Water pipes: variations and recommendations for selection

Every person wants to create comfortable living conditions for themselves and their loved ones. Convenience and safety are important points in production. The water supply system plays an important role in this. Its main part is water pipes. The service life of the system depends on their quality and characteristics. Currently, the market offers a huge range of similar products. This article will tell you how to choose the most suitable option.

Special features

Water pipes are divided into several categories according to the following criteria:

- intended use;

- material;

- type of construction.

Each species has its own characteristics. Product quality is governed by GOST standards.

There is a special marking that allows the buyer to find out the necessary information to prevent damage to the pipeline and extend its service life.

Norms

In accordance with state standards and regulations, numbers are indicated on the case of each product. They are the number of GOST. For example, on steel models, marking 8734 is used. Two more digits follow them, which are also part of the number (71, 75, 78, 81, 85). They characterize the various parameters of the product.

Steel pipes are often used for cold and hot water systems. Such products withstand high temperatures and are not deformed. Most often they are made by welding. Black steel models are used in the chemical industry, less commonly in the utilities sector.

Among the electric-welded steel pipes there are 4 categories:

- And - this includes products made of steel grades St2 and St3;

- B - these may be the same St2 and St3, but the group includes more types of steel;

- C - this category includes products made from various types of steel, therefore this group is the most extensive;

- D - this includes products for which GOST standards are not established (on chemical composition).

Product parameters can be seen in the table below.

Group | Rated quality indicators | ||

Chemical composition | Mechanical properties | Hydraulic test | |

BUT | — | + | + |

B | + | — | + |

AT | + | + | + |

D | — | — | + |

Kinds

Polyethylene (PE)

The smooth surface inside the pipe prevents the appearance of oxide on the walls. This is a big plus, given the use of water by man. It is because of this quality that people choose polyethylene pipes for the supply of drinking water. The minus of the material from which the product is made is low heat resistance, therefore, polyethylene is applicable only for cold water supply. The connection is made using fittings (plug-in connection) or welding (permanent connection).

Such products are made from a mixture of copper and zinc. Due to the combination of two substances, it has good strength. The service life of products is 50 years. Such pipes, as a rule, have no seam, this explains their wear resistance.

The great advantages of this option are resistance to temperature extremes and good resistance to corrosion.

The choice falls on brass when you need a minimum weight of the water supply system. The high cost of the product does not stop people from purchasing it.

Heated pipes

In winter, people often face the problem of freezing pipes, which is difficult to cope with. This requires a lot of money, but while repairs are underway, residents of the house have to warm themselves or look for a temporary place of residence. However, you need to understand that it is not always possible to adjust the system, sometimes you have to change it completely. In order not to face a similar situation, you can use heated pipes.

They have several advantages for a cold winter:

- the water in the pipeline will not freeze even with very cold temperatures;

- heat loss can be reduced;

- fluid flow will be stable;

- the cost of the pipes is small and pays off completely when used.

For heating, the cable system is most often used. The pipe is wrapped with a heat cable, due to this, uniform heating is achieved.

When choosing a suitable heating system, it is necessary to take into account a number of factors:

- diameter;

- depth of the highway;

- total length of pipes;

- thermal conductivity of the selected material;

- climatic conditions of the area.

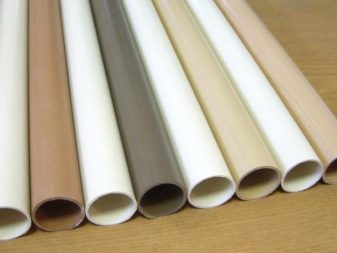

Plastic

More and more people today make a choice in favor of plastic pipes (they are also called polymer). They are created by combining polymers, used for internal and external supply and discharge of water.

The main advantages of the product:

- ease;

- flexibility and strength;

- no corrosion, unlike metal pipes.

However, plastic does not withstand too high a temperature, so there are clear restrictions on the temperature conditions of the fluids being conducted. In addition, not any liquid can be started using such a system. For example, a caustic chemical compound can easily corrode material. When you add any substances slightly change the properties of plastic.

The following markings are used to distinguish:

- polypropylene - PP or PP;

- PVC — PVC or PVC;

- metal-plastic - MP or PEX-AL-PEX;

- low pressure polyethylene - HDPE.

Polyvinyl chloride

Such products are used in production for the construction of water parks, swimming pools. It is not recommended to choose this type of pipes for domestic purposes, since chlorine is present in their composition.They should be used at low temperatures, since when heated to 50-60 degrees the material begins to melt. The price of this product is considered the lowest.

Polypropylene

This option is used to supply drinking water, since oxide does not accumulate on the inner surface of pipes. Polypropylene models are used in floor heating and central heating.

These pipes do not bend, for their bonding structures are created with the participation of special parts (angles and tees).

Metal plastic

Such products are multilayered. Outside is cross-linked polyethylene, inside - a layer of aluminum or copper. This variety differs from other plastic options in that it can withstand high temperatures and high atmospheric pressure. However, with a sharp temperature drop, material deformation may occur.

Low pressure polyethylene pipes

Compared to other plastic pipes, this type has several advantages:

- resistance to all environments (alkaline, acidic), which determines the widespread use of products in the sewage system;

- resistance to the formation of scale and corrosion;

- ecological purity, which is especially valuable in our time.

Parts made of low-pressure polyethylene are often used in industry where it is necessary to transport a large volume of any substances that have an aggressive environment.

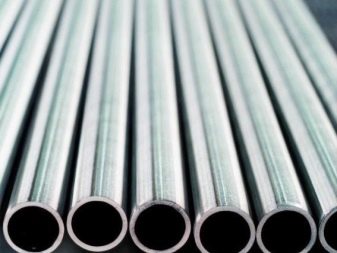

Stainless Steel Pipes

They are widely in demand in industry, engineering. It is considered that "stainless steel" is a material possessing strength, durability and resistance to various chemical compounds.

Chrome plated

Chromium plating is the saturation of steel products with chromium or the precipitation of chromium by electrolysis. This process contributes to the corrosion resistance of the product. Such products constitute a good competition to others by external signs. They are used where brilliant coating is required.

Often chrome materials are used in plumbing.. For example, instead of steel corrugated pipes, which are considered expensive, you can buy chrome copper. It should be noted that the coating carries different environments (acidic, alkaline), therefore, these pipes are often made for different plants. When buying such products need to be very careful.

Damage to the surface is not allowed, as the product may lose protection. If a similar situation occurs, you need to replace the part.

How to choose

The choice of components of the water supply system must be taken seriously. People are interested in the price, the durability of the material. Not left without attention and the question of self-installation of the system. Pipes are selected based on the destination and the place in which they need to be installed. In each case, there are nuances that must be considered.

Apartment

Usually in apartments create plastic structures. Most buyers prefer this product because of the low price, long service life, ease of installation work.

All kinds of plastic pipes are suitable for cold water; non-reinforced parts can be used. With the choice of product for supplying hot water, you need to be careful. Under the influence of high temperatures and pressure, plastic changes its size, and the pipe increases and loses rigidity. For hot water, you can use a reinforced polypropylene pipe with fiberglass, it will not deform at high temperatures and will retain its frame.

Polyethylene pipes are also in demand. They are flexible, durable, able to withstand high temperatures. Due to the density of parts they can be used for both cold and hot water. Compared to plastic pipes, polyethylene are expensive and have a welding machine for installation.

Copper and steel options in this case is not recommended. The first ones cost a lot of money, and substances that affect the quality of the water settle on the surface of the second. Steel products are bought if it is necessary to replace a part of the water supply system, the system of which consists of steel pipes.

A private house

For a private house, as well as for an apartment, it is recommended to purchase polypropylene plastic pipes. It is important to consider that UV rays affect plastic, so polypropylene products are more often used for underground or internal water supply, otherwise deformation may occur, and the system will have to be changed.

For underground water used to be used pipes made of steel or copper. Now preference is given to plastic structures.Pipes PP, PVC, MP do not rust, besides cost much less copper.

Country house

First of all, you can make an external water supply. Installation of pipes in the open way is used at the dacha as a temporary plumbing system. The advantage of this method is that such a system can be easily disassembled. This eliminates the possibility of theft of structures from the dacha during the absence of the owners.

You can also use the trenching method. The pipe is laid in a trench and covered with earth, so it is protected from exposure to ultraviolet radiation. The trench method can lay out the pipe and with the help of a specialist, and independently.

For watering in the country it is advisable to use low-pressure polyethylene pipes (HDPE). Their installation does not require a welding machine or rare professional tools.

Tips

Installation of the pipeline in the country

- First you need to make a plan and figure out how much detail will be needed to translate your idea.

- Then you should choose the type of water supply.

For giving two types are allowed:

- open, located on the ground (this simplifies installation, but does not reduce the likelihood of damage to the system);

- at a shallow depth (this allows you to save and not damage the structure).

The second method is preferred. So you can not worry about the integrity of the system.

- You can lay branches on the ground or install holders. When laying the pipeline it is better to make a small slope to drain the water from the pipes in the fall.

- At the place of branches (at the lowest point of the line), valves should be installed that allow water to be supplied to specific locations.

- Pieces of pipes must be connected by compression fittings. Before connecting, the surface must be cleaned, and the fitting cap nut must be unscrewed several turns.

- Special attention is paid to tightening the fittings. This should be done with a certain effort. Inadequate application of force will lead to leakage of the connection, and excessively large application of force will lead to breakage.

Rules for the selection of plug fittings

To pick up the plug-fitting you need:

- know the cross section of the pipe to him to pick up the appropriate part;

- take into account the material of the pipe (the cap must be of the same material);

- make a choice depending on what time of installation you expect (for the temporary effect, the cap can be set manually,for long-term use, you will have to buy a part with a threaded connection or a connection through welding).

Soldering polypropylene pipes do it yourself

To work you need the following tools, fixtures and materials:

- soldering iron for propylene pipes;

- Teflon nozzles;

- cutter for polyethylene pipes;

- file;

- pencil and ruler;

- degreasing agent.

The preparatory stage includes two main points. It is necessary to clean and degrease the surfaces to be joined, as well as to install a soldering iron.

The technology of soldering polypropylene pipes is carried out according to a specific algorithm.

- When soldering actions should be fast and confident. Better to work on trial connections before work.

- The pipe marks the place to which it needs to be inserted into the nozzle.

- A tube is inserted into the heated head.

- Then you need to fix the position for 30 seconds, after which the node will take the final position.

- Allow the structure to cool in normal conditions (cooling in water or cold is not allowed).

It is necessary to highlight a few mistakes that are made in the work.

- The soldering machine is badly heated.To improve the quality of work, take an additional 5 minutes to heat the soldering iron.

- Overexposure of the pipe when heated. Watch the time, when overheating the pipe becomes soft and loses strength.

- The connection of parts of different materials or different manufacturers. Each manufacturer creates a product line, the details of which are ideally suited to each other. Sometimes the difference between a part made by one plant and an element produced by another plant is not visible visually. Therefore, it is better to choose products from one manufacturer.

How to choose water pipes, see the following video.