Mechanized floor screed: the pros and cons

Concrete floors today are particularly popular, as they are durable and durable. The main component of such a system is a tie used to level the upper layer. Form it in several ways.

Today, an increasingly mechanized floor screed is being performed, the pros and cons of which we will consider in this article.

Its main difference from other methods is the use of special automatic mechanisms, which allows to obtain high surface quality.

Advantages and disadvantages

Mechanized screed is a new approach in the device of floors. Here, all the basic operations are performed by machines that are easy to adjust for different performance and power.

Screeds formed by mechanical systems have several significant advantages:

- The top layer of the floor is distinguished by a perfectly flat plane that is suitable for almost any topcoat.

- For the preparation of concrete solutions use much less water. This, in turn, accelerates the drying process of concrete. Grouting is done within a few hours after its installation. But at the same time using special shoes, which distributes pressure over the floor surface.

Full drying is reduced to 1-2 weeks. A small amount of liquid eliminates its leakage to the lower floors and damage to furniture or other structures.

- The use of machines speeds up the process of laying screed several times. At the same time there are no long technological breaks.

- Concrete solutions during drying do not crack. This is due to the minimum amount of water, as well as the addition of various types of reinforcing fibers to the composition (polypropylene, metal, fiberglass, etc.).

- The use of grinders eliminates the application of additional self-leveling mixtures. Machine tie allows you to save on these products, completely replacing them.

- Lack of dust indoors.This is achieved due to the fact that all the components of concrete are mixed outside the house. In this way, the maximum purity of all surfaces is ensured.

- Mechanized screed lasts much longer than the layer laid by hand.

But this approach does not differ universality, as it has several significant drawbacks:

- Installation work involves the use of several types of equipment. Their rent is quite expensive, which is not always effective for small areas.

- Laying screed is done only with the help of a few people with a certain experience.

- Construction companies do not undertake installation if the floor space is less than 100 m2, and this also affects the cost per unit area of the screed.

Considering the numerous reviews, it can be noted that machine couplers are a unique opportunity to get a high-quality surface that will perfectly cope with any loads.

When is it necessary?

Mechanized screed is fast drying and high strength.

It is used in several cases:

- Arrangement of concrete floors that will be used without finishing.Often these surfaces are found in garages or in warehouses.

- The need for hardening of old floors. This effect is achieved due to the fact that the concrete is compacted with special vibratory machines, and this allows you to form a more durable structure.

- Forming perfectly smooth surfaces. Very often, such screeds are made under laminate or parquet, which are very demanding on height differences.

- Mechanized screeds are suitable for underfloor heating, as well as for those cases when it is necessary to ensure a high level of sound insulation of the floor.

- In some cases, under them you can hide communications that are laid under specific sources (pipes, electric cable and much more).

It should be understood that the previously described tasks can be solved with the help of classical screeds. But such surfaces will not be of high quality, and it is not always possible to control their technical characteristics.

Equipment selection

The laying of concrete in a mechanized way is performed with the help of several machines. This equipment is quite complex and consists of many nodes and controllers.To arrange the screed, you need to stock up on several major devices:

- Pnon-charger. This machine is somewhat reminiscent of a concrete mixer, since it is in it that the mixture is prepared. But the design is additionally equipped with a special pneumatic actuator. It provides the delivery of ready-made concrete to the place of laying with the help of powerful pumps and hoses. Some modifications are able to raise the solution to a height of up to 120 m.

- Vibrolath. The mechanism consists of rigid guides along which the sealing rail moves. Outwardly, it resembles the usual bar, but it is driven by a special engine. This is necessary in order to better condense the concrete solution, removing excess air from it.

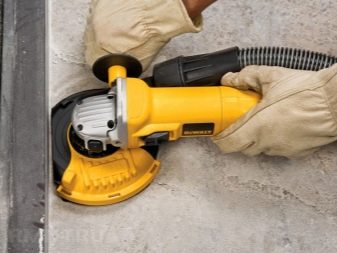

- Disk grinding machine. The main purpose of this device is to align and seal the screed. The power of these devices can be different, which allows in the shortest possible time to process large areas.

- Shverezchik. This tool is used only in rooms with a large area. The mechanisms are equipped with special circular saws, which form small cracks in the screed layer.This is necessary so that the concrete does not crack and quickly set on drying.

Preparation of the solution

Concrete mixes for these types of screeds in their composition practically do not differ from classical solutions. Here they only reduce the dose of water, since mixing takes place in special bunkers.

Concrete preparation technology consists of the following operations:

- Initially set the "mixer" near the components (sand, cement, etc.). After that, calculate the required proportions of all these products.

- When all products are ready, start filling them inside the bunker. For this you can use ordinary shovels. The main thing is to pre-measure the desired amount of each component. Dry substances are initially filled up, and then water is gradually added.

- Mixed solution using pneumatic cylinders is fed through pipes into the room where the installation will be performed. So that the mixture does not spray, the pressure is pre-reduced in a special tank-extinguisher.

During cooking, you should consider the capacity of the system, which can vary from 4 to 6 cubes of concrete per hour.

Preparation of concrete mix is practically no different from mixing with an ordinary concrete mixer. The system simply automatically pumps out the solution and feeds it to the desired point.

Technology

Laying mechanized screed is possible not only for the semi-dry solution, but also for dry mixes. The main thing is to choose the right tool and prepare all the components.

The process of filling the screed in an apartment or other room involves several sequential operations:

- Preparation of the base. This step is one of the most important, since the strength of the future structure depends on it. Fill the screed preferably on a base on which there are no cracks or other damage. If they are present, it is advisable to pre-seal them with plaster or other solutions. After that, the surface is cleaned of dirt, and on it have a waterproofing film, which is preferably attached to the walls with a margin.

- Layout level tie. To do this, use the beacons, which are mounted around the perimeter of the room. All marks are recommended to do along the walls using a laser level. Around the perimeter you also need to attach a damper tape, which will perceive the expansion of the concrete, while not allowing the floor to collapse.

- Filling the floor with concrete.This is done using the previously described technology of preparation and supply of the solution. It is important to evenly distribute the mixture over the surface, so that you do not have to add it.

- Compaction and alignment. At this stage, use the coupler, which consists of a frame and guides. The structure is installed directly into the concrete and occupies a certain width. Then the vibration compactor is activated and the carriage with the compactor is set in motion. At this point, the mixture begins to uniformly condense. When the system has leveled one piece, it is moved sequentially over the entire area of the room. It is advisable to lay the concrete in the same room at once to form a solid and solid slab. All strips where guides were placed should be leveled independently upon completion of work. To do this, apply the rule and the same concrete.

- Grouting and sanding the top layer of the screed. This process is performed 2 hours after pouring. During this time, the solution will have time to acquire a small strength. Grinding occurs using special mechanisms, which also differ in power and method of control.The quality of grinding with such a tool is very high, which allows you to perfectly align the top layer.

- Cutting expansion joints. They are formed with the help of special cutters throughout the area of the room. Often, the seams are large squares. But their specific placement depends on the structure of the building.

- Protection by film. This is necessary to maintain an optimal water balance on the surface of the screed.

The technology of mechanical fastener is quite simple, which allows it to be used both in winter and in summer. The main thing is to create a microclimate indoors.

Recommendations

Screed assembly using mechanical systems requires adherence to several basic rules:

- To reduce the risk of cracking, experts recommend adding polypropylene fiber to semi-dry mixtures.

- After laying the screed is preferably watered with water for 3-5 days. This approach is an alternative to plastic wrap.

- Avoid the formation of drafts and elevated temperatures in the room. This will lead to rapid evaporation of moisture and the formation of cracks.

- In winter, you need to ensure that the top layer of the screed is not covered with ice.

- Begin grinding should be in the case when the pressure on the surface of the foot, the solution sinks to a depth of no more than 1 mm.

Mechanized screed - a completely new approach to the device flooring. The above algorithm of actions allows you to get a solid foundation that can easily withstand high loads for a long time.

For more information on the mechanized screed, see the video.