How to choose polypropylene sewer pipes?

One of the most famous in our time materials for the installation of conventional sewage water pipes are pipes made of polypropylene. These devices are so widely used in everyday life because of their special operational features.

Special features

Polypropylene is a special polymer base, which is characterized by strength and resistance to high temperatures and various hazardous substances. The color of the product itself is gray. Such products are made by hot squeezing from high-quality polypropylene. PP pipes have such advantages as:

- small weight;

- not afraid of corrosion;

- high chemical resistance;

- excellent hydraulic properties;

- increased resistance to various actions - the material in extreme conditions can change shape, but it does not break;

- low coefficient of friction will contribute to greater throughput;

- ease of installation will contribute to the reduction of construction time; in addition, the material will not need additional use of heavy equipment;

- standard parameters of polypropylene pipes, which completely coincide with analogues from ceramics and metal, ensure quick replacement of any section of household sewage;

- the guarantee of the absence of salt deposits and the formation of bacterial sediment inside;

- excellent heat resistance - the temperature of discharges can reach up to + 100ºС;

- excellent resistance to diffusion.

If we talk about the disadvantages of products, it is worth noting the following:

- fairly high softness of pipes - for laying them in the ground will have to significantly thicken the walls;

- resistance to UV rays is much lower than that of PVC, but engineers regulate this difficulty with the help of special impurities.

Thanks to the use of polypropylene, from which sewage pipes are made, it is possible to significantly increase the temperature in closed constructions.

The gray base has excellent strength characteristics, due to which pipes made of polypropylene, intended for internal drainage, can easily withstand vibrations at low temperatures. Polypropylene is completely harmless to humans. It will not release toxic substances, will not produce harmful effects on the environment. Sewer materials from high-quality propylene that have GOST 26996, can be used in domestic drainage, without worrying about the health of the consumer.

This type of product is characterized by high performance properties. The use of various additives in the production of polypropylene pipes contributes to their excellent resistance to frost, reaching the lower limit of -50ºС. These qualities allow the use of material in the regions in the north.

The warranty period of uninterrupted operation for 50 years is the most powerful argument when choosing polypropylene. Laboratory studies prove that the material will work flawless and 100 years.

Kinds

If polypropylene pipes for internal drainage are produced evenly and in one layer, then the base, which is designed for the installation of surface networks, has a more specific structure.These products make two-layer. These types of products often have different colors, but mostly gray color is used. The layers inside the tubes are completely smooth, and the outer layers are corrugated. Such a structure makes the material more resistant to both dynamic and statistical work.

Corrugated products are made of polymer, which has a high resistance to chemical attack, as well as hardness to loads in the form of jolts. Polyethylene can easily withstand long-term wear and tear, therefore products made from this material have a long period of operation. For the installation of external piping often choose double corrugated materials from plastic. The main feature of the operating parameters of such products is their special costal hardness. Due to this, the raw material will be able to withstand various spontaneous loads, even under significant soil pressure.

Less commonly, polypropylene is used in the construction of external engineering sewage systems because of its softness. Polypropylene products are actively exploited during the installation of internal drains. They withstand significant temperature fluctuations.For cold water pipes, pipes that can withstand a pressure of 1.6 MPa are selected. Polypropylene components for pipelines are produced with the addition of various impurities, among which you need to select several options.

- Ppr. The raw material used is a static copolymer. This material has resistance to temperature fluctuations and can be used with a temperature difference from -170 to +1400 degrees. Such material is almost not subject to shock loads. Such pipes are used for installation of household sewage systems.

- PPH. This polymer has in its composition all kinds of additives that can make its mechanical strength higher. It is used in the installation of external and internal sewage. When installing such a pipeline, the pipe will serve as reliably as possible even under the weight of the ground.

This option is not suitable only for heating systems.

- PPB. This material has a special structure, because of which it can be used in heating systems.

- PRS. These products are of superior quality due to the special molecular structure. Such products are operated in the networks of heating, water supply, sewage.They are produced in a wide range of parameters - 25–1200 mm.

Knowing the characteristics of pipes, it is easier to choose the most suitable products for future operating conditions.

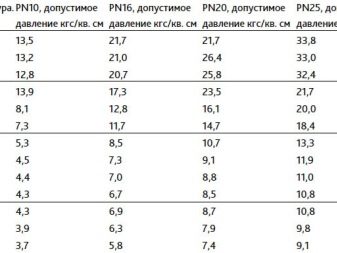

- Products brand PN 10 can be used only with fluid pressure, not more than 10 atmospheres. They can be selected for the transport of coolant having a temperature of not more than 45 ºС. In addition, they are actively used in pipelines with cold technical or drinking water. Such pipes have the lowest price in hardware stores, therefore they are quite popular.

- Marking PN 16 says that the technical characteristics of pipes of this class allow operation at pressures up to 16 atmospheres. The working temperature can already reach + 60ºС.

- Pipes PN 20 used in heating networks, the temperature of the carrier in this case may be already + 95 ºС, and its pressure - 20 atmospheres. This makes it possible to install such pipes in central heating systems.

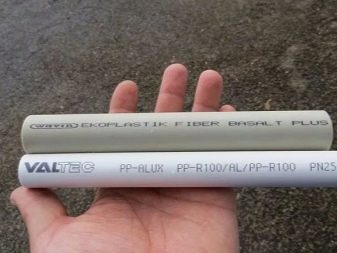

- Pipe PN 25 Experts call the strongest of the whole class of PP pipes. It has a reinforcing layer of aluminum foil. Its introduction has helped to raise the working pressure to 25 atmospheres, the temperature to + 95ºС.These products have increased strength, they are not afraid of deformation by heat with a high-quality mount. It is reinforced pipes of this class that are used in most heating systems, as well as in hot water systems.

In addition, PP pipes can be of two types.

- Free-flow used in local and general sewage networks, where the transported medium moves under the influence of gravity along the internal surface of the pipeline, which lies with a slope - in sewage and drainage systems, in the drainage network. The sewer bell-shaped pipe with the structured wall will become ideal option for arrangement of non-pressure drainage systems.

- Pressure head - these are pipes from various materials for different purposes for pipelines that transport liquid, solid and gaseous media under a certain pressure, but pressure pipes for vacuum pipelines that transfer the working medium by vacuum are also included. Pressure pipes are used in internal and external water and gas supply systems, pressure pipelines, as well as for the transfer of gas, oil, bulk materials.

Dimensions

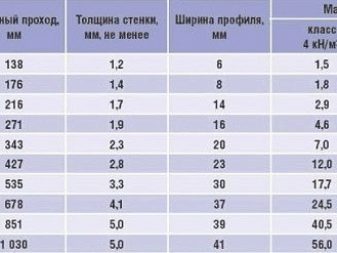

If we mention the size of PP pipes, they are not regulated by GOST, but by special technical documentation. There are products that are designed for pressure and free-flow sewage. When purchasing non-pressure pipes, you can see the following range:

- the smallest value of the diameter of the conduit is 16 mm, the highest - does not exceed 1200 mm. Products with the largest cross-section are chosen for the construction of outdoor systems;

- pipes with a diameter of 50 mm, often selected for domestic domestic systems. Products with a rating of 110 mm are attached to the riser. For the installation of external systems buy products with a diameter of from 160 to 200 mm;

- the length of the pipes themselves can be from 2 to 8 meters, and lengths of up to 12 meters are often found.

The extensive product range has a pressure type pipe. It happens that for non-pressure drains acquire products that are designed for installation in pressure. They may have parameters such as:

- diameter can be from 32 to 1600 mm;

- individual items may be 12 meters long.

- products of 50 and 110 mm are the most demanded.

Manufacturers

The German concerns Aquatherm, Banninger and Wefatherm are considered the best among manufacturers of polypropylene pipes.The main characteristics of their products are durability and trouble-free operation with the most active use.

The second place is confidently kept by Czech products, which for many consumers have become a kind of standard. For many decades of brands, the quality of their products remains consistently high. The main companies are Ekoplastik and FV-Plast.

Turkish manufacturers Tebo, Pilsa, Firat, Kalde, SPK are the most popular in the budget segment.

Next, you can mark the products of Russian manufacturers. Among them are Pro Aqua, Plastic, which manufactures pipes under the brand name RVK, Heisskraft, Politek and others. There are as many user reviews about Russian pipes, as well as their manufacturers, from rather negative reviews about RVC to quite positive notes about Heisskraft.

Subtleties of choice

When choosing polypropylene sewer pipes should be guided by several parameters.

- The very first thing to do is choose a manufacturer of pipe products. User feedback allows you to make a rating of the most sought-after companies and select the necessary equipment among their range.

- Each product is designed for a specific pressure. It can be recognized by the marking indicated on each pipe. For example, PN 25 indicates that a pipe will fit a pressure of 25 atmospheres. To use products in pressure systems, you must select the pipe with the highest pressure value. The marking of pipes can also be found and an indication of the maximum temperature of the working environment. On products that are designed for hot and cold water, can be marked “hot & cold”. It is best to choose pipes reinforced with fiberglass or aluminum foil.

- The last parameter to choose is the diameter of the pipe. For an apartment or a cottage, the internal diameter of the pipe should not be less than the diameter of the riser.

Usually in houses located outside the city, pipes with a diameter of 32–40 mm are used for wiring, and a diameter of 26 mm is enough for apartments.

Tips

Experts recommend sticking to the following simple tips:

- Before installation, you need to create a sketch of the future water supply system, after which it becomes clear which materials should be purchased and in what quantity directly;

- you need to calculate the preliminary footage of the entire pipeline, the number of all angles, fittings, various tees and other fittings that may be useful;

- After purchasing all of these materials, cut polypropylene products into pieces of the desired length;

- in order to avoid future leakage of pipes, separation of existing seams and other unpleasant consequences due to poor quality work, you should entrust the laying of polypropylene pipes to a good specialist;

- after the installation of the polypropylene pipeline in the apartment, it is necessary from time to time to check it for complete tightness for its normal functioning.

Pipes need to be subjected to pressure in several atmospheres, which will check whether there is a leak.

On how to solder pipes made of polypropylene, see below.