How to choose and lay the external sewer pipeline?

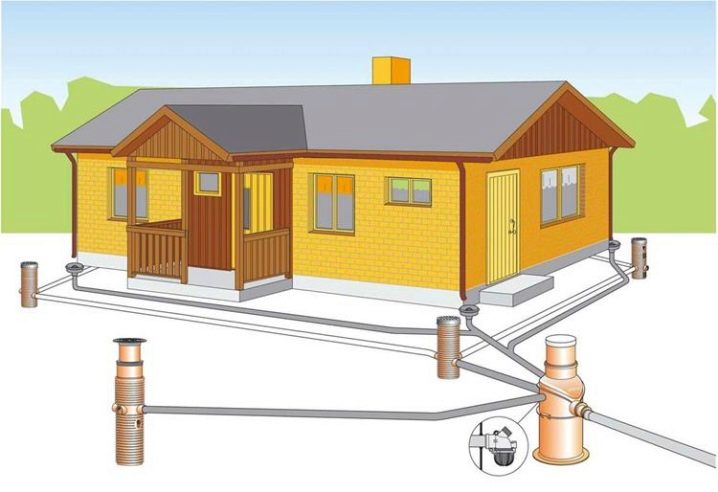

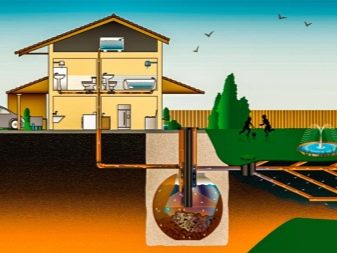

Any modern building, private building or residential complex can not do without a functional system of the pipeline and sewage. If the sewage system of the internal type is needed for the centralization and collection of drainage elements, then an external type COP is necessary for the withdrawal of drains outside the building. We will try to consider options for the selection and installation of external sewer pipeline.

Internal and external COP: differences

It should be understood that the use of internal and external (external) sewer systems has several differences. First of all, these are differences of technical nature of operation, because each of these types is in specific conditions of use.

Possible damage to the mechanical type

As often happens (especially in densely populated areas or areas with high land load), there is a need for additional earthworks. Of course, this type of work needs to be coordinated with local authorities (to determine the depth of laying various communications), however there is a big risk of accidental damage to the pipes. Internal COPs are not affected by this.

The difference in the load on the COP

If we are talking about a reinforced concrete, stone or brick building, then with proper planning, the pressure exerted on internal CS is minimal. A certain load, of course, exists, but it is more of an internal nature - the load and pressure from the runoff elements. Meanwhile, the external-type COP has far greater pressure from the ground rocks, the building foundation, and other ground objects.

Dependence on the external environment

The location of internal compressor stations allows to avoid a number of external influences, such as ambient temperature, groundwater level, soil freezing level, heaving of soil, type of ground rocks (loam, sandy loam and clay), stability of ground rocks, the presence of additional communications (underground and surface).

Differences in repair, maintenance and inspection work

The basis for repairing a CS is most often a blockage or damage to any part of it. If the blockage in the internal type is simple enough to determine and clean the blockage - in some cases, the ordinary blockage can be removed by flushing the pipes with certain solutions (soda, vinegar, special mixture), using a plunger, wire or cable. When it comes to breakage, outdoor COPs need thorough excavation work.

In the case of outdoor CS, especially in the areas of local and urban pipeline network connections, the use of conventional cleaning methods may not be enough, then plumbers use more serious methods of cleaning, for example, hydrodynamic or electromechanical cleaning.

There are a number of technical subtleties in the operation of external sewer systems:

- External or external COPs differ from underground or in-house bright orange color (there are also gray species, however we will talk about them a bit later). Some technicians call this color fiery or red.The use of this particular color scale is understandable - during any excavation work this color is most noticeable and remarkable.

- It should be said about the thickness of the walls of the segments of the outer CS - it is always more than the internal type. This is due to differences in load and pressure on the pipeline system.

- Installation of external / external CS is much more expensive than installation of internal ones. This is due both to the higher cost of elements for external systems, and to the extensive earthworks at the site, depending on the depth of placement of the pipes.

It should say a few words about the color of pipeline systems. Previously, you could meet a COP of both orange and gray type. Gray CSs are often operated on small objects with a low potential load from ground rock and pressure from runoff elements. Red tubes are much more durable, heat resistant and are made of more durable and resistant materials.

Pipe requirements and selection criteria

It is possible to single out the main qualities or characteristics that, according to GOST, external sewage systems should possess.

Strength and stiffness

As already mentioned, external-type COPs are more susceptible to environmental influences. This includes the load / pressure from the ground rocks, the load from the ground structures, and the direct dependence on the heaving of the soil and the level of soil freezing in winter.

Thermal stability

Of course, CSs are established not only in areas with a stable working temperature. External CSs are not susceptible to the pernicious influence of temperature fluctuations only if they are located below the soil freezing level (because most often problems occur precisely because of low temperature values), however, in areas with relatively constant permafrost, the level of soil freezing can be much lower. which complicates the installation of the COP.

Resistant to chemically hazardous or aggressive environment

It is no secret to anyone that CSs are used not only in a chemically stable environment. If we are talking about the installation of sewage systems in petrochemical or energy-type enterprises, there is a high risk of the harmful effects of harmful elements on the CS structure itself. And although all qualitative types of sewage systems presuppose protection from such an impact, it is still necessary to take this fact into account and, if possible, conduct preventive examinations more often.

Consider that the performance of a CS is influenced not by the characteristics of the pipes, but by their proper location.

Types and characteristics

It should immediately be said that in the modern world, it is the use of polymer (some types of plastic) models of external sewer systems that are widely used.

This trend is understandable based on a number of the following advantages:

- Polymer KSs have significantly less weight, in contrast to previously used analogues (cast iron, for example), therefore, their installation, transportation and installation are much simpler and less time consuming.

- The smooth inner surface of some polymer or plastic piping systems reduces the risk of blockages from the accumulation of runoff elements.

- Not susceptibility of polymer systems to such harmful effects as corrosion or decay is another important advantage of choosing these models, however, we note that polymers are more susceptible to the influence of chemically aggressive media.

- The life time of polymeric cops is less than the average service life of cast iron models; however, if properly installed and timely inspected / repaired, it can be equal to this mark (usually up to 50 years).

Consider what materials are used in the creation of outdoor CS most often and try to study the specifics of the installation of each of the types.

Polyvinyl chloride (or, as it is called abbreviated as PVC) is a long-time popular plastic material for the production of many industrial components, including external / internal COP.

If we consider the positive technical aspects in the use of PVC piping systems, we can distinguish the following points:

- Polyvinylchloride COPs are more resistant to mechanical stress (this refers to both damage during installation / transportation and unintentional damage during the construction of another object).

- Certain types of PVC specifically for sewage systems can be used in more open areas, as they are not affected by the harmful effects of ultraviolet rays.

There are some negative points in the use of polyvinyl chloride.

- Low resistance of the material to chemically aggressive media. This makes it unsafe to use for transporting many types of acids, alkalis, oils and other solutions / mixtures.For this purpose, special types of PVC - NPVH (specialized material specifically for sewer systems).

- Polymers are not resistant to high thermal levels. It should be careful to use PVC sewer systems when transporting runoff water or other mixtures with a temperature of more than 60 degrees Celsius.

There are several types of PVC COP depending on the pressure and stiffness of the components of the sewer system.

If we consider the first species, it is:

- Pressure head. Designed for high pressure CS (usually more than 10-15 atmospheres).

- Non-pressure. Suitable for transporting items with a stable load and transmission speed.

Briefly about the second variety, then there are hard (S), medium-hard (N) and light components (L). English figures indicate the class of the product, depending on the wall thickness, in the first case - up to 8 m, the second - up to 6, in the third - up to 2 meters. Each of the types is applicable in the individual conditions of the load of the soil, the ground load of the territory or environmental conditions.

If we talk about the most optimal diameter of the pipe, which is most often used for outdoor CS, it is usually 11-12 centimeters.Installation of PVC pipes is simple - the connection is carried out by installing the sockets. PVC pipes joined together by welding or gluing are less common.

The next polymeric material for the production of COP is polypropylene (or PP). This is a less common type among materials for external systems.

Polypropylene:

- has a relatively small stiffness and strength in contrast to PVC, corrugated or cast iron elements;

- extremely vulnerable when used in open areas, as it is strongly affected by ultraviolet radiation and direct sunlight.

Despite these obvious drawbacks, polypropylene pipes are useful for laying free-flow types of CS or when installing CS in sandy soil.

However, one should not forget about such quality of polypropylene as increased heat resistance (up to 95 degrees C) and resistance to chemically aggressive media.

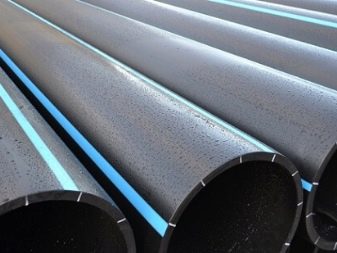

Another polymeric material for external COP - polyethylene (or PE). The use of this type is common in the installation of outdoor CS, especially pressure type.

The most obvious advantages of this type include:

- resistance to pressure surges (or to hydraulic shocks);

- long service life (on a par with cast iron models - up to 50 years);

- sufficient inertness to chemically active substances.

The most obvious disadvantage in the case of PE is the extremely low operating temperature. When used in systems with an external or internal thermal level outside the range from -40 to +40, you risk deformation and breakage of the CS. Such systems, as well as PP, are poorly resistant to direct sunlight.

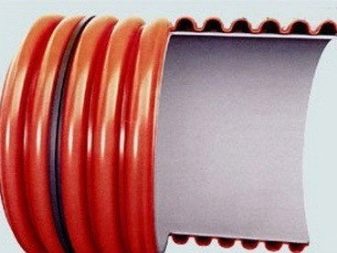

Another popular type of outdoor COP is corrugated products. They are made of PVC or PE materials. What are the advantages of this type of system, consider below.

Even the most reliable polymeric materials have much lower strength than cast iron, and, as a result, need to be replaced and repaired. To solve this problem and was designed corrugated type KS. The folded design of the corrugated type has high rigidity, it increases the area and size of the pipe and reduces the pressure exerted by the soil on a separate CS segment.

There are only two types of corrugated KS: single-layer (folded inside and outside) and two-layer (folded from the outside and smooth from the inside).The first type, of course, is much cheaper, but unlike the two-layer type, there is a high risk of holding stock items and deposits in the folds of the product, which greatly increases the risk of clogging.

In addition to polymer models, there are types of outdoor COP and with other materials. Usually it is asbestos cement, ceramics and cast iron. Below we briefly consider the features of each type.

Asbestos cement is a mixture of Portland cement and asbestos mineral fiber.

Such a composition gives asbestos-cement pipes with the following characteristics:

- long service life (up to 50 years or more);

- comparative lightness of the material (in contrast to the cast-iron models);

- chemical inertness to most types of chemical elements and mixtures.

However, these models have one significant drawback - they are fragile and highly susceptible to mechanical influence. When buying such a COP, pay attention to the presence of cracks and chips.

Ceramics is another popular and one of the most ancient types of external CS gaskets.

Positive features of this type are:

- resistance to chemically aggressive environments;

- minimal risks of deposits and debris;

- Thermal external climatic and internal resistance.

The most well-known disadvantages are the same low resistance to mechanical damage and a short length of CS segments, which means a large number of joints and sockets.

The last material worth considering for external sewer systems is cast iron. It has long been distributed in the industrial market and this, of course, has its own explanation.

The main priorities in the selection of cast iron COP are:

- high strength and rigidity of the cast-iron pipeline - they are better than other types carry external and internal loads and are resistant to mechanical damage;

- even without regular inspection, cast-iron COPs usually serve more than a few decades;

- ease of installation by mounting the sockets;

- Pig-iron systems are thermally and chemically resistant, not subject to rotting or corrosion.

Like any of the external COP, here, too, has its drawbacks.

- High price. Traditional models of cast iron COP still remain one of the most expensive on the market.

- Large weight of the structure, which means additional cash costs for special equipment for installation.

- There is a high risk of deposits of salts, fats and other waste items on the inner walls of the pipe.

- Difficulty or, rather, inexpediency of use in some types of soil (saline example).

In small private areas, and especially in new buildings, polymer analogs have long been introduced into production, they are cheaper and simpler to install. However, if you still want to install cast iron products on your territory, you should choose elements with a diameter of not more than 160 mm. External CS with a diameter of 160, 200, 250, 315, 500 mm are most often used in large industrial enterprises.

Manufacturers

It is worth paying a little attention to such a point as the manufacturers of external sewer systems.

Experienced technicians probably have heard about the German company Ostendorf Kunststoffe more than once. This is one of the leading enterprises in the field of manufacturing pipes for internal and external CS. The main specialization of this company is the production of polymeric sewer systems and fitting elements. The main market segment for the sale of these pipes is located in Germany, but it is also common in other European and Asian countries.In 2011, this company expanded to the Russian market. Service can be found in the city of Yegoryevsk, Moscow Region.

Pragma is another well-known company in the field of CS production. The products of this company are also common on the European market and specialize in the production of precisely corrugated or corrugated sewer systems made of polypropylene. Pipes of this production have long been proven on the market and have high strength characteristics, resistance to high and low temperatures (-60 to +95 degrees), exposure to direct sunlight, and long shelf life and use. The ring stiffness of Pragma pipes is SN8 and SN16, the variation of diameters is from 160 to 630, the typical length is 3-6 m.

Polytron ProKan - another well-known company producing the COP. They also specialize in the production of corrugated external sewer systems, however, the diameter of these pipes can be from 150 to 1000 mm (the latter figure is applicable in large industrial enterprises), and the stiffness class SN8 and SN16 allows installation of pipes at relatively great depths (even up to 15 16 m).

Installation Features

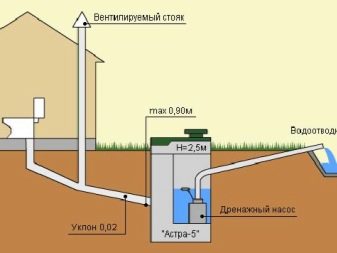

Consider some of the subtleties of installation of external sewer systems. The nuances presented below should be followed until the CS grid is connected to the central pipeline or to the septic tank nozzle.

The process of installing an outdoor (or “street”) CS begins with the installation of a pipeline with a pipe exit point from a building or structure. Further, the COP are laid in specially prepared trench paths. After laying the pipes, they should be carefully inspected for damage and cleaned of possible contamination. When checking, pay attention to the safety of rubber seals and supporting elements (if any). Experienced technicians measure the occurrence of the pipe in the socket before starting the operation of the CS; for this purpose, some types of lubricating elements are used.

Note that the connection of the pipes does not go as far as it will go - a gap of up to 1 cm should be left.

If it is necessary to turn the pipeline systems or at the end of a pipe segment, a technician uses sockets that are installed against the movement of drains. Turns are used with an angle of 30 or 15 degrees. Remember that setting angles of 90 degrees is not safe and moreover, is not allowed.

Usually, to facilitate inspection and cleaning work by technicians, inspection hatches or wells are installed on the CS segments. Installation of the latter is carried out at the stage of installation of the pipelines themselves. Mandatory step when installing an external CS is to check its tightness, for this you should use regular soap. By smearing the segments of the CS at the junctions, turns and sockets, it is easy to understand which of the elements of the CS is incorrectly installed or poorly fixed.

If the COP is located above the average level of soil freezing, the installation of insulation is desirable.

The most common types of insulation are molded or rolled insulation elements. The first ones are placed together with a waterproofing layer (such heaters are usually made in advance under the shape of the pipes), the second ones are placed in place by winding on the pipe. In addition, it is possible to install insulation cable or CS with built-in insulation elements.

Avoid mistakes: tips masters

The most important advice for novice developers is to conduct accurate computational calculations at the site of the CS installation. You should understand that the slightest inaccuracy in any measurements can lead to a complete breakdown of the entire sewer system.And if not very deep-seated CS or polymer-type CS are easy enough for self-repair (private objects are meant), then repair or inspection of cast iron and recessed types can be a big problem.

We advise you to contact the competent specialists in the calculation of all the characteristics of your territory and potential sewage system. Properly using our recommendations in the future, you can install a reliable, safe and durable outdoor sewer system.

For information on how to install the external sewer pipe and insulation, see the following video.