Water pressure switch for the pump: device and operation scheme

The water pressure switch for the pump is one of the important elements of the pipeline system and is widely used in the construction of water supply to private cottages and cottages. Not only the stable pressure in the system depends on the correct operation of this device, but also the regularity of uninterrupted water supply to the water intake points.

Device and principle of operation

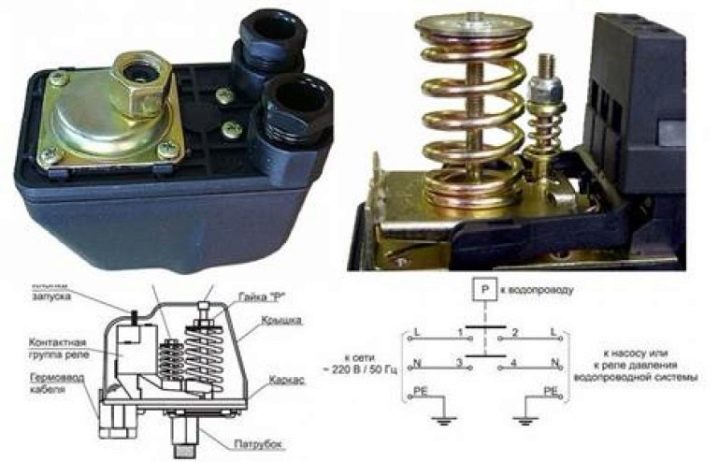

Electromechanical relays consist of a plastic case, a spring block and contacts, which are controlled by a membrane. The membrane has direct contact with the pressure pipe and is a thin plate that plays the role of an element of perception.It instantly responds to changes in the pressure level in the pipeline, which entails alternately switching contacts. The spring block of the water relay consists of 2 elements. The first is a spring controlling the minimum allowable pressure level, and is responsible for containing the main onslaught of water. The lower pressure limit is regulated with a special nut. The second element is represented by the upper pressure control spring, and is also adjustable with a nut.

The principle of the relay is that the contacts, thanks to the membrane, react to pressure fluctuations, and when they close, the pumps begin to pump water. While their opening causes an electrical circuit to break, the power supply to the pumping equipment is turned off and the forced water supply stops. This happens due to the fact that the relay has a connection with a hydraulic accumulator, inside which there is water with compressed air. The contact of these two media is due to the flexible plate.

When the pump is turned on, the water inside the tank presses through the membrane on the air, as a result of which a certain pressure is created in the tank chamber. When water is consumed, its amount decreases and the pressure decreases.In addition to standard equipment, some models can be equipped with a forced (dry) start button, a work indicator, a soft start device and special connectors used in place of traditional terminals.

Usually, an indicator of 2.6 atmospheres is taken as the upper threshold, and as soon as the pressure reaches this value, the pump is turned off. The lower indicator is set at 1.3 atmospheres, and when the pressure reaches this limit, the pump turns on. If both thresholds of resistance are set correctly, the pump will work in automatic mode and manual control will not be required. This will eliminate the need for constant human presence and ensure uninterrupted supply of tap water to the consumer. The relay does not require special expensive maintenance. The only procedure that is required from time to time is to clean the contacts, which oxidize during operation and require maintenance.

In addition to the electromechanical models, there are electronic counterparts, which are more precise adjustment and aesthetic appearance. Each product is equipped with a flow controller - a device that instantly turns off the pumping equipment in the absence of water in the pipeline. Thanks to this option, the pump is reliably protected from work at a “dry run”, which prevents its overheating and premature failure. In addition, the electronic relay is equipped with a small hydraulic tank, the volume of which usually does not exceed 400 ml.

Thanks to this design, the system receives reliable protection from water hammering, which significantly extends the service life of both the relays and the pumps. In addition to a large number of advantages, electronic models have weaknesses. The disadvantages of products include the high cost and increased sensitivity to the quality of tap water. However, the money spent quickly pays off with the reliability and durability of the devices, and the special sensitivity is eliminated by installing a filtration system.

Thus, the pressure switch is an integral component of the downhole or downhole pumping equipment., helps to fill the hydraulic tank and maintain normal pressure in the network without human help.The use of a relay allows you to fully automate the process of water supply and eliminates the need to turn on the pump yourself when the pressure drops or the storage tank is empty.

Special features

An important condition for the effective operation of the relay is the correct choice of its installation location. Experienced experts advise to place the device near the outlet to the hydraulic accumulator, that is, in a place where the pressure surges and flow turbulence at the start and operation of the pump are minimal. Installation of the relay on accumulative tanks and pumps of superficial type is allowed. In addition, some products are intended for use in strictly defined conditions with acceptable temperature and humidity. Therefore, when choosing a model, you should carefully read the accompanying documentation so that it does not happen that the relay purchased for the external pipeline can work only in the premises.

First of all, this refers to models designed for surface pumps., because of what installation of such equipment is recommended to be made in a caisson, a basement room or any other warmed place.In addition to working with centrifugal surface pumps, relays can be installed on downhole pumps, submersible drainage and submersible vibration pumps, as well as on pumping equipment of water supply stations and hydroaccumulators. The device can be supplied with the pump or purchased separately.

Relays can be made with both external and internal threads having a standard diameter of 1/4 inch. This makes the device fully compatible not only with domestic, but also with foreign pumping equipment. The cost of the devices depends entirely on the manufacturer, and varies from 200 rubles for Chinese models to 2 thousand for products of famous Italian brands. Domestic models belong to the average price category, and are the best value for money. Thus, the Russian "Dzhileks RDM-5" can be purchased for only 700 rubles, while the Danish Grundfos will cost a half thousand.

Criterias of choice

In order to understand which water pressure switch to purchase, you need to determine a number of important points. Firstly, if the product is purchased for an autonomous water supply system, then it is better to opt for household appliances.This is due to the same value of the key parameters of such systems, where the standard working pressure varies from 1.4 to 2.8 atmospheres, while the pressure in the network can reach 5 atmospheres. A reserve of at least two atmospheres must be present. This will prevent rapid wear of the membrane and increase the overall service life of the relay.

Do not forget about the additional equipment that makes the pump more efficient. For example, the joint installation of relays and pressure gauges will allow to fully monitor the operating parameters of the equipment, and to detect various kinds of failures in the system before they become visible. In addition, the volume of fluid injected into the accumulator depends on the choice of the limit values of the relay. So, with a large amount of water, pumping equipment will turn on less frequently, and vice versa, with a low relay capacity, the pump will work at its maximum capacity and will quickly fail.

Connection

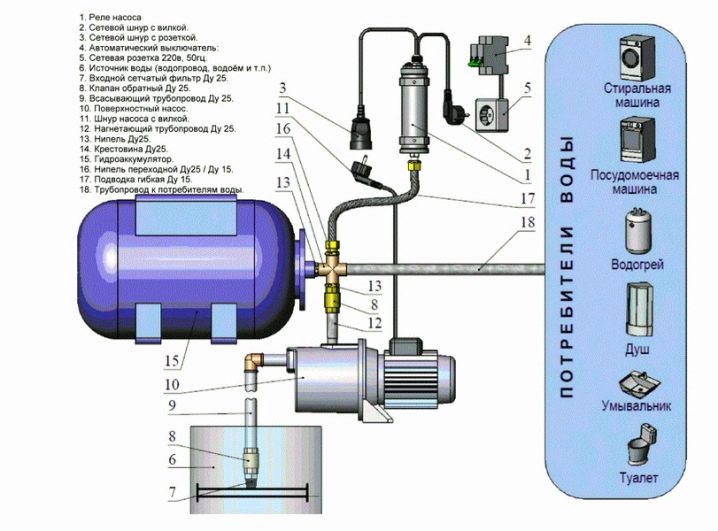

In order to connect the relay to the system using two schemes. For which of them to install and connect the device depends on the recommendations of the manufacturer and the technical capabilities of the network.Before proceeding with the installation, it is important to remember that whichever of the connection methods is used, the original relay is always connected to the water supply, and only then to the mains.

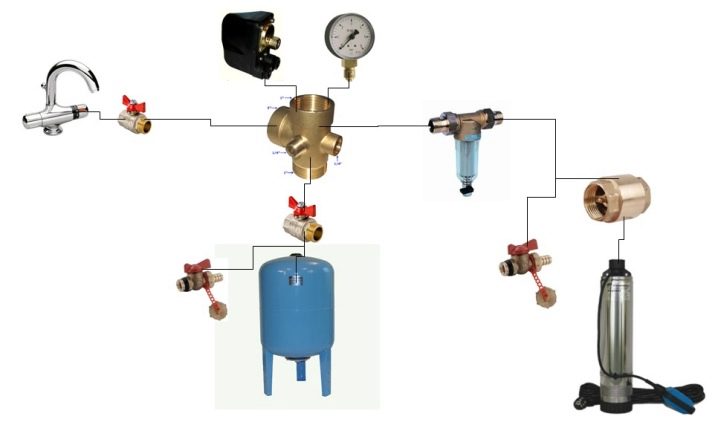

The first way is to install the device using a tee, which is connected to the connecting nipple or outlet hose. In the second case, the hydroaccumulator is equipped with a fitting equipped with 5 outlets. The first of them serves to connect the pipeline coming from the source of water intake, the second - to connect the relay, the third - the pressure gauge, and the fourth - the pipeline that supplies water to the consumer. The fifth outlet serves to connect the accumulator itself. At the same time, the relay is connected to the pumps and a 220 V electric power source.

When connecting the relay using any of the methods, it is necessary to reliably seal the threaded connections using hemp winding or FUM tape. Powering the device from the mains should be done with a cable, the size of the cross section of which is selected depending on the calculation of pump power. For example, with a device power of 2 kW, the cable diameter should be 2.5 mm.The pressure switch terminals are usually marked, which eliminates the possibility of confusing the contacts and incorrectly connecting the circuit.

In addition to the relay, installation of deep cleaning filters, check valves, fine filters and inlet valves is mandatory. However, many pump models are already equipped with check valves and a filter system. Therefore, the relay can be installed in the same unit with the pumps, and in the case of using a moisture-resistant connection, it can even be placed with it in a well or pit. The only limitation in this case is the maximum permissible temperature and humidity levels at which the relay can function normally. This is due to the fact that many models are not able to work at temperatures below 4 degrees and humidity above 70%.

How to setup?

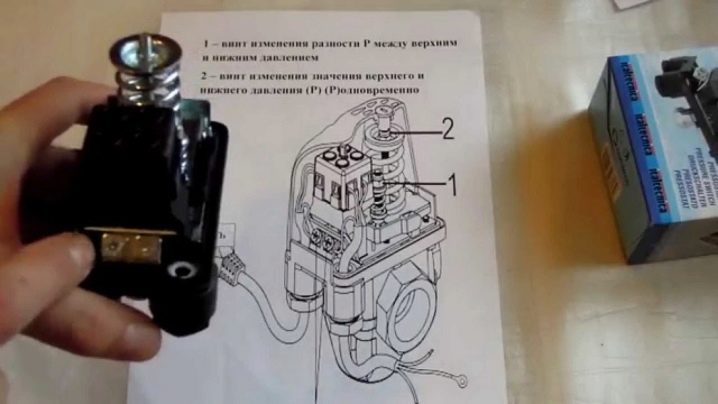

As soon as the pressure switch is installed, it is necessary to adjust it. The effectiveness of the device operation and the continuity of the water supply to the consumer will depend on how correctly this procedure will be performed. At the first stage of setup, you need to turn on the device and wait for the automatic shutdown to start.Next, you need to remove the cover and tighten the nut on the big spring.

Then you need to set the minimum pressure level at which the pump on relay will operate. Reducing pressure is achieved by turning the nut counterclockwise, and vice versa. When setting the upper level, you need to take into account that this value should not be less than 10% below the pressure level of the empty hydraulic tank. Otherwise, the rubber membrane of the accumulator will be put under very high pressure, as a result of which it will quickly become unusable and will require replacement.

Next, you need to open the faucet, empty the system and with the help of a pressure gauge to see at what pressure the automatics will work. If necessary, make adjustments and adjust the pressure again. The final stage of adjustment will be setting the pressure level at which the pumping equipment is turned off. In this case, the regulator is already a small nut, tightening or loosening which requires the necessary parameters.

Sometimes during the operation of the relay it may become clearthat the exhibited settings are absolutely not suitable for a particular water supply. In this case, the setting is not done according to the instructions attached to the device, but in fact. An important condition for conducting correctional adjustment should be compliance with the interval between the lower and upper values. The value of this interval should be 1.2-1.6 bar.

Adjusting electronic relays is much easier. Due to the absence of adjusting springs, the instrument is tuned by tightening special screws located on the device case. When you first start electronic models start to work immediately. It takes about 15 seconds for the relay to tune. Switching off the pump also occurs with a delay. This should be considered when using electronic devices and not worry about the fact that the relay is broken.

Tips

In case of malfunctions arising during installation and adjustment of equipment, there is no need to panic. Very often, the reason may be incorrect setting of both limits. So, if after installing the relay the pump does not start - you need to check the suction area for the presence of water, and also to see the voltage value of the network.If the pumping equipment, on the contrary, often starts and also shuts down as often, in this case it is necessary to regulate the pump off threshold for the second time. It is possible that the pressure exhibited was too high. And if the pump works for a long time without shutting down, then, most likely, you need to check the maximum pressure at which the pump is able to work. Ideally, it should not be higher than the switch-on pressure of the relay by more than 0.8 atm. In addition, it is necessary to exclude the likelihood of leaks in the main pipeline, as well as air system.

It is also recommended to check the pressure in the accumulator once a month and, if necessary, to correct it. The pressure switch is a practical and necessary fixture. The device effectively controls the water pressure in the pipeline, and reliably protects the pump and other equipment of the system from premature wear and breakage.

To learn how to set the water pressure switch for the pump, see the following video.