Recommendations for the selection and installation of sewer pipes

Owners of private houses are forced to think carefully over not only the communications located inside the house, but also beyond. For discharge of wastewater outside the dwelling, special pipes are used, which are designed for external sewage.

Internal and external pipes differ in many parameters, so before buying it is necessary to examine all the characteristics.

Special features

Regardless of the location of sewer pipes, they must meet certain requirements. Their main quality is durability and strength, because their installation is obliged to guarantee tenants a long and good service life. Laying external or internal sewage during the construction of the house should exclude repairs in the next few years.In addition to reliability, products must be resistant to temperature, UV and chemical exposure. The main thing is that they have enough stamina to resist the harmful effects of the environment.

High-quality sewer pipes are easy and simple installation. Due to their low weight and sturdy connections, they can be easily and quickly mounted. High throughput and a smooth inner surface is another indicator of these products. Such characteristics allow them to pass through themselves household drains of different sizes, eliminating the likelihood of clogging. External sewer networks are forced to work in difficult conditions. Besides the fact that they are under pressure from the weight of the buried earth, people can walk over the ground and ride vehicles.

In addition, they can be affected by groundwater, which cause displacement of the docking points, and eventually depressurize the sewage itself. As well as the network is constantly exposed to wastewater flowing inside the pipes. External sewer systems are underground, which increases the complexity of their operation.For this reason, they must be distinguished by their particular strength, rigidity and ability to withstand various temperature drops. Their frost resistance should allow to function even in the most severe frosts.

Pipes for external sewage seriously differ from products intended for installation inside the house. It is easiest to distinguish them by the characteristic orange color, which is needed to quickly locate the pipe in case of a breakdown. Bright color allows not to lose time when eliminating the effects of leaks or other emergencies. The wall thickness of the parts for external systems is always a few millimeters larger than for the house pipes. This is due to the fact that they are affected by a stronger load, so you can not install internal pipes outside the house, as this will sooner or later lead to a breakthrough and an accident.

Kinds

In the recent past, the choice of pipes for laying sewer networks was small and consisted of iron and steel products. In the modern world, you can find the right product by examining a significantly increased product range.

PVC

They can be made for laying both external and internal sewage. Usually they are used for systems that require a large bore.They have high resistance to mechanical stress and resistance to ultraviolet rays. But plastic has a high sensitivity to aggressive chemicals with a temperature above + 60 ° C, so if acids and oils are planned to be dumped through pipes, then they should not be acquired.

PVC pipes are divided into two types, such as:

- pressure - designed to withstand high pressure and installed in places with increased exposure to various media;

- non-pressure products are mounted in places with low pressure.

Plastic products can consist of one or two layers. The two-layer pipe is made from not plasticized material, but from recycled foamed polymer.

PVC pipes can be divided by the following hardness class:

- S are rigid pipes;

- N - medium-hard models;

- L - light components.

For laying sewage outside a private house, it is sufficient to use medium-hard products, whereas for industrial scales rigid pipes are used.

Corrugated

They have a special design, which, due to its greater mechanical rigidity, has increased strength.The folded outer surface of the pipes increases their area, which allows them to withstand heavy loads. Corrugated products have good rigidity and light weight, which makes them very popular.

Corrugated structures are divided into the following two types:

- single-layer products have a low price, but do not cope well with the drainage;

- two-layer structures have a folded outer surface that allows the flow to pass without the formation of deposits and blockages.

Ceramic

Ceramic pipes are made by burning clay. They have chemical inertness, which allows them to drain through any liquid. Their internal structure protects products from the formation of plaque and any deposits. Ceramic structures are not afraid of temperature changes and are easy to install. Of the minuses, fragility and a small length of products can be distinguished, which makes it necessary to make more joints when they are laid.

Cast iron

These are bezrastrubny products with great weight and high price. Despite this, cast iron structures have high strength, resistance to different temperatures and durability.They are quite easy to install, since the process requires the use of a socket-shaped method. Cast iron systems tend to form deposits on the inner surface, which will inevitably lead to clogging. In addition, there are restrictions on their installation on a number of soils, which is a huge disadvantage.

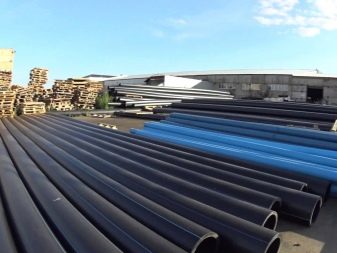

Polyethylene

They are suitable for installing outdoor networks. The advantages of PE are in the ability to withstand hydraulic shock, resistance to the effects of active substances and durability. The main disadvantage of this material is the lack of heat resistance and susceptibility to ultraviolet radiation.

Polyethylene pipes can be used only at a temperature not lower than -40 and not higher than + 40 ° С.

HDPE

Such pipes are made of low pressure polyethylene. They have a long service life, are not afraid of corrosion and aggressive environment, have low thermal conductivity and resistance to water hammer. In addition, PND-pipes are lightweight and able to function even in conditions of severe frost. From the minuses of the HDPE products can be identified low resistance to high temperatures, insufficient resistance to mechanical damage and loss of properties under the influence of ultraviolet rays. Lay PND-pipes exclusively under the ground.To create an internal sewer they are not suitable.

Polypropylene

Polypropylene pipes are rarely used for the installation of external systems, as they have insufficient rigidity. They have high heat resistance and chemical inertness, which allows to increase the service life of plastic pipes. The disadvantages of the material include sensitivity to ultraviolet rays, so the laying of pipes must occur without direct sunlight.

Asbestos cement

They are made from a mixture of Portland cement and mineral-asbestos fiber. They are durable, lightweight and resistant to the negative effects of the external environment. Among the shortcomings of the material, fragility and intolerance to mechanical action can be distinguished.

Plastic

Most often for the construction of sewers using plastic pipes, which are lightweight and affordable. Plastic does not rot, does not corrode and can last more than 40 years.

The smooth surface of products contributes to the smooth passage of fluid, which eliminates the formation of blockages and various deposits.

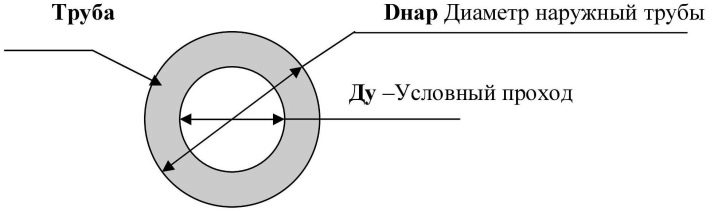

Dimensions

Modern sewer pipes have dimensions that are strictly regulated by technical conditions. Thus, the production of sewage elements provides the ability to select a path for the sewer network with any parameters. The main indicators of the diameter of products are affected by the inner, nominal and outer diameter, as well as the wall thickness and nominal diameter. The diameter of the pipe is the main parameter on which the purpose of the pipe depends. The dimensions of plastic structures can be any, which allows you to find a product that is suitable for a particular case.

To ensure the discharge of sewage to the toilet, many use a pipe with a diameter of 110 mm. But the 75 mm pipe is designed for drainage baths, sinks and other plumbing equipment. To organize the risers or diversions of wastewater from the structure, it is necessary to use large diameter pipes. To organize an outdoor sewage system on a private garden plot, it is sufficient to use pipes of 300 mm. The wall thickness is interconnected with the diameter of the product. Because what diameter depends on the thickness of the structure.

For example, if the size of the product is 110 mm, then the thickness will be 3 mm.

The size and weight of the material depends on the size of the sewer construction. The larger the diameter of the pipe, the greater its weight. The organization of the sewage system is always based on the length of the pipes. The greatest length is 6 m, and the smallest is 1 m. As a standard, products from 2 to 5 m long are used for the installation of the system.

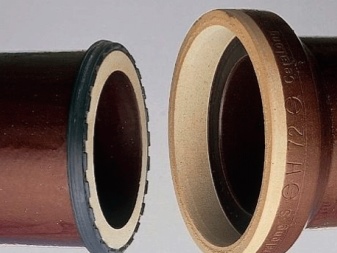

The dimensions of sewer pipes are calculated on the basis of the material from which they are made. Thus, the size of PVC pipes can have a large range, so they can be selected for any type of work. An extensive selection of products allows you to quickly and efficiently arrange a new or update the old sewage system. The standard diameter of PVC pipes has a value of 25 mm, 32 mm, 50 mm and 110 mm. At the same time, 25 mm products are used to drain the drain from the washing machine, and the 32 mm design is designed to drain liquids from the bath or sink. The inner diameter of a standard cast iron structure is 100 mm, and the outer diameter is 110 mm. The length of the products can reach 3 m.

The classification of cast iron pipes is divided into the following two types:

- SMU class products are distinguished by the absence of detachable connections;

- The SME class has a connection for a connector at one end only.

How to choose?

Previously, people did not have the choice of sewer pipes and used only the material that was available for sale. Today, in specialized warehouses you can find products made from different materials. Cast iron is gradually being squeezed out, products from plastic, PVC, polypropylene and others appear on the market. For the installation of external lines and drainage systems, it is advisable to use corrugated double-layer pipes. They are not afraid of a large amount of wastewater and soil pressure.

Pig-iron constructions have not lost their relevance and they are quite widely used for laying outdoor sewage systems in industrial enterprises. They have high strength and resistance to temperature extremes. In addition, it is quite convenient to work with them. But since cast iron is quickly polluted, which reduces the permeability of wastewater, their installation is not considered a good solution.

Cast iron can only be used if it is necessary to repair an old pipeline made from the same material.

For the organization of water supply in the apartment is best to purchase plastic structures. They are quite durable, resistant to ultraviolet rays and tolerate temperature drops well. The polyethylene system is quite flexible and rigid, which allows it to moderately discharge sewage. To create an improved throughput system in the segment, it is best to choose PVC pipes. They not only have a high ring stiffness, but also perfectly resist axial loads. They can be safely installed not only in a horizontal, but also in a vertical position.

The choice of the diameter of the sewer pipe should correspond to the average volume of water consumed. But taking this parameter into account is necessary only if the tie-in is planned in an apartment; for a private house, such a calculation is not needed. Choosing sewer pipes, it is worth considering the advantages and disadvantages of each material. It is worth remembering that steel structures easily tolerate high temperatures, but are highly susceptible to corrosion. But cast iron products are not afraid of corrosion, can withstand a large load, but they have a lot of weight and price.

To choose the right pipes for domestic sewage, you need to consider their future location. For example, waste structures with a diameter of 50–75 mm are suitable for sanitary equipment, for example, a shower cabin or a sink. For the organization of the drainage from the toilet you need to pick up a pipe with a diameter not lower than 100 mm. To install underfloor heating, you need to purchase pipes made of polybutylene, since they have elasticity and high thermal conductivity.

Polybutylene is able to withstand water temperatures up to + 90 ° C.

To create high-quality plumbing in the country, it is better to choose products made of polyethylene, as they have the strength and flexibility. For cold water you need to buy pipes with high density. If PVC pipes are selected for the installation of a sewage system, it is worth remembering that they contain a chlorine compound. You can connect them together with a special glue.

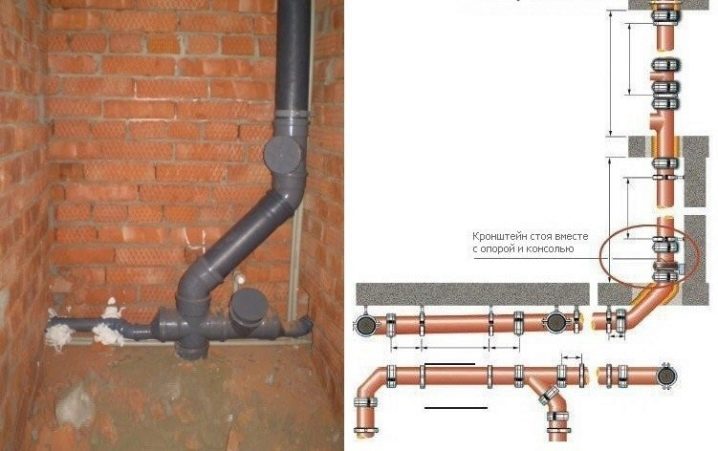

Installation

You can install the sewer pipes by hand. The main thing is to know the rules and the sequence of installation. The installation of products in the vertical part of the system is necessary for the removal of wastewater from household appliances and sanitary equipment. Intra-house network should be laid only after agreeing on a detailed project in which all household and sanitary taps should be indicated.The vertical part consists of one common riser connecting the horizontal elements of the pipeline. Multi-storey buildings have several vertical networks, and in private ownership it is one.

Installation of sewer structures requires compliance with certain rules.

- It is necessary, by bringing the upper end of the vertical product to the roof, to ventilate the riser. At the same time, the output cannot be installed near windows, since the system should be located at a distance of approximately 5 meters from the nearest window

- The horizontal part of the network can create a lot of trouble, as the pipes in this case are stacked at a slight inclination. This nuance must be foreseen at the design stage, otherwise it will not be possible to create an effective sewage system. Slope is necessary to accelerate the flow of water. Ideal speed can be achieved if the pipe is laid under a slope of 3 cm on each running meter of the system.

- It is not necessary to increase the slope of the structures, since precipitation is formed inside the products under the action of a high velocity of wastewater. A decrease in slope will slow the flow, which will lead to clogging.

- If after connecting all the elements of the sewage system there is no need to immediately crash into plumbing equipment, then special plastic plugs should be put on the pipe terminals. They are easy to put on and take off when you need to connect household appliances.

Self-made arrangement of home sewage systems must be performed using polymer elements. To cope with such work is able to do almost any person. Polymer construction is a smooth pipe with a cut with a chamfer at one end and a sealing ring and a coupling on the opposite side. You only need to make an effort to insert the pipe into the sleeve of another element, and then pull it back 10-14 mm. A sealing ring allows for good sealing of the system, and a damping gap between the two components of the pipeline protects the network from deformation. Flared method of connecting structures is characterized by simple assembly, which is the insertion of one tube element into the socket of another product.

For reliability, the joint is sealed with a rubber ring.

Assembling a sewage system using cast iron structures can only occur at the installation sites of specific sections of the network. But plastic products can be assembled at any spacious site, and only then can the assembled system be transferred to the area for further installation. To fix the sewer pipes to the wall you need to use clamps with rubber liners. This mounting method allows you to closely fix the product. Clamps can be made of plastic or metal. Metal parts are needed for heavy-duty and rigid fixation of sewage elements to the wall surface, and plastic products are more suitable for fixing moving parts. At the same time plastic differs in more reasonable price.

Quite often sewer pipes can demand replacement or warming. The problem of freezing is in the first place, so it should be solved first. Freezing of structures can lead to damage to the network, obstruction of wastewater, the formation of an unpleasant odor inside the room and the failure of the entire sewage system. In order to prevent the occurrence of these troubles, you need to think in advance about the insulation of pipes.Among the variety of insulation materials you need to choose the most suitable one so that its installation takes place with the use of a minimum of forces.

System insulation is not always required. Often, you only need to make a high-quality installation of pipes without making technological errors. Effectively deal with freezing allows the installation of products below the level of land freezing. The sewage elements in this case will remain empty, so there will simply be nothing to freeze. If it is not possible to lay the system below the level of soil freezing, then it is necessary to resort to its warming. It is possible to warm the pipes only provided that the laying depth is at least half a meter, and the network has many joints and turns.

It is possible to warm the sewage system using foam plastic, basalt cylinders, mineral wool and polyurethane foam. The choice of material depends on the prevalence of temperature in the cold season and the material of the pipes themselves. Of great importance and financial capabilities of the buyer. To insulate the sewage with your own hands you need to first prepare a trench. Then white sand should be poured at the bottom of the pit, tamped with it, and then the collected pipeline system should be lowered into the pit.After that, you need to take insulation material and tightly wrap them design. At the end of the work you need to fill the trench with sand.

Tips

Installation of sewer pipes requires careful preparation and care.

It is necessary to follow a number of recommendations that will make a high-quality and durable system, namely:

- before laying the elements you need to make a diagram of the pipeline with the calculation of the number of materials required;

- the calculations must take place in the light of all family members;

- it is necessary to analyze the system and indicate all the twists and turns of the sewer;

- insert a sewer line need to use the cross, which has three conclusions;

- it is necessary to begin the installation of plastic products from the far point of entry into the network;

- plastic elements can be easily and quickly connected using a flange or coupling method. Both methods are suitable for independent work and do not require the use of expensive tools;

- To make the socket connection completely sealed, the edge of the smooth end of the pipe must be lubricated with silicone, and only then inserted into the socket;

- To make the connection with glue, you must first clean the surface of dirt. Then the bonded areas must be plastered and degreased.

To learn how to properly lay the sewer pipes with your own hands, see the following video.