Choosing sewer PVC pipes

The main advantage of plastic sewer pipes - is their durability, so their use is preferable to the installation of analogues made of metal.

Such a long service life due to corrosion resistance and resistance to chemically active substances.

Special features

Every homeowner wants everything to work properly in his household, and nothing has ever broken, and is also easy to use. Sewerage in this sense is not an exception, the comfort of all living in the house depends on its functionality and working condition, since its clogging can cause great inconvenience, and cleaning drains is far from a pleasant experience.

If a high-quality system for removing wastewater is important to you, then we advise you to pay attention to plastic sewage pipes, which are gradually replacing cast-iron pipes from everyday life. They are easier to install, have a smaller diameter, as well as a wider range.. It is very important that deposits do not accumulate on the smooth inner surface, and such pipes can be used for almost half a century. - It is this combination of positive characteristics that led to the growth of popularity of products.

Plastic pipes are made from polymer compounds of high complexity using the most modern technologies, this explains their strength and high plasticity - with a certain heat treatment, the product can be easily bent at any desired angle, and all systems as a whole can be easily assembled with your own hands without turning to professional services.

Plastic pipes have a lot of advantages:

- affordable price;

- long period of use;

- chemical inertness;

- low thermal conductivity;

- ease.

Such pipes are available in a variety of sizes, which primarily depend on the degree of load on them.Thus, large-diameter products are designed for high loads, so they are widely used for arranging the sewage system in apartment buildings and social facilities.

For hospitals and hotels, pipes with a diameter of 20 cm are installed, but for industrial facilities pipes with a cross section of at least 30 cm will be needed, while pipes with smaller diameters will be required for removing sewage in small private houses.

Depending on the type of plastic used as a raw material, several variants of sewer pipes are distinguished.

Pipes made of polyethylene are characterized by absolute resistance to acid-base solutions. It is no coincidence that the tanks of this material are widely used for the storage and transportation of electrolytes. In addition, polyethylene is resistant to low temperatures, it does not stretch and does not deform at minus marks on the thermometer. However, the material transfers elevated temperatures rather poorly, which is why some manufacturers have mastered the production of brands capable of withstanding operating temperatures up to 80 degrees, and in recent years a new product has appeared on the market - pipes made of “cross-linked polyethylene” - they easily withstand heat up to 200 degrees.

Corrugated pipes are often made of polyethylene, which are widely used for outdoor sewage. The material is characterized by ring stiffness, so it can be laid in the ground to a depth of 20 meters.

PVC and PVC pipes are made from ordinary or non-plasticized polyvinyl chloride. This is a fairly durable material that is resistant to contact with any chemical compositions, including gasoline, alcohol and other aggressive compounds. Such pipes can withstand quite large loads, but they are not recommended to be used where the temperature of the effluent exceeds 60 degrees.

PVC and NPVH are materials that are not prone to fire, but at temperatures from 120 degrees they begin to melt and release toxic substances into the air. Pressure technology and free-flow pipes are distinguished, some manufacturers produce fiberglass modifications.

Specifications

Let us dwell on the technical characteristics of plastic pipes made of polypropylene - This material is the raw material for sewer pipes in most cases:

- material density is 0.31 g / cm3;

- the pipe from polypropylene differs in resistance to attrition, therefore it is optimum in work with abrasive drains;

- The material is used at temperatures up to 60 degrees Celsius; for working with hot drains, more durable materials are needed as the plastic begins to soften and bend;

- Plastic used for the manufacture of pipes practically does not come into contact with caustic solutions, and therefore retains its physical and technical properties even in aggressive conditions (however, this statement is true only after a short contact of the material with acid-base solutions).

In the cold, the material becomes brittle, at temperatures below -15 degrees it begins to break, so it is undesirable to transport it in the winter season, however, communications that are laid in the ground and insulated can withstand lower temperatures.

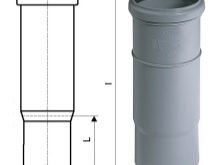

The size of plastic pipes, as a rule, is regulated by state standards and technical conditions, usually their diameter varies in the range from 32 to 160 mm, and the length starts from 1.5 meters and ends at 3 m.

Types of components

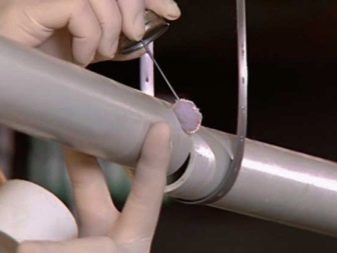

Components for plastic sewer pipes are used to create both internal and external systems, they can be mounted “under the ring” or simply fixed on the glue. Components for plastic pipes are distinguished by a large number of advantages:

- low cost - such additional elements are much cheaper than their metal counterparts;

- a wide variety of models to facilitate the selection of the optimal option;

- ease of installation - as a rule, all components can be mounted by hand without the use of special tools;

- long period of use;

- small dimensions.

The basic components include several elements:

- Coupling. These are components of the internal pipeline, visually they resemble a small pipe, from the sides of which there are special sockets that greatly simplify installation. Couplings can be smooth, corrugated or with stiffeners. Smooth variants are most often used because they are simple and easy to use, and their cost is rather low. Such a sliding coupling is optimal for ensuring uninterrupted sewage operation under regulatory loads.

- Corrugation The corrugated pipe can be bent in different directions - it does not lose its operational properties.Such pipes are widely used as an alternative to bends.

For areas with increased loads it is worth using products with stiffeners, since they retain their functionality with significant pressure drops.

- Audits. These are special parts that are used when a blockage occurs, the component gives access to the pipeline to facilitate the elimination of the malfunction. Visually, they resemble a tee, a lid is placed in place of the socket, which opens if there is a need to clean the pipeline section.

- Tees These devices are used to form a branching pipeline, they can be used for both internal and external type of sewer systems.

- Crosses Needed when you need to connect a number of local pipelines into a single network. Externally, they look like long pipes in which several nozzles are perpendicularly embedded. The market of plumbing today offers a wide range of different types of crosses, with which you can create drainage of any configuration.

- Bends. Necessary to change the direction of the axis, thanks to the bends, it is possible to form any turns of the pipelines without increasing the load.

- Compensation Nozzles. Used for tapping a new sewer branch into the existing water supply system. Very often there is no technical possibility to move the pipes in order to make room for a new adapter or to replace a failed part. It is in this case that the compensation pipe helps, which levels the gap between the pipes by lengthening the socket part. Outwardly, it looks like a familiar pipe, but with an elongated bell.

- Check valves. A device that avoids the outflow of fluid in case of blockage. This element overlaps the pipe throughout the cross section, so that the movement of fluid is possible only in one direction.

- Valves. These are shut-off components that are responsible for shutting off the pipeline in the event of an emergency.

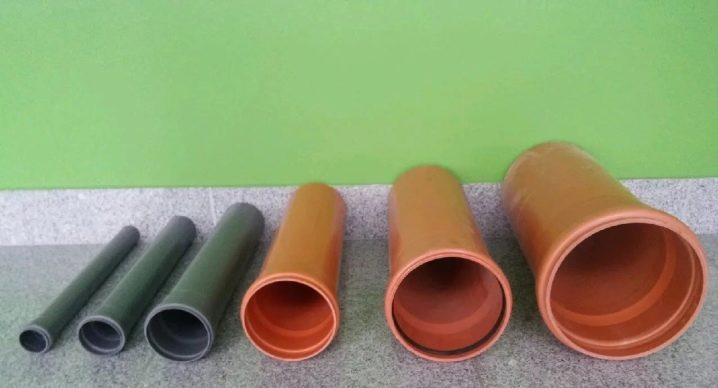

Colors

Sewer pipes presented in stores where sanitary ware products are sold are painted in different colors. And this is not a design move at all, it is a kind of marking,since the pipes of each color differ in their technical features and have a separate purpose.

Gray sewer pipe

Used for installation of the pipeline inside the building. It fully complies with all the necessary requirements for materials from which the internal sewage is made. Gray pipes are lightweight, durable, corrosion resistant and easy to install.

The disadvantages of such products include the response to mechanical stress, low impact resistance, which is why they cannot be used for the external parts of the drainage system.

Products with gray markings are afraid of low temperatures, and any ice plug can lead to significant damage to the pipeline.

Red (Red) Sewer Pipe

This is one of the most popular models, which is widely used in the construction of the outer part of pipelines. As a rule, such products are made of PVC, the materials are resistant to corrosion and are not subject to the detrimental effects of dangerous microorganisms. At the same time, the cost of red plastic pipes is significantly lower than that of metal counterparts.

Red tubes are usually produced with a diameter of 11 and 16 cm and it is much stronger and stronger than models of other colors. Pipes of this shade can withstand quite substantial mechanical loads, including soil pressure, therefore they are often laid where the road or path passes, they do not change their physical and technical properties under the influence of high temperatures and do not begin to break even in cold weather.

Green sewer pipes

Such products are commonly used for arranging underground drainage, such pipes, as a rule, are slightly perforated, since they must leak water.

Black sewer pipes

These pipes are less common than gray and orange, however, they are no less effective - they are made of high-pressure polyethylene and are used to conduct both internal and external water supply. They are rarely used independently, often in combination with other variants of plastic products.

White plastic tubes

Such pipes are used extremely rarely, they can serve to create the inside of a sewer system, that is, they are an alternative to gray pipes.From a technical point of view, they do not have significant differences.

This option is optimal for the category of homeowners who care about the aesthetics of the dwelling itself, since the gray color does not always fit well with the design of the kitchen or bathroom, and the installation of a decorative box is not always enough.

Manufacturers

Production of plastic sewer pipes are engaged in both foreign and domestic companies. Let us dwell on the most common brands.

- Rehau - this is one of the universally recognized world leaders, which is characterized by exceptional manufacturability of the production process and, as a consequence, high quality products. This is an enterprise that has established the production of pipes for arranging domestic sewers, their pipes are distinguished by excellent noise insulation, and besides, they are resistant to high temperatures, the products serve to remove hot effluent and can last at least 50 years.

- Wavin - a leading European manufacturer, whose products have won the trust of consumers around the world due to the high strength and durability of products.A distinctive feature of Wavin is the widest range of pipes for external and internal sewage.

- Ostendorf - Another global manufacturer that specializes in the production of polypropylene pipes that are resistant to the effects of elevated temperatures and inert to aggressive chemical environments. Pipes of this brand do not burn, so they are widely used in the most fire hazardous places.

- "Korsis" - pipes of this manufacturer are made using an extrusion method, they have 2 layers: smooth inner and corrugated outer. Products of this brand are optimal for arranging storm sewers, as well as laying communications on a strong burial in the vicinity of groundwater.

Pipes "Korsis" are characterized by exceptional ring stiffness, so they are often used for the arrangement of trunk pipelines.

- Pragma - domestic manufacturer, all products of which are distinguished by an optimal ratio of price and quality. The company has become famous for its corrugated products from 2 layers made from polypropylene with high resistance to temperature fluctuations.

- "Polytron" and "Politek" - another responsible brand specializing in the production of pipes for internal and external sewage. Products of this brand have a fairly high quality, and the cost is available for most Russians.

Tips

In order for the pipes to remain in a functional state as long as possible, it is necessary to promptly resolve any problems.

Most often, plastic sewage is faced with such problems as:

- blockages;

- mechanical damage;

- too much noise when working.

If the pipeline was mechanically damaged, then repair of the damaged section with full or partial replacement of the part will be required.

It is possible to eliminate the blockage on your own using a special tool, but most often you have to turn to the services of specialists who combine means of mechanical and chemical cleaning.

Any problems with the sewer system can be solved only if equipped with an inspection hatch with a sealed plug. Of course, this is a very unpleasant task, but, unfortunately, the problem itself does not go away.

The functionality of sewage pipes depends largely on the prompt eliminationbreakdowns, since the condition of the pipes largely affects not only the performance of the life support systems at home, but also the level of comfort of its inhabitants.

Further you watch a master class on installation of pressure head sewer pipes.