Mixtures for floor screed: types and composition

Creating a high-quality flat floor surface is provided by its screed. There are different types of mixtures that differ in composition. The use of a particular product is due to a number of reasons, among which an important role is played by the type of rough surface, as well as the desired result.

Types and characteristics

There is a huge variety of different types of mixtures, differing in composition and additional components. However, the main types of screed are the following options.

Cement

Cement is taken as a basis. Among the additional elements can be found as natural components, and artificial. There are different types of composition. They depend on the type of floor treatment. These include mixtures for rough coating, final processing, self-leveling mixture, as well as the composition for floating floors.

Plaster

The basis is taken gypsum.Solutions differ in rather small cost, and also are quick-drying. Such coatings have good sound insulation, heat resistance, environmental friendliness. Gypsum plaster coatings are not used in rooms with high humidity. They do not withstand heavy loads, giving cracks.

Dry screed

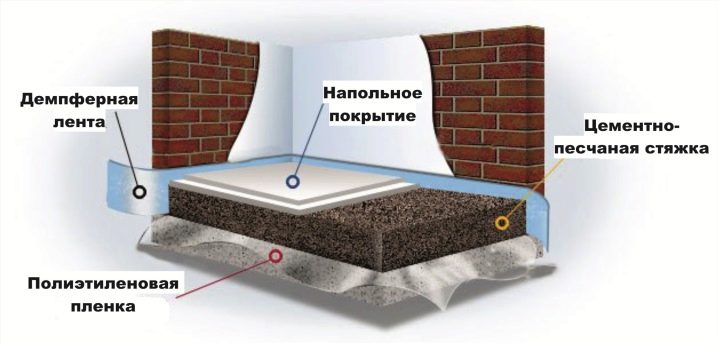

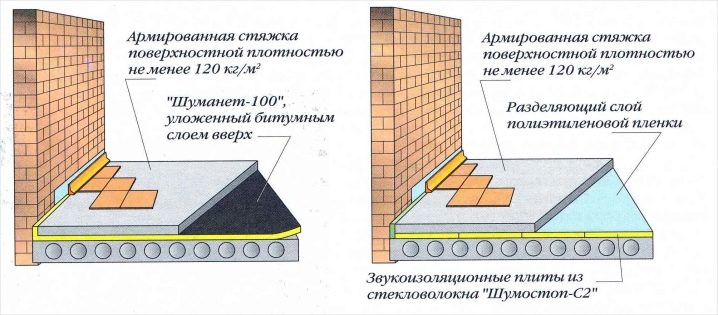

The main feature of this treatment of floors is the lack of water. As a waterproofing can be used plastic film.

Due to the excellent quality, simplicity and convenience in carrying out repair work, ready-made compositions are very popular.

Such compositions for screed bases can be divided into stages of repair work, for example:

- For coarse primary coating. The size of the screed reaches 10 cm. The finished composition is used for large irregularities and poor quality base. The screed is made on the basis of cement, sand, and such components are added as: expanded clay, perlite, granite grains of sand. If the composition contains plasticizers, the thickness of the screed may be less than 1 cm.

- Self-leveling masses are used for the final coating. The size of the coating layer is usually not more than 1 cm.This texture dries quickly, smoothing small irregularities, evenly distributed around the perimeter. During the work with it it is necessary to observe temperature condition of the room (more than 5 degrees). A primer can be used to better bond with the previous coat. All surfaces must be perfectly clean before final coating.

- Universal blends do not require additional coatings., which significantly reduces the treatment time for floors. However, such processing requires considerable experience, skill and qualifications.

Thus, choosing any type of mixture, it is necessary to carefully study its composition.

The compositions

The composition of the screed may differ not only the main filler, but also the number and type of additional elements. Sand cement screed, the main component of which is cement and sand, is used to cover virtually any surface.

Depending on the type of base obtained, the sand mixture contains expanded clay crushed stone, granite, plasticizers. Self-leveling compounds differ in the small size of the grains of sand, which allows to make the surface as smooth as possible.

Cement-sand screed is moisture resistant.However, it should be remembered that it shrinks, as a result of which cracks can form.

When diluted screed fiber and fibers obtained from polypropylene, increase the strength properties of the composition, its elasticity. This option has advantages over the use of steel mesh. Evenly distributed around the perimeter, reliable reinforcement is provided with less labor.

To improve the waterproofing, as well as before the coating of linoleum or carpet, primer can be used additionally. If it is impossible to observe the temperature mode of the room, special components are added to the mixture, which allow operation at cold air temperatures.

Peskobetonnaya screed on the basis of concrete less moisture resistant, as it contains less cement. However, it does not shrink much and is less prone to cracking.

Gypsum mix contains in its composition fine sand and special fibers that increase strength. The plaster on the basis of gypsum dries quickly, does not shrink, but it is better not to use it in wet areas. The dry screed often contains granulated polystyrene or expanded clay.

The presence of such a variety of compositions in which these or other additional components are combined may confuse any buyer. Therefore, before choosing a composition, it is better to get advice from professionals.

Advantages and disadvantages

The appearance of ready-made solutions greatly facilitated the repair process.

Their undeniable advantages include:

- The optimal combination of all necessary components.

- Rapid hardening of the solution.

- The possibility of obtaining the thinnest layer. It can be, for example, 5-6 mm.

- The ability to improve the quality of the solution due to additives. Due to the presence of certain components, it is possible to increase the strength of the surface, and, consequently, extend its service life, extend the operating conditions.

- The low weight of the mixture reduces the cost of its delivery.

- For the application does not require special technical devices.

- Large selection of formulations allows you to choose the right solution for any room.

- Packages contain detailed instructions for use. This allows you to produce work without a special qualification.

The disadvantages are much smaller. Among them are:

- Cost

- The inability to control the quality of the components used, their environmental friendliness.

Before using the finished solution, you must carefully study the instructions on the package.

Failure to comply with the rules may lead to unexpected results. Along with ready-made solutions are applied screeds, made by yourself. In skilled hands, they can easily compete with the most modern methods.

Cooking

Preparation of mortar for screed does not require much work. Knowing the necessary proportions and sequence of actions, you can prepare a mixture that will have a decent quality. In order to prepare a screed with your own hands, you need cement, sand and water. To improve the surface quality, a plasticizer and a polypropylene fiber are added for reinforcement.

To prepare the solution using a special mixer or concrete mixer. The strength of the material depends on the ratio of cement and water. The less water, the greater the strength. Personally made mixture should not contain grains or impurities.

The texture should be homogeneous, so it is very important to respect the proportions that depend on the brand of cement.

- For example, to get a solution of grade 100, you need to take 1 part of cement M300 and 3 parts of sand.

- To obtain a solution of mark 200, you need to take 1 part of cement M300 and 1 part of sand.

Dry and liquid components are mixed separately. Then dry mixture is slowly added to the container with the liquid solution. At the same time all mixed using a special mixer or concrete mixer. If, on the contrary, we begin to add water to the dry mass, then this will aggravate the mixing process and will also contribute to the formation of lumps.

After cooking, the prepared mixture is gently applied to the floor using special equipment for leveling.

Quantity calculation

To determine how much screed is needed for processing floors, a calculation is required. Dry mixes are sold in paper bags of 25 or 50 kg.

First you need to determine the area of floors to be leveled in square meters, then the height of the screed. The bag usually indicates the proportion of material consumption per 1 sq. M. The standard proportion is 20 kg per 1 sq. M with a height of 1 cm. Based on this proportion, a calculation can be made.

For example, if it is necessary to fill the surface with an area of 10 sq. M by 3 cm or 0.3 dm in height, take 20 kg x 3 cm = 60 kg per 1 sq. M. Then 60 kg x 10 sq. M = 600 kg. This is 12 bags of a mixture of 50 kg or 24 bags of 25 kg.The calculation did not take into account m3 of water. As a rule, it is 1/3 or 0.3 of the volume of cement.

Which is better to choose?

There is a huge number of types of mixtures that are produced by various manufacturers. As a rule, each manufacturer says that only his product is the best, so you should not focus on advertising or price. Cheap screed is not always bad.

The choice of a composition should be based primarily on the type of floors, the purpose of the room, the evenness of the base, the availability of communications and heating elements. It is important to consider the operating conditions. At each stage of processing, you can use only a certain type of mixture. For example, compounds with sufficient strength, moisture resistance, sound insulation, thermal conductivity, and the ability to withstand loads are often used for repairs in an ordinary apartment. The type of screed is also determined from the stage of earlier construction work.

Much depends on the type of initial surface. These can be concrete slabs or wooden floors. It is important whether the installation of heating elements is planned or not. In the case of wooden coatings, it is better to avoid water solutions.It is preferable to use plaster, semi-dry or dry screed.

For the initial rough casting of floors suitable composition with the content of coarse sand. Concrete or cement mixtures are often used. There are types that allow to align the irregularities of large sizes. It should be remembered that such a coating takes a considerable time to solidify, from 1 to 2 months. Cracks may occur after shrinkage.

Self-leveling compounds are usually used for the final leveling and sealing of small protrusions. They have a lighter weight and a nice look (as opposed to a rough tie). They dry quickly enough.

Any additional elements allow you to achieve a particular result. For example, when covering electric heated floors, it is recommended to use mixtures with the addition of fiberglass, since the temperature fluctuations of the floors may slightly deform the dimensions of the heating elements. If such parts come into contact with the metal mesh used as reinforcement, damage may occur. Thus, the quality of warm floors will decrease.

Such surfaces require a careful approach to the choice of the mixture.In case of violation of the compatibility of coatings, the quality and reliability of the coating operation decreases, therefore, before using, you should carefully study the instruction of ready-mixes and their compatibility with heated floors.

To be sure in the choice of screed, it is recommended to consult with professionals.

Brands

When choosing a dry ready mix, preference should be given only to quality products. There are well-known brands that have proven themselves on the positive side. These include the following companies.

Knauf

A UBO Knauf cement-based blend using granular expanded polystyrene has good thermal insulation and soundproofing. It is used as a universal solution that does not require additional coatings.

A mixture of gypsum-based Boden Knauf using polymers allows the creation of very thin surfaces from 2-15 mm. Thanks to these mixtures, alignment of irregularities reaching 35 mm in height (even 80 mm) is possible.

- For roughing a mixture suitable Boden 30. In

- Boden 15 is used as a self-leveling gypsum-based plaster with the addition of plasticizers.

- For universal processing use Boden 25 on a plaster basis with the addition of mineral components.

Ceresit

A mixture of CN 80 is used for coarse processing. Universal mortar with the marking CN 175, CN 76, CN 88, Tomsit DG does not require additional coatings and dries very quickly. CN 68, Thomsit D, Thomsit DD is used as self-leveling. Levels bases up to 60 mm thick.

“Founds” “Staroline T-41”, “Mixline T-44” are universal blends. Level up surfaces to 150 mm thick.

Grupa altas

A mixture of "Typhoon master number 44, №45" suitable for primary surface treatment.

- The mix "Typhoon Master No. 41, No. 48" is applied as self-leveled.

- "Typhoon Master No. 40, No. 47" is used as a universal mixture.

"Sarmat"

Mixtures "Optimal", "Sarmat NV-42", "Sarmat NV-40" are suitable for the initial processing of the base with large irregularities.

- The mix "Sarmat NV-45" can be used as self-leveled.

- "Sarmat NV-43" is used as a universal solution.

Unis

A mixture of "Horizon" is suitable for primary processing of the base with large irregularities, and "Horizon-2" is used as a self-leveling. For universal treatment of floors applied "Horizon Eco-Pol."

Bergauf

A mixture of Base, Easy Boden suitable for primary processing of the base with large irregularities. For universal surface treatment applied Boden Inter Gross.

Ilmax

The mixture ilmax X-plan is used as a self-leveling, while Ilmax 6600, Ilmax 6650, Ilmax 6705 gypsplan, Ilmax 6715 rapidplan are used as universal floor covering.

Compositions based on well-known brands have similar components, and differ only in the type of sand. Small grains contribute to the formation of a more liquid consistency. The type of initial surface determines the use of a particular brand.

Universal tools are convenient because they do not require additional coatings. However, their use requires special skills and knowledge. The mixture is better to buy in large stores.

Pay attention to the release date. The earlier it was released, the worse the quality.

Application tips

Before applying the finished screed should carefully read the instructions and follow it clearly. Any deviation can lead to a reduction in surface quality. Special attention deserve the surface of the floors in the bathroom and toilet.

So, the floor covering in the bathroom must meet many conditionsamong which we can distinguish sound insulation, waterproofing, resistance to temperature extremes, maintaining heat, as well as durability and durability. In this case, a floating screed on a cement-sand base is often used. Its quality can be significantly improved by the addition of plasticizers.

Increased waterproofing is achieved by pre-treatment of the floor with bitumen mastic and further application of polyethylene. However, if you plan to do a heated floor, you should carefully study the composition of the mixture and its compatibility with such structures. To cover floor surfaces in a bathroom or toilet, a primer is often used, which provides a more dense adhesion of the coating layers.

It is better to entrust the repair work on the alignment of heated floors with the help of universal compounds, semi-dry, dry or gypsum-based mixtures by qualified professionals. Any erroneous action can lead to an unfavorable result, as well as loss of money and time.

On what types and composition of the mixture for floor screed, see the following video: