What is the minimum floor screed thickness?

While the floors in the house do not creak, and the feet do not feel the cold, few people think about repairs. When there are obvious distortions of the floorboards, the laminate swells, and the linoleum breaks, without emergency measures for re-equipment of the floor is necessary. The first thing that comes to mind is to fill the floor with cement mortar, returning it to the previous stability, and maybe even significantly renewing it. At this stage, many questions arise.

Special features

The main purpose of the screed - leveling the floor under the topcoat. Most often floor screeds are made on the basis of cement. The basis under a floor covering can be different.

Its appearance, thickness and composition depend on such factors as:

- floor covering material (wooden flooring, concrete slab);

- building type (residential, residential, industrial);

- floor operating conditions (load, temperature conditions);

- soil type (when laying screed directly to the ground);

- the need for laying an additional layer of sound or heat insulation;

- floor heating system equipment.

In each case, the tie will have a different thickness. The height of the concrete layer screed are divided into:

- Minimally thin. Their thickness is less than 20 mm. A thin screed is obtained using self-leveling compounds. Small thickness does not provide for the installation of valves.

- Medium thickness. This screed reaches 70 mm in height. It can be reinforced with steel mesh or fiberglass.

- As thick as possible. A layer of concrete can reach 150 mm. Monolithic slab reinforced on a mandatory basis. This option can act as a foundation for buildings located on soils with low bearing capacity.

The thickness of the cement or concrete layer depends on the building materials used for its preparation.For example, it is impossible to provide the minimum thickness when pouring concrete with a filler of crushed stone. The rubble itself is quite large. In addition, it has sharp edges.

What should be: requirements

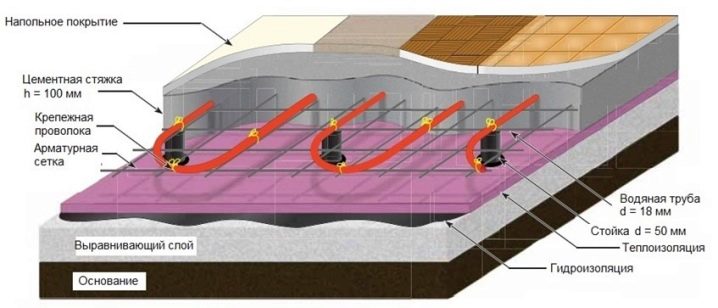

According to building codes and regulations (SNiP), the minimum thickness of the floor screed is 20 mm. In everyday life, such a minimum is mounted infrequently. It increases significantly if you need to hide the equipment located on the draft floor. Thus, the thickness of the screed when equipping a warm water floor should be determined with regard to the basic parameters of pipes.

Usually for the heating system used pipes of small diameter, up to 25 mm.

It is well known that the solution layer above the heating system should not exceed 40 mm. With a greater thickness, a floor heating device is inefficient, since the main part of the heat produced simply will not reach the consumer. The inner layers of the screed will heat up, and the floor covering will hardly get any thermal energy. The simplest calculations show that the thickness of the screed with a pipe diameter of 25 mm should be in the range of 50-70 mm. A standard screed consists of several components or layers.

The sequence of laying upwards is as follows:

- waterproofing;

- heat insulation;

- fittings;

- warm floor;

- screed.

Various designs of a heat-insulated floor demand different tyazhechny layers.

In some cases, at first a rough floor is leveled with a thin screed, sometimes the solution is laid directly on the insulation. Its thickness should not be less than 2 cm. One month is given for the drying of the layer, and only after it is completely dry you can begin to install the heated floor, further closing the installed communications with another screed.

For an electric floor heating need a low screed, especially if the film was chosen heating. Infrared film is ideal for laying under the laminate, carpet and linoleum.

If you plan to tile the floor, you should use a heating cable. In this case, you will need a less thick screed than when creating a water floor.

Fill the concrete screed to any floor heating is performed only after it is securely fastened, connected to the main communications and complete performance testing.

Types and materials

The term "screed" combines a lot of different species. The composition of the screed can be:

- cement and sand;

- concrete.Concrete, in turn, differs in fillers:

- rubble;

- expanded clay;

- gravel;

- bulk.

The tie layer, depending on the interaction with the base, is:

- Related. It is laid directly on the base;

- Floating. The layer of mortar does not touch either the base or the walls of the room.

According to the design of the screed is divided into:

- Solid;

- National teams. They can be single-layered and multi-layered. Here the coupler is placed in separate layers, each of which has a grip with the previous one.

Most often screeds consist of a mixture of sand and cement - sand concrete.

Less commonly used materials such as:

- gypsum and polymer blends;

- sheet materials;

- dry bulk materials.

The screed can be reinforced, self-leveling, contain special additives that affect the density, strength, fluidity and other characteristics.

The content in the composition of the water screed is divided into:

- Dry This species requires a dry base. Wet subfloor (floor or slab) must be dried beforehand. The prepared base is covered with vapor barrier to prevent the ingress of moisture.Guides are mounted on the film, between which a dry mix is poured and leveled. On top of the bulk material is covered with flooring, preventing the penetration of dust particles.

In a residential area, a dry look is unacceptable.

- Semi-dry screeds are concrete and cement-sand. They include plasticizers and fillers from fiber fibers. The first give the mixture elasticity, and the second increase the strength of the screed. The semi-dry screed is good because it dries much faster than wet, suitable for residential and office space, and can also be mounted under any floor coverings.

- Wet option has fluidity. With it, even large irregularities can be corrected, since this type fills in the cavities and shells on the floor slabs. Self-leveling effect is achieved due to the free spreading of the solution.

The main disadvantages of this type are the impossibility of using them in apartment buildings on floors above the first and a long period of solidification.

Determine the optimal value

The thickness of the screed depends on the characteristics of the base and the requirements for the flooring.With the help of a screed, it is possible to significantly increase the life of the base on which it is applied, because if it is applied, the load is distributed evenly over the entire area, and therefore, the wear will occur evenly. Along with leveling, pouring the cement layer is able to create a given slope where necessary.

The screed should not collapse under the influence of the loads to which it is subjected, that is, it must have a thickness that provides sufficient hardness and strength. Too high a layer can damage the base of the floor.

If the load on the base will be more permissible, then the entire structure will be destroyed, which will result in a major overhaul and substantial costs.

It is necessary to find the "middle ground" by solving the issue of thickness.

For each individual room with its individual characteristics should be selected individual option.

- The minimum value of the thickness of the screed according to SNiP is at least 20 mm. As practice shows, the minimum may be different. A layer of 20 mm is appropriate where there is already a roughing screed, and you only need to trim the top layer for laying decorative flooring.In rooms such as a kitchen or bathroom, the recommended minimum thickness of the screed is 40-50 mm. The same smallest height should be at the screed reinforced with steel mesh.

- When laying the solution on the ground, the permissible lower limit may be 150 mm. The coupler turns out multilayered. Mixed with sand rubble is poured on the well-packed ground. After trapping it, a layer of waterproofing is laid on which the reinforcement is laid. Next is pouring concrete.

- The maximum value is due to common sense. Screeds above 150-170 mm do not. If necessary, raise the floor to a greater height using other methods and designs.

The thickest screeds are appropriate in garages, workshops, and with the equipment of slab foundations.

Consumption

As materials for screeds, it is customary to choose:

- self-leveling mixture;

- cement and sand solutions;

- cellular and lightweight concrete.

Preference is given to those materials that cope with the alignment of the surface without overloading it, and are suitable for finishing. In order to determine the flow, you need to know the area of the room and the height of the screed.The easiest way to do the calculation when using ready-made mixtures, because all the necessary information is already available on the package.

To obtain a solution of cement and sand, the components are taken in different proportions:

- 1: 4 for cement M500;

- 1: 3 for cement M400.

Other options for screeds are not recommended. So, you get the composition of the desired consistency, without lumps, if the dry ingredients are first thoroughly mixed, and only then add water.

For a wet screed water will need more. A wet screed can be laid in a thinner layer than a semi-dry screed.

Features screed on penoplex

Penoplex (extruded polystyrene foam) - a reliable and durable tiled insulation. It is widely distributed due to its ability to withstand any load, but if you do not comply with the technology of laying, all the positive qualities of the material may disappear.

The surface under the polystyrene should be level. If the plates are put on the ground, it is necessary to equip a sand pillow, tamp it up and check the horizon level. Draft floor must be clean and level.

If there are significant differences in height, it is better to pre-fill the leveling screed, eliminating them.

Joints between adjacent layers of polystyrene tightly pressed to each other, securely glued with foil tape or wide tape.

Penoplex is available in plates of different thickness and density. For residential premises suitable insulation thickness of 20-30 mm with a density of 31-35 kg / cu. m. For houses and apartments on the first floor without a system of warm floors, slabs can be taken thicker - 40 mm. In garages and other premises with floors laid on the ground, thick polystyrene foam is used up to 100 mm thick with an increased density of 45 kg / cu. m

Insulation plates are covered with a waterproofing layer. Asphalt, roofing felt or polyethylene film can be used. Waterproofing is designed to protect the foam from moisture penetration from the screed layer.

A damping tape is installed along the perimeter of the room on the walls. It provides the temperature gap necessary to compensate for possible expansions. The minimum thickness of the cement-sand screed on the penoplex is indicated by the manufacturer and is 40 mm.

If you need to raise the floor to a greater height, then fit a concrete screed with a lightweight filler, for example, with expanded clay.

Recommendations for selection

Experts share some tips designed to help you find the right option.

- If your apartment has an uneven or too cold floor, then you should think about the device screed. A self-leveling compound is suitable for easy leveling.

- You can warm the floor in different ways. In a private house, there are more options for floor heating equipment than in an apartment. In it, any redevelopment or similar work will require coordination with other owners, housing organizations and regulatory authorities.

- When installing on the floor slab insulation agreement is not required. Penoplex will be an excellent choice, because it is suitable for both tile and laminate and other popular coatings. The only requirement is that the screed should not be thinner than 4 cm, otherwise it will soon begin to crack and crumble, which will inevitably lead to deformation of the finishing floor finish.

- The choice of screed for a wooden house depends on the type of base. Wood flooring will not withstand a large load, namely the indicator of resistance to stress is fundamental when choosing the thickness of the screed.If a reinforced concrete slab is used as a subfloor, then the grout layer may be thicker.

- Minimally thin screed in the garage is comparable to the thickest in the premises. Screed on the ground can not be thin. If alignment of a draft reinforced concrete floor is to be achieved, then the height of the screed layer can be reduced.

You can find out how to do a do-it-yourself tie with the video below.