Knauf coupler: the pros and cons

Increasingly, when leveling floors in residential and non-residential premises, they abandon the traditional method of overhauling the floor (pouring a concrete screed) in favor of a dry base leveling method. One of the technologies of this method is the world-famous company in the field of building and finishing materials Knauf.

Dry screed of this manufacturer is a modern building material, thanks to which you can quickly and effortlessly level any floors.

The topcoat can be immediately laid on the foundation created with this screed, in contrast to the “wet” leveling method.

Advantages and disadvantages

Dry screed has a number of indisputable advantages compared with the traditional method of device base floor:

- the ease and speed of the process device tie. In this way, the floors are aligned fairly quickly. And the time costs for drying are absent. Immediately after the dry screed device, a floor covering can be laid;

- there are no so-called “dirty” works. The dry screed device can even be carried out in a room with already repaired walls, not worrying about the fact that they will be damaged in the process of doing wet work;

- minimum overlap load. The traditional screed with the use of concrete has a rather impressive weight, which in some cases makes its use almost impossible. In this situation, the screed comes to the rescue;

- increased noise insulation and thermal insulation. Dry backfilling contributes to the preservation of heat in the room and isolates it from extraneous noise, so the need for additional insulation of floors disappears by itself. On the dry screed, you can immediately lay the finish coating - laminate, linoleum, floorboard;

- does not require the use of special self-leveling mixtures, leveling devices and other products to level the floor;

- the use of dry screed does not significantly reduce the height of the room;

- in the dry screed, you can lay all the necessary communications;

- dry screed can be mounted in parts, which is not the case for a concrete screed, which must be poured immediately in full;

- installation of a dry screed can even be performed by a layman. No special tools are required, only a shovel for the spreading of claydite and jigsaw to cut gypsum-fiber sheets;

- dry screed can be repaired or redone any number of times;

- in the presence of such a foundation, the owners of the premises will never encounter the problem of the appearance of floor squeal;

- such floors are safe for human health and fireproof.

Despite the abundance of merits, the dry screed has a number of drawbacks that you should pay attention to:

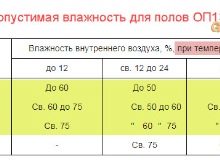

- If water gets on the expanded clay base, the screed can cause a number of problems - the development of a fungus, the appearance of an unpleasant smell

- It is not allowed to use a dry screed in unheated rooms, because at high humidity and low temperatures, the clay will begin to absorb moisture, which will lead to swelling and, consequently, to the deformation of the floor;

- when mounting a dry screed, there is a lot of dust, so all work is done in respirators;

- The price of dry screed is higher than traditional concrete.

Specifications

Knauf company offers two technologies of dry-screeding device: Knauf-superfloor and precast base with the use of moisture-resistant small-format superlist (lightweight screed).

Both systems have the following characteristics:

- construction thickness: 40-100 mm;

- thermal conductivity - 0.22–0.36 W / m0С;

- compressive strength: 22 MPa;

- The airborne sound insulation index increases by 2-4 dB;

- the impact noise index is reduced by 18-22 dB.

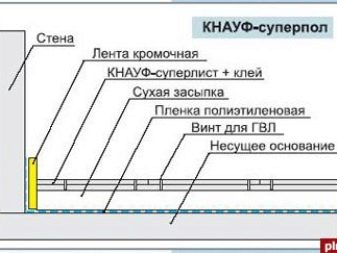

To level the floor with a dry screed, the following materials are required:

- dry fill;

- moisture-resistant gypsum-fiber single sheets or floor elements (moisture-resistant gypsum-fiber sheets double with folds for ease of joining);

- adhesive mastic;

- edging tape;

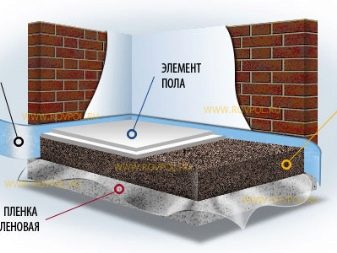

- polyethylene film;

- screws for super sheet;

- Putty Fugenfüller.

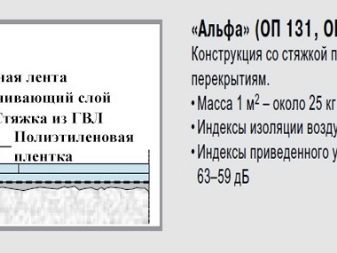

A dry screed with a precast base is easier, since one square meter of such a base with a minimum thickness of 4 cm has a weight of 25 kg in contrast to the Knauf-superfield system, in which the weight of the same screed area is more than 30 kg.

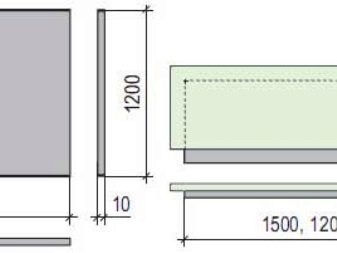

The panels used in the dry screed device have:

- dimensions 650 × 1250 × 20 mm;

- Brinell panel hardness - 22 MPa;

- dry backfill compressive strength - 10 MPa;

- sound insulation: 55 dB - from the noise of the shock, 58 dB - from the noise of the air;

- fire safety in flammability - G1, in flammability - B1, in smoke formation - D1, in toxicity - T1.

Gypsum-fiber sheets used as a topcoat for a dry screed device are a gypsum component mixed with reinforcing cellulose fibers.

Such material has high strength characteristics, is not combustible and is environmentally safe.

Knauf dry fill is a finely expanded clay sand with a particle size of not more than 4 mm. It is this size of the fractions that ensures the resistance of the floor to shrinkage and deformation. The bulk density of the material is 600 kg / m. cube, strength - 2.5 MPa.

Kinds

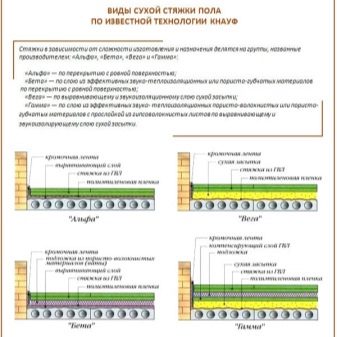

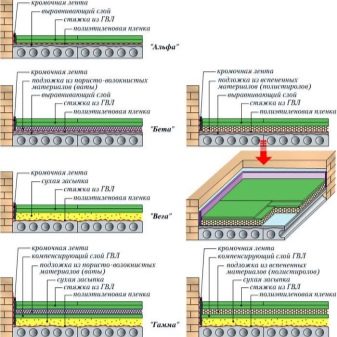

The manufacturer identifies the following types of dry screed structures:

Alpha

This type of screed is used without the use of a loose component, so the base of the floor must initially be leveled. Overfalls should be no more than 3 cm. For the alpha coupler device, only gypsum-fiber boards, plastic film and edgeband will be needed;

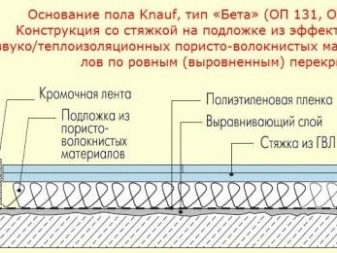

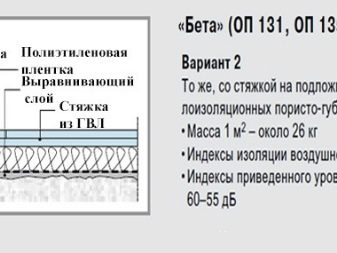

Beta screed

It involves the use of porous spongy or porous fibrous materials (for example, polystyrene foam) instead of expanded clay backfill. In this case, the base must also be aligned. The difference of this screed - increased sound insulation characteristics;

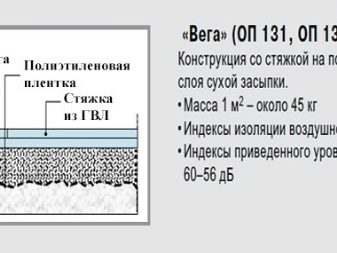

Vega

The most common option is dry screed. There are no increased requirements for the degree of flatness of the base. Any drops are eliminated with the help of expanded clay backfill. Gypsum fiber sheets are laid on claydite;

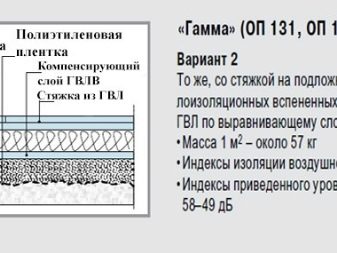

Gamma

The most expensive type of screed. He repeats the previous version, but on the gypsum-fiber sheets on top of the insulation is laid and covered with another layer GVL.

How to choose?

To choose the type of floor screed, you need to be guided by the characteristics of the existing base, the requirements that apply to the screed and strictly follow the manufacturer's instructions.

So, if the base of the floor is already fairly even and additional protection from noise and cold is not required, then the alpha option can also be avoided. If, on the contrary, you need to achieve maximum performance of noise and heat insulation, and at the same time the height of the ceilings allows you to raise the level of the floor, then, naturally, you should opt for a gamma screed. The most acceptable in all respects, both technical and financial, is the vega option.

Whichever option is chosen, it is imperative to follow the manufacturer’s instructions. If the technology provides for the use of expanded clay backfill Knauf, then it should not be replaced with other materials with large fractional sizes.

This can lead to sagging and deformation of the floor.

In addition, you should not arrange a dry screed in wet areas where there is a high probability of flooding (bathrooms, showers, toilets, kitchens), as well as in unheated areas (garages, basements). And one more important detail: before you make a choice of the type of tie, you need to calculate the weight of all possible options and consult with a specialist on whether the floor structures will withstand this or that type of tie.

Piling

Before starting the screed device, the necessary geodetic work is carried out - the level of the top of the screed (2-3 marks) is carried out on the walls using a level. If installation of alpha or beta is planned, then the base is pre-leveled using a thin layer of leveling mixes or a conventional cement-sand screed. Then it should be spread on the basis of a plastic film with an influx on the walls above the marked level.

In order to protect the clay from swelling under possible adverse conditions, an edgeband is glued to the walls along the entire perimeter. Then on the film begin to pour out a dry fill. Moreover, this is done by ridges with a step determined by the size of the rule or 1 m from each other (from the walls 0.3 m). On the ridge stack guides, which are set at a marked level. Between them continue to scatter clay. The minimum layer of backfill is 4 cm, the maximum is 10 cm. The surface is leveled by a rule, after which the guides are removed and the remaining notches fall asleep.

After the expanded clay layer is level, proceed to the laying of gypsum-fiber boards. Start from the wall farthest from the entrance.In the presence of folds, they are smeared with glue for reliable connection of the panels. When all sheets will be laid, they are additionally fastened with screws. The joints of the panels are puttied, and the entire surface of the floor, after drying, is putted with a penetrating primer. These are just the general rules for a dry screed device. For each particular type, they vary depending on the number of layers and how they are laid.

Can I lay tiles?

Many consumers who have decided to overhaul the floor are interested in the question whether it is possible to put ceramic tile on a Knauf dry screed.

Master finishers claim that it is quite possible. On the dry screed, you can install a variety of flooring, including ceramic tiles. But some experts advise at the same time to additionally strengthen the base by laying moisture-proof GVL. At the same time, to improve the adhesion of gypsum fiber board and glue for tiles, it is better to treat the floor with a primer or concrete contact. In addition, the laying of the floor covering should be made on a special glue for bases prone to deformation.

Reviews

If we consider consumer reviews on the Knauf coupler, then we can find both positive and negative opinions. But not everyone can be adopted.

It is best to listen to the opinion of these professionals, for whom finishing work, including on the device of the floor, is a professional activity.

The most common negative point that is found in the reviews, is an indication of increased fragility of the floor. Such a phenomenon can occur only when using materials that are designed for completely different purposes when using the floor. For example, the same drywall. Naturally, if you replace the gypsum plasterboard with drywall, you can face the problem of pushing the floor. When using the materials intended by the manufacturer for the device of the dry screed, this problem does not arise.

Another negative point is associated with the development of mold on the GVL. This may be the case when using dry screed technology in wet rooms. The manufacturer directly indicates that its product is not intended for such conditions.

Some consumers also point out that during the operation, the floor made with this technology sags. Such processes can be observed if during the installation all the preparatory stages were incorrectly performed.If claydite is filled up according to all the rules, plastic film is laid under it, and the walls are taped with a damper tape, then backfill held on all sides (by the floor, walls, GFL panels) cannot go anywhere. Such a problem can also be caused by the fact that some consumers use ordinary claydite instead of a special composition of Knauf, without taking into account that it must be of a certain size.

The rest of the buyers of the floor Knauf note its following positive properties:

- perfect flatness of the floor;

- good heat saving performance. The floor made by this technology is always warm. It is pleasant to walk on it even barefoot;

- lack of floor squeak;

- ease of installation. Perform work on the device of such a foundation may not be a professional;

- short turnaround time. All necessary steps can be performed in a maximum of 2 days;

- possibility of increasing the height of the room. Some consumers note that when replacing the old floor on lags with a dry screed, they managed to win a height of up to 5 cm.

The process of laying the Knauf dry screed can be seen in the video below.