PND-pipes for water supply: technical characteristics and installation diagram

The times when pipes were made exclusively of metal, are long gone. Products from this raw material came to replace products from the new generation, acting as a worthy alternative to metal plumbing systems. Among these products is to provide a PND-pipe.

Special features

The demand for polyethylene pipes for water supply is due to the inherent advantages of the material, due to which laying on the ground or in the soil highways that supply hot and cold water has become one of the main areas of use of products, and easy installation of pipes allows you to collect water supply with your own hands.

Technology of production of polyethylene involves strict adherence to GOST. In the regulatory documentation there are tables containing applied in practice the technical characteristics of such products.

Taking into account the regulatory documentation regarding the qualities and characteristics of products, PND-pipes must meet the following requirements:

- regardless of the diameter and size, the outer and inner surface of the product must be absolutely smooth: the presence of bubbles, cracks or any other inclusions is not allowed;

- the entire range of products must be resistant to a pressure of 20 atm.

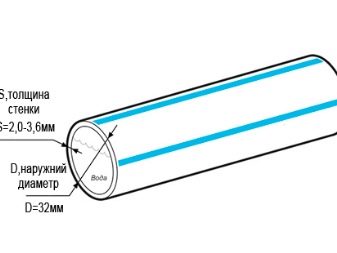

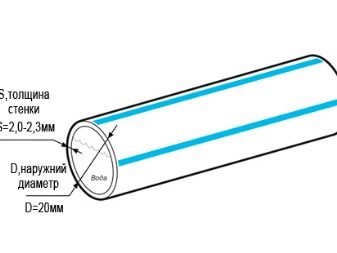

Pipes that meet the above indicators are manufactured with a diameter of 16 to 1600 mm. The sale of goods takes place in bays of 100–200 meters or by individual products 12 m in length. The products are painted in black with longitudinal stripes around the circumference. Polyethylene pipes for cold water supply and hot water supply have certain parameters, based on which they are classified according to the scope of application.

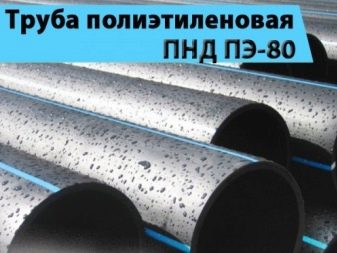

Raw materials used for the manufacture of products. PE 80 pipes are distinguished by high consumer properties, since they are capable of withstanding high internal pressure on the walls while maintaining the integrity of the structure.Due to the characteristics of the material, they find their use in the construction of pipelines with a diameter of not more than 90 mm.

Products for the production of which used polyethylene brand PE 100, provide good throughput to the product with a smaller diameter. They are in demand for arranging cold water supply schemes. PE 63 are used in residential and industrial construction for the drainage of foundations, as well as basements in buildings. In most countries, almost 100% of water pipelines consist of polyethylene pipes.

The level of resistance of pipes to internal pressure. This coefficient is calculated based on the ratio of the diameter of the product to the wall thickness. Products with lower rates are more durable.

Diameter of PND-pipe. For use in the private sphere, for example, when laying water pipelines at a summer cottage or in a country house, it is recommended to purchase products with a diameter of 25 or 32 mm.

It is necessary to highlight the main advantages of PND-pipes:

- resistance to aggressive media, including salt, acid and alkali;

- durability - the average operating life of products is about 50 years;

- inertness to the liquid medium that passes through communications;

- resistance to the formation and development of microorganisms on the walls;

- resistance to corrosion, which is important when laying the pipeline in the soil, which is characterized by high humidity, for example, in garden plots and cottages;

- the small mass of production at the expense of what installation is facilitated;

- resistance to negative temperatures - pipes made of polyethylene retain their properties at -70 ° C, due to which they function effectively not only in summer but also in winter.

In order to have a comprehensive understanding of the products, it is necessary to highlight some of the disadvantages of products, which are discussed below.

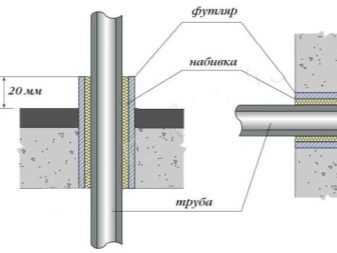

- The material has a low level of resistance to ultraviolet radiation. On this basis, the installation of PND-pipes is recommended to be carried out in the soil or placed in special protective cases.

- The strength indicators of polyethylene products are inferior to those of metal pipes.

All products are subject to mandatory control for compliance with state standards established for the products with which the arrangement of the water supply system is carried out.

Kinds

The range of such pipes, presented on the modern market of building materials, is quite diverse.They are classified by scope, as well as technical characteristics, for example, by diameter, length, and other parameters.

It is possible to identify the main types of used pipes made of polyethylene for water supply:

- SDR 9;

- SDR 11;

- SDR 13.6;

- SDR 17;

- SDR 21;

- SDR 26.

The abbreviation is a dimensional characteristic of the product, which is the value of the ratio of the outer diameter of the pipe to the wall thickness: the thicker the wall of the pipe, the greater the load the material can withstand.

In addition, pipes for water supply are divided into the following types:

- PE 100;

- PE 80;

- PE 63;

- PE 32.

However, among them only the first two types are related to PND-pipes, since they have a higher density.

In addition, manufacturers distinguish the following options for PND-pipes:

- pressure products;

- free-flow products.

The latter type of pipes is used in the construction of gravity sewers or storm drains. Also, they are a fairly effective solution that allows the laying of communications. Their main difference is the fact that the products can not be used when transporting liquid media under pressure.

Pressure structures are in demand when laying water or gas communications,in which the medium moves under a certain pressure.

Based on the cross section, polyethylene products are with a diameter of from 10 mm to 1200 mm. The most popular are pipes with a diameter of 20 to 32 mm.

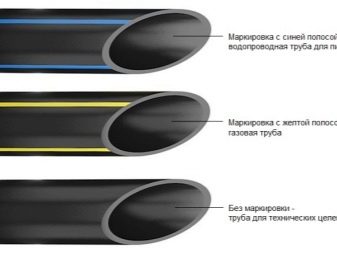

PND-pipes can be distinguished by a strip printed on the base. The blue line will indicate that the product is intended for transporting cold water, and the yellow bar indicates that the product is allowed to be used in the gas pipeline system.

Scope of application

Due to the large list of positive features of such products has a wide range of operation in completely different branches of life. \

Below are the main areas of application of products.

- In the first place is the use of PND-pipes in the sewer system, especially for domestic purposes. Almost the entire sewer system for private use includes technical pipes made of low-pressure polyethylene. It should be noted that similar pipes are applied to external and internal installation.

- Products proved to be excellent, acting as a shell when connecting electrical, television and power cables.They perform a protective function for communication channels and electrical wiring, since they reliably cover communications from mechanical damage.

- PND-pipes are very popular when arranging greenhouses in agriculture of various sizes. In this area, products are used for laying irrigation systems of crops, moistening the soil, as well as feeding plants with carbon dioxide.

- When creating ice fields of temporary or stationary value, pipes made of low-pressure polyethylene are given a special role.

- Products act as a formative element in the monolithic structure of buildings of various kinds.

- Large diameter pipes are necessary for arranging the drainage system and pressure pipes.

Due to their high corrosion resistance, they can be successfully used in many other areas. Resistance to electrochemical corrosion is an important feature of the products - such pipes are used in the construction of modern communications systems.

Installation

In order to increase the efficiency of installation of polyethylene pipes, it is worth exploring options for connecting two products with each other.

The following methods are distinguished:

- welding;

- compression fittings;

- electrofusion welding;

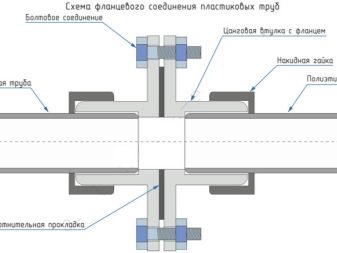

- flange connection.

The first method is used in practice most often because it has a high degree of reliability and forms a tight and durable joint between the structural elements of the water supply system. The welding technology is as follows: the ends of the products are subjected to heat treatment using a welding machine, after which they are bonded to each other - due to this a connection is formed. This method is particularly relevant in the arrangement of the underground pipeline.

Fittings are the second most popular way of fixing products among themselves. Today, various compression parts are available for sale - tees, couplings, transitional and angle fittings. Such a variety makes it possible to make the transition to the thread. For even the use of such elements can pave the water supply system of any configuration. However, the connection of communications that will be located underground, such fasteners are not recommended to perform, because the fittings need regular maintenance.

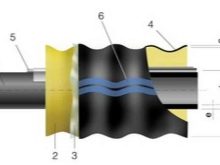

Electrofusion welding is performed using a special kind of fittings - couplings. They incorporate heating elements and plugs. The latter are needed to connect with the heating equipment.

The process of connecting products is as follows: the fittings are inserted at both ends into the pipes, after which the heating device is connected, through which the spiral element melts the sleeve and the base of the pipe. As a result, at this place a solid one-piece seam is formed.

Flange mounting is used when moving to the thread. This connection option is not widely used, however, when installing a water supply system from PND-pipes for cold water supply, the flanges are very popular.

The low weight and fairly simple technique, which allows to combine products into one integral design, make it possible to significantly reduce the time for installation work, as well as to perform them independently without large financial costs and the use of specialized equipment.

In favor of simple installation of PND-pipe says and a wide range of connecting elements, which are used in combination with pipes.They provide an opportunity to lay the system of any configuration, and also allow you to connect elements with each other quickly and reliably. Experts identify a number of general recommendations that will help to install low-pressure polyethylene pipes without the risk of making a mistake.

There are several basic rules.

- All installation work should begin with creating a detailed layout for the future water supply system. Drawn up drawings will help to make the most accurate calculations of the number of pipes and connecting elements that will be needed for the highway.

- In the process of self-transporting purchased products, you must take precautions to avoid situations in which products may be damaged by sharp objects or cutting tools.

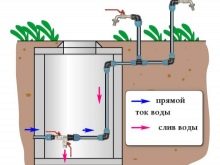

- If it is planned to install PND-pipes into the soil, you must first carry out preparatory activities related to arranging a sand cushion in the trench;This additional layer is needed in order to protect products from the risk of damage to the walls on the sharp edges of various objects that may be in the ground. Before laying the pipe protective layer must be carefully tamped.

- Products that will transport cold water should be laid in such a way that the joints of the elements of the aqueduct are slightly recessed into the bulk pillow.

- Laying products involves several options for connecting elements with each other: permanent fixation and detachable fastening. The first option assumes the presence of welding equipment. In some cases, the method of soldering pipes butt using electrical couplings is used. This method is effective in the case of arrangement of pressure water systems when using products with a large cross-section.

In the second case, the work is done to help flange or socket fittings, which are composed of an elastic seal. This option is suitable for communications in which the movement of a liquid medium inside occurs without pressure (for pipes with a diameter of up to 35 mm).To connect pipes using the split method, there is no need to use specialized equipment or tools.

- If there is a need to bend products for laying the system, then the sun will help in this matter in hot weather: when the product heats up, it can acquire the desired bend. When working in the cold season, you can pour the pipe with hot water or heat it with a building hair dryer. However, such manipulations may be fraught with violation of the integrity of the product. For example, if heating the PND-pipe is not enough, then when bent, it will break, and in cases of excessive heating the polyethylene may catch fire, which will result in damage to the product and disruption of the structure of the water supply system.

With the observance of simple rules, the pipeline, made of low pressure polyethylene pipes, will be able to supply the residential building or to the section of cold water in the shortest possible time.

Tips

For the average area of the PND-pipe, it is best to purchase in bays of 25 meters. The most acceptable wall thickness of products for laying domestic water supply is 2 mm.

The cross section of polyethylene pipes is different, therefore, products should be selected based on the level of pressure in the future system:

- if the water pressure is high, you should opt for a product with a diameter of 25 mm, provided that the casing has a diameter of more than three quarters of an inch;

- in situations where a metal pipe, whose diameter does not exceed three-quarters of an inch, acts as a source of liquid, you should buy a product with a cross section of 20 mm.

When purchasing products, it is also worth remembering that the size of the cross-section of the outlet should be smaller than that of the main pipe. This design feature will provide a stable water pressure in the pipeline. The corresponding marking on the product will tell you what type of product is allowed to be used for the construction of household or drinking water supply.

An important point when working with PND-pipes for arranging highways in open ground is the depth of the excavated trench: the pipes must be laid in the ground below the level of soil freezing. Locator will help determine the depth and location of communications, laid under the ground.

In the next video you will find the scheme and assembly of water from the PND-pipes.