Fittings for copper pipes: design features, types and installation rules

The creation of heating, water supply and air conditioning systems is carried out to transport the liquids and gas necessary for a high-quality human life. The key element in these communications is the pipe. However, we must not forget that in some situations it must turn, move to a different diameter, join the equipment. All this can be done with the help of special elements - fittings.

Specifications

Fittings for copper pipes are connecting elements, the advantages of which over other materials are strength, ductility, resistance to aggressive media.These products withstand high temperatures, do not react to the influence of solar ultraviolet radiation. This is the most "running" part of pipelines, the main function of which is to ensure branching and turning, pipe joints.

The material determines the variety. The most commonly used brass, copper, steel and bronze fittings for copper pipes, sometimes brass chrome version is used. Regardless of the manufacturer of fittings, all fittings are created in sizes that are regulated by international standards. The warranty period for copper pipe fittings is 80 years.

Virtually all modern copper fittings comply with ISO 9002, BS2 standards and German DIN standards adopted in Europe. They are resistant to temperature differences, resistant to pressure of gas or working fluid, do not react to external influences during storage or transportation.

Purpose

Fittings perform different functions, so they are divided into the following types: corners and contours, tees and couplings, plugs. Connectors are used in the installation of such types of plumbing communications, such as:

- for water supply (cold and hot);

- for heating system;

- gas supply;

- air conditioning (under flaring);

- in designs for discharge of drains.

Species

Fittings with different sizes and shapes (coal, arc, tees, plugs, couplings) are available to consumers. Thanks to such a wide range, every potential buyer can find components that meet all requirements. The method of fastening is one of the factors influencing the type of fitting. Connectors are of several types.

Capillary

Capillary (solder) fittings are used to fix metal pipes. The connection is as follows: the copper pipe is inserted into the fitting sleeve, then the remaining space is filled with flux and solder. After that, they are melted with a special burner (soldering iron), ensuring the reliability of all the compounds formed. Then they wait for the pipe to cool and thoroughly clean its surface.

Compression

They are usually called crimp or collet, because for their installation requires a special crimp ring. Soldering is not used for installation.They are distinguished by an incontestable advantage: these products can be used in places where the installation of other types of fasteners is impossible (for example, due to the high fire risk).

Crimping parts are used not only for household work, but also when installing communications on the street, even for transporting toxic chemical compounds. They are easy to install, provide a high-quality, tight connection, but periodically all the joints need to be checked and tightened. For this reason, pipelines using collet fittings must not be sutured into floors and walls.

Crimp models are produced in these two versions:

- press;

- with retaining rings.

With their help, the pipeline is going to any complexity. The most popular diameters of compression fittings are 10, 16, 20, 26 and 32 mm.

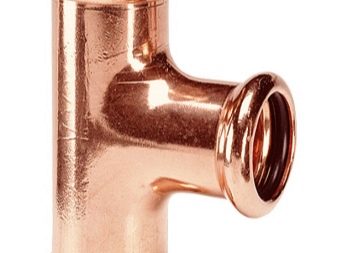

Press fittings

Such products are designed for permanent connection, they are used in cases where it is not possible to carry out the soldering. They are used extremely rarely for copper pipes. For their installation, it is necessary to use a special tool - a press machine. Connection press fittings are durable and impermeable.Installation does not take much time.

Press fittings can be used to connect pipes in thick walls. The connection of these elements is more durable (compared to a compression fitting), but because of the need to use special equipment, it is more expensive in financial terms. Press fittings are used, as a rule, in mass construction.

Press fittings are:

- triple;

- bypass;

- straight;

- transitional - to connect pipes with different diameters;

- angular.

Self-locking

Self-locking fittings are new on the market today. These elements are mechanical devices with a system of inner rings, where one of them has small teeth. When pressing on the ring with a special key, these teeth fix the structure. This type of connection is considered very reliable and durable; you can use a self-locking fitting several times. They are removed as easily as they are installed - by pressing the key.

Threaded

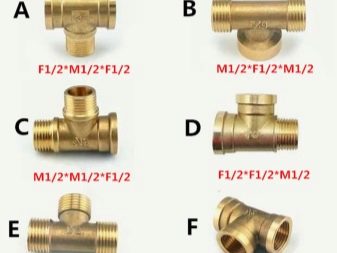

Threaded models are the most frequently used fasteners for copper pipes, since they can be easily replaced or reused if necessary.Because of this distinctive feature, an important requirement is put forward to the junction: free access to the junction, so that nothing interferes with the repair or dismantling work. The fittings of this type have external or internal cylindrical thread.

The process of connecting threaded fittings is quite simple. A fitting wind on a pipe, observing the requirement for full tightness of a joint. Special materials are needed for this: fum-tape, thread, rubber or polymer gasket.

Connection with a threaded fitting is reliable and durable, the main thing is to carry out all the installation work correctly, do not forget about the sealing material. Typically, threaded fittings are used in homes and cottages, garden farms and private buildings, where it is not always convenient to perform welding. Externally, threaded fittings are divided into the following types:

- couplings;

- squares;

- nipples;

- caps;

- elbows.

Installation Methods

Creating communications from copper pipes, at the beginning of the design it is necessary to remember that for durable operation of the pipeline it is necessary to use only homogeneous materials. If copper and its alloys cannot be applied, it is worth adhering to the following rules:

- Do not crimp unalloyed galvanized and unalloyed steel with copper. Otherwise, corrosion of steel elements is inevitable.

- Copper can be combined with acid-resistant steel.

Steel and copper pipes are best not to combine. If it is impossible to avoid such connections, it is better to carry them out in such a sequence: first, steel parts are mounted, and then copper elements. Installation of copper pipelines is carried out in several ways.

To determine which method is most optimal, it is worth considering the conditions under which the subsequent operation of the system will be carried out. An important role is also played by the principle of the device of the pipeline itself: will it be detachable or non-detachable, serviced or unattended.

If the pipeline is hidden in the screed floor or in the wall, you will need a solid non-separable type connections that are made by welding / soldering, pressing. Maintenance-free connections are characterized by reliability, long service life, resistance to temperature drops and pressure in the working environment.

If according to the plan the pipes will be in open access (for example, on the walls), any type of connection will be suitable, but most often the fastest and easiest compression connection is chosen when compression fittings are used. Such structures must be periodically checked and maintained. For all sorts of connections it is necessary to use different tools. Crimping pipes do press tongs or a wrench.

To connect copper pipes with your own hands, it is better to arm yourself with crimp options or fittings for soldering. Inside the crimp fittings there is a crimp ring, which guarantees hermetic fastening. It is better to tighten the ring manually with a wrench. It is important to remember that it is appropriate to use such fittings only in those places where there is no possibility to work with fire and you can easily check the tightness of the connection.

The connections with crimp fittings must be periodically checked and tightened.

The connection of copper pipes with steel and plastic pipes for heating and water supply is carried out with the use of compression fittings.To connect such a fitting to the pipes, you need to disassemble it, then you should put a clamping nut and a clamping ring on the pipe.

A construction consisting of a pipe, a compression ring and a compression nut is inserted into the fitting. The nut is tightened with a key for a certain number of revolutions, which depends on the diameter of the pipe and is determined by the passport data for the fitting. The specialists do not call the systems of connection with crimp fittings absolutely reliable, because you need to constantly check them, monitor the work and take care of, and also eliminate all problems.

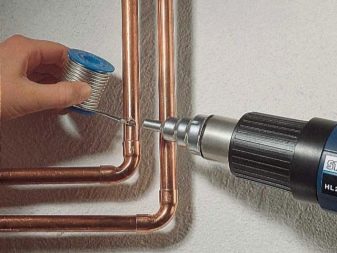

In the circle of professionals, it is believed that brazing is the highest quality and most reliable way of joining pipes from any material, and copper is no exception. It is carried out in different ways: by the method of high-temperature or low-temperature compounds.

Some consumers prefer to work with parts in which the manufacturers, even at the stage of their manufacture, have foreseen to lay a certain amount of solder. Often it is located in a specially allocated cavity in the socket, and most often you can find fittings with low-melting solder.To heat it up, the temperature of the blowtorch or building dryer is sufficient. Pipe fitting technology using a fitting is quite simple and includes the following steps:

- at the first stage, the ends of the sections of copper pipes are cleaned;

- on the second - the pipes are inserted into the fitting;

- the junction is heated by a blowtorch or hairdryer so that the solder melts and, spreading, solders the pipes;

- until complete cooling it is impossible to move or move the structure with the joint.

This method is considered the simplest of all existing methods of connecting copper pipes. It is quite popular among Russian consumers, and the most - in Europe and Asia. Some craftsmen cannot work without seeing how much solder they used. The soldering process can be simplified by using fittings that have a solder roller of a certain size inside.

Thanks to such products the soldering time is significantly reduced. A pipe is put on a pipe that is coated with flux, then the whole structure is heated by a torch so that the solder melts and becomes liquid. Then they wait for complete cooling to occur, and that’s all - the pipeline design is ready for operation.

You can learn more about copper pipe fittings in the following video.