Inset rules in the water pipe

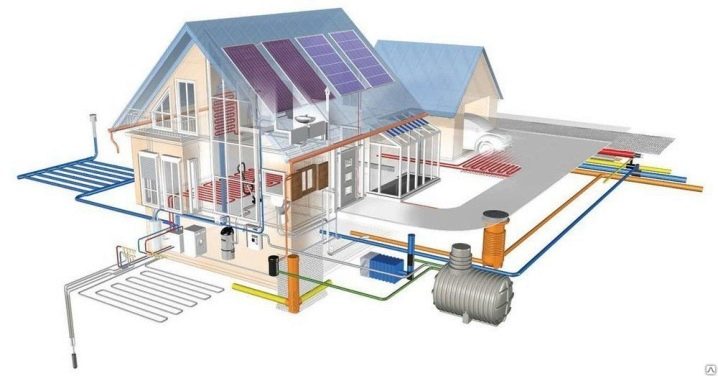

Laying plumbing on the garden plot or in a built house in the country is a common thing for country farms. But if you do not want problems in the future, then you need to do this work correctly, without violating laws and technical norms. The plot or house is settling down for a long time, so cheating here is inappropriate.

Special features

All work related to the additional use of the city or town water supply system is coordinated with the local water utility. Unauthorized connection to the main pipeline or even to an individual on a site, in a house, apartment up to the meter is an administrative violation for which large penalties may be imposed on the guilty person. If permits have been obtained, works on trunk lines for inserting additional layouts with shut-off valves with a common meter should be carried out by water supply specialists.The applicant performs the water distribution inside the house or the plot independently, but according to the floor plan and the profile drawing of the water supply pipelines, which were documented when the permit was obtained.

It is necessary to understand that any illegal connection to the public utilities water pipe will be detected sooner or later.

Employees of water supply organizations each week make raids to identify violators, especially in cases of large disperses in terms of consumption of instruments and actual water consumption. The offender can use water only for two days, and the penalty is calculated using the calculation formula for at least six months. The risk of being detected over these six months is more than 20 times greater. Is the game worth the candle? Of course not.

Payment

In order not to do the work twice, you need to approach the issue of water supply of your site, house, additional buildings or home appliances thoroughly. To do this, it is necessary to make a competent calculation of the required water flow according to the plan and schematic sweep of the pipes of the connected sanitary and utility rooms - bathroom, shower, toilet, kitchen,with sanitary facilities (toilet with flush tank, sink with faucets, shower, washing machine and dishwasher) and watering.

There is a formula for calculating water supply to domestic water supply taking into account (according to SNiP 2.04.01-85 "Internal water supply and sewerage of buildings") the standard water consumption in l / s of each device, devices and number of family members using them:

Qmax = 5 · q, where:

- Qmax is the maximum second water consumption through one sanitary device;

- q is the total fluid flow rate of one consumed device, determined according to sanitary norms and rules;

- 5 is a coefficient determined by the tables in the SNiP applications depending on the probability of the specific device and their number.

The determination of the probability of operation of the devices is calculated by the following formula:

P = (U · Qnorm) / (q · N · 3600), where:

- U is the number of family members (water users);

- Qnorm is the total normalized water consumption by one consumer per hour of the highest water consumption (equal to 10.5 l / h);

- N is the number of such devices;

- 3600 is the time of the hour in seconds (3600 seconds).

Having obtained the N and P indicators, the coefficient is determined from their dependencies in Table 2 of Appendix 4 of SNiP 2.04.01-85 and the maximum second water consumption is calculated through a separate device Qmax.By adding the data and converting it from seconds to hours, you can easily get the daily water supply of the entire object. And already on the basis of the data obtained on the daily water consumption, the value of the minimum internal diameter of the pipe is determined, which will approach the site or house from the main or secondary water line. This pipe should be cut into the central water supply. And the calculated formula for the diameter of the pipe looks like this:

d = √ [(4 · Qmax) / (· V)] m, where:

- d is the internal diameter of the pipeline being calculated in meters;

- V is the flow rate of water, m / s. It is assumed to be 2.5 m / s in accordance with clause 7.6 of SNiP 2.04.01-85, indicating that the velocity of the fluid in the internal water supply system should not exceed 3 m / s;

- Qmax is the already calculated water consumption per object, m³ / s.

The choice of pipe for separation depends on the pressure in the pipeline, where the inset will be made, and the material from which this water supply is made. According to SNiP 2.04.02-84, SNiP 2.04.01.85 and GOST, for normal supply of cold water for drinking purposes for the urban population, the pressure in the supply main pipeline must be within 10 kgf / cm². Water should come to the consumer with a pressure of not less than 0.3 and not more than 6.0 kgf / cm².It is impossible to achieve the same pressure among consumers living in different distances and heights from the source of water supply. Even in one house the pressure of the water will be greater in the apartments on the first floors.

For the proper functioning of most sanitary appliances, consuming water, enough pressure in the range from 2 to 3.5 kgf / cm ². The situation is worse for private houses in the country: not everywhere you can find a water supply network nearby, and if there is one, then its possibilities are much weaker. Pressure in rural areas rarely rises even in the line above 2.5 kgf / cm². And for effective irrigation of the site you need a pressure in the irrigation tap not less than 3.5 kgf / cm². In this case, you can use the booster pump with a pressure of 4-6 atmospheres.

For laying water pipe use pipes:

- steel from ferrous metal;

- stainless steel;

- cast iron;

- plastic;

- polyethylene.

Pipes made of stainless steel are used by owners of luxury holiday villages, as well as in important or hard-to-reach places of installation. This is done in order to exclude in the future frequent repairs with rotten metal piping from the “chernushki”.Steel and cast iron pipelines are used for laying high and medium pressure trunk lines with diameters from 100 to 2500 mm. Sometimes high pressure plastic pipes are used for the central water lines. Secondary water lines are more often satisfied with low pressure polyethylene pipes (HDPE) with a diameter of up to 70 mm.

All further preparation depends on the pipe chosen for tie-in, namely:

- issues of providing safe conditions for tie-ins are solved;

- the necessary tool and material is selected;

- determines the method of tie-in water supply.

Working conditions depend on the place where the possibility of tapping is permitted. If there is a well near the water main, and even there will be a backup tee for a slider, then the insert will be the simplest option of all the others. If there is no well, then you will have to arrange it with the forces and means of the customer. To do this, dig a hole 0.5 m deep below the level of the central water supply piping, and its foundation is concreted with a waterproofing gasket. And already on top of the foundation, a shaft is laid out or a concrete ring is installed.It will be easier to weld a caisson from 5 mm of metal and install it in a hole. In any case, the well should be coated with an anti-corrosion compound. The outer part of the well is filled with soil, on top of it is placed a plate with a hole for the hatch.

Methods

Often, the material of the water supplying pipeline determines both the material of the branch pipe and the method of tie-in. If the central or secondary pipe is steel, then it is also better to use a steel pipe. In extreme cases, make the transition section in the form of a union of a steel pipe with a valve, to which then connect the pipeline from another material.

Insert steel pipes produced in two ways, such as:

- with the use of a welding machine by welding the fitting to the water supply;

- by means of a steel clamp without welding.

Both methods are used as inset in the pipeline, which is under pressure, and without pressure. But on high-pressure pipelines, welding is recommended to be used only in emergency, emergency cases, as well as in the organization of additional safety measures. In the normal mode of work, actions are needed to completely shut off the section of the water supply system, where the insert is made using welding.

The algorithm of work with the use of welding on the existing pipeline is as follows:

- excavated pit to a level above the laid pipeline about 50 cm;

- the section of the pipe to which the tie-in is planned is cleared from soil;

- the tie-in place is freed from the anti-corrosion coating and other protective layers, and the specific connection area of the choke or pipe slips is trimmed to a shiny metal;

- the union with the crane is welded;

- after the metal is heated, heated by welding, a drill is inserted through the tap into the fitting and a hole is drilled in the wall of the water supply system;

- when water goes through the nozzle, the drill is removed and the faucet is closed (the tie-in is completed, the further installation of the water line starts from the valve at the nozzle).

The tie-in collar is a common piece consisting of two halves of semicircular shapes. These halves are put on the pipe and bolted together with nuts. They differ from ordinary clamps only in the presence of a threaded hole on one of the metal parts. A fitting is inserted into this hole, which serves as part of the branch line.The hole for the branch pipe can be positioned anywhere in the water supply system, and when the fitting is screwed in, it will always be at a right angle to the linear plane of the pipeline surface.

The rest of the process takes place in the same way as a tie-in by means of welding: a drill is inserted into the fitting through the valve and a hole is drilled. If the outlet of small diameter and pressure in the water supply system is within 3-4 kgf / cm², then the valve can be screwed on without problems even after drilling (if it is threaded and not welded). Additional lines are also connected to the cast iron main by means of clamps.

Welding can not be used because of the low ductility of cast iron, because it can crack in places of overheating.

Insertion in pipes made of plastic or polyethylene is carried out with the help of plastic clamps or saddles (half-clip on fasteners). Clamps and saddles are simple and welded. Working with simple devices is not much different from the tie-in with the clamp in the steel pipe. And in welded saddles or collars there is all the equipment necessary for welding. Such a saddle assembly is installed on the pipe in the intended place, the terminals are connected to electricity and in a few minutes the tie-in will be automatically performed.

How to crash?

When the removal from the line is made by specialists, the customer can independently or with the help of the same professionals lay a line from the crane at the fitting to the site, house or a separate building on its territory. Having made the input to the site, you need to install another valve in the well (if it is installed), or install it in a convenient and warm place in the house, for example, in the basement. It will be needed for an emergency shutdown of the water supply. After the inlet valve leave a small section of the pipeline of the same diameter as the line to the valve, from which the lines of smaller diameter will follow the planned wiring. The open end of the pipe is drowned out by welding and a sheet of metal of appropriate thickness.

When the input valve is closed, wiring is convenient to install with your own hands, slowly and thinking through all the future tie-ins to the resulting common collector of home plumbing. In a steel pipe, they weld by welding a hole with a diameter somewhat smaller than the outer diameter of the distribution line, and weld the fitting with the primary valve on it. It is recommended to drill the holes: the hole turns out to be neat and it is difficult to make a mistake with the size if you take the drill with the necessary diameter of the outlet pipe.

Wiring around the house from a plastic pipe make plastic tees according to the following algorithm:

- a piece of pipe is cut at the tee installation site according to its size;

- Both ends of the cut pipe section are lubricated with sealant;

- a tee is put tightly in place of the cutting and tightened with flare nuts;

- a tap is screwed into the tee socket;

- piping is easy to install using fitting clamping sleeves (collets) having various configurations.

It is worth paying attention to the fact that all work relating to the welding machine, it is better to entrust a professional welder.

You can install an electrically welded clamp or saddle for working with polyethylene or plastic and only in the absence of water in the system. All other works also require attentiveness and at least some experience, therefore, to eliminate any risks, work with clamps on steel and cast-iron water pipelines must be entrusted to specialists.

See the following video for a cold water tie-in to the urban water supply network.