Finishing walls with gypsum plaster: the pros and cons

Plastering walls with plaster composition has found wide application in removing surface irregularities for the purpose of further painting or wallpapering. This composition is environmentally friendly, does not cause allergies, does not smell, is quite simple to use, economically consumed, is not afraid of fire, has insulating and noise-suppressing properties.

The indisputable advantages can also include the ability to maintain a constant microclimate in the room, because gypsum quickly absorbs excess moisture when it appears, and then also gives it away easily when the air becomes excessively dry.

Also, the surface, pre-treated with gypsum mortar, is not afraid of hammering in nails and screwing in the cores.

Most often, the walls, ceilings and partitions of residential premises, as well as offices and other buildings of similar purpose, are finished with plaster composition. It is not recommended to use it for leveling walls in bathrooms and laundries, where high humidity levels are always present. For these purposes, moisture-resistant dry plaster mixture is better suited. It is also undesirable to use a plaster mortar for leveling walls in unheated rooms and in open street facades.

Gypsum plaster is applied on a variety of bases - concrete, foam concrete, brickwork, cement-sand, as well as other surfaces. The only condition is the lack of material susceptibility to moisture.

Please note that if the surface to be coated has serious damage, you must first cement them, since the gypsum coating is applied with a thin layer and will not be able to hide cosmetic defects.

Gypsum plaster is highly plastic and therefore makes it possible to create roundings on the ceiling area.

Finishing walls with gypsum plaster due to the characteristics of the material has certain nuances, which will be discussed in detail below.

Special features

Taking into account the technology and observing all the recommendations of the instructions for use, even an inexperienced person in plastering can cope with leveling the walls independently.

First you need to prepare a work surface., namely, to remove dust and possible pollution and to prime it first. This manipulation will provide better adhesion and tighter adhesion of the treated surface with the composition. Before applying the composition, determine the desired thickness of the plaster layer: the thinner it is, the more liquid the composition should be. Spread the composition on the wall with a thin spatula, and for leveling use the rule - a long, flat rail 1.5-3 m long.

In the case of applying plaster in several layers, before proceeding to the next, let the previous one dry properly - this will take at least 3 hours. Distribute and align the first layer, moving horizontally, the second layer - on the contrary, vertically.

Gypsum plaster does not form cracks, so the surfaces treated by it, provide ample opportunities for decorative processing.For work with concreted bases, a plaster mix with priming materials is used.

As you apply the plaster falls evenly, and then gets perfect smoothness. It takes at least 5 days to completely dry the coating, after which the surface is ready for final finishing.

Views and Design

For a long time, stucco was used as a base and as a leveling component. Currently, its ornamental varieties are widespread, which can easily compete with wallpaper in popularity. It is easy to combine it with other types of finishing and, as a result, to realize the most daring design ideas. It can be smooth or textured.

Decorative plaster can be divided into types according to the binder:

Acrylic Elastic, perfectly applied to a wide variety of surfaces, suitable for creating decorative elements and patterns with a roller or spatula. Present in the market as a ready mix. Optionally, you can add the desired dye. Suitable for work in bathrooms and kitchens. For putting plaster on the basis it is possible to use special installations that is usually done with a large amount of work.Please note that to obtain a uniform shade and equal texture it is necessary to constantly mix the composition so that it does not lose its uniformity, and if possible not to interrupt work for more than half an hour. The resulting surface can be cleaned using mild detergents.

Mineral As a binder in it is used cement. This composition is sold as a powder. From the positive aspects can be identified its strength, resistance to mechanical damage, good sound insulation properties. Allows the possibility of dyeing or varnishing.

- Silicone produced on the basis of synthetic resin. It is plastic, easy to apply, upon completion of drying forms a water-repellent film on the surface, which allows it to cover the surface in the bathroom. Durable, not afraid of mold and mildew. It is used exclusively for decorative purposes and does not need preliminary preparation of the surface for application, as it perfectly aligns the walls. The price category of such plaster is somewhat higher than in previous species. Sold in containers of various sizes, which is extremely convenient for creating a unique interior design for the final finishing works.

- Silicate - made using liquid glass. It is the most durable and durable type of coating, prevents the walls from rotting and mold, therefore it is more often used for exterior facades, although it is sometimes used for indoor work. Does not suffer from temperature changes and wind. It happens in white color or it can be colored. Great for porous substrates, such as foam concrete.

To work with other surfaces requires careful preliminary preparation. Also of the disadvantages is to indicate the possible change in the color of the coating under the influence of direct sunlight.

By appearance, gypsum plaster is divided into the following types:

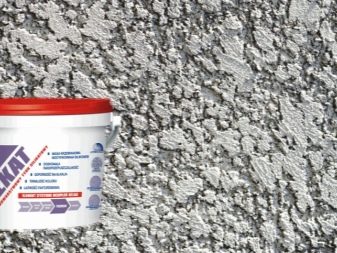

Structural - with the addition of marble chips or quartz, it looks like a heterogeneous granular surface. Possesses high breathability and is resistant to moisture.

Textured - demonstrates high adhesion with brick, wooden and simply smooth plastered surfaces. Easily creates an imitation of wood, fabric or stone, it is possible to paint the composition in different colors. This type of plaster perfectly masks irregularities.

Venetian - imitates marble or onyx, often used in the decoration of interiors in the classical style. Applying this plaster requires careful preparation of the walls, including reinforcement, putty and primer. After which the paint is applied with a rubber spatula. Each smear requires thorough drying. Can matiru or gloss.

Flock - a new development containing acrylic flakes in the composition. Creates imitation suede or velor, is widely used for finishing ceilings and columns.

I would like to briefly highlight the most popular at the moment types of finishes:

"Bark Beetle" - contains mineral granules, which, when applied, imitate a pattern similar to the path of a wood beetle. It is used only for finishing work, it fits perfectly on the basis of plasterboard, brick and concrete.

"Lamb" - contains a mineral crumb. As a rule, it is used for facade works, perfectly fits on any kind of surface, previously cleared of dirt and primed. After drying, staining is possible in any desired color.

"Fur coat" - For a long time, ranked first in popularity.Before starting work, mix the composition thoroughly, since decorative elements tend to settle to the bottom of the container over time.

How to knead the composition?

The solution recipe is extremely simple:

In a deep trough or bucket clean water is collected at the rate of 0.5-0.7 liters per 1 kg of powder.

The mixture is poured into the container and thoroughly mixed using a construction mixer or a drill. If there is no such technique, the solution is mixed by hand until homogeneous.

Next, the mixture is allowed to stand for 5 minutes, kneaded again, after which it is completely ready for work.

Compared to cement, plaster mix hardens very quickly, keep this in mind, this is an irreversible process and it cannot be slowed down.

Tips and tricks

When carrying out work, pay attention to the following nuances:

Gypsum plaster hardens very quickly, so there is no more than half an hour to apply it to the surface.

After solidification, the composition is unsuitable for work. It is unacceptable to try to dilute it with water or add new ingredients to slow down the process of hardening.

In the room where the work is carried out, there must be dry air and the temperature was not lower than +5 and not higher than +25 degrees.

Make sure there are no drafts, otherwise the result of the work can be spoiled.

Before plastering, make sure that all necessary wires are laid (for example, electrical or alarm related).

Remember that gypsum irritates the respiratory organs - it makes sense to protect yourself if you do the work yourself.

If there are parts made of aluminum or steel in the walls, dismantle them or treat them with anti-corrosion agent, since gypsum tends to oxidize metal objects.

Upon completion of work, make sure that there are no unwanted marks or stains on the plastered surface. If they are found, remove them with a special degreasing agent or water vapor.

It is better to re-inspect the surface ready for the final finish in good light.

Take the mix seriously. It is better to give preference to brands that have long been known in the market and have good reviews from buyers.

When kneading it is allowed to use a construction mixer for faster and more uniform mixture preparation.

Do not forget to thoroughly study the base and prepare it for work - priming the concrete and wooden wall before plastering is necessary in different ways.

Application details

Before starting work, it is necessary to prepare to cover the floor with a protective film in order to avoid the composition getting on it. Carefully read the instructions for use of the powder with which to work.

Before breeding the plaster mix, you need to prepare the work surface so that it is as clean and dry as possible.

It will be correct to do this in several stages:

chipped concrete pieces that do not adhere well to the base surface;

knock a wall - if there is a dull sound, the concrete has become loose, it must also be knocked down;

cracks and shells are scrubbed and filled with cement;

dry surfaces are polished with a steel brush;

dust from the walls can be brushed with a soft brush or removed with a vacuum cleaner;

the gypsum coating will not stick to the oil paint, so the latter must be removed with a special nozzle on the drill, sand the surface of the stain with a stiff steel brush or wipe off with a solvent, and then apply a layer of gypsum compound;

For pretreatment of walls of basalt and granite, specialized compositions are applied, applied to the surface in the form of an aerosol. After a period of time, the frozen mass is removed from the surface in the form of a film that absorbs all the pollution, after which the walls are primed with an acrylic primer - it is important to prevent the walls from falling off and the formation of air bubbles;

in order to improve the adhesion of the base and the coating, a primer is used, the concrete-contact tool is suitable for concrete walls;

walls of bricks and blocks are treated with soil that has the characteristics of deep penetration to reduce their hygroscopicity. Before working with a wooden base, also use specialized tools.

Plastering of walls is done with or without beacons, as well as with the installation of reinforced mesh or without it.

Work without a beacon is carried out in the case when you need to slightly trim the wall in the plane or create an outer decorative layer. Often this is done by hand. Using the rule, irregularities on the ceiling and walls are determined - the tool is pressed in different places, thereby indicating the area of work. Plaster composition is applied to these areas and spread over the surface.Next, using the rule determines the presence of a gap between the tool and the treated surface.

If the tool fits snugly, the same algorithm is worked out in the next section. All scheduled sections are processed in the same way. The approximate thickness of the layer will be 2-3 mm. After the composition has dried and polished its surface, you can proceed to the decorative finish of the base.

Work with lighthouses is appropriate when working with large areas of the base, when it is impossible to carry out plastering by machine. As beacons, specialized metal profiles, fishing line or thin cables are used.

The technology is as follows: the lighthouses are set at a level, while striving to ensure that the plaster layer is as thin as possible. Use the level to create markup for installing beacons. At the indicated places, apply a little solution and attach the beacons, by all means referring to the level. Please note that the distance between them should be between 30 and 50 cm - small gaps guarantee a simpler procedure. Try to keep the step between them no longer than the length of the building rule.Then, with an eye on the beacons, the composition is applied to the substrate and distributed, the excess is removed.

The rule is also used for this manipulation. After the layer of plaster dries out a little, its surface should be leveled with a cutter. Keep in mind that it is necessary to start this stage no less than half an hour after the end of work.

After two hours you can begin to putty surface. To do this, spray with water spray give moisture absorb in the upper layer of gypsum composition. When the plastered surface becomes matte again, using a special brush, the moistened top layer is rubbed over the entire wall, filling the smallest irregularities and making the surface perfectly smooth. Then the surface is again well ironed with a specialized trowel.

If you want to give the plaster a glossy shine, after a day it is again moistened with water and quickly rubbed with a spatula until the proper effect is achieved. It is highly desirable to get the metal profiles after the work is finished, and the remaining pits can be easily repaired with a small portion of the solution, if it has come to an end, you can always dilute the additional amount.

Over time, beacons can rust and ugly spots appear on the surface, thereby violating its appearance. If the metal profiles are not bent or damaged, they can be used next time. The only case where the profiles can be left under a layer of gypsum plaster is the desire to lay tiles on top of the plastered base.

Reinforced mesh is used when it is necessary to plaster walls of insufficient strength or in the case when the layer of plaster must exceed 2 cm. In most cases, if the walls are sufficiently smooth, they are treated with a layer of primer. Gypsum or gas concrete foundations are grounded in several layers.

How long does it dry?

As mentioned above, the solution sets very quickly - depending on the characteristics of the mixture, the setting time varies from 45 minutes to 1.5 hours. The maximum setting time is demonstrated by mixtures for hardware application - they freeze in two hours.

To increase the durability and reliability of the plaster layer, it is necessary to let the layers dry properly. The second layer is applied only after complete drying of the first.

When the work is finished, the surfaces are allowed to dry for 5-7 days, then plastered walls can be sanded and prepared for decorative finishing works.

The process of finishing the walls with plaster plaster, see below.