Cement-sand screed: features of choice and pouring

Cement floors are the main type of coatings used in virtually all types of buildings. The structure of this system assumes the presence of several layers that perform various tasks. One of the main elements of this design is a leveling screed. Depending on the composition, the material may have different technical properties.

The cement-sand screed not only levels the surface, but also strengthens the base.

Special features

Cement-sand screed is a decorative layer of a special solution, located on the surface of the subfloor. The thickness of the structure depends on its purpose. Screeds can be formed both on concrete and on compacted soil.

In addition to leveling the floor, these systems solve several important tasks:

- Screed increases the insulation of the floor, which is important for surfaces on the ground or between floors.

- Strengthening the base. The composition of the screed includes cement, which forms strong bonds between the components. This allows you to increase the strength of the subfloor.

- With an extra layer, you can hide pipes, electrical cables, or other communication lines.

- If the screed is formed in the bathroom, then you can create the necessary slopes (for example, to collect water).

One of the advantages of sand-cement screeds is their simplicity and quick installation. Even an inexperienced person who has never worked with these materials can cope with this task. The only drawback of such structures is a large weight, which does not allow using them for wooden floors and other fragile bases.

Types and characteristics

Cement-sand screed is classified according to several criteria. Depending on the application technology, these structures are divided into the following types:

- Wet screed. The formation of a protective layer is carried out with the help of liquid solutions, which can themselves evenly distributed over the floor surface.Among the disadvantages of this technology can be identified a long period of drying and thorough preparation of the base.

- Semi-dry. Screeds of this type are also solutions, but they contain the minimum amount of water. Preparation and application of these mixtures is carried out using special devices. These mechanisms evenly distribute the tie between the beacons. This type of screeds can significantly speed up the drying of the surface, which makes it possible to optimize the construction time.

Today, there are ready-made cement formulations, in which you only need to add water.

This type of materials has several advantages over the compositions that are prepared independently:

- All components are already carefully prepared, which allows you to quickly get a solution with the desired strength parameters.

- Manufacturers add to the composition of several types of polymeric binders, which allows to increase the strength and service life of the screed after solidification.

- Polymer-cement mixture can be purchased at almost any hardware store. Manual preparation is not always possible due to the lack of ingredients.

Depending on the method of laying cement screed can be divided into the following types:

- Connected. Structures of this type are mounted directly on the concrete subfloor. At the same time, the cement mortar forms a strong bond with the base, strengthening and supplementing it. This type of screed is the most common. It is perfect for leveling concrete floors in high-rise buildings. In order for the formed layer to serve for a long time, it must have a thickness of at least 3 cm. In another case, the material after curing will quickly crack and become unusable.

- Incoherent. Screeds of this type are separate surfaces that do not have a strong bond with the subfloor. The minimum thickness of the concrete layer should be 5 cm. Installation of the mixture in such cases is carried out either on polished concrete or a thin layer of hydro- or vapor barrier.

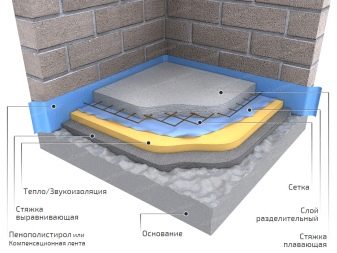

- Floating The solution in such systems is applied to a thick layer of insulation. It does not allow to form a strong bond with the base. Often mineral wool or other similar material is placed between the subfloor and the screed. After solidification, the layer of concrete will sag,therefore, its thickness must be at least 65 mm.

Composition and proportions

Cement-sand screeds are great for leveling surfaces.

The composition of these substances is quite simple:

- Cement. To obtain screeds, products of various grades are used, which allows you to change the strength of the solution.

- Sand. The technical characteristics of the screeds depend on the quality of the products used. The best option is river sand, which contains the minimum amount of clay.

- Plasticizers. Fillers are added to the screed composition only in semi-dry mixtures directly at the plants. As such products, fine crushed stone, marble chips, expanded clay and other substances are used.

Moisture-resistant mixtures can include several types of polymers, which contribute to the formation of the necessary properties.

The basis of the classic screeds are cement and sand, which are thoroughly mixed together with the addition of water. The proportions of such a mixture depend mainly on the brand of cement and the strength of the screed. For the preparation of a solution of cement brand M400 using cement and sand in the ratio of 1 to 3.

The volume of water is taken with the calculation of 0.5 liters per kilogram of cement.

But this percentage allows you to get a screed, the strength of which is suitable for residential buildings. If the solution is used in industrial facilities, then use other recipes. At the same time, the amount of cement is significantly increased in order to obtain the necessary indicators of strength and resistance to external factors.

Calculation and thickness

The thickness of the screed depends primarily on the draft base and the desired technical characteristics, which should receive a finishing floor. Often this value varies from 3 to 8 cm depending. When forming a layer, do not make its thickness less than the minimum, as this will lead to the peeling and cracking of the concrete. Thin surfaces are always quite fragile and not able to withstand significant loads.

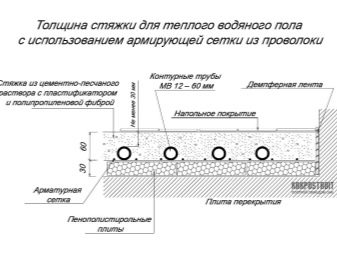

If you want to fill the solution with a thickness of more than 7 cm, then it must be reinforced. To do this, inside the mixture is placed a metal or plastic reinforcement, which is connected in the form of a grid. An alternative option for the wire will be a fiber-based fiber tie, which increases the ductility and strength of the surface.

To calculate the consumption of the screed, you can use the following algorithm:

- Initially, you should know the density of cement and sand. At the same time, we do not take into account the volume of water, since the liquid weighs 1000 kg per m3. In turn, this indicator for a cubic meter of cement is 1300 kg, and for sand - 1600 kg.

- Knowing the density of each component, it is necessary to calculate the required volume of solution for the formation of a particular layer of screed. For example, a mixture of a thickness of 5 cm and an area of 1 square. m occupies a volume of 0.05 m3. When the area of the room has a size of 100 m2, the total amount of the solution will be 5 m3.

- At this step, it is necessary to calculate the parameters of all components of the solution, to obtain the desired total amount. Make it pretty simple. The amount of water is equal to half the volume of dry ingredients. Therefore, we need to get 2.5 cubic meters of dry mix of cement and sand. With a ratio of 1 to 3, the volume of the first component will be 0.625 m3, and the second - 1.875 m. Then we simply multiply these values by the specific weight of each of the materials. As a result, the cement mass will be 812 kg, and sand - 3 thousand kg.

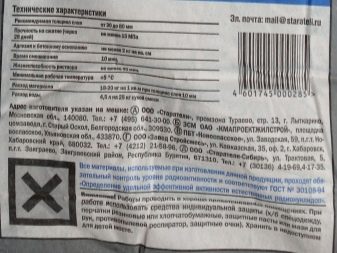

As for the factory mixes, it is much easier to find out the material consumption here. Most manufacturers indicate the rate on the packaging.The optimal indicator here is 20–22 kg of product per 1 m2 with a layer thickness of 1 cm.

But it all depends on the method of preparation and components used.

Fill technology

Arrangement screed is quite a simple process that can be done by hand.

Leveling the floor involves the following sequential operations:

- Preparation of the draft basis. Installation of the solution should be made on a clean surface. Therefore, you need to remove all dust and debris with a vacuum cleaner. If the old plinth is nailed to the old floor, they must be dismantled.

Before applying the mixture, it is desirable to cover the base with special primers that will increase adhesion between materials.

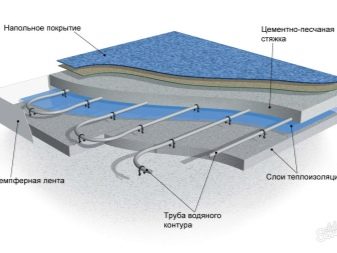

If you plan to install a heated floor, then it is desirable to lay waterproofing on the rough surface. For this you can use both special mastics and plastic wrap.

- Markup. The surface of the screed must be flat. To get this result, you should mark the walls according to the horizontal plane. It will help to solve this problem laser level, with which it is easy to make smooth marks.

- Installation of beacons. These designs are strips that help align the tie in one plane. Therefore, their location should be approached responsibly. As beacons use a plastic or metal profile, which is placed in several rows parallel to one of the walls. The distance between them should not exceed 2-3 m.

Structures are fixed with cement mortar or plaster. It is important that the ends of the lighthouses coincide with marks on the walls and lie strictly on the level (horizontally). At the same time, it is necessary to check both the upper part of the lighthouses and the plane between them.

- The procedure ends with the formation of the screed. For this, the prepared solution is placed between the lighthouses. Do not immediately use a lot of mixture. After application, it is aligned with the rule (long, flat bar), which should be the same length as the distance between the beacons. If the thickness of the mortar is significant, a reinforced mesh is formed on the floor before it is laid.

Drying time

A feature of cement-sand mortar is quite a long period of hardening. Many experts argue that The screed of average thickness dries out in about 28 days, if several basic conditions are met:

- Humidity. The best indicator is 60-70% of moisture over the entire drying period. If this value is less, then the water will evaporate very quickly, and cracks will form.

- The temperature should vary in the range from 20 to 25 degrees. For any other values, the substance will either begin to crack, or it will dry longer.

The drying time also depends on the thickness of the concrete layer. The mixture, having a thickness of 4 cm, dries completely in 28 days. But if this value is increased to 60-80, then this screed will dry only in 2-3 months.

Recommendations

The quality of the screed depends not only on the used sand or brand of cement.

To get a durable surface in an apartment, you should follow a few simple rules:

- The first 3 days of the screed should not be subjected to any mechanical stress. Only on the 4th day, you can remove the leveling beacons and fill the holes with concrete mixture.

- To prevent cement from cracking, it is advisable to water it several times a day. To minimize evaporation, you can use a plastic film, which is simply laid out on the surface of the screed.

- Wait until the cement has completely set.If this is not done, then over time the surface will begin to subside or crack.

- When laying the solution, be sure to attach the damper tape to the walls around the perimeter of the room. It will allow the mixture to expand normally when the temperature changes.

- Be sure to calculate the load that a certain layer of screed will create. It should be less than the strength indicators overlap the rough base. If the load is much greater than the optimal performance, the thickness of the solution should be reduced.

Installation of cement-sand screeds should be carried out only after preliminary calculations of all the technical characteristics of the working layer.

How to make a floor screed with your own hands, see the next video.