Shaped parts of sewer pipes: design features and purpose

Shaped parts are an important component of the sewage system and are widely used for the installation of communications in all types of buildings and structures. The modern market of sanitary products represents a huge variety of elements that ensure the integrity and operability of the sewer network.

Device and purpose

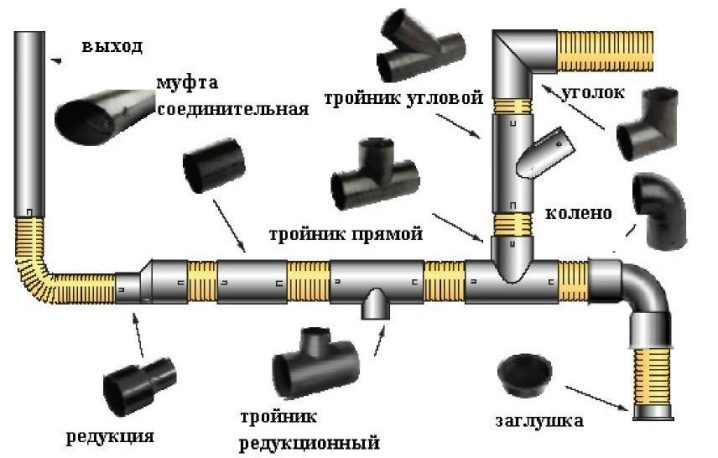

Structurally shaped parts are connecting elements made in the form of tees, elbows, couplings and other curved parts. They are designed to give the sewer pipe a given configuration. With the help of fittings or, as they are also called, fittings, the docking of knots and branches is performed,a pipe plug, turns are made, the vertical direction of the system is changed, different elements cross-section are connected, and additional pipes are inserted.

Products correspond exactly to the cross sections of sewer pipes and are fully compatible with any pipeline. This greatly facilitates the choice, makes it possible to purchase parts of any diameter, ensuring complete tightness of the connection.

Shaped parts are ready-made solid parts, and are not subject to trimming in order to shorten. The inner walls have a smooth design, so that their diameter remains unchanged within the entire element, despite the external relief of the products.

Kinds

Pressure sewage pressure varies from 6 to 11 atmospheres, which requires the use of highly durable shaped elements, providing a tight connection of pipes in the system, protection from leakage and quick replacement of damaged parts in case of need. Fittings are available in a huge range and are represented by a number of products of various sizes and purposes.

- Knee (elbows) intended to change the direction of the structure at an angle of 45, 90 and 120 degrees. The elements are used for both vertical and horizontal changes of direction and are equipped with a sealing ring. For installation of the pipeline under a slight bend, a flexible bend is used, equipped on one side with a socket with a gasket and having a smooth design with the other.

- Tee It is used to form a branch pipe from the main pipeline and is available in two versions. The first type is represented by a model with a bending angle of 90 degrees and two sockets fitted with sealing rings. The spout of the branch pipe is designed for a pipe of smaller diameter, and the straight part of the element must be inserted into the socket of the attached pipe. The second type is represented by an oblique tee with an angle of 45 degrees and is used during the installation of sewage in cases where it is necessary to branch at an acute angle.

- Cross it is intended for ensuring withdrawal in two directions and is issued in two options. For the formation of branches in the same plane, a single-plane model is used, and for the formation of a node, the elements of which are located in two planes, a two-plane model.

- Clutch it is intended for connection of two pipes on a direct site of the pipeline. On both sides of the part are sealing rings, providing a tight connection. Available in hard and corrugated versions. The second type is used when connecting pipes with a slight bend in the domestic sewage system.

- Cap It is intended to close one end of the pipe and is often used in the process of replacing a part of the pipeline during its maintenance and repair. The part provides a tight connection to the pipe and prevents the spread of unpleasant odors during the replacement of communications.

- Adapter serves to interconnect pipes of different diameters, and also provides a tight transition between cast iron and plastic pipes. With the adapter, you can easily connect not only the most common sizes with a diameter of 110 and 50 mm, but also any other pipes.

- Inspection coupling it is designed to provide access to the inside of the pipeline and is installed for the purpose of conducting preventive maintenance and caring for communications.

- Check valve protects sewage from scavenging, preventing leakage. In case of clogging, the valve will not allow contaminated liquid to rise through the pipe and will shut off the system in an emergency. The valve is closed by a tight valve that allows quick access inside to clean it.

- Sewer aerator made in the form of an air vacuum valve and is used to prevent the penetration of unpleasant odors and gases from the sewer system. The part is installed at the highest point of the riser, located vertically, and vents the air when the pressure rises. Thanks to the work of the aerator, the breakdown of the traps becomes impossible

- Ventilation Umbrella performs a protective function to prevent mechanical debris from entering the system from the outside. Mounted on the roof at the top of the pipe.

- Siphon performs the role of a connection outlet and the main pipeline. Due to the curved shape, the element provides a water lock that does not allow unpleasant smells from the system into the room.

- Hose clamps Available in a wide range of sizes and designed for mounting hardware sewer pipes.

- Compensation nipple It is a small pipe with a length of 17 to 25 cm. It is intended for building up the pipeline and replacing damaged sections. One side of the nozzle is equipped with an elongated bell, and the other has a smooth design and is attached to the pipeline with a coupling.

- Hatches to monitor the state of the sewer system are an indispensable element of communications. Their installation is made in a particularly vulnerable, in terms of clogging and breakage, places of the pipeline. There are two types of hatches: end and remote. The first is installed on the vertical and horizontal pipes of the sewer system with Y-shaped tie-ins. To eliminate blockages, the manhole cover is removed, and the pipes are cleaned through the opening. The external hatch is characterized by the presence of a plug on the T-shaped fitting, which can also be located on both vertical and horizontal pipes. The advantage of this type is the possibility of cleaning the pipes not only in the direction of fluid flow, but also against it.

The role of each shaped element of the sewer pipeline is very significant.It is these parts that make it possible to form drain diverting systems in the form in which they are present in modern facilities, ensuring the proper functioning and integrity of intra-house and underground communications.

Manufacturing materials

To facilitate visual selection, parts for home use are available in gray, while exterior work items are brown in color. This greatly simplifies the selection of the necessary parts and eliminates errors during installation. Fittings for external use have higher strength and thickened walls.

The ability of such elements to withstand the pressure of soils and not to collapse under the influence of groundwater and runoff is due to the high rate of ring stiffness of models designed for large volumes of fluid and extreme external conditions of their operation. Their dimensions somewhat exceed the dimensions of the house parts, due to the more serious load on external communications and the unfavorable conditions in which they are used.

The connection of plastic fittings is carried out on the basis of adhesive, welding and threaded method.To ensure complete tightness of the joint, all PVC models are equipped with rubber sealing rings, which allows you to create a reliable connection and avoid leakage.

In some cases, in particularly difficult areas it is recommended to strengthen the joints with silicone sealant. This will ensure the strength of the joint in the case of rubber drying and prevent leakage of fluid. If the socket is not equipped with sealing rings, use a special adhesive, which after drying forms a structure that is almost identical to the structure of the plastic pipe.

The only restriction on the use of the adhesive method is its use on pipeline sections prone to sagging. In this case, it is recommended to use threaded or welded connection methods.

Plastic elements easily transfer the temperature of the liquid to 75, and in cases of short-term exposure up to 95 degrees. This allows you to boldly use PVC products for arranging sinks from washing machines and dishwashers. When installing these types of communications should consider the expansion of elements from thermal effects.Therefore, the connection details "until it stops" is not allowed. The impact of negative temperatures also does not affect the integrity and performance of the fittings: in cases of pipe freezing, the fittings do not crack or deform.

In addition to the cost, weight and ease of installation, plastic products are also not prone to the formation of blockages. This is due to the absolutely smooth inner surface of the elements, where the solid particles simply have nothing to cling to. The system, mounted from plastic elements, does not require the cost of its maintenance and does not need to be repaired for a long time.

Shaped parts of cast iron are designed to connect cast iron pipes in the sewage system. For their production using high-strength nodular cast iron. Models are available in a wide range with a wide variety of shapes and sizes. As sealing elements, fittings are completed with cuffs or a special stopper. The inner walls of cast iron parts are made of cement-sand coating that protects the metal from corrosion and increases the tightness of the joints.

The outer part of the elements has a zinc coating and is additionally covered with bitumen varnish. This coating ensures high resistance of parts to aggressive environmental influences and significantly prolongs their service life.

Cast iron fittings can be effectively used with both cast iron and some polymer pipelines. Products are often used in industrial water supply, in the arrangement of sewage systems and for snowing the ski slopes. Due to the resistance to diametral deflections and the preservation of tightness during heavy road loads, cast iron products can fit into any type of soil and be used in any climatic conditions without restrictions.

Selection features

Before proceeding to the selection of fittings for sewage pipes, a project should be drawn up on which all connections, outlets, tie-ins and other structural elements of the pipeline must be clearly identified. In drawing up the scheme, it is necessary to indicate the marking of the pipes to be used for installation, and the size of their section.

Sewerage equipment is quite a serious matter, and the installation process and overall performance of the system will depend on the correct selection of components.

For the device sewage in private and multi-family residential buildings, as well as in public buildings and institutions is recommended to use more modern plastic material. PVC pipe significantly reduces the load on the foundation and supporting structures, is less prone to the formation of blockages and condensate, and also has a comfortable cost and a wide range of models. In addition, many types of polyethylene models are threaded, which greatly simplifies self-assembly.

Cast iron fittings are used in industrial plants that discharge highly contaminated or poisonous effluents, as well as for pumping large masses of liquids in particularly aggressive environments under adverse external conditions, including in areas with high seismic activity.

Competent installation and proper use of shaped parts greatly simplifies the process of installing a sewer system, makes its operation effective, and maintenance is low-cost and easy.

On how to install sewage pipes with their own hands, see the following video.