator that measures vapor permeability - Sd, which demonstrates how the resistance of the film relates to the resistance of an air layer of a certain thickness. For example, if Sd = 0.02 m, then this means that the vapor barrier material resists the pair as a 2-cm layer of air.

It is necessary to choose a material with a low value of this indicator.

Durability

The durability of the film depends on its quality, density and thickness, as far as it is subject to mechanical damage. The lower the price of the material, the lower its strength. Films weighing 60-270 g / m2 are on sale. Many reviews say that using ordinary polyethylene 180 g / m2, you can not go wrong in terms of value for money.

Labor intensity

Different types of film are mounted differently.Before buying, you need to decide on the installation and those who will produce it - a qualified specialist or you do it yourself. The most convenient in terms of self-assembly Ondutis B (R70) smart film with an integrated mounting strip, the price of which per roll of 75 m2 is about 1,400 rubles.

Cost of

Last selection criteria. You can refer to the low price category, and choose a simple polyethylene film, you can choose expensive material or the average price category. It can not be argued that the most expensive vapor barrier - the most reliable, and the cheapest - the worst. Also, the price depends on the width and length of the roll. Many do not pay attention, choosing a film cheaper than most dooming themselves to an additional purchase of material.

Also, when calculating the material for use in ceilings, it must be remembered that the vapor barrier material will be a kind of “blanket” for insulation, and its ends should go beyond the limits of the mineral wool. Also, when arranging the ceiling insulation, the mineral wool is wrapped in a vapor barrier and firmly, without gaps, attached to the lags. From this material consumption increases.

Most often it is advised to take the latest generation Ondutis film, which is considered to be better than the rest of its predecessors.

The choice of manufacturers of vapor barriers is huge today. In addition to conventional films of polyethylene, there are films reflecting. Their advantage is that having a layer of foil in their composition, they retain heat. Such material is often used in cases where it is impossible to achieve sufficient insulation using mineral wool. Overview of major brands represented on the aluminum foil market:

- "Folgoplast FB" (the company NPP "StroyTermoIzolyatsiya", St. Petersburg);

- "Megaizol S" ("Mega", St. Petersburg);

- "Teploizol Foil on Kraft Paper" ("Teploizol", Ekaterinburg).

Kraft is treated wood, which is the most effective material for insulation. When used together with a reflective foil, it is possible to prevent the passage of thermal radiation and apply such material for insulation. Manufacturers of foil and kraft paper with incorporated layers of polyethylene or lavsan:

- Alucraft (Plastex, St. Petersburg);

- "Izospan FB" (Hexa LLC, Tver region, TM "Izospan").

Tips and tricks

If you decide to perform a vapor barrier with your own hands, you need to know the details of the device and installation. Wall unit:

- It is necessary to determine the type of attachment to the walls - it depends on the destination location. In non-residential premises unilateral fixation of the material is possible. Although most often directly on the packaging of the material indicate the desired type of fastening.

- If not construction, but repair work is carried out, then first the complete disassembly of the structure to the wall is carried out.

- Perform work in the warm season in the absence of rain.

- For fastening material, where there is no fastening tape, a construction stapler is used.

- The tension should hold tight insulation against the wall.

Ceiling mounting:

- Do not try to perform the insulation and vapor barrier of the ceiling alone. To carry out these works need at least two people.

- Begin work only when the ceiling is dismantled and only the base of the lag remains.

- To begin with, fasten the film in several places, and after that, having checked its correct location, fasten it all the way around.

- Below the film is fixed with wooden slats.This is necessary no matter what the ceiling coverage will be in the end.

- In case of accidental damage to the membrane, it is necessary to make a patch with large allowances on the sides. It is necessary to glue the piece “from the inside”, and not on top of the film. To do this, the patch must be inserted into the hole, straighten and glue the allowances.

Vapor barrier frame walls:

- It is important to observe the correctness of the overlay. A common mistake is laying the film on the wrong side. Also among the most well-known errors include fixing the film on the wrong side of the wall. When the frame walls of the barrier should be mounted exclusively indoors, but not outside.

- It is necessary to choose the right fastener method.. There are two of them: the film is attached to the frame of the wall, and the facing material is fixed on top, or the film is fixed to the wall frame, then the slats are additionally mounted, and only then the cladding. The first option is used only when working with expensive and high-quality materials or with non-residential premises or not used all year round. The arrangement option with ventilation is more practical and durable.

Steam insulation:

- since the steam rushes upward during the circulation in the room, it is necessary to smear the boards with clay before the thermal insulation and vapor barrier, and wait for it to dry completely;

- materials for arranging the walls of the bath are purchased only after a well-thought-out plan for insulation, hydro and vapor barrier;

- do not use roofing material to isolate the steam room;

- for a bath it is better to choose ordinary polyethylene or foil, and for decorating the changing room and washing room - kraft paper.

Floor insulation:

- the vapor barrier must be laid smooth side to the heater, and protected - to the source of steam penetration;

- reflective films that return heat to the house are considered optimal for the floor;

- when installed on the first floors and basements, the floor is protected by a waterproofing layer, and on top - by roll-on vapor-insulating materials.

Roof vapor barrier:

- when installing a vapor barrier, it is necessary to install a ventilation gap, but when using any type of membrane, this can be waived without compromising the quality of the insulation;

- in the case of the roof, the vapor barrier is already placed on a fixed layer of insulation;

- overlap size - from 10 cm;

- no difference, vertically or horizontally, you fasten the insulation.

Remember that when installing the insulation, the web material must be a single fixed web. Do not spare the material for overlaps and fastenings. Watch the film tension. Insufficient tension will lead to wrinkles, and excessive tension will cause damage to the web. And in fact, and in that case, the necessary characteristics of the material will decrease or disappear altogether. Remember about ventilation. Do not waste time and money on the device vapor barrier in a log house - unlike other materials, this is not necessary.

Always isolate the ground floor floor. Do not confuse the sides of isolation - usually internal is considered the one that faces the roll. All surfaces must be dry during installation. When purchasing roll material, check the equipment. It is more profitable to buy the material includedin which the fixing tape is already in place, the necessary rails and other parts for fixing this particular model. If you still doubt self-selection and installation, rely on professionals.

For information on how to steam insulate a frame bath, see the next video.