PVC sewer pipes for the internal system: dimensions and characteristics

Sewerage is a system without which no structure can do. For general convenience, it should be of high quality and thought out to the smallest detail. Therefore, when installing sewage polypropylene pipes for the internal system, it is necessary to carefully study all the characteristics of this material. This must be done in order to be completely confident in their quality and durability.

Special features

PVC sewer pipes are made from a special type of thermostat that retains its shape. It is called polyvinyl chloride. Use such pipes mainly for domestic sewage.

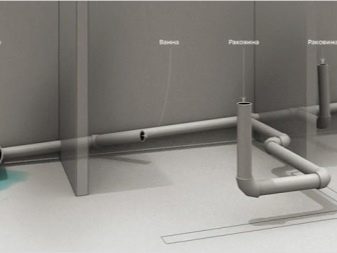

They are more qualitative due to the use of stabilized chlorine and ethylene.These are materials that are not only resistant to various chemical substances, but also provide greater resistance to corrosive phenomena. The internal sewage disposal system of the pipes is painted gray and is used to install in the middle of the room a drain for sewage.

Pros and cons of PVC pipes

Like any material, sewer pipes have both advantages and disadvantages. However, it is immediately worth noting that, despite all the disadvantages, they occupy a leading position in the construction markets.

First you need to consider the benefits:

- They have the most affordable price among other pipes made from other materials. This makes them very popular.

- Installation work on their installation is easy. There is no need to use any special equipment, because the entire installation process is done by the socket-shaped method.

- Repair work and dismantling are also quite simple.

- The walls inside the device are particularly resistant. This is a useful feature that prevents the possibility of corrosion.

- Plastic pipes are resistant to aggressive substances.

- They also have great mechanical strength, and because of this, such a pipeline is installed to a depth of eight meters.

- They can withstand an internal pressure of up to sixteen bars.

- Also products can be used for a long time.

- The design is lightweight.

- They have a rather small linear expansion coefficient.

There are not so many drawbacks to such pipes, some temperature limitation applies to them. The temperature must be no more than sixty five degrees above zero, and no less than ten degrees below zero.

Such pipes are characterized by increased brittleness and react rather poorly to organic solvents that destroy the base of the pipe. They also contain large amounts of chlorine.

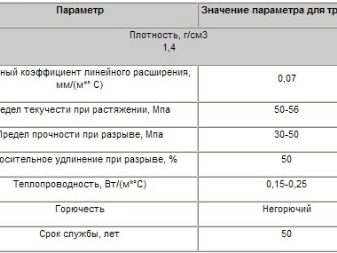

Sewer plastic pipes have the following technical characteristics:

- Linear expansion of the estimated coefficient - 0.07 millimeters.

- The density is equal to one quarter of cubic cubic centimeter.

- When stretched, the yield point reaches up to fifty six megapixels.

- At rupture, the relative elongation of pipes reaches up to fifty percent.

- Thermal conductivity of PVC pipes - 0.25 watts.

- They are distinguished by incombustibility; in case of fire, they quickly die out independently.

- Their term of service reaches fifty years.

Norms

Today there is GOST only for unplasticized polyvinyl chloride used in pressure sewers. This is GOST R 51613-2000. It consists of standards that have the following criteria:

- dimensions;

- dimensions of pressure pipes;

- safety during assembly work;

- operational safety;

- rules of storage and transportation;

- method of conducting all tests.

Kinds

PVC material can be divided into two types:

- Plasticized material or PVC. Pipes made of such material are characterized by increased elasticity, but the fact that it has low strength characteristics practically does not allow its use in production.

- Unplasticized the material, in a different way it is called NPVH. It has a rigid structure, as well as resistance to aggressive environment. It is from this material that pipes for sewage inside buildings are made. They are used for pressure and gravity systems.

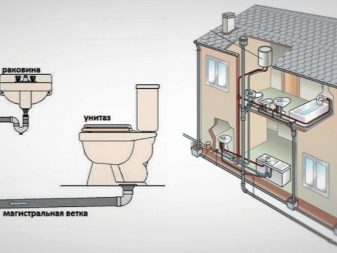

These pipes can also be different according to the method of connection.For example, coupling or socketless connections. In addition to these, there are also socket-shaped mechanical and socket-type adhesive bonding methods. The most popular of these are bell-shaped mechanical connections. They are used for domestic sewers.

Connect pipes in such a system is quite simple and reliable. The end of one product has a specially made socket, the size of the diameter inside which coincides with the outer normalized. An additional seal is a rubber ring that is inserted into the slot specially made for this. To connect the two pipes together, it will be enough to insert them into each other.

To make an internal sewage system, other additional elements will also be needed.

They are not so much, but still you need to familiarize yourself with them. These are fittings or fittings that serve for different turns, branching, as well as the transition of the aqueduct from one to another diameter. Among them are the following:

- Knee. It is used for different turns in the sewer system. The knee differs in angle of inclination, which ranges from twenty to eighty seven degrees.

- Tee. This is a connecting element that is made for two pipes with different diameters.

- Cross. It can be used to connect four pipes to a common system at once.

In addition to these most common fittings, there are also indirect elements that are used to create an internal sewage system.

- Inspection hatch, which is needed to check the inner surface of the pipe;

- coupling connecting the socketless pipes;

- and also the element serving as an adapter from plastic pipes to pig-iron.

There are different types of PVC sewer pipes that need to be considered in detail:

- Sewer plastic pipe the size of 32 millimeterstra It is most often used for the construction of industrial or sanitary sewer system. It has a high chemical wear resistance. The peculiarities of such a sewage system also include resistance to wandering wastewater. Its design is bell-shaped, such pipes are mainly used for storm sewers.

- Sewer plastic pipe the size of 75 millimeter used to organize the drainage system in the bathroom.It is installed in the event that the bathroom is some kind of plumbing, for example, shower, toilet or washbasin. There are no deposits on the walls, as they are not rough at all. They have good throughput due to the ratio of wall thickness and pipe diameter.

- Sewer plastic pipe the size of 50 millimeters. They are used to organize the layout of the sewer system, which conducts wastewater from sanitary appliances to the house risers. They are lightweight, flexible, resistant to various chemical agents and too hot water.

- Sewer plastic pipe the size of 100 millimeterat. It is used for internal sewage system and removal of internal wastewater from the inside to the outside. Also, this design is perfect for removing wastewater from the toilet. She is not afraid of high temperatures and the effects of various chemical agents.

- Sewer plastic pipe the size of 110 mm. Such pipes are used to remove wastewater from the toilet. They can withstand quite a lot of pressure, do not form blockages in the form of food and hair.

Plastic pipes for domestic sewage can be divided into several types. They are:

- polyvinyl chloride (abbreviated PVC);

- polypropylene (abbreviated PP);

- polyethylene (abbreviated PE).

Polyethylene pipes are most rarely used, but polypropylene pipes are often used to create internal sewage systems PP. They can withstand a sufficiently high temperature, so they calmly laid in residential buildings. In addition, they have some advantages. The most important of them is a fairly high level of flexibility, which allows even after freezing to return the pipes to their initial form.

It is also worth noting the high vibration-proof qualities that allow the pipeline to remain silent. Polypropylene pipes have a lower price than those made from polyvinyl chloride. They are also resistant to various mechanical stress.

Such pipes also have disadvantages, for example, a decrease in strength in a high temperature environment, as well as the possibility of using connection elements made of polypropylene only.

How to choose?

The choice depends on many factors. PVC equipment is used in the sewage system of private houses and industrial facilities, as well as in hospitals and urban high-rises.Since all sewage systems are divided into internal and external, as well as stormwater, the pipeline requirements may change.

It is necessary to pay attention to the diameter of sewer pipes. It depends on where the equipment will be laid out. So, for internal systems, a diameter of fifty to one hundred ten millimeters is selected. For the external system, the diameter of the pipes used should be larger - from 110 to 600 millimeters.

There are several rules for determining the diameter of pipes for sewers:

- To divert sewage in a private house or apartment, equipment is used that has a diameter of 100 millimeters.

- For washing machines are connected white pipes having a diameter of 32 to 50 millimeters.

- For toilet bowls, as well as for multi-storey buildings, pipes are selected with a diameter of one hundred millimeters.

You also need to pay attention to the features of installation work. For quick and easy installation, you will need bell-shaped plastic parts, which, in the case of using rubber seals in sockets, make installation much easier.

It is also worth noting that plastic pipes having a diameter of up to 200 millimeters are cut fairly well using a grinder or a regular hacksaw. In addition, the sections are very smooth.

Tips

When working with sewer pipes you should not refuse advice or recommendations of experts. After all, sometimes without them can not do.

- Starting laying PVC products for domestic sewage, you must, above all, lay the pipeline itself on the floor or table. In general, any smooth surface will do. Its height will be no more than two hundred centimeters. Next, using the chamfering tool, the pipes are cut. Its edges must be sharpened and mowed at an angle of one hundred and fifty degrees.

- Do not shorten the fittings. All the details of the design must be combined into one system. Then you need to check the sealing ring. So that the tightness is complete, you can use sealant.

- The end of the pipe, which has a smooth surface, must be lubricated with silicone grease, which makes it easy to slide while installing the system. It will also significantly reduce the friction coefficient of the elements. Walls inside should not be greased.

- The smooth nipple should be pushed into the socket and mark the point of contact. Then it is necessary to push this smooth edge of the pipe ten millimeters out of the structure and fix it well.

- By means of a fixing collar the system is fixed. The gap between the coupling and the device itself must be sealed. Do not forget about sound insulation, so that the noise at work does not interfere with others.

- When doing the installation work of PVC sewer pipes for the internal system, be sure to carefully study all the characteristics and dimensions of the elements necessary for this. Only after this is recommended to start work.

On the intricacies of the internal sewage device, see below.