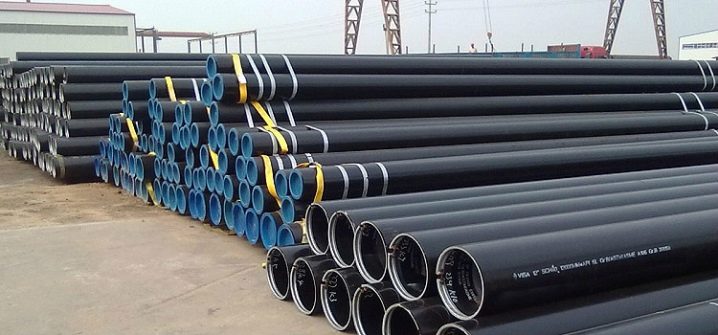

Varieties of seamless tubes

Seamless pipes that do not have a welded joint are designed for operation under heavy load conditions. Due to their peculiarities, they are widely used in manufacturing, construction and service industries.

Special features

The seamless pipe is an integral metal pipe design without seams and connections. Requirements of standards imply production at large factories, where quality control takes place at each technological stage. The cost of seamless pipe elements corresponds to the reliability of products during operation.

When using seamless pipes, the following advantages are highlighted:

- reliability;

- high strength under pressure;

- damage resistance;

- thermal stability and fire safety;

- variety of sizes;

- attractive presentation;

- long service life;

- multifunctional use.

Negative qualities of seamless pipe systems are considered to be a high thermal conductivity coefficient and the severity of large-section products. Along with the strength appears rigidity. Installation of pipes is impossible to make independently - special training and equipment are needed.

To protect the outer coating needs color or other methods of protection from atmospheric exposure.

Kinds

Varieties of pipeline elements can be classified into categories, in accordance with the method of production, product shape, wall thickness. Manufacturing techniques vary depending on the temperature regime during production. The following products can be distinguished:

- hot rolled;

- cold deformed;

- heat deformed.

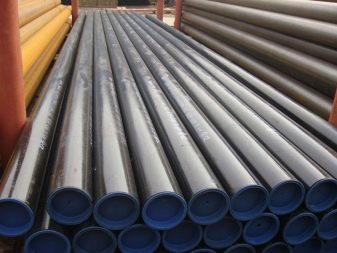

The raw material for the manufacture of pipes is a metal billet. The blank is made in the form of a cast ingot - forged or rolled. Rolled metal is heated to plasticity, giving a hollow shape by rotation. For obtaining the necessary size the mandrel is located in a cavity.Hot-rolled pipe is processed on the rolling mill with further hot rolling and rolling. At the last stage, cooling, calibration and cutting of the product in accordance with GOST 8732-78 takes place. Hot-deformed pipe is tested for mechanical and chemical properties.

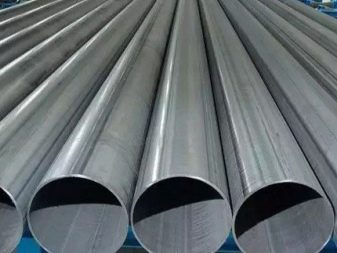

Cold-rolled pipe products have high strength and stable characteristics. It meets the requirements of GOST 8733-74 and GOST 8735-75. Cold-formed pipes are made by rolling and pressing.

For the production of cold-rolled elements, the blanks are annealed and formed in the piercing mill. Annealing relieves internal stress in the metal, eliminates structural inhomogeneities, increases ductility. Then, in the cold rolling mill, rolling of the workpiece with the inner core of the mandrel takes place until the set parameters are obtained. To obtain products with high technical properties in the process of forming the pipes are etched with acids, followed by neutralization and drying.

Heat-deformed production involves dragging on machines and then pulling on the drum.Pipe blanks are processed on the mill, where the temperature rises slightly, making the broach effective. Seamless pipe is made with a large wall thickness.

Depending on the wall thickness of the pipe is classified into the following types:

- thin-walled;

- thick-walled;

- especially thin-walled;

- especially thick-walled.

The thinnest tube structures are made with a thickness of less than 0.5 mm and a circle up to 20 mm. A thin-walled pipe is determined by the indicator of the multiplicity of the diameter to the wall thickness, which varies from 12.5 to 40. Within the limits of the multiplicity from 6 to 12.5 lies the thick-walled tube structure. Particularly thick-walled is considered a product with a multiplicity ratio less than 6.

According to the shape of the section, seamless pipes are divided into round and profile variants. The round shape is made according to GOST 8732-78 with an outer diameter of from 20 to 550 mm. The profile tube can be square, oval or rectangular. Steel oval pipes are made according to GOST 8642-68. The cross-sectional area varies depending on the size: from 0.06 to 5 cm2.

Square products are regulated by GOST 8639-82. Its outer side varies in the range from 10 to 180 mm, the wall thickness is from 0.8 to 14 mm, the maximum cross-sectional area is 89.5 cm2, and the minimum is 0.3 cm2.The rectangular shape is made according to GOST 8645-68. The area varies from 0.4 to 70 cm2.

The shape of a square or rectangle in the design allows for high bending strength.

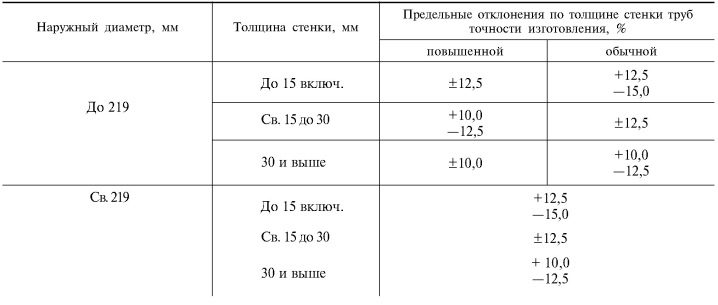

In the manufacture of pipes, the accuracy of production should be monitored for the outer diameter and wall thickness. Pipe products are made of high and ordinary accuracy. For a conventional pipe, the allowable deviations in diameter should not exceed 1%, in wall thickness - 12%. Precision tube does not allow deviations of more than 0.8% in diameter and more than 10% in wall thickness.

The method of hot rolling does not get a pipe with a diameter of less than 16 mm - the outer surface is unclean in scale. Dimensional accuracy may vary, and is therefore not suitable for use in industrial applications requiring standardized products. Hot-rolled pipes are not used in contact with caustic chemicals, fuel, are not used to transport hot steam and water.

For this purpose, cold-drawn pipelines are used - they are resistant to high temperatures, static and dynamic loads, the effects of acids and petroleum products.Such products withstand hydraulic pressure up to 20 MPa.

The scope of pipe elements is divided by their purpose and properties. Seamless pipes are distinguished by the type of destination:

- trunk;

- stainless;

- bearing;

- oil pipelines;

- cracking for the oil refining industry;

- casing for wells;

- boiler for transportation of heat carriers and boiler installations.

Conventionally, pipe structures have classes. For example, for the manufacture of fences and the transfer of fluid in irrigation systems used 1st class. For the transportation of water, gas, fuel at low pressure used 2nd class pipes. Grade 3 is suitable for the production of boilers, oil refining, used in nuclear power.

High strength has a 4th class of pipe products, designed for drilling and installation of casing structures for oil production and geological exploration. Pipes of the 5th class are used for the production of road and rail transport, in aircraft and shipbuilding. For the manufacture of parts in mechanical engineering, bearings and cylinders using the 6th class of pipes.

Materials

The main production material for seamless pipes is rolled steel. Depending on the application, the composition of the steel from which the pipe products are made varies.

The basis is the steel mass of different grades:

- carbon steel (St 10, St 20, St 3-6);

- low-alloyed and doped (10G2, 09G2S, 17GS, 15H5M, 12GSB);

- heat resistant alloyed alloys (12X18H12T, 08X18N10T, 12X18N10T).

Carbon steel products are made for poles and fences. High carbon steel is used to make a pipeline with a low pressure for general use.

Pipelines with anti-corrosion protection are made of alloy steel containing chrome, nickel, titanium. Often this metal is called stainless steel. The corrosion-proof pipe will serve longer in natural atmospheric conditions and chemically aggressive environments. Products from the alloyed steel will maintain operation at a high temperature and pressure.

Dimensions

Hot-rolled seamless pipes are manufactured with a diameter of 2 to 55 cm and a wall thickness of 2.5 to 75 mm. Cut to length according to standards. Such products are measured, unmeasured, approximate and multiple lengths.

Values range from 4 to 12.5 m. In GOST 8732-78, a table is presented according to mass and diameter and thickness of the product. Weight with a diameter of 55 cm and a thickness of 7.5 cm reaches 878.5 kg / m. A weight of 1 kg will be a meter tube with a circumference of 20 mm and a wall of 2.5 mm.

Cold-deformed pipes have a diameter of 5-250 mm and a wall thickness of 0.3-24 mm. The measured length is 4.5–9 m, unmeasured - 1.5–11.5 m, and a multiple is 1.5–9 m.

Pipes of small diameter have parameters up to 114 mm. Pipe products from 114 to 480 mm are considered to be of medium diameter, and more than 48 cm - elements with a large diameter, are produced by hot deformation.

Oval seamless pipes vary in size: wall thickness - from 0.5 to 2.5 mm, width of the sides - from 6 to 90 mm, length - 3-32 mm. Weight varies depending on size: from 0.05 to 4 kg / m.

For rectangular tubular elements, not only the size but also the shape changes. The smallest pipe is a product with a size of 15x10 mm and a thickness of 1 mm. The maximum wall thickness is 1.2 cm, the length of the outer side is 18 cm, width is 10 cm with a step of 1 cm. The weight of the structure does not exceed 50 kg / m.

Square tubes can be from 10 to 180 mm in increments of 5 mm. Seamless hot-rolled pipes produce the following sizes: diameter - from 60 to 180 mm, wall thickness - from 4 to 14 mm, length - from 4 to 12.5 m.Cold-deformed structures have the following dimensions: diameter - from 10 to 120 mm, wall thickness - from 1 to 8 mm, length - from 1.5 to 11 m.

Manufacturers

Domestic enterprises occupy a leading position in the market of seamless pipe products. They are located in the Sverdlovsk, Volgograd, Chelyabinsk, Nizhny Novgorod, Belgorod regions. Products are manufactured in accordance with GOST, undergoes a quality check.

The oldest enterprise in Russia for the production of hot-rolled seamless pipes is located in Polevskoy. OJSC “Seversky Pipe Plant” produces seamless casing products with a diameter of 168-340 mm, seamless products of oil and gas and general purpose with an external size of 168-325 mm.

Volzhsky Pipe Plant OJSC since 1970 has been producing seamless pipes for industry. Products comply with the certificate of "Environmental Management Systems", the requirements of the international standard ISO 14001: 2004. The products undergo ultrasonic quality control.

Since 2007, seamless pipes have been manufactured from PCF ship steel. The plant’s assortment includes hot-rolled seamless general-purpose pipes, oil and gas pipelines, cracking pipes,for engineering, steam boilers and steam lines, for the manufacture of bearings, seamless casing, as well as pipes made of corrosion-resistant steel.

OJSC “Sinarsky Pipe Plant”, located in Kamensk-Uralsky, since 1934 has been producing seamless hot-rolled and cold-deformed pipes from various grades of steel. Products are in demand in the oil and gas, chemical, construction industries, in agriculture and energy.

Seamless hot-rolled pipes as well as pipe billets are produced by Taganrog Metallurgical Plant OJSC. Pervouralsky Novotrubny Plant OJSC produces seamless hot and cold-formed pipes from carbon and alloyed steel, corrosion-resistant alloys, seamless boiler pipes.

The top ten of the world's largest pipe companies include Chelyabinsk Pipe Rolling Plant OJSC, which manufactures pipe products for the main areas of production. The plant produces seamless hot-rolled pipes, stainless steel, cold-deformed pipes.

The company from the city of Belgorod LLC "Belenergomash-BZEM" is engaged in the manufacture of seamless products by the method of hot deformation and electroslag smelting followed by processing, boring and drilling.

On the territory of Ukraine, Interpine is engaged in the production of equipment for pipelines. The product line includes seamless pipes for fuel transportation, for the engineering industry, and general purpose pipes.

The production of cold-deformed pipes according to Ukrainian and international standards is specialized by the Nikopol Steel Pipe Plant YUTIST. The assortment of pipes for various purposes with a diameter of from 6 to 90 mm with a wall thickness of from 0.5 to 12 mm.

How to choose?

The choice of seamless pipes is carried out according to the following criteria: gradation by the size of the walls, the size of the circle, the footage, weight, maximum deviations. By the size of the walls is determined by the desired thickness of the product - thin-walled or thick-walled. Circumference is characterized by external diameter. If there is a need for a large diameter of 25 cm, then choose hot structure. Cold rolled pipes are suitable for small diameters.

The length is determined by the type of pipe. Cold-deformed products can be supplied with a length of 1.5-11.5 m with a pitch of 5 mm. Hot-rolled products are cut from 4.5 to 12.5 m.

Weight depends on the size of the diameter and wall thickness: the thicker and more massive the product, the more it weighs.

Discrepancies in technological dimensions are governed by the state standard. For seamless pipes, deviations along the length of the product up to 1 cm (dimensional production) are allowed, for the non-dimensional variant - no more than 1.5 cm. Deviations in wall thickness should not exceed 12%. Curvature for cold-rolled pipes per linear meter should not exceed 1.5 mm for products with walls greater than 10 mm. For hot-rolled products, the curvature per meter does not exceed 2 mm for walls up to 30 mm and 4 mm for wall thicknesses greater than 30 mm.

Tips

On the production of seamless products mark - it helps to keep records when selling, transporting and storing products. Marking can be applied with paint, stamp or electrograph. Place of application depends on the dimensions of the pipe. For pipes of small and medium diameter marking is attached to the entire party. Pipe products with a diameter of more than 16 cm are marked separately from the outside.

If the wall thickness is more than 1 cm, the marks can be applied to the end of the pipe. Pipes with a diameter of over 53 cm are marked on the inner surfaceUsing the paint color on the marking, you can determine the steel grade from which the product is made.

Seamless pipes of different caliber can be connected by electric welding. To connect products of the same diameter, a thread is made at the ends of the pipe, because it is convenient, especially for thick-walled products. Gas welding is suitable for the installation of a thin-walled pipeline.

For long-term operation, pipelines are used, molded from steel grade 12X18H10T, characterized by anti-corrosion properties, ductility and high toughness. The most heat-resistant products are made of steel grade 20Х23Н18, used for hot water supply pipelines. Steel 10X17H13M2T exhibits high resistance to acids and temperatures.

How to produce seamless steel pipes, see the following video.