Knauf dry screed: laying technology

Laying modern flooring is impossible without prior leveling of the surface, which in the professional language of builders is called a screed.

Traditionally used type of screed is concrete, perfectly eliminating significant drops and irregularities and creating a magnificent even coating. However, for a long time in the construction practiced dry screed. Especially often used technology laying, developed by Knauf.

Features, Pros and Cons

The dry screed method has been practiced by domestic builders for quite a long time, so today we can judge both the advantages and disadvantages of this type of work.

pros

The main distinguishing feature of the dry screed method is the lack of so-called “wet work”.The resulting base does not take time to dry, as in the case of a classic screed with concrete. This fact can be attributed to the obvious advantages, allowing to reduce the time required to carry out repairs, and maintain cleanliness in the room.

Due to the absence of “wet work”, this method allows leveling the surface of old wooden floors without requiring their dismantling.

Another advantage of the owners of the premises is the possibility of easy dismantling of the covering of the screed in case of need access to the floors or built-in communications and elements of the system of warm floors.

If with a concrete screed in these cases, it would be necessary to break the coating, then in the case of using the dry screed method, it would be difficult to open the gypsum fiber sheets and remove the claydite.

In parallel with the alignment of the floor, there is an increase in its soundproofing qualities., because the fine fraction expanded clay used in the dry screed is an excellent silencer.

If only a 6 cm expanded clay layer is poured in, noise is absorbed within 60 dB, and the effectiveness of sound insulation is enhanced by the sheets of gypsum fiber on the surface of expanded clay.

The next advantage is that a dry screed allows insulating floors even if they do not install a heating system. This effect is achieved due to the insulating qualities of expanded clay and gypsum fiber sheets.

Since the work on the technology Knauf "Superpol" does not provide for the fixation of beacons inside the backfill, such floors more evenly settle, without creating pressure zones around the perimeter of beacons.

Also a significant advantage is not too much weight of materials required for leveling the floor using the Knauf dry screed technology, which the floors in old buildings can withstand. And using this method you can level any differences in the height of the base of the floors.

Minuses

The main drawback of the dry screed Knauf is its vulnerability to moisture. This point is associated with the use of gypsum sheets as the main structural element.

One of the characteristics of GVL is swelling with moisture. Therefore, it is believed that in the kitchen, for bathrooms and basements to apply a dry screed floors is not rational.

However, today the manufacturer has developed a waterproof GVL, which is referred to as Knauf-Superpol.A similar innovation is recommended for use in showers and unheated premises, as well as in those where the air temperature drops below +10 degrees.

In all rooms without exception, for maximum durability of the system, it is necessary to strictly follow the manufacturer's instructions and apply steam and waterproofing. In those situations where the leakage still could not be avoided, it is imperative to open the floor and thoroughly dry all layers of the screed, if necessary, replacing the sheets GVL.

One of the significant drawbacks, users consider the fact that the gypsum board laid as a subfloor cracks during operation, falls through heavy furniture and women's heels.

To avoid this effect, the manufacturer recommends not laying as the top layer of dry screed plasterboard sheets. For this it is necessary to use only gypsum fiber (GFL), which will be somewhat more expensive, but will last longer and will not cause such complaints.

The disadvantages include the fact that the dry floor system is able to reduce the height of the room for a decent distance, from 5 cm to 12 cm.It is also necessary to remember that dry floors can be effectively used only in residential premises and are not designed for objects with high traffic.

The minus of "Europol" Knauf consumers call a high price. Among the inconveniences of laying work, builders also mention the large dustiness of the room, which is associated with the characteristics of expanded clay, the need to cut sheets of gypsum sheets, which requires the use of respirators.

Species

Depending on the challenge for the builders, they can choose one of the technological options for laying dry screed, developed by Knauf.

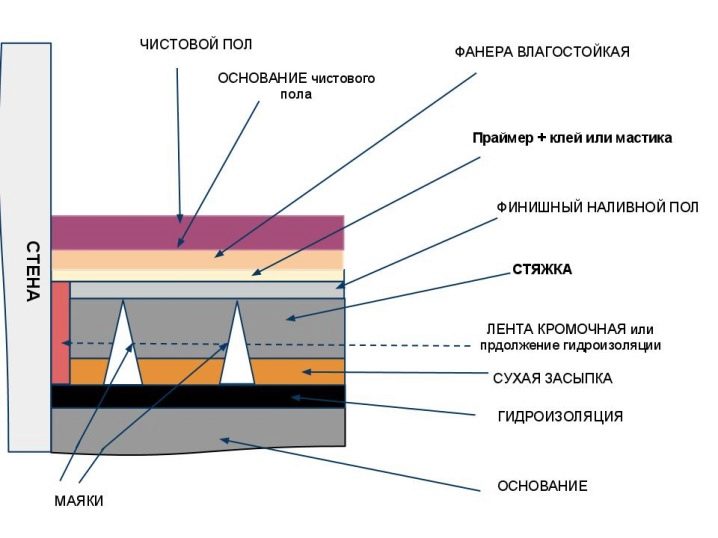

The composition of "Europol" may be as follows:

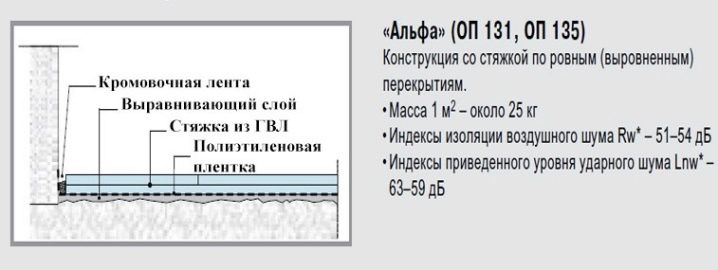

"Alpha"

This is an option in which two layers of gypsum fiber sheets (a super-floor element) are punctured on flat slabs without prior isolation.

"Beta"

In this embodiment, first put on the floor:

- sound insulation layer;

- above two layers of sheets GVL.

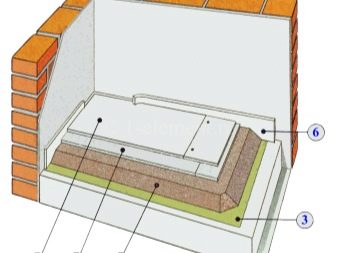

"Vega"

Equalizing option where:

- expanded clay is poured to smooth out irregularities;

- on top of the clay is placed two layers of GVL.

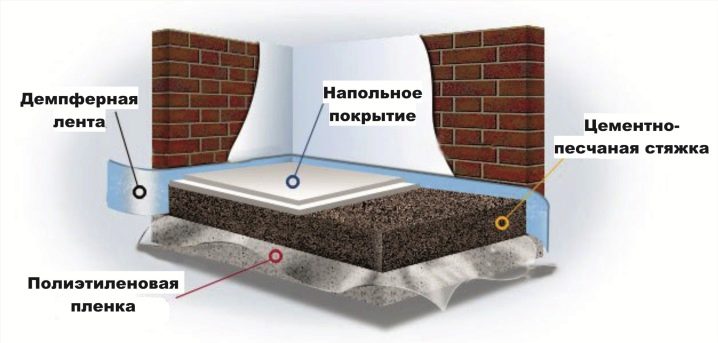

"Gamma"

The leveling option with sound insulation at which:

- filling with expanded clay is made;

- expanded clay is covered with a waterproofing layer;

- fit sound-proof material;

- everything is covered with two layers of GVL.

Most often, the “Vega” variant is used in practice, as it is the most economical and provides the least load on the ceiling.

Training

Installation of a dry screed requires specific equipment and experience from performers. Especially it concerns the leveling works.

One of the most important moments is to determine the maximum level of lifting the floor, since deviations from the horizontal can reach significant values in different corners of the room.

For the most accurate estimate, you should use the laser level. This equipment is very expensive, so in cases where the owner of the building has building skills and wants to level the floors on its own, it will be wise to rent a laser level for a couple of days.

You will also have to rent a specific tool such as the special profile of Knauf Alu-Abziehlatte and the rule for expanded clay, produced by Knauf, and which is a metal strip based on guides.

The peculiarity of the Knauf Alu-Abziehlatte profile is that it allows leveling the surface without placing anything under it. Also, it can be quite simply removed from under the layer of aligned claydite, without disturbing the flat surface.

The following tools are needed:

- screwdriver - it will need to fix the sheets GVL among themselves;

- jigsaw, or jigsaw - will be required for cutting gypsum fiber;

- shovel - needed for filling expanded clay;

- knife - will be needed to cut the waterproofing film.

Not be superfluous will also be a vacuum cleaner, which will be convenient to collect the dust remaining after cutting gypsum fiber.

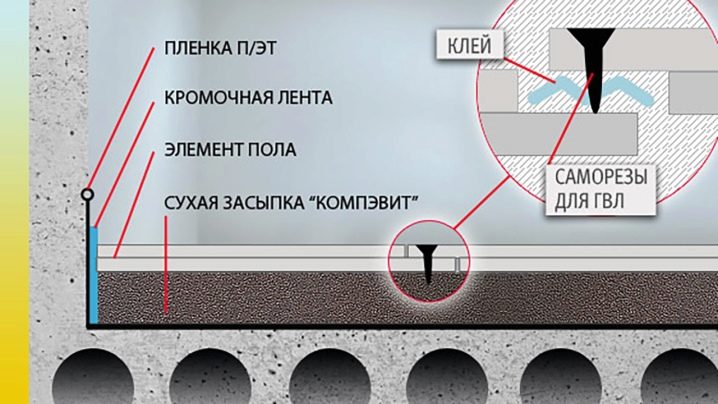

Materials required for laying dry screed (Vega variety):

- vapor barrier film;

- expanded clay fines (preferably using the original material of the company Knauf);

- damping tape;

- sheets GVL (prefabricated superfloor);

- self-tapping screws for GVL (length 19 mm);

- GVL glue;

- putty.

The important point is the calculation of the flow of the expanded clay mixture, which will be required in each particular case. The minimum thickness that can be backfilled is 2 cm.

Calculation of filling is carried out using a laser level, a ruler and a calculator:

- we mark the premises in squares 1kv. m / 1 square. m;

- we set the same height of the floor and mark it on the adjacent walls;

- measure the height of the backfill for each square with a centimeter;

- addition method determines the amount of backfill required for the entire floor;

- since there are 40 liters of material in one bag of expanded clay, divide the resulting volume by 40 and get the required number of bags of backfill.

Calculation of the number of sheets GVL, paroizoliruyuschey film and damper tape can be done directly in the store, informing the seller-consultant the size of the room.

Preliminary preparation of the base consists in sealing serious cracks and cracks.

Laying technology

The process of laying dry flooring Knauf is best entrusted to proven professionals who give a guarantee of their work for at least 6 months. If it is impossible to find such masters, it makes sense to try to master this type of work independently, thoughtfully and responsibly approaching the process.

Stages of work on the installation of the team dry screed:

- We clean the base from dirt and dust.

- Put a mark of the top of the tie with a laser level.

- We lay plastic film for waterproofing, necessarily carrying out the overlap of cloths,fixing them with scotch tape and withdrawing the edges 200 mm above the level of the screed mark.

- Along the perimeter to the walls we fix the edge (damping) tape.

- We scatter on the surface of the base of expanded clay.

- We carry out leveling of expanded clay from the wall opposite to the exit from the room:

- set the leveling profiles at a distance slightly shorter than the length of the rule;

- we set the lower planes of the guides to the calculated level (this moment in the work is especially important);

- using a leveling rail (rule) we align claydite.

- On a flat surface, we carry out the cutting of sheets GVL, starting with cutting the fold to the wall.

- On the surface of the lengthened claydite lay out the walkways of gypsum fiber scraps of at least 50 cm / 50 cm in size.

- Laying GVL start from the wall with a doorway, the movement is carried out from right to left; joints fix on glue-mastic

- We fix each glued layer with screws, the pitch should not be more than 300 mm, the heads of the screws should be recessed to a depth of 1 mm.

- Each new row begins with the fact that we place the element remaining from trimming the previous row, thereby minimizing waste and ensuring the displacement of the end joints of the elements.

- Under linoleum, carpet, PVC laminate, we seal joints and screws with a putty.

- Under the porcelain stoneware, ceramic tiles and tiles made of natural stone, we treat the surface with a primer for glue.

Reviews

Among the reviews that the dry screed method receives, there are both positive and negative ones.

Of the benefits mention:

- speed and dry work performance;

- possibility to level the floor in any buildings;

- disassembly of the structure;

- the presence of soundproofing and insulating effects.

The discontent causes:

- the high cost of original Knauf materials;

- the fragility of the floors in the case when they are trying to perform from a substitute material (drywall);

- the need to dry the floors especially thoroughly in case of flooding.

Successful examples and options

On top of the dry floor you can lay almost any floor covering. Parquet or laminate, carpet or porcelain tile - the choice remains with the owner of the room and is limited only by his imagination and financial possibilities.

For example, lovers of the exotic can install the soft and warm cork floor Knauf, designed specifically for use with a dry screed system.Floor cork is warm and soft tones, typical of natural wood, while having high performance.

Fans of bright effects can pamper themselves by laying vinyl tiles or unusual linoleum over dry floors, creating an unusual and memorable design.

In the bedroom or the nursery, the dry-screed method will allow for quick repairs with the installation of carpet or evaplast, which will make you feel comfortable and warm.

For how to lay a Knauf dry screed, see the next video.