Installation of suspended and floor installation of a toilet bowl

Not so long ago, interesting alternatives appeared on the market for simple floor toilets - suspended installations. Today, they are chosen by many consumers, noting the interesting design of such products. But not all users know how to install such plumbing items correctly. The article will discuss how to install simple and suspended installations.

What it is?

The installation is a special system that represents a well-thought-out construction, which allows fixing the toilet and other plumbing equipment as reliably and firmly as possible. In addition, these elements are necessary to hide plumbing connections.

Special features

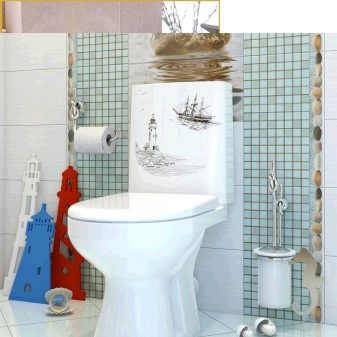

According to consumers and specialists, modern suspended and floor installations are very convenient.Using such an interesting system, you can put the toilet so that its tank will be safely hidden behind the wall. At the same time, it is additionally protected by thermal insulating material, which provides sound insulation for plumbing during its use.

When installing the installation, only the toilet bowl itself remains visible. Thanks to this feature, the room in the bathroom or toilet will seem much more spacious, even if in fact its area is modest.

Professionals argue that the installation of such systems is quite possible to make their own hands. To do this, just stock up on all the necessary tools and clearly follow the step by step instructions. Of course, if you are not very confident in your own abilities or are afraid to take on such work, then you better summon experienced masters,

If you decide to install in your home floor or suspension installation, then you should familiarize yourself with the advantages and disadvantages of such systems. First, consider their advantages.

- First of all, the compact dimensions of such products should be noted.Due to this characteristic, suspended or floor installations can be installed even in very small spaces, where every centimeter is counted.

- Such systems are distinguished by their quiet operation, since the cisterns of toilet bowls hide behind the walls.

- Many housewives say that it is much easier to clean rooms with such structures - there are less hard-to-reach areas.

- If you decide to install a suspended structure, then you will be able to lay out a mosaic or a beautiful tile pattern on the floor - such a composition will not interfere with anything, disrupting the integrity of the pattern.

- Properly installed installations save water. This is due to the fact that in such structures there are two buttons. One of them is responsible for a large flow of water, and the second - for a small one.

- Such types of plumbing are not subject to breakage. If they do happen, they can be easily eliminated.

- Installation is quite possible to install in the "Khrushchev".

- Suspended and floor installations are reliable and durable designs. They seamlessly withstand impressive loads (up to 400 kg).Of course, this advantage occurs if the toilet was installed correctly, and the bowl itself is made of quality material.

- Suspended and floor installations look very original. Their design attracts attention and makes the interior of a bathroom or toilet more stylish and modern.

Installations have their own weaknesses, consider them in more detail.

- Such systems are expensive. It is necessary to take into account the fact that, together with additional expenses for installation work, such a design can cost a pretty penny.

- In such structures there are always hidden items that become inaccessible for repair and maintenance.

- Replacing classic toilets is a fairly simple job, but if you decide to replace the installation, you will most likely have to repair the entire room.

Kinds

There are several types of suspended and floor installations. Let's get to know them better.

Block

Block installations have support racks and fasteners. Such designs can be used for installation and floor, and hanging products. Block systems are reliable, robust and durable.Their installation is considered quite simple.

However, block installations have one serious drawback - they require the presence of a permanent wall in the room.

Framework

Frame (or frame) system is no less reliable, strong and durable. These structures can withstand loads up to 400 kg without any problems.

Frame options can be mounted on four points on the wall or two points on the floor and two on the floor. Sometimes these structures are installed directly on the floor.

Frame construction is not required capital wall, as block options. Such systems can be mounted not only on concrete and brick, but even on gypsum partitions.

The basis of these structures is a durable steel frame. On it you can install not only the toilet, but also other additional elements. For example, it may be a sink or bidet. Installation of the frame system can be made not only near a straight wall, but also in the corner.

Corner

If you want to choose an original and fashionable design, far from the usual standards, then you should pay attention to the corner installations.However, it should be noted that such a construction can be installed only if there are right angles at 90 degrees in the room.

Corner assembly is more complex. In addition, such installations are more expensive than other options.

Types of toilet bowls

Contrary to popular belief, toilet bowls can be different. They differ in the shape of the bowl, the method of flushing, the release into the sewage system and the material of manufacture.

By type of bowl

Toilets are equipped with bowls that have different shapes.

- One of the most popular are funnel-shaped models. They have several advantages for which many buyers choose them. The main thing is that the funnel-shaped products are hygienic, because in this design the funnel is located in the central part of the bowl. There are no serious flaws in the funnel-shaped models, however, when using them, a splash is likely to form.

- The second most popular are dish-shaped toilet bowls. They are simple flat platforms. Such models are cleaned only by the action of a water jet.Such models are considered obsolete, but differ in that they exclude splashing. Unfortunately, dish cups can not be called highly hygienic, so recently they are not so popular.

- And there are also common canopy bowls. In such products there is a special projection that prevents the formation of a splash, as well as a slope, with the help of which the walls of the toilet bowl are cleaned.

By type of flush

Toilets also vary in flush mode. This parameter depends on the direction of water flow. Modern manufacturers produce toilets with direct and circular flush.

- Direct flushing occurs with the help of a water stream on one side of the bowl. Such models are durable and reliable, but they do not guarantee sufficient flushing of the entire surface of the toilet bowl. In addition, these products are quite noisy and create a lot of splashing. But models with such flush are inexpensive.

- As for the circular flush, the water jets in it are directed at different angles and move in different directions. Thanks to this system, up to 95% of the bowl surface is processed and cleaned.In addition, circular flush toilets are not noisy.

- Less common are toilet bowls with non-standard drain systems, which provide for pre-filling the bowl with water, and then its quick descent. With this method, flush fills the entire cavity of the toilet. The disadvantages of such products include excessive water consumption during operation. This indicator may exceed 8 liters.

On release in system of the sewerage

Modern types of toilet bowls differ in the method of drainage to the sewer.

- Oblique method was popular in the construction of riser structures in apartment buildings 70-80 years of the last century.

- Horizontal descent in our time is the most common. Most of the current buildings are designed for use of toilet bowls with such a system.

- And also there is a vertical descent. Today, such systems are used on both American continents.

By production material

Floor and wall toilets are made from different raw materials. Each model has its own characteristics and positive qualities. Let us consider in more detail what materials modern toilets are made of.

Earthenware

Toilets made from materials such as earthenware, can not boast of high strength. And also they have a small porosity, so cleaning such products is not an easy task. At present, such raw materials are used less frequently, since as a result very fragile objects are obtained from it, on which chipped, cracked and other mechanical damages easily remain.

Of course, in modern production, special technologies are used, thanks to which faience sanitary ware becomes more reliable, however, the earthenware is much inferior to other materials from which toilets of various modifications are made.

Porcelain

Porcelain toilet bowls are stronger and more durable. They are easy to clean. Such models can often be found in public institutions, as they seamlessly withstand impressive loads and do not fail.

As for the disadvantages of porcelain toilet bowls, then they can be attributed to the high cost of such products. In order to reduce costs, more affordable specimens of ceramics have become common.

Steel and cast iron

Metal plumbing refers to the classics.Metal toilet bowls are most commonly found in public places. Such products are distinguished by durability, strength and resistance to wear. They are almost impossible to damage or scratch. Steel and cast iron structures easily withstand heavy loads.

The disadvantages of such products include relatively high cost. Cast iron toilet bowls are considered the least popular, as they have impressive weight and poor durability of the enamel coating.

Stone and glass

Glass and stone toilet bowls (natural or artificial) belong to products from the category "modern". Such plumbing items are expensive, but they have an elegant and attractive appearance.

Glass models can not boast of excellent strength characteristics. However, there are many analogues of glass and stone, from which are made not less beautiful toilets, which are more reliable, but are inexpensive.

Plastic

Thanks to modern technology, you can find toilets made of such material as reinforced acrylic. Many consumers mistakenly believe that such products are not durable. In fact, it is not.Acrylic models have a long service life. In addition, these products are quite practical - they have almost no porous surfaces, so they are easily cleaned from any contamination.

The disadvantage of such plumbing is its susceptibility to deformations, which can be caused by mechanical stress or too high temperatures.

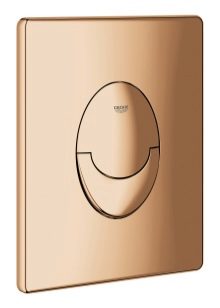

Flush buttons

For modern installations, special buttons are available. As a rule, they are quite large in size, because it is through them that one can get close to a hidden tank.

If necessary, the button is seamlessly removed from the special latches with a simple thin screwdriver. After that, the decorative panel is unscrewed, which surrounds the button. Similarly, the dismantling of other similar structures.

If you have a pneumatic stop-drain button installed, then the causes of problems with such structures can be:

- power failure;

- fault in the opening valve system.

To fix a pneumatic button, you must have special knowledge. If you have not previously worked with such elements, then you should call the wizard.

There are also touch buttons. Such details look interesting, and it is convenient to use them. It is worth considering that the lion's share of damage to the touch buttons is due to violations of the integrity of the power cable. To repair such mechanisms should only an experienced person.

Accommodation options

Regardless of what kind of installation you choose, you must begin the installation work with a good choice of space for the toilet. In urban apartments of standard planning, you can select a truly suitable space - a niche in which there are water and sewage risers.

To install the installation you will need to alter a little niche by placing risers in the corners. If they are made of metal, they are recommended to be replaced with plastic.

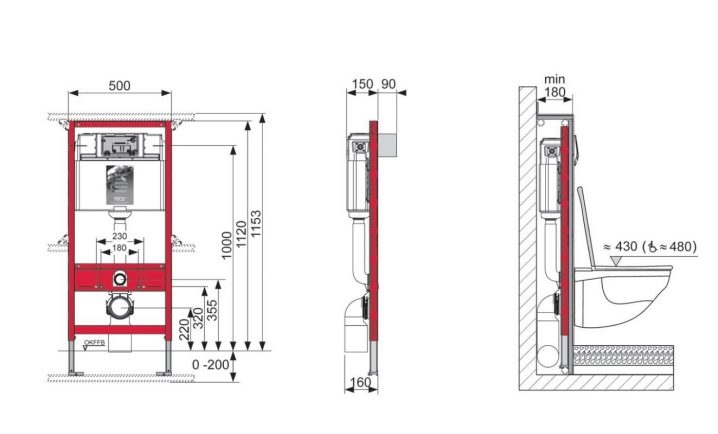

Before proceeding to installation work, it is necessary to apply the correct marking. To do this, you need to know the exact dimensions of the installation.

Dimensions

Currently, stores sell toilets and installations of various sizes. However, the standard dimensions of floor models are 520x340 cm. The seat height in such variants is 400 mm. There are models of toilet bowls, which have an increased length of 7-10 cm (such models are especially popular in America).

Suspended copies have different parameters:

- small models have a length of not more than 54 cm (perfect for compact rooms);

- medium ones are produced with a length from 54 to 60 cm (they are considered the optimal products, the most convenient to use);

- large models with extended lengths up to 70 cm (ideal for older and obese users with disabilities).

What is included?

The following components are included in the complete set of floor and suspended installations:

- frame;

- toilet bowl;

- seat with cover;

- tank;

- exhaust pipe;

- insulation;

- flush buttons;

- fasteners.

Installation

Many owners believe that it is very difficult to install the installation, and it’s impossible to cope with such work. In fact, it is not. Consider step by step how to mount such a system with your own hands.

Instruments

To install the floor or wall installation yourself, you need the following tools:

- laser or bubble level (choose a tool with which you will be more comfortable to work);

- special construction pencil or marker for marking;

- perforator;

- concrete drill;

- roulette;

- spanners (overhead).

Preparatory work

Installations assume that there is a separate niche in the room where the frame will be located. It should be borne in mind that the walls in the room should be quite reliable and strong.

The niche in the room should have the following parameters:

- 1000 mm in height;

- 600 mm wide;

- 150-200 mm in depth.

There are cases when requirements on depth are quite difficult to fulfill. Then you need to make the niche as deep as possible. However, its disadvantage should be sheathed (closed) with drywall and covered with a finishing material.

Installation

After preparing the niche, you can proceed to the installation installation.

- First you need to mount the metal frames to the wall. As a rule, in these constructions there are initially openings with the help of which the frames are mounted on the dowels.

- There should be two points of attachment - to the wall and to the floor.

- Further to the place of installation it is necessary to bring sewer and water pipes.

- Be sure to check whether the frame is level. Nowhere should there be distortions and significant deviations from the level.

- Horizontal adjustment should be done with wall clips.

- At this stage, the height of the suspended toilet is also set. First of all, this parameter will depend on the growth of households. Most often, the height of the toilet in this case is 0.4 m. The height of the bowl can be adjusted at its discretion in the future.

Mount such structures should be with full responsibility. All parts of the box must be fastened as smoothly and firmly as possible. Otherwise, the system may fail.

Connection of sewage and water supply

After fixing the toilet is required to bring water to the tank. For this you can use a flexible or rigid system. Most experts use exactly the supply, because it is more reliable, durable and durable. Of course, it is permissible to install flexible hoses, but if they get damaged or deformed, then they can be easily reached and quickly removed. During installation of the supply line, the tank valve, as well as the drain, must be closed.

After connecting all the necessary elements you need to check the reliability and quality of fasteners. To do this, open the water in the faucet and fill the tank.If you notice a leak, you need to fix it. At the same time, water may remain in the tank.

Next you need to connect the toilet to the sewer. To do this, the drain hole of the sanitary device must be inserted into the drainage pipe of the sewer pipe using a suitable corrugation. There are also models that can be assembled without using it.

Having completed all the work, you should ensure that the installed system is sufficiently tight. To do this, it is necessary to screw the bowl to the frame for a while. After that, it will need to be removed again. You can mount this part only at the completion of all installation work.

Note that the wiring of the sewer pipe must be connected before the installation of the installation itself. Its diameter should be 100 mm (normal). It should be laid with a special slope.

Finish

After installation of all components it is necessary to close the design with a plasterboard sheet. Functional elements must be sewn up with similar sheets / panels. For the bathroom, you should buy only moisture-resistant drywall, which is more durable and wear-resistant than a simple material.

To finish more reliable, it is recommended to fasten it to the metal frame, assembled from the profile, as well as the frame from the toilet.

The trim can be made in two ways:

- throughout the plane of overlap;

- only on the plane where the installation is located.

The second method of finishing involves the formation of a small shelf, located directly above the bowl. It is permissible to use to accommodate the necessary owners of items. After that, the closed barrier must be trimmed with tiles or PVC panels - it all depends on how the rest of the partitions in the room are decorated.

Useful tips

As you can see, self-installation of mounted or floor installation can be done by hand. It is worth listening to some of the advice and recommendations of experts, so that the design turned out to be more reliable and quality.

- When installing the installation, the tank is always “hidden” in the wall. However, one way or another, access is needed. To do this, you need to install the audit hatch. It is better to place it just below the installation button.

- The installation location of the button must be planned. At the same time, it is necessary to take into account the layout of the tile on the walls.It is recommended to mount this part between adjacent tiles or in the central part of one of them.

- The thickness of the structure covering the installation should be no more than 70 cm.

- Keep space between plumbing fixtures. It should be 180-230 mm.

- To save water, it is recommended to choose the appropriate buttons, equipped with two types of drain.

- If the toilet on the floor has leaked, then you need to make sure the high-quality sealing plumbing. All joints and the connection with the corrugation should once again be treated with sealant.

- If the toilet is installed unstable, then you should tighten the bolts. However, this should be done carefully, so as not to disrupt the thread.

- Most often when laying polypropylene pipes are used. In addition, all metal risers must be replaced by plastic.

- Before proceeding with the installation, it is worth making detailed drawings and a diagram of the future construction. This is especially important if you decide to install a complex corner installation.

- If the bathroom is located in the central part of the living area (far from the capital floors), then it is necessary to install only the frame structure in it.

- Before installing the installation, it is desirable to change the niche and remove the risers in the corner.

- Note that installation of overhead plumbing should be started only 10-14 days after fixing the frame.

- Adjusting the height of the suspended toilet, you must rely on the distance from the center of the horizontal sewer outlet to the level of the clean floor. It is also necessary to take into account the slope of the pipes.

- Do not proceed with installation of the installation until you have carefully studied the instructions that came with it.

- Before installing the toilet, do not forget to “pull out” cold water pipes.

- Remember that any problems in the inside of the barrel are quite easy to identify: carefully examine all the nodes. All moving elements should “walk” without problems, the junction should be as dense and reliable as possible, and there should be no distortions in the design.

- The frame can be installed only after the screed and waterproofing of the floor is made.

- It is recommended to install lower and wide installations in a wooden house. Thus, the load on the wall will be significantly reduced. Otherwise it is better to attach the structure to the floor.

On how to install a wall-mounted and floor-mounted toilet, see the following video.