Charcoal water filter: how to choose and manufacture?

The water flowing from the tap, it is difficult to call clean, harmless to health, suitable for cooking and drinking. Clean and disinfect it, eliminate residual chlorine and other disinfecting additives, remove the unpleasant odor filters. One of the most affordable and environmentally friendly is the coal type of filtering devices.

Special features

The carbon filter is designed for the purification of tap water, and is also used as a water treatment system for water supply of an autonomous type. The cleaning agent in these constructions is activated carbon. It, in turn, is a product based on hardwood or coconut shell, which is exposed to thermal effects.The final step is the pore opening procedure, called activation. In addition to coal, the composition may contain other components containing highly concentrated carbon.

The result is a porous substance that has the ability to adsorb, that is, the retention of pollutants and the passage of moisture.

Most often, carbon filters are produced in the form of cartridges, which are a multilayer block. The outer part is at first larger, and then gradually tapering mesh. They serve to contain mechanical impurities. The inner part of the cartridge - activated carbon, which needs periodic replacement.

Acting as a sorbent, activated carbon in the filter performs the following functions:

- elimination of unpleasant taste and odor of water;

- rust removal;

- retention of organic elements, including microorganisms;

- removal of residual chlorine and other elements used for disinfection from water.

The activated carbon filter does not cope with the purification of water from radioactive elements and metal ions.

Only coal meeting the following criteria will cope with these functions:

- Small pore size, and for each type of cleaning systems the concept of "small" individually. For household filters, coconut shell coal is commonly used, since the processing of these particular raw materials makes it possible to achieve the required parameters.

- High chemical hardness that prevents coal from washing out of the filter system when microparticles pass through it.

- Small granule size. The smaller this indicator, the better the substance filters water. The size of the granules is directly related to the pore size.

Types and principle of operation

The coal composition can be enclosed in various types of filters. The bandwidth of the filter layer, and hence the quality of water purification, depends on the characteristics of the latter.

The simplest filter can be installed on the tap used to supply drinking water. Installing the device on the main water supply can cause a pressure drop in the latter.

More powerful models can be installed on the main branch or on the supply pipes. If we are talking about the need to use the system at the stage of water treatment for delivery, it is more logical to install the device in the well or well system. The specific location is usually determined by the type of filter used.

The following types of activated carbon filtration are distinguished:

- The jug-type filter is a nozzle installed in a special jug. The duration of its service life is about 2 months, after which the filter needs to be replaced. Their advantage is low cost, ease of installation and use. Such a device can be a good way to purify water for a small (2-3 people) family. However, these filters do not provide a high degree of purification, passing along with some types of bacteria, salts of heavy metals.

- Flow-through filters are tap nozzles. According to their technical characteristics, they significantly exceed the pitcher systems, but the degree of their purification is also far from optimal.

The flow filter is easily mounted on the faucet, but reduces the water pressure in it. The cartridge used in the system lasts up to 3 months, and if necessary, the entire filter can be removed and installed on another tap.

Such a device is suitable for residential and office space with a centralized sewer system, that is, one that does not require additional water treatment.

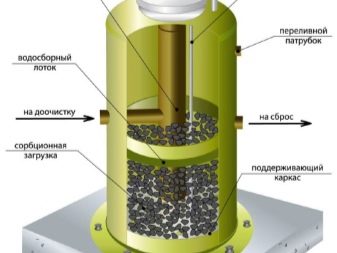

- Balloon (cartridge systems) are a construction of several cartridges with different degrees of purification. Such a device is included in the general water supply system and can consist only of a carbon filter or several different filter complexes.

Balloon filters provide an average degree of water purification, however, along with the efficiency and productivity, the cost of the unit also increases.

Under urban water supply conditions, such a filter is usually sufficient to purify water from the central water supply. In other cases, a wood-based sorption filter should be included in a multi-stage purification system, since it cannot cope with all contamination.

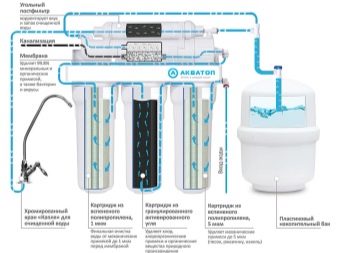

- The coal filter as a part of system of the return osmosis. This water treatment system is a device with multi-stage purification, one of the steps of which is the passage of water through a carbon filter.A feature of the system is the presence of a membrane in it, which transmits only water and oxygen molecules. In other words, it provides a high degree of water purification.

As a rule, the system has several layers of membranes, each subsequent one characterized by a smaller diameter of the holes. The last membrane has such small perforations that only water molecules pass through them. Thanks to the use of these systems, even distilled water can be obtained, so they are used not only in everyday life, but also in production.

The increase in the performance of the device entails additional costs - for the purchase and installation of the system, as well as in connection with the increasing volume of water consumption.

Thorough cleaning is not only positive, but also negative. The water leaving the membranes is completely demineralized, that is, it is devoid of not only harmful, but also useful substances.

Such systems are rarely used in domestic needs, often such equipment has industrial or medical purpose.

Depending on the form of coal production, the following filters are distinguished:

- Cartridges filled with granular composition.They have higher sorption characteristics.

- Powder cartridges have a large working area, so the liquid is cleaned more slowly.

- The carbon block includes different types of coal, which prevents rapid leaching of particles.

The basis of carbon filters can be the following components:

- Coal which well copes with clarification from pesticides, phenols.

- Activated carbon has a bactericidal effect, eliminates the smell of chlorine, is considered the most affordable option. If it has a silver plating, it is characterized by a bactericidal property.

- Natural zeolite is characterized by heat resistance, capable of removing heavy metals from water.

- Coconut coal is characterized by versatility of action, copes well with organic pollution, eliminates the smell of chlorine, and is distinguished by its ability to regenerate. Available in the form of granules or pressed fibers.

- Copper zinc filters not only cold but also hot water, retains suspended particles. It is available in granules.

- Granulated aluminum silicate absorbs suspended colloidal particles and has a high filtration rate.

Each of the cleansing components has a different pore size, which affects their filtering ability. Thus, substances with large pores are suitable for purification from organic particles, with small pores - for chemical retention.

Small (micropores) pores contain coal based on coconut nutshell, their diameter is up to 2 nanometers. Mesopores have dimensions in the range of 2-50 nanometers (cartridges with coal). Macropores are called pores with a size of 50 nanometers and can be observed in charcoal.

As already mentioned, most of the carbon filters have the appearance of a cartridge, but release in bags is also possible. In them the metal or polypropylene bag acts as a replaceable sorbent element.

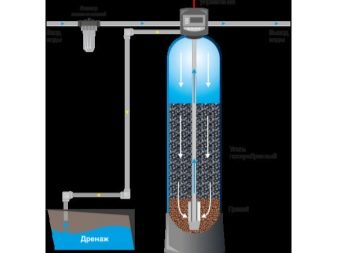

All devices have the same principle of operation. Consider it on the example of an automatic system based on coconut coal, which does not need to be added and cleaned by reverse flow of water.

This filter has the form of a plastic container with a compartment for the sorbent and a distribution cylinder inside. Water flows from the top down through the sorbent, and the retained contaminants are sent back to the drainage during the backwash.Chemical agents are not used for washing; coal dust is removed and air allows the device to be filled with water. Effective cleaning is achieved only under the condition that the contact of water and coal lasted for at least 5 minutes.

How to do?

The simplest carbon filter for home use can be made with your own hands.

This process consists of several stages and looks like this:

- It is necessary to take a plastic bottle for water and cut off the bottom of it.

- Prepare a container with a lid; a simple bucket with a lid is usually used. In it perforation is made the size of the diameter of the neck of the bottle.

- Connect the bucket with the lid and the bottle, ensuring the reliability and tightness of the junction. For these purposes, you can use the seal.

- The bottle is filled with a sorbent consisting of a mixture of activated carbon (it is the basis), sand, gravel. Ready coal can be bought in a store or made by yourself. To do this, the crushed wood particles (the simplest option is the branches) of hardwood need to be cleaned of leaves, buds and dirt, and calcined in a metal pan.

- Through the resulting filter should drain a few liters of water, this will wash the sorbent,remove coal particles from it. After the water begins to flow through the filter, it is ready to use.

If you use a large volume canister with a tap, you can make using the system more comfortable.

For those who are looking for an economical option to create a carbon filter, it will be useful information on how to restore the filter, extending the period of its operation.

The recommendation of one of the manufacturers of the cartridge suggests to restore the coal as follows:

- Coal is poured into enameled dishes, rinsed 2-3 times with running water, after which it is recommended to leave the composition in water to settle for 2-3 hours.

- Strain, pour 3 liters of water with dissolved 3% bicarbonate soda. Bring to a boil, boil for 30 minutes.

- Drain the solution, rinse with water, drain.

In this way, coal can be regenerated up to 3-4 times. It will not be possible to restore the composition more times, it will be necessary to replace it.

Tips

To ensure high-quality filtering and prevent early filter failure, compliance with the following recommendations will allow:

- The system can be used only with a water pressure that is considered permitted for this model (the maximum pressure value is indicated on the package or in the instructions for the device).

- Do not filter hot water (exception - copper zinc cartridge).

- When used as a filter of coal for a day soaked in water before use.

- Do not install a filter near heat sources and boil water near it. This will lead to the loss of its properties by the sorbent.

- If the air humidity increases by more than 70%, the operation of the filter is impaired, so it should be installed only in rooms with good ventilation.

- It is important to properly organize a drainage system to remove contaminated water.

The most effective carbon filters are demonstrated in the purification of tap water. The system removes residual chlorine and rust.

If the water comes from a deep well and contains almost no organic matter, such a system will be ineffective. It can be used only at the stage of water preparation, and filters of a different principle of action are necessary for purification.

For how to make a carbon water filter with your own hands, see the video below.