How many days does the floor screed dry?

The screed is an integral part of the renovation, a difficult moment of aesthetic improvement. Base filling is a preparatory stage on the eve of designer decorating an apartment, house, conducted at the beginning of a transformation path. About the nuances associated with the floor screed, tell our article.

Special features

Dryness of the screed has a direct impact on the ability to produce the following scheduled techniques without the negative effect of fumes. An important mission in drying the floor is played by the selection of circumstances organized by man. Drying is directly subject to many factors: the external situation, the composition and volume of the screed, the kind of interior decoration provided for by the design, the atmosphere of the object's environment.Concepts should be mastered: complete freezing - dehydration of the solution and surface readiness for cladding, decoration, installation of the “warm floor” system and setting - the stage of permissible movement without fear of flooring without fear of damage.

What does it depend on

Packing packaging of trademarks of well-known manufacturers carries information about ready-mix mortars, which are divided into types, depending on the type of source material.

Gypsum leveling - one of the most popular composite deckingUsed for many years, environmentally friendly, has a high thermal conductivity. The ingredients are alpha gypsum, first class quartz sand with a fine fraction. For its production they use gypsum grades G-2 - G-7. Durability - 0.3– 0.8 MPa. Plasticizer additives are responsible for plasticity.

The advantages must include:

- absolute smoothness and uniformity of the coating;

- the ability to independently spread on the installation site;

- the composition is a moisture regulator that can both absorb and give off moisture;

- the possibility of applying the automatic or manual method of lining.

It is not recommended to be mounted in bathrooms and kitchens, painted, it is incompatible with adhesive solutions, it is applied to the primer, compaction must be carried out with a needle roller of the whole plane.

The cement base is a stabilizer of the degree of heat and moisture content with significant heat capacity.

Benefits include:

- increased hardness;

- long operational period;

- good vapor permeability;

- ease of installation;

- minimum price.

Peskobeton is a modern universal industrial powder. Intermediate option between cement and concrete. Material components: portland cement, river sand, granite, plasticizers, hardeners. The proportions depend on the variety. During laying, you should try to get rid of air bubbles, compacting the source material.

The mixture is excellent for this type of work: frost-resistant, simplified in use, does not sag, high-strength, inexpensive, harmless to health. Distinctive features: exact proportions, easy way of preparation, does not give in to corrosion.

Concrete screed - classic versionoccupying a leading place for the duration of drying.Successfully operated in the construction of residential and industrial facilities. It withstands extreme mechanical pressure, is immune to dampness. Ideal for outdoors, resistant to precipitation and temperature changes.

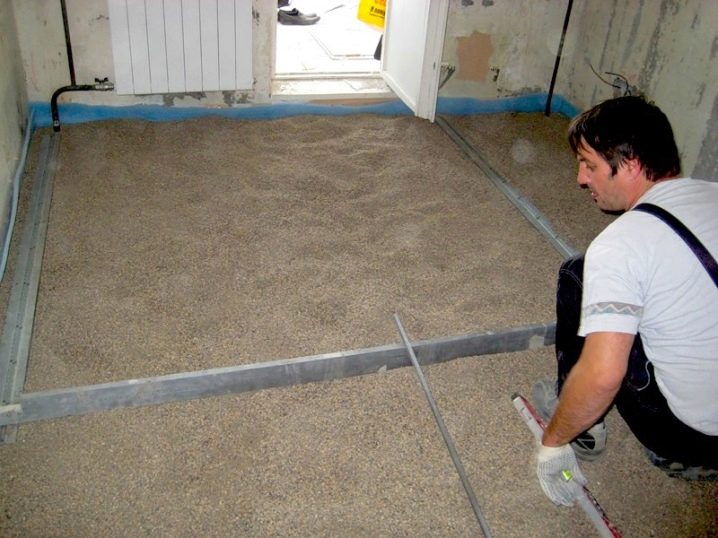

Semi-dry type of leveling layer. Its distinctive feature is the lack of a water resource, a dense consistency. Appeared relatively recently. Does not possess fluidity, the consistency of thick porridge. Dries quickly.

To reduce the risk of cracking, reinforcing additives are introduced - fiberglass. Dry filaments firmly bind the monolith in all directions. Using conventional mesh is unreasonable and costly.

Advantages:

- quick drying;

- perfect surface;

- the smallest compression;

- small thickness with sufficient durability;

- the possibility of walking on the screed without flooring and ladders.

Disadvantages:

- poor fluidity;

- the need for maximum qualification of the dresser;

- manual cooking and filling;

- the complexity of the calculation;

- freshly laid coatings are afraid of water.

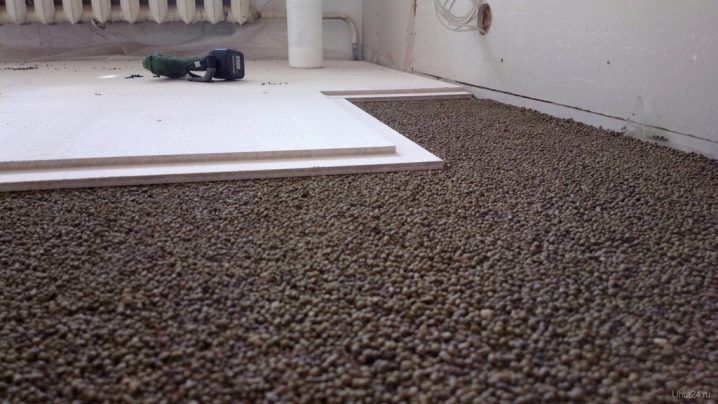

Dry - a new, sought-after development of German specialists. Analogue of traditional methods.It consists of fine-grained expanded clay and panels, which are made of glued gypsum-fiber plates. As backfill, you can use perlite, vermiculite, slag.

Such compositions are used on wooden floors and while working in the cold. The fastener is simple and quick. Needs waterproofing. The repair process is literally 48 hours, does not delay.

Benefits:

- accuracy of installation, exclusion of stains, drips, dust;

- does not require drying;

- ease of construction, the lowest pressure on the ceiling;

- the use of embankments for laying communications;

- record short drying time;

- work at any time of the year;

- rational attraction of labor, special equipment.

The main disadvantage is the fear of getting wet.

Time calculator

A plaster cast will take four hours to grab and seven days to freeze for a sufficient set of stability. Then you can proceed to the finishing with linoleum and parquet, arrange flood floor. Using tiles in the interior, work can be done on the fourth day.

Terms are relevant if the thickness of the composition is 40 mm. Thickening the size of the layer, add hours of drying. The builders derived a waiting formula: a centimeter dries out 42 hours.

For every 5 centimeters of cement mortar it takes eight days of drying and two weeks for complete solidification. Each subsequent centimeter needs an additional 15 days. Bulk draft bases will require a minimum of 26 calendar days. To reduce the load on the bearing structure will allow lightweight combinations, but they will prolong the drying.

For readiness of 50 mm of sand concrete it will take about a month. Quick-drying expensive formulations will reduce the length of time.

Concrete belongs to the “wet” groups, without waterproofing innovation. For uniform distribution of the layer, water filling is used. It remains moist for a long time inside, it freezes for a long time. To dry 3 cm will take 28 days. Flooded 1 cm above the layer will increase the time 1.5 times. As a percentage: 30% of the mixture will dry after 2 days, 50% after 3 days, 70% after 10 days, 100% a month.

Semi-dry screed - a solidification time of 14 days, hardening occurs after 12 hours.

How to change the humidity?

By investing in additional materials, you can speed up the repair process.Almost all methods of acceleration lead to certain defects of the coating, so they must be used strictly in accordance with the manufacturer’s instructions.

To change the parameters of the original composition is used:

- Expanded clay, basalt fiber - affect the modification. The amount of wateriness is reduced by 41%. Laying tiles can be on the fifth day of downtime, and lay laminate in 22 days;

- Thinner - slows the setting, increases the fluidity of the solution, the water leaves the lower level;

- Formers pores - accelerate the maintenance of fluid, reduce strength. Special resins are added to compensate. A porous sand concrete mixture conducts cold and heat worse;

- Sound insulators - perform the role of interfloor insulation.

How to dry

The stable condition of the created conditions will allow to keep the average indicator of drying time.

It is possible to improve the quality of the coating only by observing simple requirements, in accordance with regulatory guidelines throughout the process:

- correct air exchange, inaccessibility of drafts;

- thermal frames within 25 degrees Celsius, in winter - 6 degrees above zero;

- the elimination of freezing, the effects of low temperatures;

- protection from direct sunlight;

- humidity from 58 to 72%, otherwise the air will give off moisture;

- forced temperature rise is prohibited;

- sudden changes in temperature level are excluded;

- the creation of 9 days of "greenhouse effect";

- Shelter polyethylene, polymer film, wet water-holding fabric.

It is extremely important to meet the deadlines for the procedures. With a dry basis, irregularities are inevitable. The volatilization of the liquid goes only up, the insulation is interfering at the bottom.

Violation of technology will lead to the following negative consequences:

- the increased humidity of the room will be able to enter through the ceiling;

- due to the capillary reverse movement of the condensate, the lower layers get wet;

- in buildings with a cold basement condensate accumulation will occur in the thicker.

To ensure compliance with technological standards will help modern devices:

- electronic moisture meters (have a lower accuracy class);

- carbide hygrometers.

The purchase of such equipment is justified in the case of large-scale construction, for one room it is inexpedient.You can determine the moisture of the screed without using special devices: you just need to put a paper napkin on the surface of the coating and fix the edges with adhesive tape. Then cover it with foil and leave overnight. If the napkin remains dry, the drying of the screed is complete.

Accelerate the process irrational. Ignoring the recommendations will lead to sand dust, hillocks, spalling, sagging, cracking, cracking with subsequent delamination. The quality of the screed is determined by the naturalness of drying and the completion of chemical processes between the binding elements. In case of violation of technology, the finish coating will undergo shrinkage, cracking, rotting.

Professional Tips:

- The choice of screed depends on the availability of raw materials, their own preferences, technological features of the coating, etc.

- The optimal time of year for this kind of work is early summer, then by the autumn the process will be completed completely.

- Consider all the nuances and advice of experts. Responsible approach to the installation of the screed will save you from doing the laborious and expensive work again. Hurry can cause dismantling of coverage and inappropriate recurring costs.

To check the dryness of the screed, see the video below.