Chrome pipes: characteristics and scope

There is a large number of pipes from a variety of metal and plastic materials. But chrome-plated products stand out against the background. It is only necessary to know well their key nuances and subtleties of application in order to prevent absurd mistakes.

Special features

Chrome-plated pipe differs from simpler structures by increased protection against corrosion. This solution turns out to be particularly practical where the corrosive effect is very strong, but for some reason one cannot use structures made of stainless steel or non-ferrous metals.

Along with the improved protective characteristics, it is impossible not to mention the attractive appearance. In most cases, a layer of chromium is applied using an electrolytic technique. It is most economical, both in money and in time.

Where are they used?

It is customary to single out several varieties of electrolytic chrome plating:

- milky;

- with glitter;

- hardened.

“Milk” is made at temperatures from 60 to 80 degrees, the overall density will be relatively small. The decrease in strength results in such a useful property as high elasticity.

Slight bending does not lead to the loss of an attractive appearance.

But the brilliant type of chromium is very widespread in the creation of furniture and furniture fittings. It is actively used in the decoration of visible elements of water systems. Moreover, the luster of chrome was appreciated by designers using this metal to form accent objects in the interior. To make such a coating, use is heated to 45-60 degrees, and the current density reaches from 30 to 100 A per 1 square decimeter. The wear resistance of the layer being made makes it possible not to be afraid of practically any deformations.

As for the solid type of chromium, the technological requirements here are much stricter. The maximum temperature during operation is 40 degrees, and the current density is 1 square meter. dm must be exactly 100 A. The increased strength of such a layer is accompanied by the loss of all decorative properties.The durable coating conceals the secret of low-intensity friction related to each other parts. The thickness is quite significant, and therefore it takes longer to apply the coating.

It is possible to reduce the number of pores in the chromium layer by treating it with oils and varnishes. It is worth knowing that chrome plating is possible even for plastics, pipe geometry also does not play a special role.

Almost always, this method of treatment is designed to improve the aesthetic properties of the source material. It is for this reason that it is often carried out for pipes used as part of commercial equipment. Therefore, the typical dimensions are small, although technologically there are no obstacles to the processing of structures of all used sizes.

Most often, the corresponding products adorn the interior, decorated in modern and avant-garde styles. With a pipe size of 2.5 cm, it can be used as any supporting and external unit in the frame of a furniture product.

If the section is increased to 5 cm, it will be possible not to be afraid of the application of a load within 60 kg. Almost always, such strength characteristics are sufficient for the needs of a commercial enterprise.The cross section of 4-5 cm performs well when used in the construction of the railing. They are not only strong, but also look much more modern than the simplest wooden products.

Plumbing chrome pipes can be even larger than other cases. The application of non-ferrous metal allows you to confidently cope with the traditional lack of steel systems, that is, with their susceptibility to corrosion. At the same time, decorative characteristics remain much higher than that of plastic plumbing circuits. In many cases, chromium coating is used for visible elements - the soul, siphon, tap, conclusions from the radiators and inputs to them.

According to experts, preference is given to annealed copper with a chrome layer. This option is a compromise between the requirements of strength and flexibility.

The use of chrome pipes is not limited to the described possibilities. So, for sanitary purposes, they can be used to create towel warmers.

Industrial enterprises are in dire need of reliable pipelines for:

- freezing and refrigeration units;

- conditioning circuits;

- steam power equipment.

Brilliant thresholds and exhaust pipes of cars are also chrome. If we talk about commercial equipment, its application is most in demand there:

- railings on the stairs;

- shelving;

- carts for the transport of goods in the hall;

- exhibition devices and stands;

- bar counters.

Kinds

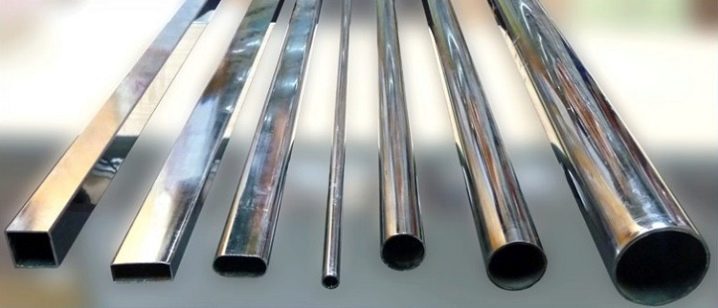

Such a wide scope of use naturally led to a large variety of geometric shapes in a chrome pipe. In some cases, a decorative variety of it is required, having a cross-section in the form of a square or a rectangle with an offset type of facets. This is a practically universal option, which shows itself well in the railings, in the sales area, and in the balcony lattice. Even from it you can make awnings and decorating the room objects, decorative grilles on the windows, supports for visors, handrails. Along with a straight contour, metal products can also have a twisted look.

Oval chrome pipe in many situations is more practical than its round version. When working you can use the same tools as usual. So, metal cutting is possible using electric or gas cutters.

An oval is better than a circle, when the installation site is narrow, and at the same time the highest pipeline capacity is needed. With an identical diameter, it is possible to increase the total cross section and pump more liquid or gas.

An important advantage of the oval is the aesthetics of this configuration. Especially often remember about it when you have to do the pipeline in a residential or office space. Comparatively easily such an object of infrastructure is decorated or used to decorate a variety of interiors. The best way to apply paint professionals consider using powder technology.

The oval-shaped tube looks attractive when creating an arbor, granary, greenhouse or greenhouse.

Thin-walled tubular products are mainly used in the production of furniture products and commercial equipment, exhibition systems. For the most part, metal-rolls with a cross-section of 2.5 cm fall into this category in manufacturers' catalogs. You should not be afraid of the toxic effect of chromium in any method of its application; for the decorative and protective purposes, safe trivalent modification of the element is used.High-quality coating does not flake off and remains intact even at the breaks of pipes. However, you can bend them altogether without such breaks.

Chrome-plated brass pipe is actively used not only in the above areas. It is used for:

- engineering machines for various purposes;

- production equipment;

- instrumentation equipment;

- transport.

Along with cold rolling, pressing and broaching can also be used to produce pipes made of brass. Depending on the technological nuances, it is not only the diameter that changes, but also the thickness of the structures, and the calculated weight of 1 running meter. m, and even manufacturing accuracy. Thus, extruded structures have the same degree of accuracy in any case, while for cold-rolled objects obtained by pulling, it is increased and standard. The rectangular tube is considered a classic of metal structures. Such blocks are in demand as beams for floors, supports for suspended elements and frame profiles.

The round version bends well, and this allows you to make holistic turns on the pipelines.But when it comes to the creation of rigid canopies, this property is already sharply unfavorable. It is important to consider that the latest technologies allow the formation of even very complex sections.. There is no need to limit your choice to the three basic forms mentioned above. The rectangle is recommended for elements of a metalplastic window, for steel entrance doors.

Tips

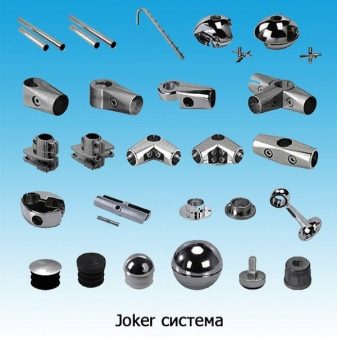

Fittings for fastening chrome pipes can be the most diverse, but many experts consider the Joker system to be the best option. It includes special holders for products and a variety of functional, design details. The only drawback is that these pipes are not suitable for water supply. To bend the pipe in a vice or in a pipe bender is best, pre-filling it with sand or other fillers and tightly plugging both ends. For work, you can use both hot and cold method. Aluminum and copper (in pure form or in alloys) bend very well.

Chrome plating of pipes even with their own hands at home is quite possible. This helps save money and ensure quality.Such work should be done in a respirator and protective apron.

Electrolysis is best carried out in a wooden box with insulation in the walls. For tightness it is recommended to use a plywood cover.

You can learn more about how to install chrome pipe fencing.