Damping tape for screed: the purpose and types

Temperature extremes and high humidity are factors that can harm even the most durable building materials, which include the screed, leveling the floor. To protect the cement layer from negative external conditions, it is worth using high-quality damping tape.

Features and Purpose

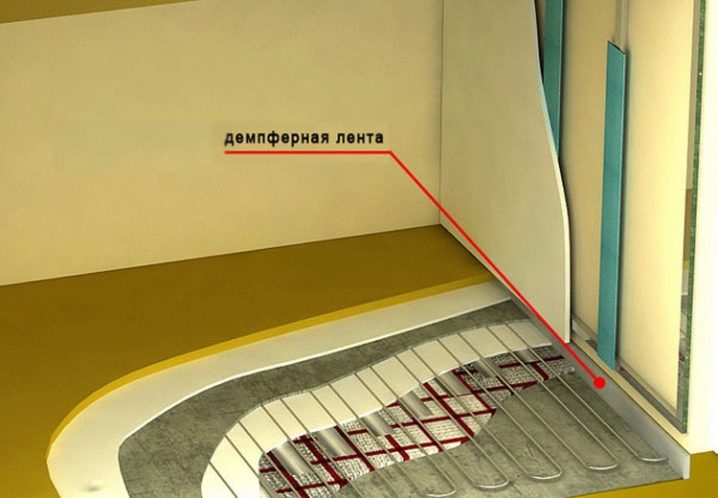

The importance and commitment to the use of a damper tape during construction work on pouring the floor in a room is difficult to overestimate. The compensation gasket is mounted not only between the tie and the vertical surface, but it also shares with it large arrays of concrete when constructing a blind area on the street.Convenient and technological screed accelerates the repair and prolongs the life of the floor, and also ensures drying without defects. What is the edge layer, and what problems it helps to avoid, you can understand, referring to the physical properties of concrete mixtures.

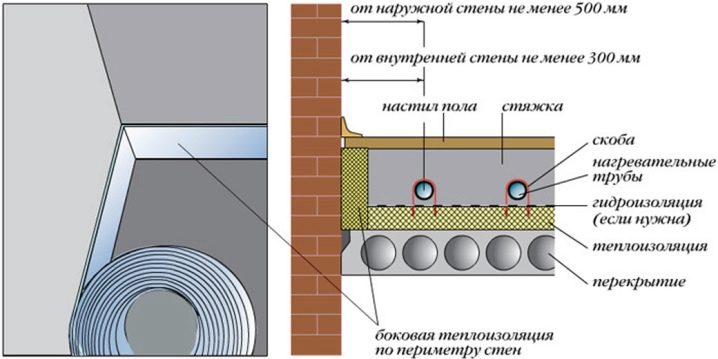

All types of mixtures have the property of changing sizes with temperature fluctuations that are unavoidable during drying, as well as seasonal changes, which amount to 0.5 mm for concrete per square meter of area when the temperature increases by 20 degrees. With an average area of typical residential premises of 20 sq m, the expansion in summer will be a whole centimeter. The thickness of the mortar and humidity also affect the degree of expansion.

Such fluctuations in the size of the floor threaten further unpleasant consequences:

- The block mass will start to exert great pressure on vertical surfaces and building elements (columns, arches, podiums for plumbing), causing dangerous stresses in the base bearing building structures.

- Stress will appear in the concrete layer and cracks and deformations are possible.

- In decorative coatings, deformations and cracks may also form, as well as the destruction of fragile plasterboard or wooden partitions.

- Excessive heat in the wall.

- Disastrous moisture.

- Damage to pipes and other components of warm floors.

Modern rules and standards of construction impose very strict requirements on the quality of work performed and do not allow the occurrence of such defects. To solve these problems, earlier builders used as a buffer boards no more than 30 mm thick, cloth, foam plastic, but these fillers have a number of serious unavoidable drawbacks.

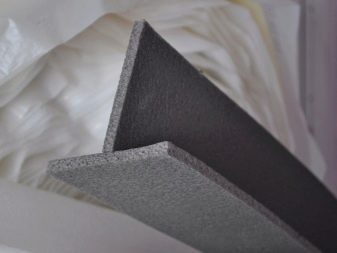

Especially for solving the problem of compensating for thermal expansion and a number of other tasks (heat insulation, moisture insulation, vibration absorption) an innovative material was developed - expanded polyethylene, a special porous dense structure of which has the property to contract, due to which the material can expand without deformations. From it and made damper (compensation), or edge (deformation) tape.

Advantages and disadvantages

The damper has almost no competitors in its properties.

Its advantages include:

- High heat and sound insulation performance, as well as absolute moisture resistance.

- This material takes the stress of a layer of concrete;

- High ductility is inherent in the damping layer.It is repeatedly compressed and unclenched without breaks.

- Ability to absorb vibrations.

- This layer is characterized by the absence of deformation due to temperature drops, unchanged indicators with their sharp changes (when the system of warm floors is turned on and off).

- Environmental friendliness and safety: the damper does not rot. He is not loved by rodents and insects, and he does not form toxic compounds during operation, and also has no smell.

- The damper has a convenient shape, flexibility, ease of transportation and installation, manufacturability and durability.

The only disadvantage of the edge seal can be considered a relatively high cost, but the use of this material significantly pays for all the costs incurred.

Kinds

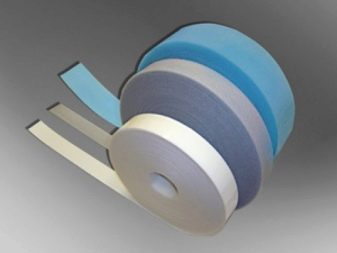

Edging tape is made in the form of a strip of polyethylene, rolled into rolls or coils with a fairly wide size range. The width of the strip is from 50-100mm to 150 mm, and the thickness is in the range from 3 to 10 mm, the length varies from 10-20 to 100 m, which ensures an optimal selection of material, and, consequently, budget savings. For quick trimming of surplus, the manufacturer made special cuts at regular intervals of width.

There are several different types of deformation products, specially designed for different characteristics of the room:

- Screed thickness.

- The area of the room when the separation is necessary compensatory seams.

- High humidity.

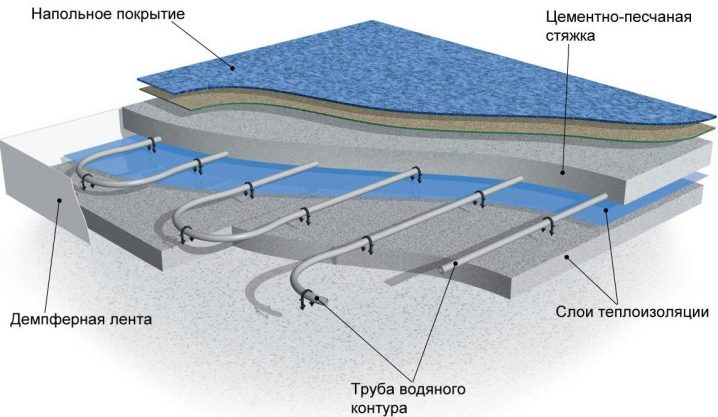

- Installation of warm floor.

The following main groups of deformation bands are divided:

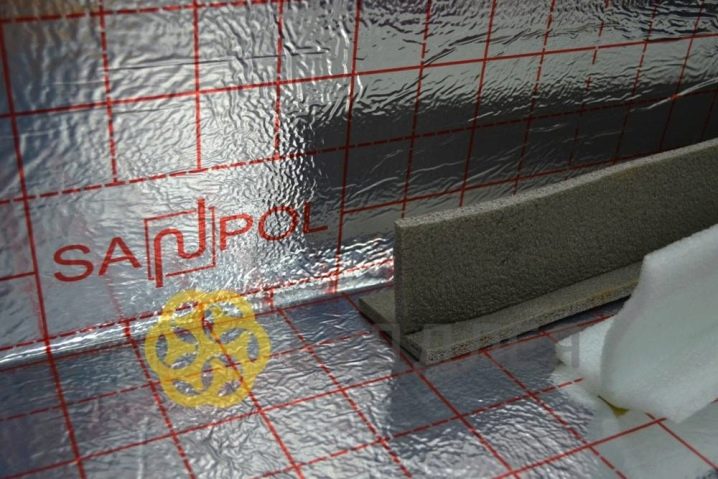

- The usual edge compensator in the form of a strip of predetermined width of polyethylene foam. It is mounted to a vertical surface around the perimeter of the room and around building structures (columns, partitions, podiums for plumbing) with glue, mortar, brackets and furniture stapler, screws (depending on the wall material).

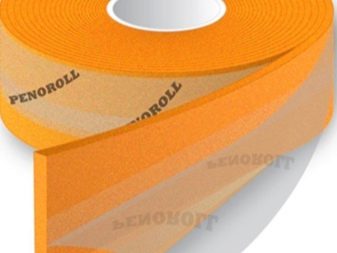

- Cloth with self-adhesive base on the back side, closed with a paper strip. Mounted on the wall quickly and easily. It is only necessary to remove the paper strip and glue the seal. Ideal for walls with ceramic tiles.

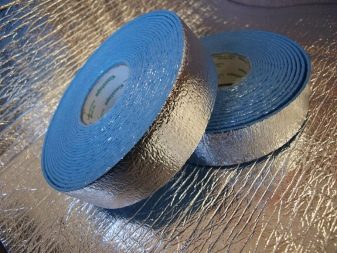

- The product is equipped with a special skirt, attached to the front side by a strip of thin oilcloth with a width of 30-100 mm, which provides additional waterproofing.

- T-type to compensate for seams.Such a device is used when it is necessary to divide an array of concrete into parts in rooms of more than 40 sq m in size, configurations of the P- and L-shaped form, or when pouring a screed simultaneously in all rooms on the same level.

- L-shaped type. This seal has a fold and divides the canvas into two unequal parts. It can be equipped with a skirt and self-adhesive.

How to choose?

The choice of the optimal model and size of the damper tape can significantly reduce the estimated cost, facilitate and speed up the repair process, ensure the reliability and integrity of the screed. It directly depends on the layer thickness and characteristics of the room - heat loss, humidity and the degree of temperature difference, as well as the area of the room.

The selection of the thickness of the edge band depends on the application:

- The walls need a thickness of about 1 cm.

- To fill the separation of the seams, you can take a thinner, preferably T-shaped.

The height of the buffer is chosen so that it is 2-3 cm above the layer of frozen solution. The length of the roll depends on the perimeter of the room. It should close the entire perimeter, and the overlap at the junction should be 5 cm.

What to replace?

The market does not offer a full replacement for this reliable and high-quality material, but there are situations when there is no factory tape, or a small budget forces you to look for a cheaper alternative. The main selection criteria are the properties of the analog. The easiest way to cut into strips is rolled polyethylene foam, which has all the necessary properties, simply cutting a piece of the desired thickness from the roll with a construction knife or scissors.

Wood used to be used as a buffer for screeds, but drawbacks make it unsuitable for these purposes:

- Wood does not have pronounced plasticity and depreciation properties, like polyethylene foam.

- Wood fibers absorb moisture well and change their geometry.

- Short service life. Without air and moisture, the tree begins to rot, becomes a favorable environment for bacteria and mold fungi, insects, and damage can occur and decorative coating. Also, the material begins to exude an unpleasant odor, and after complete rotting leaves empty gaps between the floor and the wall.

All natural materials, such as felt, have these disadvantages.

The foam is not able to take the original shape after compression. So, leave empty areas. Folgoisol can be used as a sealant, but it is thin (only 2-3 mm), so it will have to be laid in several layers, which may cause dislocation. Foam rubber accumulates moisture, and linoleum is not plastic enough. Also, izolon, penofol are used for replacement, but their heat-insulating and sound-proof properties are inferior to foamed polyethylene.

Laying technology

Installation of edge tape is made before pouring the screed. The strip must be securely fastened so that when it is poured, the solution does not move and does not come off. To this end, preparatory work should be carried out. Plastered walls, prodded the bottom of the walls, install the frames and trim the slopes. It is better to perform these works before pouring the roughing screed, then you can use construction debris as a binding element for concrete.

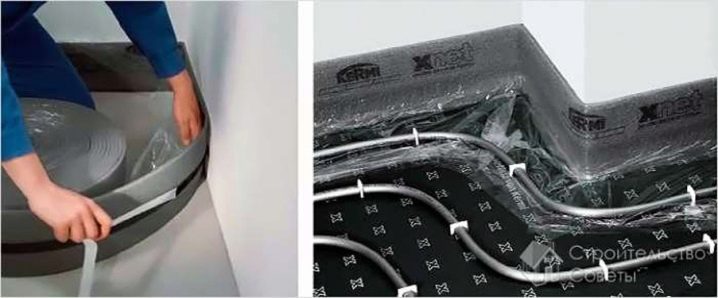

It is also necessary to eliminate level drops, cracks, chips, irregularities and height differences (no more than 5 mm is allowed) on the rough base. The junction angle between the wall and the floor should be 90 degrees. It is necessary to carefully remove all debris and dust.Despite the high adhesion of the adhesive coating, it is better to walk down the primer, wait until the primer dries. The sealant for a warm floor is laid after the construction of waterproofing and is located either under the vapor barrier or between the heating elements of the floor heating system and the vapor barrier layer.

Now you can glue the usual strip with liquid nails or any quick-drying polymer glue, and then fix it with small nails or use double-sided tape. Self-adhesive product is even easier to mount. To do this, gradually unwind the roll, removing the protective strip and press the tape to the wall, attaching around the perimeter. It is advisable to go with a roller on top for a closer fit of the material.

If there is a canvas with a skirt, then it should be flattened out horizontally, and the skirt should be completely hidden under the tie. The compactor should be placed continuously without breaks, and when the roll is over, the next one begins to overlap by about 5 cm. A damper should also be laid around all architectural and decorative structures. If the width of the compensator is chosen correctly, it will be 2-3 cm higher than the frozen solution.

Surplus should be cut off after flush filling or cut them off with the help of special cuts. If the finishing of the floor involves the installation of baseboards, then you can not remove unnecessary elements, as they will close the plinth, and if the tile is laid, the unnecessary should be removed after grouting.

Successful examples and options

Thanks to the high-quality damping layer, the flooring will retain an attractive appearance for a long time. This is very important for absolutely any room in an apartment or private house.

For example, such a detail for many years will save a beautiful bright linoleum in a modern stylish kitchen with white walls and a glossy suite, having a surface of crimson hue.

How to install the damper tape, see the next video.