Reinforcing mesh for floor screed: how to choose?

In the construction for strengthening the floor is widely used screed. It is a layer between the subfloor and the finish. Of great importance when pouring the screed has a reinforcing mesh, which is placed under the screed base.

Thanks to the grid, the floors become even and durable, acquire excellent insulating characteristics. Thereby significantly increases their lifespan.

Special features

The screed is made of concrete, the composition of which may be different - cement with sand, sand with rubble, foam concrete, expanded clay concrete and other mixtures.

There are the following types:

- classic screed.It is poured on the subfloor, and it is completely bonded to the base (ground or base plate);

- monolithic coating is created with a combination of various concrete, and fittings are placed on special supports, and not on the floor. With such a screed usually put several layers of the grid;

- Floating screed - the concrete is poured onto the insulating material that covers the base of the floor. Reinforcement is mandatory when forming a subfloor. However, reinforcing mesh can be used to strengthen any screed. This is a universal element that is used when pouring floors and plastering of walls, during finishing works.

Reinforcing mesh has the following features:

- promotes uniform distribution of the load on the floor;

- reduces vibration and dynamic load on the coupler;

- prevents the formation of chips and cracks on the screed;

- increases the density of the concrete composition;

- saves the amount of concrete used;

- ideal for floors with large differences.

When is it applied?

Reinforcement of the screed should be used to make the floor smooth, to prevent cracks, chipping during drying and shrinkage of the floor, and if the future floor will be subjected to heavy loads.When reinforcing the mesh is fixed above the surface of the floor and covered with concrete mix.

The reinforcing mesh will save concrete from destruction and deformations.

The mesh should be applied in the following cases:

- when arranging the floor with an insulating layer, for example, when arranging a warm water or electric floor;

- if the foundation of the floor is mobile and covered with rubble or expanded clay, then the grid will act as a support;

- if the floors will be exposed to moisture, vibration, pressure and temperature changes in the future (garages, utility blocks, industrial buildings, in the house - under the fireplace, in the kitchen or in the bathroom);

- to strengthen the floor, if the thickness of the screed is not higher than 5 cm.

Types: advantages and disadvantages

Reinforcing mesh is made of metal, plastic, fiberglass. Cell sizes and wire thickness have different parameters. Quality of a grid depends on them. For example, the smaller the cell size, the stronger the mesh.

Another important point - correct selection of the type of reinforcement. Long fittings are made of fiberglass, metal, polypropylene. Dispersion reinforcement of steel, basalt and fiber. Should consider more details.

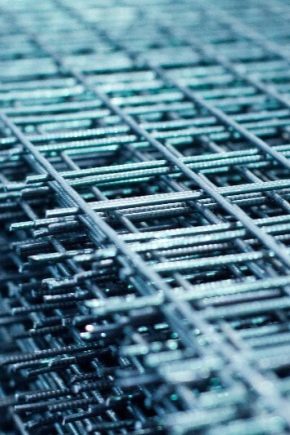

Metallic

Such mesh can be twisted or welded from wire. Due to the rigidity of the material, it will provide strength to the floor covering, help eliminate cracks when the drying solution dries. Not afraid of changes in temperature.

Suitable for screed on the ground, that is, for the subfloor.

Metal mesh is often used in industrial buildings. It has considerable weight, high price and may be subject to corrosive processes. Therefore, when buying it is necessary to choose a grid covered with polyvinyl chloride, or stainless steel.

In general, when self-reinforcing, you can use the following samples of steel with galvanization: woven, reinforcing, masonry, plastering, galvanized, all-metal.

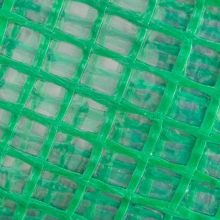

Plastic

This mesh, unlike the metal one, is not afraid of rust and chemicals, is more elastic, has light weight and an acceptable price. It is ideal for use in screeds up to 8 centimeters thick and with a small load. Elasticity allows you to withstand tensile loads during shrinkage.

Polypropylene mesh is easily cut and stacked, it is sold in rolls.An additional advantage is the fact that plastic does not interfere with the operation of equipment and communication facilities.

However, plastic nets Do not use in areas with a large load on the floor.

More suitable for self-leveling or underfloor heating, but not for the floor in draft form.

Fiberglass

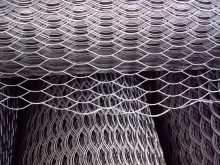

Glass cloth mesh is made of aluminoborosilicate glass, to which is added impregnation of polymers. It protects the material from the effects of the chemical composition of the cement mixture.

Such material is light, inexpensive, resistant to corrosion, plastic, durable, has low electrical conductivity. However, it cannot withstand high temperatures, in conditions of more than 180-200 degrees a fire may occur.

The fiber-reinforced screed will protect the flooring from small cracks in the form of cobwebs. It consists of fiberglass, basalt, steel, polypropylene fibers. The fibers are introduced into the concrete solution and when it hardens, they form a solid monolith. In combination with any mesh reinforcing fiber will create a very strong tie.

Fiber made of glass and polypropylene is suitable for light screeds, metal fiber for floors with a significant load,for work on the air, it is better to choose a basalt fiber.

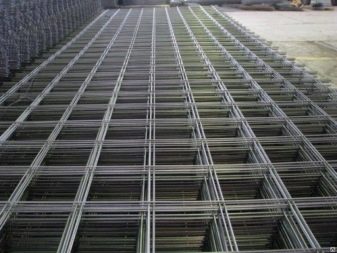

Sizes and consumption

The metal mesh is made of wire brand BP-1. This abbreviation means that it is made of steel and contains little carbon in its composition. The wire is connected by a spot welding method, the diameter varies from three to six millimeters. Cells in the form of squares or rectangles.

To strengthen the screeds, wire mesh with a minimum thickness of 2.5 mm is used. Steel wire, the nets themselves are produced in the form of cards, sheets and rolls. Dimensions of a standard sheet - modifications 0,5 / 1,5 / 3/4 meters by 2 meters.

Products with a wire thickness up to 2.5 mm are produced in rolls, the roll width is up to one and a half meters, the length can be up to 25 meters. Frequently used cell sizes are 50x50 mm, 100x100 mm, 150x150 mm and 200x200 mm. Manufacturers put special notches on the surface of metal wire, this increases the adhesion of the mesh with the concrete mix.

Approximate consumption of metal material: weight 1.45 kg per m2 with a sheet size of 100x200 cm and a wire diameter of 3 mm.

The larger the diameter of the wire and the smaller the cell size, the greater the weight of the mesh and the stronger the reinforcement.

Polymer mesh, fiberglass and fiber are much lighter than metal mesh. Plastic nets are produced in rolls of up to 60 m and a width of up to four meters, the mesh with a density of 120 g / m2 and a mesh size of 45x45 mm is best suited for reinforcement.

Fiberglass has a diameter of 4-14 mm, is made in the form of webs or rods. Fibers are interlaced. Can be ribbed or quartz coated - for better adhesion to concrete.

Only fiberglass is used to reinforce screeds. with alkaline impregnation, or made of glass that is resistant to alkali.

Fiber is a small fiber with a length from 6 to 20 mm, less often metal - 50-60 mm. They are added directly to the solution with the calculation of 1 kg per cubic meter of concrete mix.

To calculate the consumption of material should carefully examine the description of the goods, which always indicate the data on the batch number, weight, density, size of the roll, sheet or fibers. Knowing the area of the room, you can independently calculate how much production you need.

What to reinforce?

The technologies used to fill the floor screed are described in such documents as “Building codes” (SNiP), standards for housing construction, recommendations on the design of flooring.

According to the SNiP concrete reinforcement is performed with a screed thickness less than 4-5 cm, and if you need to increase the strength of the floor in warehouses, industrial buildings, garages. If a large load on the floor is predicted, choose a grid with a wire of large diameter. It is better to use for reinforcement a grid with small cells, but with a thick wire.

The mesh is located strictly in the middle of the screed. If an insulating layer is put, then the distance from the walls to the grid is made about 30-50 mm.

Products from polymeric grids and fiberglass are well suited for underfloor heating in individual construction, but they are not used for subfloor on the subfloor. Fiber will make the concrete mortar durable and protects against small cracks during shrinkage, but it will not withstand the tensile and flexural stresses and will not be suitable for screeds on the ground.

Metal mesh is ideal for arranging screed on a rough base. They are considered the most effective if a large and constant load on the screed is expected. Sometimes stacked double layer.

Piling

It is better to work in a building with a room temperature not lower than 20 degrees, and where there are no drafts. It is more practical to do all the work on arranging the screed within one or two days.

The process of reinforcing the tie with nets occurs in several stages:

- First you need to decide on the type of screed, mesh and measure the area of the room, calculate the amount of material required. It is worth remembering the overlays, add an area for trimming;

- if the screed is placed on the subfloor, first, remove the top layer of the soil, and secondly, tamp the substrate of claydite and sand (up to 10 cm);

- when working with old floors, the concrete is dismantled and the surface is cleaned of dirt. Then treated with solutions against mold and primer;

- if the draft floor has large drops, then the surface needs to be leveled with concrete, or make expansion joints. For monolithic screed stack concrete, sand or crushed stone. Then they are covered with a film;

- if the screed is floating, it is necessary to put a layer of waterproofing or insulation. Warming of the floor is carried out with the help of expanded clay, mineral wool or polystyrene foam. On both sides, the insulation is protected by a waterproofing layer of film, roofing material or membrane.

Often the concrete mix is poured on penoplex or penofol. All these materials should be put overlapped and put on walls up to 15 cm;

- Special profiles or beacons are required to install a reinforcing layer.It is better to fix them in one and a half meters from each other, to make a distance from the wall from 10 to 30 centimeters. This is done so that the grid is in the thickness of the concrete;

- in the water heated floor system, the height of the screed is 45-50 mm greater than the diameter of the pipes;

- then make the laying of the reinforcing mesh on the beacons with the imposition of a single cell. Then place the elements of warm floors (if necessary);

- further poured concrete solution and leveled. For a couple of days, the floor surface is moistened with water. After 6-7 days, the beacons are removed, the elimination of voids occurs by pouring the solution. After one month, the floor will be completely ready for finishing;

- the best option is the use of cement and sand in the ratio of one to three, with the addition of fiberglass;

- It should be noted that the fiber, in contrast to the mesh, is added to the cement, then poured with water. Thoroughly mixed mixture is applied to the substrate and flatten;

- Toppings can be used as a topcoat. Topping consists of cement, dyes and various plasticizers, which give it strength. This composition is applied to the top layer of concrete to harden it.The method of application can be both styling and rubbing.

With proper reinforcement, the screed will last more than a dozen years and will not require repair.

Recommendations for selection

The need for reinforcement of screeds in the apartment and in a private house often arises for such rooms as a bathroom, kitchen, bath. Here are suitable mesh of polymers and fiberglass. For the garage and the warehouse is better to choose the metal mesh, they are the most reliable.

You should purchase reinforcement parts which are compatible with concrete mix.

They should not be covered with paint, grease or dirt.

In the store, check the products for defects, how well the welding is done or the mesh elements are connected. Perhaps there are signs of corrosion, cracks or the material may be thinned in some places.

The best option is Purchase mesh with small cells and thick wire. To strengthen the floor in the apartment, an excellent mesh of fiberglass or galvanized wire with a diameter of 4 mm, with cell sizes of 100 x 100 mm or 150 x 150 mm, is ideal.

Successful examples and options

Fiberglass reinforcement nets are installed on special beacons, they do not touch the draft layer.The base of the floor is covered with an insulating layer of polyethylene film. It is easy to work with such a mesh, it is light and plastic, therefore it is convenient when laying.

Fiberglass products are not afraid of water and various chemicals in the concrete mix. Another plus is that in the future it will not create radio interference for cellular communications or the Internet.

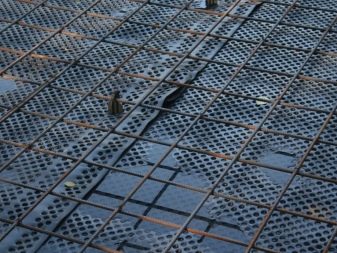

If the floor will experience stress, then it is better to use welded metal mesh for reinforcement. The gulf of concrete mortar begin parts from the far corners, then finally level the entire surface.

Warm floor be sure to reinforce. For the reinforcement of the screed used metal welded mesh with a large cell. At the base of the floor is a heat insulator, which will reflect heat from the base upwards. Then installed beacons for reinforcement. On them the grid is laid. Then the tubes are laid through which the warm liquid will flow.

For the insulation of floors in a wooden bath, fiberglass mesh is used. It does not corrode and is not afraid of mold. Under the base of the floor there is a reflecting screen of aluminum foil and polystyrene foam.However, it is worth remembering that in the bath when arranging and pouring the floor should be left special holes for the drain hole and drainage.

The photo shows the finished industrial floor, it is reinforced with metal mesh and is filled with concrete mix with the addition of polypropylene fiber. This floor has double strength, it is resistant to shock, stretching and constant loads.

To learn how to install a reinforcing mesh correctly, see the following video.