Types and characteristics of sewage taps

Currently, for the construction of high-quality sewage system for sale has everything you need. So, to turn the pipe at a certain angle, use special parts - bends. You can install them yourself, but before that you need to choose them correctly.

Purpose of products

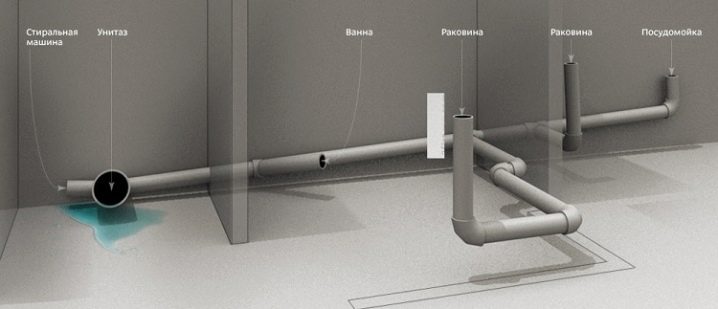

These components of the sewer system are very important. Without them, simply can not do, if we are talking about the arrangement of the rotary structures of the pipe with a certain angle.Usually, the taps are used in the installation of systems for the elimination and discharge of contaminated water in residential as well as administrative buildings. Connecting plastic parts have an interior with a smooth surface. Due to this feature, the probability of blockages during the operation of such structures is reduced to zero. In addition, these elements are notable for silent operation - the liquid moves through them without emitting unnecessary sounds.

In the production of taps, materials are used that are not afraid of aggressive detergents and high-temperature water. Such parts are made with different dimensions.

Materials

Few people know that there are several varieties of sewers. Different options differ from each other not only in cost, but also in constructional features, as well as in operating characteristics. Let's get to know them better.

Polyethylene

Such sewers are produced from characteristic black raw materials. Connect it end-to-end or using a special coupling. In the first case, the end parts of the pipe and the outlet are heated by a special device, and then dock with each other until the material is completely dry.As for the couplings, they are already in the production process equipped with a special spiral-shaped part, which is heated by the welding machine in order to completely seal the joint.

Polyvinyl chloride

Such sewers are considered the most common. Such parts are connected in the following way: the pipe is put on a pipe with a perfectly smooth surface. The main advantage of these types of taps is that to work with them there is no need to use any power tools. Components designed for use inside the living area, painted in gray.

There are also other sewers of PVC, designed for private houses (meaning areas that are not heated or pipes that are installed in outdoor conditions). These elements are painted brown.

Polypropylene

Polypropylene sewers are also equipped with sockets and ends with smooth surfaces. These components are designed for proper and accurate docking.

Such types of taps are used only together with pipes,made from exactly the same raw material. The main purpose of polypropylene parts is the discharge of groundwater / wastewater. It should be noted that these elements can pass the water flow at a speed of 4-7 m / s.

Cast iron

Found in stores and cast iron sewers. Such parts are considered obsolete and are used less frequently. They have an impressive weight. In addition, they are quite difficult to lay, as there are no special sealing rings. It should also be borne in mind that their inner part has a slightly rough surface, which over time can become covered by precipitation and growths.

However, cast-iron bends are good because they serve for a very long time - more than 70 years while inside the building. If such parts are in the ground, then over time they inevitably begin to rust.

Steel

For the construction of sewer systems Often used sewers galvanized and stainless steel.

- Options made of galvanized boast good strength characteristics. However, these types of bends are subject to the formation of corrosion (in this they are inferior to popular plastic parts).Usually, when welding parts made of stainless steel, the sheeting of the material is damaged, which is why rust appears on the area where the seam is located.

- As for stainless steel, then it should be noted that it is more resistant to corrosion. In addition, such sewers are considered stronger, stronger and more durable than the same plastic options.

Species

There are also other types of sewers. Let's get to know them better.

For corrugated pipes

Similar types of sewer branches join by means of special couplings. On all sides, these elements are complemented by sealing rings. At the fold points, the outer part of these products has a more modest diameter. Similar types of taps are used to dock pipes made of different materials using cuffs.

"Wavin"

This is a separate patented system. On the corrugated part of such taps outside is a groove of a triangular shape, which plays the role of a kind of lock. Such elements are made from high-quality raw materials, which are not threatened with increased pressure. These taps are guaranteed to last up to 50 years.

Magnum

Sewage pipelines "Magnum" can have an inflection angle of 90 or 45 degrees. A distinctive feature of such parts is that they lack any rounding. For this reason, the “Magnum” branch elements often acquire clogs. Use them when installing sewer systems is extremely rare.

Dimensions

Sewerage taps are made with different dimensional parameters. So, there are parts in 100 and 50 mm. In this case, it is customary to measure the diameter of the inner hole.

As for such a parameter as an angle, here it is considered to be standard values:

- 30 degrees;

- 45 degrees;

- 87 degrees.

With a combination where there are elbows and half-bends that have different bending angles, they turn the pipes on:

- 30 degrees;

- 35 degrees;

- 60 degrees;

- 75 degrees;

- 90 degrees.

There is also a sewer outlet, the diameter of which is 110 mm. It has an exit on pipes of small diameter. Such parts are usually used to build custom designs.

For them use products with angles of rotation in:

- 15 degrees;

- 30 degrees;

- 45 degrees;

- 67 degrees;

- 87 degrees.

Installation

In most cases, people choose sewers from polyvinyl chloride, as they are inexpensive and are pliable in their work. The coupling of such elements is carried out using special seals, which in many cases are initially present in the interior of the pipe. It so happens that the rubber ring comes with an angular detail and is located in a specially prepared recess near the point of direct connection.

Of course, it is possible to mount such parts in another way, which seems simple to many people - using glue. However, in reality, this method is more difficult to implement, so it is rarely used. If the connection is adhesive, then rubber seals will not be needed.

Quite often in the sewer system it is necessary to connect pipes, originally made of different materials. In this case, you should apply specialized sanitary sealants, as well as cuff seals. With such components, sufficiently reliable and well-sealed connections are obtained.

Sealing of joints

Reliability and durability of the sewer system is dependent on the tightness of the corner joints of pipes. That is why with self-installation, due attention should be paid to this stage of work.

For example, laying drainage pipes for removal under the ground (when organizing a sewage system of a private house), the joints between them should be sealed as carefully and scrupulously as possible. Otherwise, leaks may occur, due to which large sums will have to be spent on repairs to the existing structure.

Pipes and connection sections of the taps are treated with specialized sealing compounds, which include many necessary components.

Similar solutions are subdivided into two types:

- neutral products that have a high price;

- acidic compounds that are much cheaper (note that you can not use them if you work with parts made of cast iron or metal).

When purchasing a particular sealant, be sure to familiarize yourself with its composition, which is usually indicated on the original packaging. Even if you dock sewers of polyvinyl chloride, equipped with rubber seals, it is still recommended to use sealing compounds.Thus, you will make the connection as reliable as possible. If for the arrangement of the sewage system you used cast iron pipes, then it is necessary to use a sealing compound (but not acidic) to process their joints.

Recommendations for selection

Since today the assortment of sewers is diverse, the choice of a particular model has become more difficult.

Consider a few simple recommendations that will help the buyer to choose the best option.

- When installing external structures and drainage systems it is recommended to refer to corrugated pipes and the corresponding branches for them.

- Cast iron parts in our time are not as popular as before. More relevant today are plastic and polyethylene varieties of bends, because they are inexpensive and are quite practical (do not rust). If you want to use steel elements, it is recommended to give preference to stainless steel, as it is not susceptible to corrosion.

- It is advised to contact cast iron options only if it is about repairing the old sewer system.

- If you select pipes for the internal system, then you definitely need to consider their future location.

- As for the size of the bends, here you need to keep in mind the material from which they are made. So, the popular polyvinyl chloride options have standard parameters from 25 to 110 mm. In this case, 25-mm parts are suitable for draining the drain from the washing machine, and 32-mm elements can be used to drain the liquid from the bath.

Useful tips

When designing a sewer system, it is recommended to use offsets of one type. If it is necessary, you can refer to the use of special adapters, which will make it possible to combine any components. If it is necessary to connect massive pipe structures, special segmented bends should be used. When designing a sewer system, a large number of joints and swivel joints should be avoided, since such areas can cause leakage.

The most popular are bends, the inside of which has a smooth surface. For such details are much easier and faster runoff.These characteristics can boast PVC parts, which makes them more relevant than metal options. Sewage pipes need to be further warmed if it comes to low temperatures. Usually such materials as foam plastic, polystyrene foam or mineral wool are used for this. In addition to the sealant, the sewers joints can be treated with such compounds as bitumen mastic, pitch, technical sulfur or a special sealing tape.

Experts recommend buying elbows made by popular manufacturers. Such parts are usually found in specialized plumbing stores. You should not save on the purchase of such products, especially when it comes to plastic options, since they are already inexpensive.

In the next video you will find the installation of plastic sewer pipes.