Screed floor with expanded clay: the pros and cons

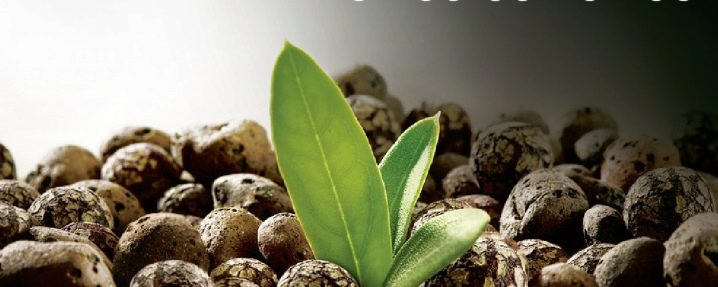

In the harsh conditions of our country with traditionally frosty winters, many people think about the insulation of their houses and apartments: they thicken and compact walls, floors and ceilings. Technologies are improving year after year. The range is constantly updated with various mixtures, dry fillings and insulation. One of the solutions for floor insulation is the use of screed with expanded clay.

Special features

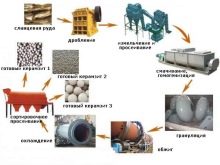

Floor screed is the first layer above the base. Choose it based on the type of room, the purpose of its use, the condition of the house and the intended decorative flooring. Expanded clay is known for a long time, but does not lose its relevance and popularity as an additive in the composition of modern screeds. The mixtures sold in stores, do not lose their properties when using it.This material is made of clay, cleaning it from unnecessary impurities. Porous granules are formed from a liquid consistency solution under the influence of high temperatures.

Advantages and disadvantages

In order to use a clay aggregate, you need to understand what the advantages of such a method are, and why it should be done.

- This screed can significantly increase the height of the floor. In cases when it is necessary to raise the level to a considerable height because of base distortions or simply to reduce the distance between the floor and the ceiling, it is impractical to fill in a thick layer of concrete.

- In old houses and structures with hardwood floors, even with a small layer of casting, the base may not be able to withstand the load of concrete mortar. Backfill floors in this case minimize the risk of damage to floors.

- Even strong drops, pits and cracks can be filled with expanded clay composition and get a flat surface.

- In cold climates, an important advantage is the frost resistance of expanded clay.

- Safety of use is conditioned, among other things, by resistance to heat.

- The material is very durable - does not corrode, does not burn and does not rot.

- For ecological qualities of the coating, excellent vapor and air permeability is required.

- Despite the natural base, expanded clay screed is not affected by microorganisms, fungi, mold and rodents.

- Due to its light weight, the material can be transported without any problems even in large volumes.

- The technology of laying allows to cope with work to the unprepared person. Handling is quite simple.

- Expanded clay additives are very budget. The product is easy to find in stores. Often, those whose choice falls on the purchase of expanded clay, do not want to isolate the coating, but to save on the screed, because concrete mixes are quite expensive.

- The material is moisture resistant. Its water absorption reaches 20%. This means that when flooded, it does not deform for a long time.

- If you need a good sound insulation, then the choice should definitely fall on the clay. At the same time, unlike polystyrene and polystyrene foam, it has greater strength and lower thermal conductivity. The best sound insulation is achieved by adding expanded clay to concrete.

The expanded screed does not have many disadvantages:

- If you make a dry screed, you need to protect the base from water penetration. It does not absorb, creating dampness and mold in the room. Waterproofing is always given great attention when finishing with expanded clay.

- Avoid the same granule size when dry-filled. Heterogeneity will give greater density and uniformity to the coating.

- To retain heat, small granules will be useless, just like a narrow layer of screed. You must raise the floor level by at least 10 cm.

Technology

First of all, you need to prepare all the tools and calculate the right amount of materials.

You may need:

- bucket;

- mixer, construction mixer or just a stick;

- brush or needle roller;

- spatulas;

- the rule;

- construction beacons;

- building level (water or laser);

- ruler and special marker;

- brushes and rollers.

At the initial stage, the foundation of the floor should be prepared. If you are doing repairs in an old apartment or house, gently remove the old tie with a scrap or punch. Next you need to get rid of debris, dust and dirt. Evaluate the opening ground. It should not be chipped, cracked, oily stains.If you find gaps more than 1 mm wide, they should definitely be repaired.

In this case, it is recommended to pretreat them with a primer, and then apply one of the composition options:

- cement-sand mixture;

- putty or sealant.

Priming deep penetration is necessary so that the mixture is properly set to the surface of the base. Grease stains should be removed or cleaned. Next, treat the entire surface of the floor using a primer.

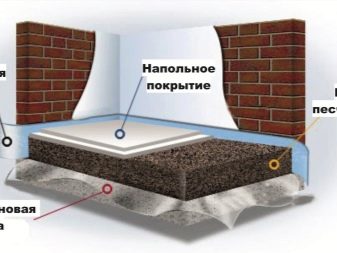

The next item will be the selection of the zero mark. This is the definition of the height at which the top layer of the floor covering that we create will be located. This can be done using laser or water levels. As a rule, it is set no higher than 15 cm from the base. The device flooring involves the laying of a waterproofing layer. It may seem to many that this stage is not necessary in the living rooms in an apartment, but this is not so.

Waterproofing can be done in several ways:

- If you live in a private house, it is better to apply the long-known laying of roofing material. Layers overlap, winding on some height on the walls.The base is pre-coated with bitumen mastic for gluing the web material to it. Seams also need to be treated with mastic.

- In apartments it is enough to apply insulation with a film. Choose dense materials for layer strength. The film is also fixed with an overlap and with calling on the walls. Glue it with construction tape. To minimize the impact of coating layers, the perimeter of the room is covered with a damper tape.

- It is also possible to use a waterproofing coating of special water-soluble mixtures. They process the entire surface of the floor and the bottom of the walls.

The thickness of the layer is indicated in the recommendations on packages. Next you need to give the coating to dry. It takes more time than previous methods. Then self-laying of the lightweight aggregate layer is performed. When the coating is completely dry (the period of drying varies depending on the composition of the concrete mix), you can proceed to the finishing of the floor covering.

Types of backfill

An important indicator in relation to expanded clay is its density. It depends on the size of the fraction used. In construction, GOST 32496-2013 is applied,which regulates the technical features of the expanded clay granules, but due to the optional certification, manufacturers can produce various options according to their specifications.

The most common division is:

- Expanded clay gravel. The sizes of granules are large - 20-40 mm. The lightest backfill is obtained from granules of this size.

- Crushed stone smaller. Its particles have sizes from 10 to 20 mm. They are usually produced by crushing gravel.

- Expanded clay size less than 10 mm. All remnants of expanded clay are included in this category.

If we talk about the insulating properties of expanded clay, it is advisable to use gravel and rubble, and use the waste to obtain a more porous coating.

Fill Ways

In total there are three ways to screed with the use of expanded clay. It is necessary to analyze the method of use and the advantages of each of them in more detail.

Semi-dry screed with expanded clay

This method is used in cases when it is necessary to raise and warm the floors in the room. To achieve thermal insulation, the expanded clay layer must be at least 10 cm. Here it is important to take a large fraction of the backfill - at least 20 mm.If it is important for you to only raise the floor to the required level, you can use smaller particles. In this case, waterproofing is necessary in order to protect the layer of expanded clay from moisture. Beacons are put up to the required height, and claydite is backfilled. Walk through it as a rule to tamp and level the layer.

After that, you should stop pouring concrete screed. Can be used cement-sand mortar or a special mixture. For convenience of work, it is better to shed a claydite layer with a concrete mix that is highly diluted with water - cement milk. This will prevent the floating of grains of claydite and facilitate pouring the main solution. Also for these purposes may be suitable for laying a layer of granules with a film. Only in this case, the laying should be done very carefully so that the film does not break.

These two methods are also needed to ensure that the moisture from the concrete layer goes less into porous expanded clay granules. Then the coating will be more reliable and durable. For pouring concrete solution, you can use a reinforcing mesh. So it will be easier to gradually fill the layer with areas and align it to get a smooth surface.

Claydite

This is the so-called wet screed.In this case, it is necessary to carefully measure out all the irregularities of the base and decide what thickness the screed layer will be. This method is beneficial to apply if you have to raise the floor level to a considerable height, as well as to save concrete mix. Expanded clay is combined with peskobeton, diligently stir the composition and spread it over the floor. It is better to first impregnate the clay granules with water so that the consistency of the mixture does not turn out to be too dry. Mixing is best done using a construction mixer, because no blades and sticks do not achieve a uniform consistency without clots and lumps.

To reinforce the expanded clay aggregate, you can use a reinforcing mesh, and as beacons - any slats that are easiest to reach. The grid should not reach a required level of height by a couple of centimeters. Then distribute the solution evenly over the grid, aligning it with the rule. After the laying of the mixture is not wait until it dries. Prepare a solution for the upper leveling layer. This may be a cement-sand screed, and self-leveling floor.It is already applied to zero, aligned with the rule and left to dry.

About a day is necessary to remove the lighthouses. Apertures from them surely process a primer and fill in with cement. Plus, expanded clay-cement screed is that it can be poured without any problems with your own hands, all proportions are done by eye until you get the desired viscous consistency. Such a screed can be part of a multi-level system and used as a draft under the floor. It may also be sufficient for laying a finishing covering that does not require a smooth base (for example, a tile floor).

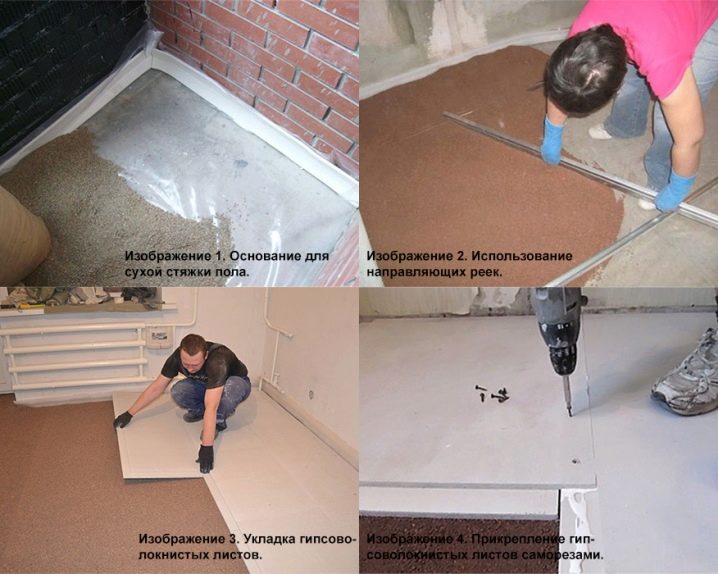

Dry screed floor with expanded clay

If the semi-dry method is a combined screed, the filling with expanded clay granules does not require subsequent pouring with any solutions. The base is prepared as usual, but any possibility of moisture ingress on the waterproofing layer should be excluded. Lighthouses are set to the required mark. The minimum thickness of the expanded clay layer using this technique is 5 cm. The granules should be selected of small or medium size, it is desirable to combine different sizes to distribute the layer more evenly with fewer voids.It makes no sense to use small wastes, because they will need a huge amount, but they will not create the necessary insulating effect.

It is better to divide the surface into strips with the help of wooden slats - it will be easier to level the granulated layer, and to lay the following materials. Do not tamp with expanded clay, and gently roll. Next, you should lay a layer of moisture-resistant drywall. If the sheets are thin, it is better to lay them in two layers, gluing them together, and the seams should be coated with a putty. You can also use waterproofing mixtures. After the installation of drywall is necessary to cut off all protruding pieces of tape or film.

This kind of screed has a lot of advantages:

- The smooth surface is suitable for applying any kind of finishing coatings.

- Layer can tolerate high loads.

- The flooring is quite light, so it can be used on old dilapidated floors without any risk.

- Thermal insulation at height. There is no need to install underfloor heating on an expanded clay cushion.

- Work can be done very quickly, and immediately after the end, you can break into the next stages of repair.

- Dry screed gives excellent sound insulation.

- The coating is not deformed.

Sometimes builders propose to use expanded clay for bedding in the roughing screed directly on the ground instead of sand or rubble. This can be done only if the groundwater level is low, otherwise increased humidity will lead to negative consequences for the entire climate in the house, and good heat saving here will not play its role.

Layer thickness

The thickness of the coating will depend on many aspects: the size of the granules, the level of required floor raising, and the functionality of the screed. The minimum layer of screed with the use of expanded clay is better to take at least 3 cm. Depending on the method of coating the layers can vary greatly. For filling with keramsit concrete in order to raise the height and leveling, a thickness of 3-5 cm will be enough. If you want to get an insulating effect, the layer must be at least 10 cm.

Light screed with a thin layer is better placed with the use of small granules. This saves money and reduces workload. In the case of dry backfilling, fine fractions with a layer of 3-6 mm can be used to level the floor, but for thermal insulation it is necessary to lay a layer of special materials.If you are interested in, first of all, heat-saving properties and anti-noise effect, then you need to fall asleep 10-15 cm from the base, and take large fractions.

How long does it dry?

This question concerns the wet and combined type of screed. Peskobeton dries long enough. With a mixed type of screed, you must wait at least 14 days before the top layer dries to continue the finishing work. Full strength and the ability to perceive the maximum load the coating will acquire in 28 days. However, these recommendations vary depending on the layer thickness. If you used the wet method, and the thickness of the screed is more than 5-6 cm, then you need to increase the period to 6 weeks. In any case, if you doubt the timing of the drying of the coating, cover the area of the floor with a film and press it in several places with wooden slats.

If after 1-2 days condensation appears, the screed must be dried further, because if all the accumulated moisture does not evaporate, the strength and integrity of the coating will be jeopardized. Such a floor is no longer reliable and durable. If you are preparing a mixture with the addition of modern components or special plasticizers, this increases the chances of obtaining a high-quality surface and, of course, reduces the drying time, sometimes even twice.Information is usually indicated on bags with ready-made formulations. This method is more expensive, but more guarantees are given. It is only necessary to choose quality mixtures of proven manufacturers.

How to calculate the flow?

The consumption of expanded clay for different rooms will depend on the strength of the base and its maximum load, the thickness of the layer, your preference for thermal and sound insulation. The more clay you add, the more heat will be able to maintain the coating, but the strength will suffer. For a wet solution, it is better to take expanded clay filling and concrete in proportions of 1: 1. The amount of granulated material is measured in liters, and not in kilograms. Usually, a layer with a thickness of 1 cm is taken for calculations. It is necessary to determine how many liters of expanded clay are needed to cover 1 square meter. m square. This value will be equal to 10 liters.

To find out the consumption of expanded clay per standard flat area (usually 20 sq. M is taken), you need to multiply 10 liters by 20 sq. M. m. It turns out 200 liters. The height of the layer is chosen based on the purpose of the room. On the ground floor and in cold rooms, a height of 10 cm is chosen, in other types of housing a layer is taken from 3-4 cm.Thus, in a new building in a one-room apartment with an area of 40 meters, you can apply a layer of 5 cm. So, for 1 square meter. m will account for 50 liters of expanded clay. Therefore, the entire area of the apartment will require 40 * 50 = 2000 liters - 40 bags of 50 liters.

Kitchens in "Khrushchev", having a small area, require a layer of 3 cm. For such a room, you will need 150 liters of expanded clay. It must be remembered that the surfaces may have irregularities and deviations, therefore the calculation formula is only approximate. It is better to take expanded clay with some margin. For pouring a layer of concrete, an approximate consumption of 1 cu. m of expanded clay will require 300 kg of cement "M500" and the same amount of sand.

Reviews

Experts note that with a dry screed, you can get a perfectly flat and reliable surface. Subsequently, the premises with such a finish perfectly store heat. Wet or combined pouring, in the opinion of untrained repairmen, does not cause any special problems in transportation and preparation of solutions. In the combined method, the convenience of working together for the preparation of both the expanded clay mixture and the top layer is noted. The floor is strong and warm with a layer of 10 cm.Finishers advise that when drying such a coating, sprinkle it periodically with water so that the concrete base does not crack when it dries, and avoid drafts in the room. In new buildings, expanded clay floors are very popular, as there are no problems with the delivery of building materials to the upper floors.

Successful examples and options

The process of semi-dry pouring of a large area is shown below. The work is carried out in stages. Screed reinforced reinforcing mesh fixed concrete solution. Long rule aligns the top layer.

The following is a diagram of the dry backfill with the subsequent installation of drywall. As a waterproofing film is used. Damper tape for the correction of deforming load stands for the boundaries of the flooring on the walls.

The illustration shows the alignment process of the expanded clay layer in a wide room. Dry filling is evenly distributed, and with the help of substrates and the rules are carefully leveled, not tamping.

Below is the process of laying a wet screed on the balcony. Large granite clay is laid for additional waterproofing.This is a rough layer of the screed because the surface is too uneven due to the size of expanded clay.

How to make a screed with expanded clay, see the following video.