Floor screed solution: composition and proportions

During Soviet times, apartments were rented completely ready for a comfortable stay. Today, the owners receive “bare” walls, “bald” ceilings and a slab of slabs under their feet, spattered with mortar. To bring an apartment in order often have their own hands. Repair work begins with the installation of a reliable floor screed.

Species

There are various technologies for pouring floors. All of them give excellent results if the technologies are fully complied with and high-quality materials are used.

In residential construction most often use the following types of screeds:

- concrete;

- cement;

- anhydrite.

Concrete screeds have the greatest strength. For their arrangement requires cement, sand, gravel, expanded clay or gravel. Concrete will receive its inherent strength characteristics with accurate compliance with the proportions of its components. At the construction bases and enterprises ready mixes are sold. Their use will relieve from a number of operations, but will require large financial costs.

Universal cement screeds are suitable for any premises: residential, utility, office, industrial. With their help, different types of bases are aligned. A good result is obtained by carefully mixing the dry ingredients. Otherwise, there is a high probability that the cement floor will crack, especially when it is laid out in a thin layer.

Anhydrite screeds are more durable, can be laid out in a thin layer. This look does not change the sizes at low and high temperatures, and therefore, does not need arrangement of deformation seams. Positive qualities are compensated by a disadvantage - susceptibility to moisture. For this reason, anhydrite screeds should not be laid in showers, bathrooms and kitchens - where the air is often filled with water vapor.

Functional purpose

At its core, floor screed is an intermediate element between the base and the finishing flooring. In private houses and cottages for floor screed prepare a special foundation. In multi-story apartment buildings, it is laid on reinforced concrete floor slabs. In the production shops often screed can be a finishing coating.

The coupler eliminates uneven floors and bases. Floor coatings will last a long time only if applied to smooth surfaces. Particularly demanding to the condition of the substrate parquet and laminates.

The condition of the floors affects the furniture in the room. It will be a pity when expensive pieces of furniture made of natural wood, bought in a new apartment, will twist on low-quality floors, start squeaking and cracking. To eliminate the drawbacks and prevent various troubles, a tie is applied.

On the first floors and in private buildings, the layer laid on the floor does not allow moisture from the basements to penetrate into the living rooms. In addition, it performs the functions of insulation and sound insulation.

If necessary, the coupler can be made with a slope.This structural feature allows you to choose the direction of water flow in the baths and showers.

Do not do without screed when the device floor heating. It was she who reliably closes communications, providing a comfortable atmosphere in the premises, protects them from mechanical damage.

Composition and components

Standard screeds consist of two basic elements - this is cement and sand. On the technical characteristics of materials may vary significantly.

For example, sand is river and quarry, may contain impurities or be used only after washing. It differs in size: small or coarse-grained.

To designate the physical and mechanical properties of the cement assigned brand. Cement having a high grade in the screed will have greater strength than that in which the grade in the dry state is lower. Both main components have a certain moisture content. Depends on the need for water in the solution.

For concrete screed suitable cement brand M200 and above, and river sand with a small amount of impurities. To prevent the penetration of large foreign particles into the solution, sand is sieved.

In addition to the main components, additional components can be introduced into the screed:

- plasticizers;

- fiber fibers.

Plasticizers are synthetic fluids that add plasticity to the solution. They facilitate the laying of the screed, have an impact on the time of its hardening, increase wear resistance. Fibers are able to replace the reinforcing mesh, increase the strength of the screed, counteract its plastic shrinkage, do not allow the surface to crack.

Screed mortars require water. It should be clean, preferably plumbing.

Possible proportions

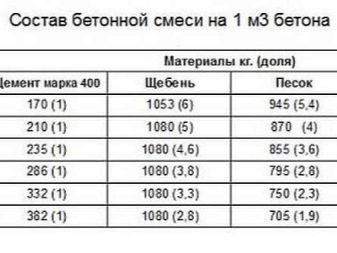

In solutions for floor screeds, the optimum ratio is 1 to 3, when one share of sand cement requires three shares. In relation to water, a different proportion is observed: 2 to 1. If the components are measured by buckets, then 1 bucket of cement will have 2 buckets of water.

The higher the grade of cement, the less it will be required for more sand, and the strength of the screed will not be affected. For example, when using M-500 cement, the proportion of cement / sand will be 1/4.

Logically, the more cement in the solution, the stronger the screed. However, the ratio of 1 to 2 is not justified.With a small amount of sand, the cement will set too quickly. The required screed parameters, such as providing a flat surface, will be almost impossible to achieve. Alignment will have to be performed using technical devices.

However, an excess of water and sand in the solution is also useless. It will reduce the strength. The solution needs a certain balance. If the preparation of the solution is made at home, you need to correctly calculate the amount of screed. This should be done for the reason that the calculation of the individual components is carried out precisely from the obtained value.

With a floor space of 40 m2 and a screed thickness of 50 mm, the cubic capacity of the screed will be: 40 x 0.05 = 2 m3. Based on the ratio of cement / sand 1/3, we obtain the volume of cement: 2m3 / 4 = 0.5m3.

It is known that 1 m3 of cement weighs 1300 kg, therefore, 0.5 m3 will require half as much - 650 kg. The mass of sand will be three times more than cement: 650 x 3 = 1950 kg.

Plasticizers are added to the solution at the rate of 1 l per every 100 kg of cement: 1 x 6.5 = 6.5 l. To improve the strength characteristics of the screed, 0.7-0.8 kg of fiber fibers are added to each cubic meter of solution. 0.8 x 2 = 1.6 kg. When volumes are calculated, you can buy material and make a solution.

Mixing rules

In order to prepare the mixture for a tie, you will need a large container, buckets, shovel, trowel and a construction mixer or electric drill.

Dry components are first sieved, then poured into a container in the desired ratio and mix well.

The quality of the screed will depend on how evenly the cement and sand are distributed throughout the volume.

If it is uncomfortable to interfere with a shovel, a trowel is taken in hand. Then time is spent more, but the result will be better. If fiber is used, they should be added to dry mixes.

From the prepared components build a hill, on top of which form a depression. Some water is poured into it. The kneading proceeds gradually when small batches of the dry mixture are mixed with water and water is added when it is absorbed. The plasticizer is introduced into the solution with water, pre-mix them well. To give homogeneity, the resulting “porridge” is mixed with a mixer or a drill with a special nozzle.

The consistency of the composition is determined as follows. On the surface, make a shallow incision. If it is filled with water, then you need to add cement.Dry edges of the cut indicate a lack of moisture. Ideally, the damaged part of the mixture should be slowly drawn out.

Kneading the mortar is much easier in a concrete mixer. The technology works here is different. Pour water with a plasticizer into the bunker and turn on the device. Cement, and then sand, fall asleep in a rotating bowl. Fiber fibers can be added at any time.

After all the components are in the concrete mixer, it should “work” another 5-6 minutes. This time is sufficient to obtain uniformity.

The best brands of dry mixes

You can speed up the process of arranging the screed, by abandoning the traditional labor-intensive method for the independent production of cement mortar. In the building materials market, dry mixes are sold for flooring. The mixture is combined with water in the proportion indicated on the package and the solution is prepared for laying. All that is required for leveling the floors, for the strength and durability of the screed, in such mixtures already exists.

Among foreign manufacturers of building materials, the most famous are:

- Knauf;

- Ceresit.

Both companies produce several types of mixtures for floor screeds.Some are designed to strengthen the base, others for finishing, others are specifically designed for pouring underfloor heating.

The cost of imported goods is quite high. For less money you can get a less well-known, but no less quality mixture of Russian and Belarusian production.

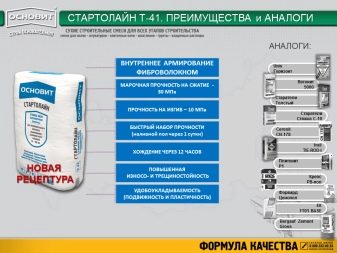

The domestic industry offers consumers two kinds of blends. The first one - “Founds Staroline T-41”, is suitable for installing underfloor heating. The second one, “Founds the Mixline T-44,” allows you to install high couplers up to 150 mm.

Belarusians produce the Lux mix dry mortar, suitable for screeds from 10 to 100 mm high.

Fill recommendations

It is possible to fill in solution on the basis cleared of dust and garbage. The presence of cracks and potholes in the base is unacceptable. Therefore, even before the start of work, they conduct thorough training. Cracks are puttied, the gaps are filled with mortar or filled with building foam.

When the device is a floating screed lay the appropriate material. When using underfloor heating, pipes or cables are installed and fixed. In addition, the operation of the heating system is checked.

In large areas for pouring it is advisable to use a mortar pump. The feeding of the mixture begins at the farthest corner of the room. From this point there is a movement to the exit from the room.

Lay out the solution should be tamped. This is necessary to remove air from his body. If this is not done, voids will appear inside the screed, which will lead to heterogeneity of the layer and its destruction.

It is necessary to level the solution as it is laid out. The treated surface is left to dry. At this time, temperature fluctuations, forced heating and drafts should not be allowed. With a stable temperature regime and ventilation, the coupler will set evenly.

How to correctly and quickly make a solution without a concrete mixer, see below.